Mechanical cutting systems have long been a crucial tool in agricultural work, enabling efficient handling of crops. This section explores the various elements that come together to ensure a smooth and precise operation in crop management machinery. These systems require both durability and precision, making the understanding of their components essential for anyone involved in their upkeep.

When it comes to maintaining these tools, recognizing the functionality of each component is key. The assembly involves several moving parts that must work in unison to achieve effective results. Proper care and attention to detail during maintenance ensure that the machinery operates at optimal levels, prolonging its life and improving overall performance in the field.

In this guide, we’ll break down each element, focusing on its role within the broader structure. Understanding how these pieces interconnect will provide valuable insight into keeping the equipment running smoothly and efficiently.

Overview of No 9 Mower

This model, designed for efficient fieldwork, is known for its durability and ability to handle a variety of terrain. It has become a reliable tool for those in agriculture, offering consistent cutting performance across large areas.

Key Features

- High-quality blade system that ensures a smooth and uniform cut.

- Adjustable settings to cater to different ground conditions and grass types.

- Sturdy construction for long-term use in demanding environments.

Maintenance and Adjustments

- Regularly inspect the cutting mechanism to maintain peak performance.

- Ensure lubrication of moving components to avoid wear and tear.

- Check the tension of the driving system for smooth operation.

Key Components of the Sickle Mower

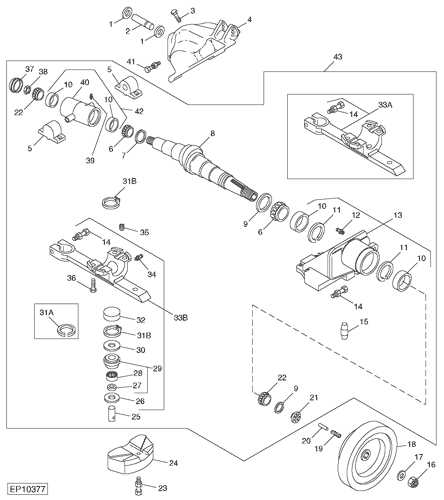

Understanding the primary mechanisms of this cutting equipment is essential for maintaining its performance and ensuring efficient operation. Each element works together to deliver precise cuts and durability in various conditions.

The cutting blade assembly is one of the critical components, designed for swift and accurate grass or crop trimming. It moves in a reciprocal motion, slicing through vegetation efficiently. This mechanism is supported by guides and sections that stabilize and direct the cutting motion.

The drive mechanism powers the movement of the cutting unit. It converts rotational energy into linear motion, which is crucial for the tool’s operation. Proper lubrication and alignment of the drive ensure smooth functionality and longevity.

The framework provides structural support and stability, ensuring the cutting tool can be mounted securely. Additionally, the lifting system allows for easy adjustment of cutting height, making it versatile for different terrains and tasks.

Understanding the Cutting Mechanism

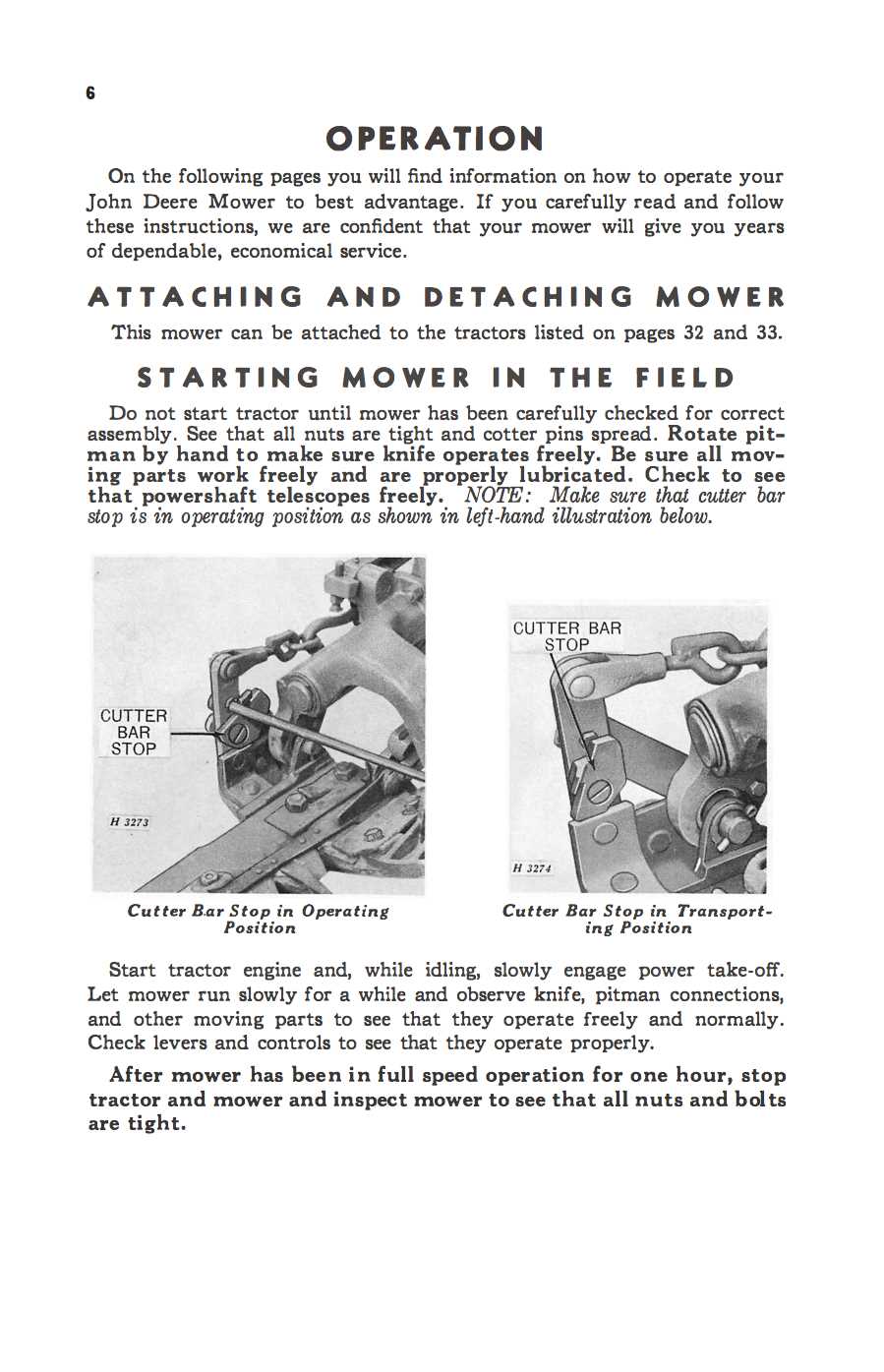

The cutting mechanism in agricultural equipment operates through a series of synchronized actions that ensure an efficient harvest. This system typically includes a set of sharp blades designed to slice through plant material with precision. The mechanism relies on a combination of motion and force to produce clean cuts, minimizing waste and ensuring a smooth operation during fieldwork.

Key components within the system work together to ensure consistent performance. The blades move in a rapid back-and-forth motion, driven by mechanical power, which allows for continuous cutting even in tough conditions. Regular maintenance and correct alignment of these elements are crucial to guarantee optimal functioning.

The design of the cutting apparatus is engineered to handle various field conditions, from dense vegetation to lighter growth. By maintaining the sharpness and integrity of the blades, the overall efficiency of the equipment is preserved, allowing for prolonged use without significant wear.

Blade and Knife Assembly Explained

The assembly of cutting elements plays a crucial role in the efficiency of agricultural equipment designed for harvesting. This section delves into the components that contribute to the functionality of these cutting mechanisms, ensuring optimal performance in various conditions. Understanding the intricacies of this assembly can help in maintenance and troubleshooting, enhancing the longevity of the equipment.

Key Components of the Assembly

At the core of the cutting mechanism lies a series of interconnected components that work in harmony. These include blades, which are designed to slice through vegetation with precision, and knives that assist in the shearing action. The arrangement and alignment of these elements are critical for achieving a clean cut, minimizing damage to the crops while maximizing efficiency.

Maintenance and Adjustment Tips

Regular upkeep of the cutting assembly is essential for maintaining performance. Ensuring that blades remain sharp and free of debris can significantly impact cutting effectiveness. Additionally, periodic adjustments to the tension and alignment of the components are necessary to prevent wear and extend the lifespan of the assembly.

Adjusting and Maintaining the Mower

Proper adjustment and upkeep of your cutting equipment are essential for achieving optimal performance and longevity. Regular attention to these tasks ensures that the implement operates smoothly, cuts efficiently, and maintains its overall condition.

Here are key aspects to consider when caring for your equipment:

- Blade Tension: Ensure that the cutting edges are properly tensioned to facilitate effective operation. Incorrect tension can lead to uneven cutting and excessive wear.

- Height Adjustment: Modify the cutting height according to the type of vegetation being managed. Adjusting the height appropriately promotes healthy growth and minimizes damage to the soil.

- Lubrication: Regularly apply lubricant to all moving components to prevent friction and reduce wear. Check for any signs of rust or damage that may require attention.

- Sharpening: Regularly sharpen the blades to maintain a clean cut. Dull edges can tear the vegetation, leading to increased stress and potential disease.

By following these guidelines, you can ensure your equipment remains in peak condition, resulting in efficient operation and enhanced durability.

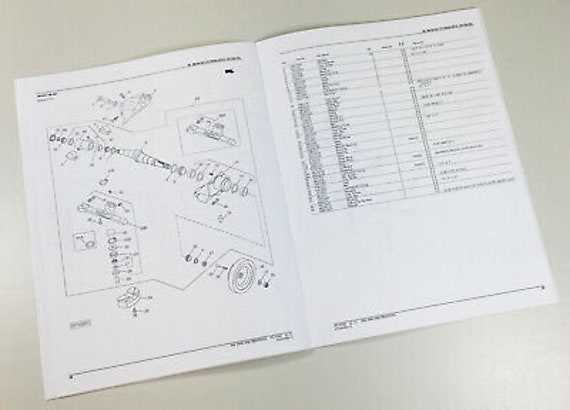

Common Replacement Parts for the Mower

Regular maintenance of your cutting equipment is essential for optimal performance and longevity. This section highlights frequently needed components that ensure the machinery operates efficiently and effectively. Understanding these essential elements will help you keep your device in excellent working condition.

Among the crucial items are blades, which play a significant role in achieving a clean cut. Over time, these can become dull or damaged, necessitating replacement for maintaining cutting precision. Another important component is the drive belt, which transfers power from the engine to the cutting mechanism. A worn or frayed belt can lead to reduced performance or complete malfunction.

Additionally, bearings are vital for smooth operation. These support moving parts and help minimize friction, ensuring efficient performance. Regular inspection and timely replacement of these elements can prevent further wear and tear on the machine.

Lastly, gearboxes are essential for the proper functioning of the equipment. They allow for the transmission of power at the required torque and speed. If any issues arise, it’s crucial to address them quickly to avoid costly repairs.

Troubleshooting Issues with the Mower

When operating a cutting implement, various challenges may arise that affect its efficiency and performance. Understanding common complications can help operators address issues promptly and maintain optimal functionality.

Here are some frequent problems and their potential solutions:

- Inconsistent Cutting: If the blade does not cut evenly, inspect for dull edges or misalignment. Regular sharpening and proper adjustment can restore cutting quality.

- Excessive Vibration: Unusual vibrations may indicate loose components or imbalanced blades. Tightening fasteners and ensuring balance can alleviate this issue.

- Difficulty in Operation: If the implement is hard to maneuver, check for obstructions in the mechanism or inadequate lubrication. Clearing debris and applying lubricant can enhance mobility.

- Overheating: Excessive heat may signal friction or insufficient cooling. Ensure all moving parts are well-lubricated and consider letting the machine cool during extended use.

Regular maintenance and timely interventions can prevent most complications, ensuring a smooth and efficient operation.

Benefits of Using the John Deere No 9

This implement offers numerous advantages for those engaged in agricultural practices. Its design and functionality enhance efficiency and productivity, making it an excellent choice for various farming tasks. With a robust construction, it ensures durability and reliability over time, allowing users to achieve consistent results.

One of the key benefits is its adaptability to different terrains and crop types. This flexibility enables farmers to maintain their fields effectively, regardless of the specific conditions they encounter. Additionally, the ease of operation minimizes the learning curve for new users, facilitating a smoother integration into existing workflows.

Moreover, this tool promotes better crop management by allowing for precise cutting, which helps in maintaining the health of the remaining plants. Its compatibility with various attachments further expands its utility, making it a versatile asset in any agricultural setting. Investing in such a reliable implement ultimately leads to increased productivity and improved harvest quality.