In the realm of outdoor maintenance equipment, comprehending the individual elements that contribute to its overall functionality is essential. Each machine consists of various components that work in unison to achieve optimal performance. Analyzing these elements allows users to maintain their equipment effectively, ensuring longevity and reliability in its operation.

By delving into the intricate details of each section, one can gain insight into how these components interact. This knowledge not only aids in troubleshooting but also enhances the ability to replace or upgrade parts as needed. Familiarity with the structure empowers users to tackle repairs confidently, ultimately leading to a smoother experience in maintaining their machines.

Furthermore, a well-organized reference guide serves as a valuable tool for both novice and experienced operators. It simplifies the process of identifying specific components, making it easier to source replacements or modifications. Understanding the layout of the assembly contributes significantly to efficient upkeep and maximizes the effectiveness of outdoor machinery.

Understanding the Scotts L2048 Parts

Having a comprehensive knowledge of the components within a specific machine is crucial for efficient maintenance and repair. By familiarizing yourself with the various elements that make up this particular model, you can ensure optimal performance and longevity. This section aims to break down the essential features, allowing users to navigate their machinery with confidence.

Key Components Overview

Each unit consists of several key elements that work in harmony to deliver effective functionality. Understanding how these pieces interact can enhance your troubleshooting capabilities and reduce downtime.

| Component Name | Function |

|---|---|

| Engine | Powers the machine, providing necessary energy for operation. |

| Transmission | Transfers power from the engine to the wheels for movement. |

| Deck | Encloses the cutting mechanism, ensuring safety and efficiency. |

| Wheels | Facilitate mobility across various terrains. |

| Controls | Enable user interaction, allowing for adjustments and settings. |

Importance of Regular Maintenance

Regular upkeep of these elements is essential for preserving functionality and preventing costly repairs. Familiarity with each component not only aids in routine checks but also empowers users to perform minor repairs independently. Understanding how to care for these integral parts will ultimately enhance the overall efficiency and lifespan of your machinery.

Overview of Scotts L2048 Model

This model represents a robust and efficient tool designed for residential lawn care, combining innovation with user-friendly features. Its construction prioritizes durability while ensuring optimal performance in maintaining outdoor spaces.

Equipped with a powerful engine, this machine delivers exceptional cutting capabilities, making yard maintenance a breeze. The ergonomic design promotes ease of use, allowing users to navigate various terrains effortlessly.

With a focus on reliability, this equipment integrates advanced technology to enhance the overall user experience. It stands as an ideal solution for homeowners seeking to achieve a pristine lawn with minimal effort.

Key Components of the Diagram

The illustration serves as a crucial reference for understanding the various elements that contribute to the overall functionality of the machine. Each section provides insights into specific features and mechanisms that work together seamlessly to ensure optimal performance.

| Component | Description |

|---|---|

| Engine | Drives the system and powers all operations. |

| Transmission | Facilitates the transfer of power from the engine to the wheels. |

| Chassis | The framework that supports the machine and houses various components. |

| Control Panel | Interface for the operator to manage settings and monitor performance. |

| Wheels | Provide mobility and stability, enabling movement across different terrains. |

By familiarizing oneself with these essential parts, users can better appreciate how each contributes to the machine’s efficiency and effectiveness.

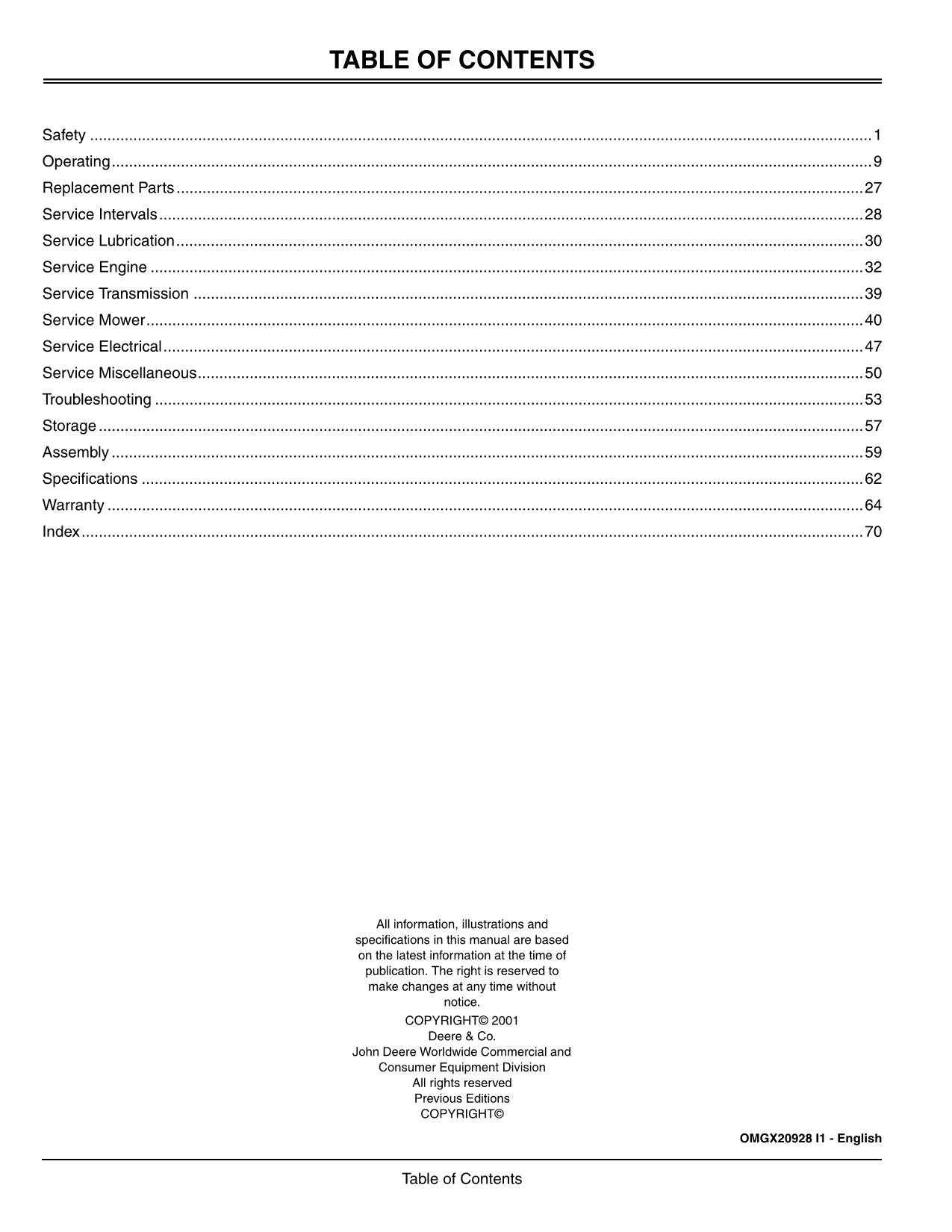

How to Read the Parts Diagram

Understanding the visual representation of components is essential for effective maintenance and repair. This guide will help you navigate the schematic, ensuring that you can identify and locate each element efficiently.

Key Elements to Identify

- Labels: Each component typically has a unique identifier that corresponds to a list.

- Connections: Arrows or lines often indicate how different parts interact or fit together.

- Grouping: Similar components may be clustered, making it easier to understand their function within the system.

Steps to Interpret the Schematic

- Begin by familiarizing yourself with the overall layout and structure.

- Locate the legend or key that explains symbols used in the illustration.

- Cross-reference the identifiers with the accompanying parts list for clarification.

- Take note of any specific notes or instructions that may affect assembly or repair.

By following these steps, you can enhance your ability to work with the schematic, leading to more efficient troubleshooting and repairs.

Common Issues and Replacement Parts

Understanding frequent challenges encountered by users of outdoor equipment is essential for maintaining optimal performance. Many common malfunctions can arise due to wear and tear or improper use. Identifying these problems early can save time and resources, ensuring your machine remains functional for longer periods.

Some typical issues include:

- Engine starting difficulties

- Ineffective cutting or uneven results

- Unusual noises during operation

- Frequent stalling

- Loss of power

To address these problems, specific components may need replacement. Here are some of the most commonly needed items:

- Air filter – to improve airflow and efficiency

- Spark plug – essential for ignition performance

- Blades – to ensure clean and even cutting

- Belts – for smooth operation and power transfer

- Fuel lines – to prevent leaks and ensure proper fuel delivery

Regular maintenance and timely replacement of these components can significantly enhance the longevity and effectiveness of your equipment.

Maintenance Tips for Longevity

Proper care and regular upkeep are essential to ensure that your equipment operates smoothly and lasts for years. By following a few straightforward practices, you can enhance performance and prevent potential issues, ultimately saving time and resources.

Regular Cleaning

Keeping your machine clean is crucial. Debris and dirt can accumulate and cause damage over time. Follow these steps for effective cleaning:

- Remove grass clippings and dirt after each use.

- Use a soft brush or cloth to clean surfaces.

- Check and clean air filters regularly to maintain optimal airflow.

Scheduled Inspections

Routine checks can help identify wear and tear before they become serious problems. Consider the following:

- Inspect belts and cables for fraying or damage.

- Examine blades for sharpness and replace if necessary.

- Check fluid levels and replace oil according to the manufacturer’s guidelines.

By adhering to these maintenance tips, you can prolong the life of your equipment and ensure its reliability for many seasons to come.

Where to Find Original Parts

Finding authentic components for your equipment is crucial for maintaining performance and longevity. Ensuring you source high-quality replacements can make a significant difference in functionality and durability. There are several avenues to explore when searching for genuine items.

Manufacturer’s Website: The first and most reliable option is to visit the official website of the manufacturer. They often provide a dedicated section for customers to browse and order original components directly.

Authorized Dealers: Look for authorized retailers who specialize in selling certified merchandise. These dealers typically have a good inventory of original replacements and can offer guidance on compatibility.

Online Marketplaces: Reputable online platforms also list genuine items, but it is essential to check the seller’s ratings and reviews. Ensure that the products are verified as authentic to avoid subpar substitutes.

Local Repair Shops: Many local repair establishments maintain relationships with manufacturers and may stock or order genuine items for you. They can also provide expertise in selecting the right replacements.

Forums and Communities: Engaging with online forums or community groups dedicated to your equipment can provide valuable insights. Members often share tips on where to find original components and can recommend trustworthy sources.

By exploring these options, you can ensure that you obtain authentic replacements that enhance the efficiency and reliability of your machinery.

Comparing with Other Scotts Models

This section explores the distinctions and similarities between various models, emphasizing features and functionalities that set them apart. By understanding these differences, users can make informed decisions based on their specific needs.

Key Features Overview

- Engine power and efficiency

- Cutting width and adjustment options

- Durability of materials used

- Ease of maintenance and repair accessibility

User Experience and Performance

- How user feedback varies across models

- Performance in different terrain types

- Adaptability to various tasks

- Comparison of warranty and support services

User Experiences and Recommendations

When it comes to maintaining lawn care equipment, the insights from users can be invaluable. Their feedback often highlights the strengths and weaknesses of various models, guiding potential buyers toward informed decisions. Engaging with the community allows for a better understanding of what to expect in terms of performance, reliability, and ease of use.

Common Feedback

Many users emphasize the importance of quality components that enhance durability. A frequently mentioned aspect is the ease of access to replacement items, which can significantly reduce downtime during maintenance. Additionally, several individuals report that investing in genuine parts leads to a noticeable improvement in performance, ensuring that the equipment runs smoothly over time.

Tips for Optimal Use

To maximize efficiency, users recommend adhering to the manufacturer’s guidelines for maintenance schedules. Regular checks and timely replacements of essential elements not only prolong the life of the machinery but also ensure optimal performance. Furthermore, engaging with online forums or local communities can provide ongoing support and tips that enhance the overall user experience.