The efficient functioning of any lawn maintenance machine relies on the intricate relationship between its various elements. Each piece plays a crucial role in ensuring optimal performance and longevity. A comprehensive exploration of these components not only enhances your understanding but also empowers you to tackle maintenance and repairs with confidence.

In this section, we will delve into the essential components that make up a popular model of garden machinery. By breaking down the assembly into manageable parts, users can gain insights into their specific functions and interconnections. This knowledge is invaluable for anyone looking to maintain their equipment effectively.

With the right information at hand, you’ll be equipped to identify any issues that may arise and determine the necessary replacements or adjustments. By familiarizing yourself with the layout and design of your machine, you can ensure that it remains in peak condition, ready to handle the tasks at hand.

Understanding the John Deere D130

This section provides insights into a popular model of lawn care equipment, focusing on its features and functionality. The machine is designed to enhance efficiency in yard maintenance, combining power with user-friendly controls. Whether you’re a homeowner or a landscaping professional, this equipment aims to meet a variety of mowing needs.

Key Features

The machinery boasts a robust engine that ensures reliable performance. With a cutting deck designed for precision, it allows users to achieve an immaculate lawn finish. Additionally, the ergonomic design enhances comfort during operation, making it suitable for extended use.

Maintenance Tips

To ensure longevity, regular upkeep is essential. Checking fluid levels, sharpening blades, and cleaning the deck can significantly enhance performance. Following these guidelines will ultimately keep the equipment running smoothly and efficiently.

Key Components of D130 Lawn Tractor

This section explores the essential elements that contribute to the functionality and performance of the lawn maintenance machine. Understanding these components is crucial for both operation and maintenance, ensuring that users can achieve optimal results while caring for their lawns.

Engine: The powerhouse of the machine, the engine provides the necessary energy for various operations, making it vital for effective grass cutting and maneuverability.

Transmission: This system enables smooth shifting between gears, allowing for adjustments in speed and power based on terrain and task requirements.

Cutting Deck: A key feature, the cutting deck houses the blades that perform the actual mowing. Its design influences both the quality of cut and overall efficiency.

Wheels and Tires: The wheels and tires are critical for traction and stability, impacting the machine’s ability to navigate different surfaces and inclines.

Control Panel: This interface allows users to easily operate the machine, providing access to various functions and settings necessary for an efficient mowing experience.

Chassis: The frame supports all components and plays a significant role in the machine’s durability and stability during use.

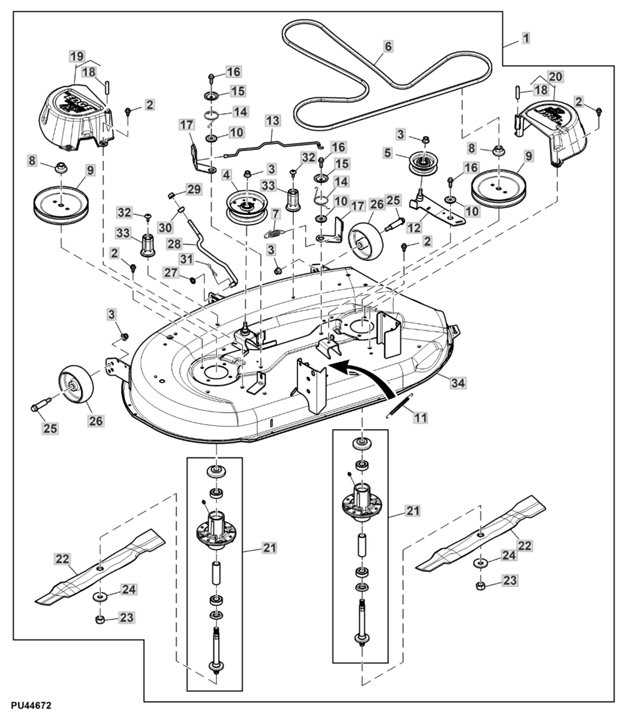

How to Read Parts Diagrams

Understanding the visual representation of components is essential for effective maintenance and repair. These illustrations provide a clear view of individual pieces, their relationships, and the assembly process. Familiarity with the layout can significantly enhance your ability to locate and identify the necessary items for your equipment.

Identifying Key Elements

Start by examining the legend or key, which usually explains symbols and color codes used in the illustration. Familiarize yourself with these elements to quickly navigate through the image. Each component is typically labeled with a reference number that corresponds to a list, making it easier to find details about specifications and availability.

Understanding Component Relationships

Next, focus on how the elements connect. Pay attention to lines or arrows that indicate assembly order or functional relationships. This knowledge allows you to visualize how different pieces work together, facilitating repairs or replacements and ensuring optimal performance of the machinery.

Common Replacement Parts for D130

Maintaining a lawn mower is essential for optimal performance and longevity. Regularly replacing worn components ensures that your equipment operates smoothly and efficiently. This section focuses on frequently needed components that users often seek to replace, helping to keep your machine in top condition.

Essential Components

Among the most crucial elements to consider are the blades. Sharp, well-maintained blades are vital for achieving a clean cut and promoting healthy grass growth. Additionally, air filters play a significant role in engine performance; replacing them regularly can prevent dirt and debris from affecting the engine’s efficiency.

Other Noteworthy Items

Another important item to keep an eye on is the battery. A reliable battery ensures that your mower starts easily and runs consistently. Furthermore, drive belts are essential for the proper functioning of the cutting mechanism. Regular inspection and timely replacement can prevent potential issues and maintain smooth operation.

In summary, focusing on these key components will help you maintain your mower effectively, ensuring its reliability and performance over time.

Maintenance Tips for Longevity

Regular upkeep is essential to ensure the extended life of your equipment. By implementing a few straightforward practices, you can significantly enhance performance and reliability over time.

1. Routine Cleaning: Keep the exterior and components free of dirt and debris. Regular cleaning prevents corrosion and promotes optimal functioning.

2. Check Fluid Levels: Regularly inspect and maintain fluid levels such as oil, coolant, and fuel. Proper lubrication is crucial for smooth operation.

3. Replace Filters: Frequent replacement of air and oil filters ensures that your machinery operates efficiently and remains free from contaminants.

4. Inspect Belts and Cables: Regularly examine belts and cables for wear and tear. Timely replacements can prevent larger issues down the road.

5. Follow Manufacturer Guidelines: Adhering to the maintenance schedule provided by the manufacturer is vital for preserving warranty coverage and ensuring longevity.

6. Store Properly: If the equipment will not be in use for an extended period, ensure it is stored in a clean, dry place to prevent damage from environmental factors.

Implementing these practices will help you delve deeper into the care of your machinery, ultimately enhancing its lifespan and performance.

Where to Find Authentic Parts

Locating genuine components for your machinery is essential for ensuring optimal performance and longevity. Whether you are a professional or a hobbyist, finding reliable sources can make all the difference in maintaining your equipment’s efficiency.

Authorized Dealers

One of the best ways to obtain legitimate components is through authorized distributors. These dealers are certified and offer products that meet manufacturer standards, ensuring compatibility and quality.

Online Retailers

Many reputable online platforms specialize in machinery components. Look for those that provide detailed descriptions and have positive customer reviews to ensure you are purchasing authentic items.

| Source | Description |

|---|---|

| Authorized Dealers | Certified sellers offering genuine components directly from the manufacturer. |

| Online Retailers | Reputable websites providing a wide range of authentic items with customer reviews. |

Identifying Faulty Components Easily

Recognizing malfunctioning elements in machinery can significantly enhance maintenance efficiency. A systematic approach helps pinpoint issues before they escalate.

- Visual Inspection: Regularly check for signs of wear, cracks, or corrosion.

- Listen for Unusual Noises: Odd sounds can indicate mechanical failure.

- Check for Leaks: Fluid leaks often signal damaged seals or gaskets.

Utilizing these methods allows for swift identification and replacement, ensuring optimal performance.

DIY Repair Guide for D130 Owners

This guide is designed to empower owners with the knowledge and skills needed for effective maintenance and troubleshooting of their lawn equipment. By understanding key components and their functions, you can enhance performance and prolong the lifespan of your machine. Whether you’re facing minor issues or planning for routine upkeep, this resource will provide essential insights to assist you.

Common Issues and Solutions

Many users encounter typical problems such as engine starting difficulties, uneven cutting, or drive issues. For starting problems, check the battery condition and connections; clean or replace spark plugs if necessary. If cutting is inconsistent, inspect the blades for sharpness and alignment, adjusting as needed. Regularly examining belts and pulleys can prevent drive-related challenges.

Routine Maintenance Tips

Performing regular maintenance is crucial for optimal operation. Schedule oil changes based on usage, and always use the recommended oil type. Clean the air filter periodically to ensure proper airflow and efficiency. Additionally, keep the exterior clean to prevent rust and corrosion, which can affect performance over time. Following these practices will help you maintain your equipment in peak condition.

Benefits of Using Original Parts

Utilizing authentic components for machinery offers numerous advantages that contribute to the overall performance and longevity of equipment. These specialized elements are engineered to meet strict quality standards, ensuring optimal compatibility and functionality.

Enhanced Performance: Original components are designed specifically for your equipment, allowing for seamless integration and improved efficiency. This tailored fit ensures that your machinery operates at its best, reducing the risk of malfunctions.

Durability and Longevity: Genuine parts are typically crafted from high-quality materials, providing superior durability. This resilience translates into a longer lifespan for your equipment, minimizing the frequency of replacements and repairs.

Warranty Protection: Using authentic components often helps maintain warranty coverage. Many manufacturers require the use of original items to keep warranties valid, protecting your investment in the long run.

Safety Assurance: Original components adhere to rigorous safety standards, reducing the likelihood of accidents or failures. This commitment to safety ensures peace of mind for operators and minimizes potential risks.

Better Resale Value: Equipment that has been maintained with genuine parts tends to retain a higher resale value. Prospective buyers are often more inclined to invest in machinery with documented use of original components, knowing it has been well cared for.