In the realm of lawn maintenance and outdoor equipment, having a clear understanding of a machine’s structure and its essential elements is vital for effective maintenance and repairs. This section delves into the intricacies of a specific model that has gained recognition among enthusiasts and professionals alike. By exploring its components, users can enhance their knowledge and ensure optimal performance throughout the seasons.

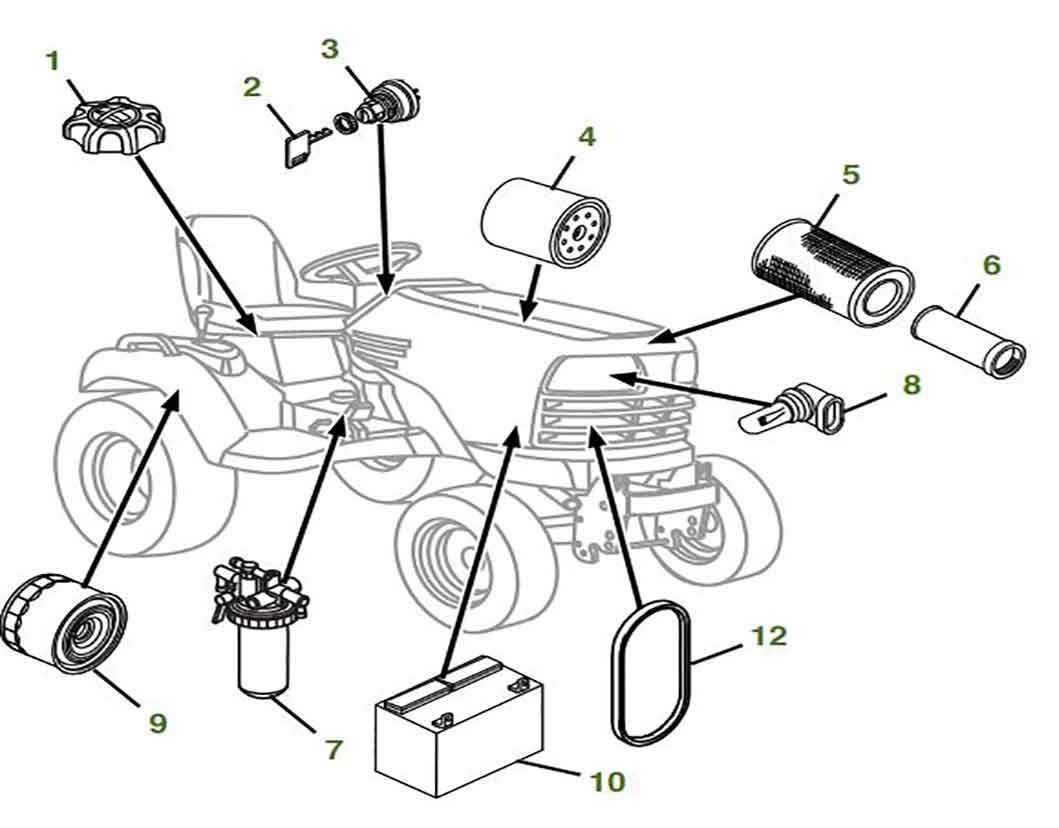

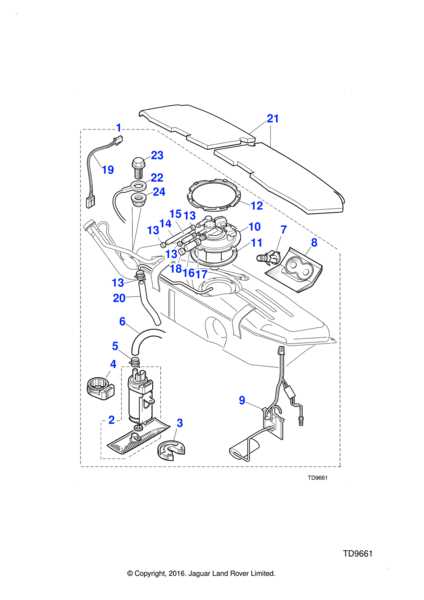

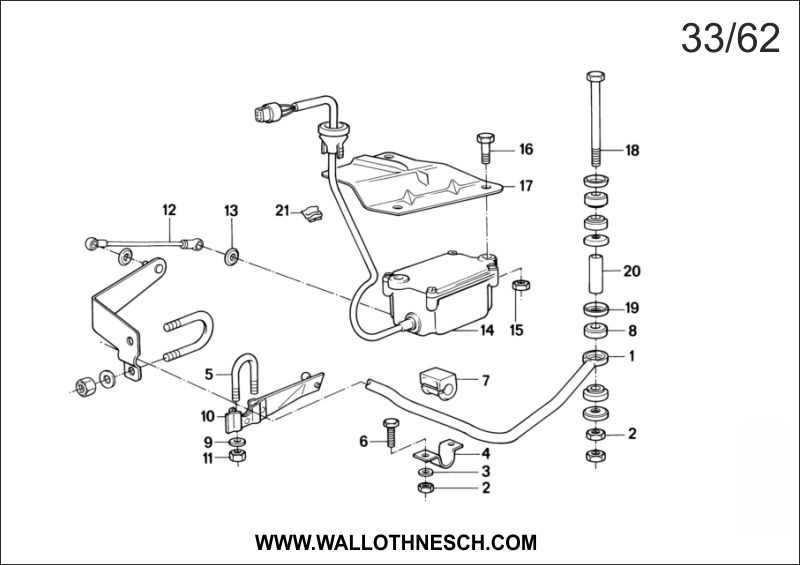

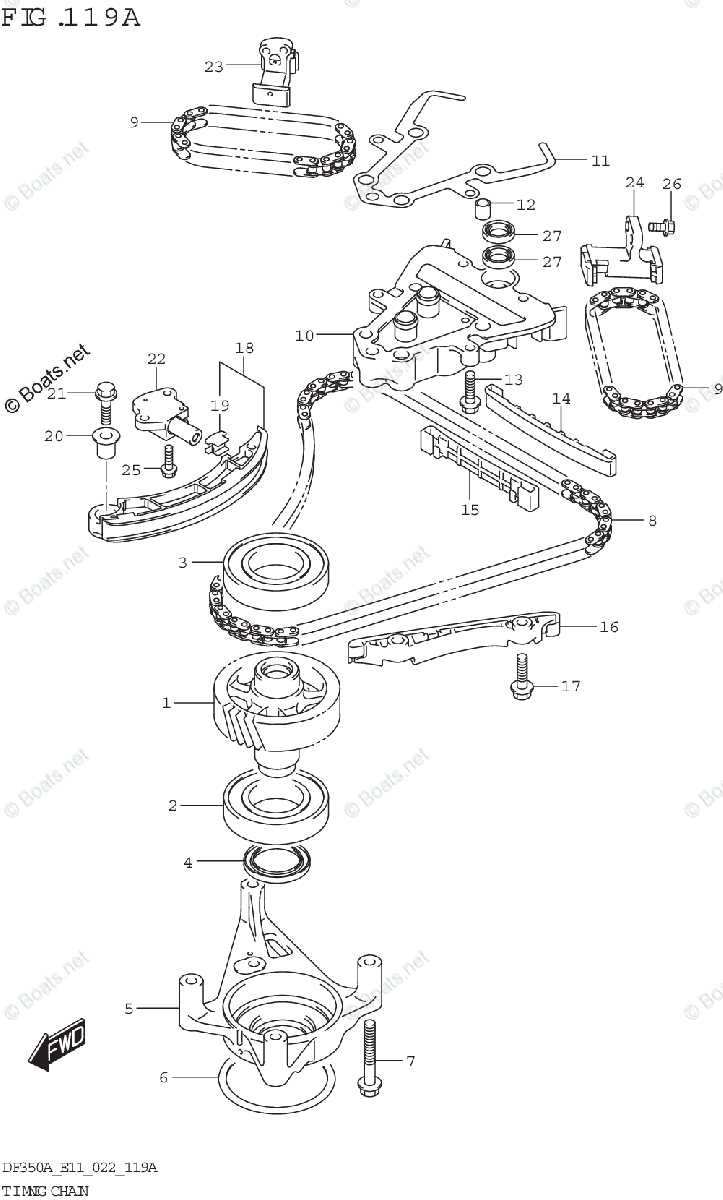

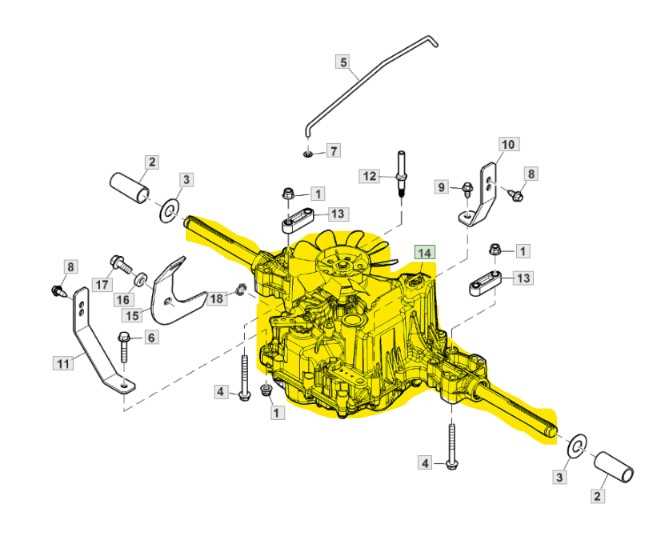

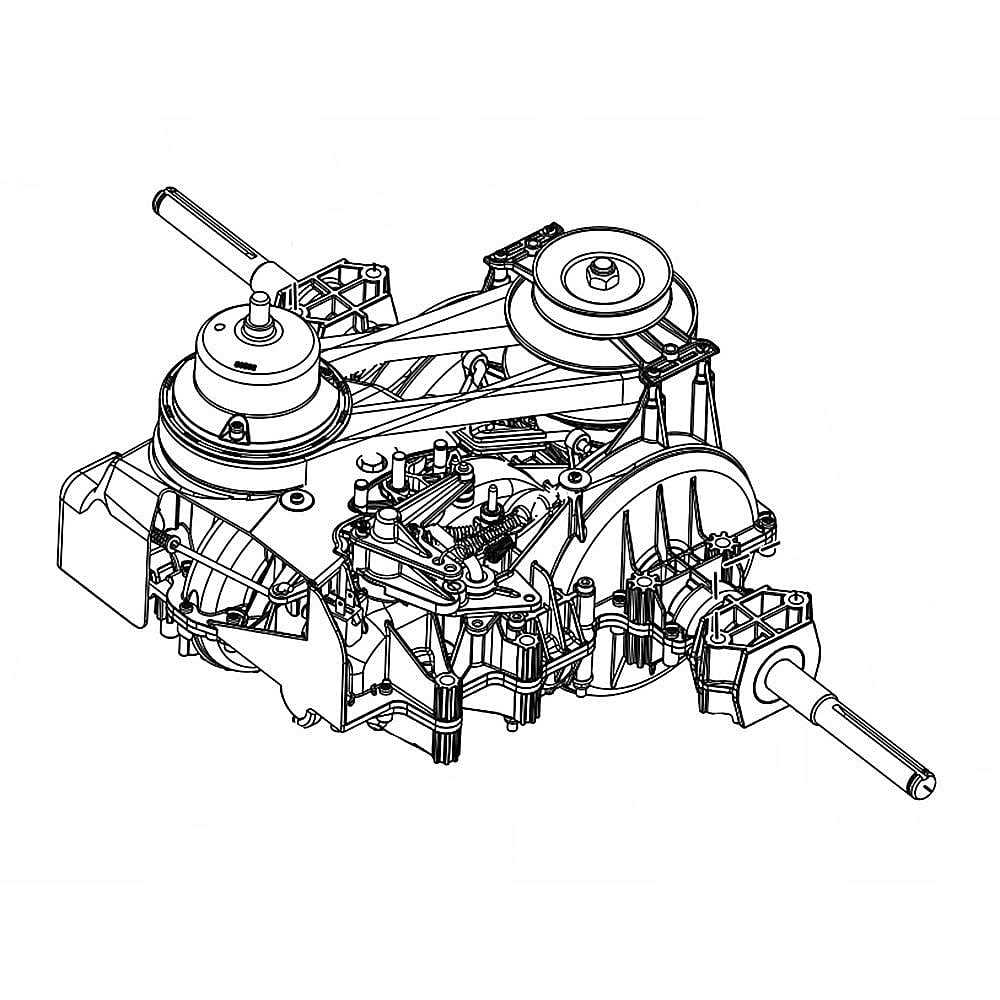

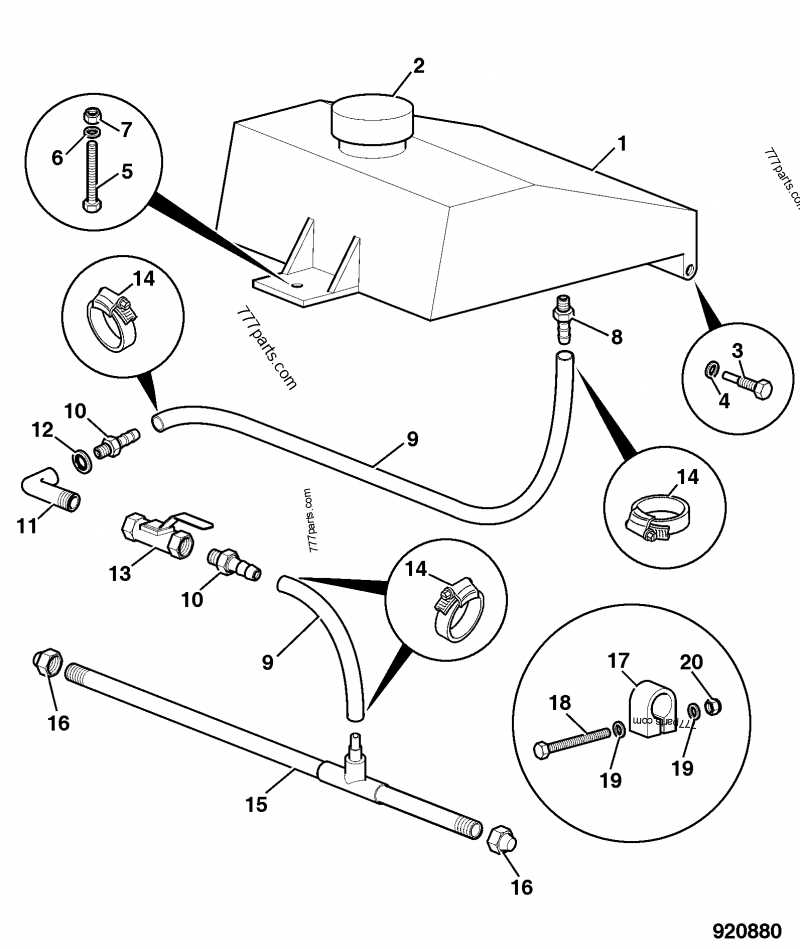

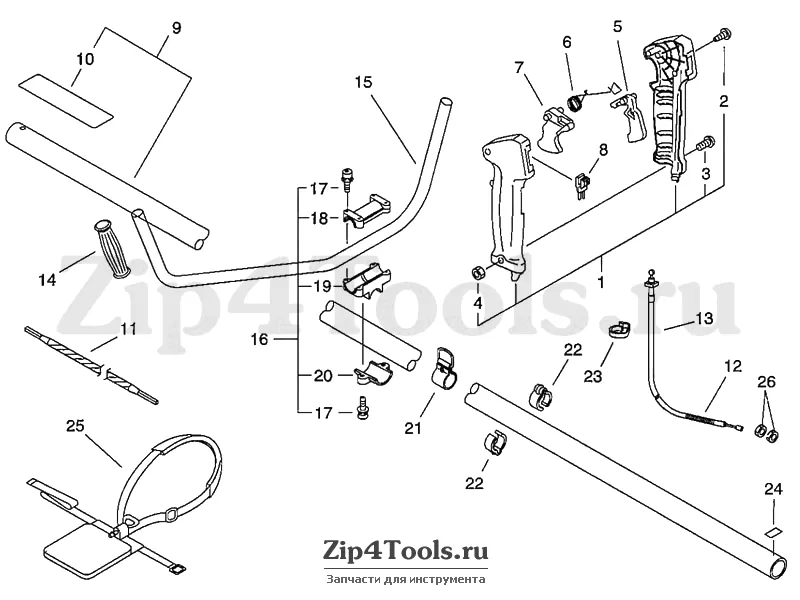

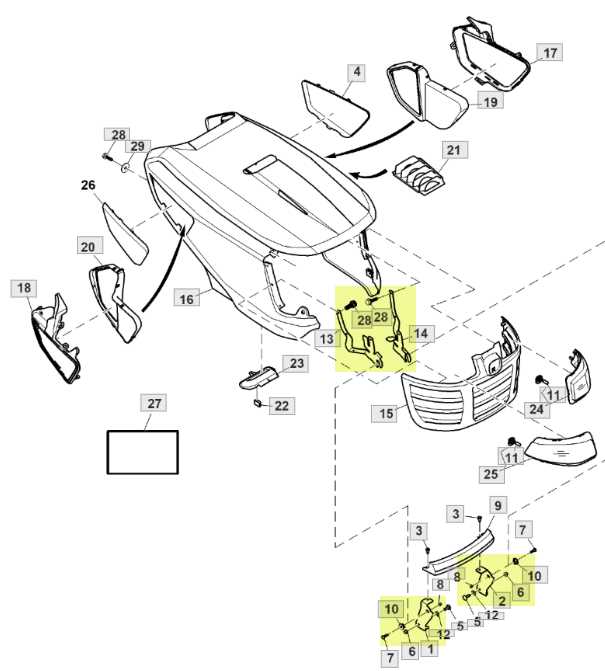

Each element of the machine plays a crucial role in its overall functionality, making it important to familiarize oneself with the configuration and relationships between various parts. This information not only aids in troubleshooting but also empowers users to make informed decisions when it comes to repairs and upgrades. With detailed visual aids, one can easily navigate through the complexities of the machinery.

Understanding the layout of each component provides insights into how they interact, facilitating smoother operation and longevity of the equipment. Whether you’re a seasoned user or new to the world of lawn care machinery, grasping these details will help you maximize efficiency and performance. Let’s embark on a journey to uncover the essential elements that keep your outdoor equipment running smoothly.

Understanding John Deere D105 Components

Every machine is composed of various elements that contribute to its overall functionality and efficiency. Recognizing these components is essential for proper maintenance and troubleshooting. A comprehensive understanding of each part enhances the user’s ability to optimize performance and extend the life of the equipment.

Engine: The heart of the machinery, this component provides the necessary power for operation. It converts fuel into mechanical energy, ensuring smooth performance under varying conditions.

Transmission: This system plays a critical role in controlling speed and torque. By selecting the appropriate gear, it allows for optimal handling of diverse terrains and tasks.

Chassis: The framework supports all other parts, providing stability and durability. A robust chassis is crucial for maintaining balance and absorbing stress during operation.

Electrical System: This component powers lights, ignition, and various accessories. Understanding its layout can assist in troubleshooting electrical issues effectively.

Deck: The cutting mechanism, essential for maintaining lawns, is designed to achieve precision and efficiency. Familiarity with its structure allows for better care and adjustment.

By delving into these key components, users can enhance their skills and ensure their equipment operates at its ultimate potential.

Importance of Parts Diagrams

Understanding the intricacies of machinery requires clear visual representations. These illustrations serve as essential tools for both maintenance and repair, offering a detailed overview of components and their interrelationships. By utilizing such visuals, operators can effectively identify issues, streamline repairs, and ensure optimal functionality of their equipment.

Enhanced Maintenance Efficiency

Visual aids provide clarity and precision, allowing users to pinpoint specific elements that may require attention. This leads to quicker diagnosis of problems and reduces downtime. When individuals have a clear reference, the process of troubleshooting becomes significantly more straightforward, ultimately saving time and resources.

Improved Safety and Understanding

In any machinery-related task, safety is paramount. Clear illustrations help operators comprehend the layout and functioning of various elements, minimizing the risk of accidents. When individuals understand how components interact, they are better equipped to handle repairs and maintenance tasks, promoting a safer working environment.

In conclusion, visual representations are invaluable resources that enhance both the efficiency and safety of equipment management. Their role in facilitating effective maintenance cannot be overstated, making them a crucial aspect of any operational strategy.

How to Read Diagrams Effectively

Understanding complex visuals can be challenging, yet it is essential for successful troubleshooting and maintenance. Whether you’re working on machinery or any technical equipment, grasping the layout and relationships depicted in these illustrations is crucial. This section will provide strategies to enhance your comprehension of these representations.

Key Steps to Interpretation

- Familiarize Yourself with Symbols: Each visual representation often employs specific icons and notations. Take time to learn what each symbol means.

- Identify the Main Components: Start by locating the primary elements. Understanding their positions can give context to the entire layout.

- Follow the Flow: Many visuals depict a sequence. Trace the paths between elements to see how they interact with one another.

Tips for Enhanced Understanding

- Take Notes: Jot down your observations as you study. This can help reinforce your understanding.

- Use Color Coding: If applicable, highlighting sections can aid in differentiating between various parts or functions.

- Consult Reference Materials: If you’re unsure about certain aspects, look for guides or manuals that explain the details further.

Common Issues with D105 Parts

When dealing with components of lawn care machinery, users often encounter a variety of challenges that can impact performance and longevity. Understanding these issues is crucial for maintenance and efficient operation.

- Wear and Tear: Components may deteriorate over time due to regular use, leading to decreased efficiency.

- Improper Alignment: Misalignment can cause parts to function incorrectly, resulting in noise and potential damage.

- Corrosion: Exposure to moisture can lead to rust and deterioration, particularly in metallic components.

- Blockages: Debris accumulation can obstruct airflow or movement, hindering functionality.

- Fluid Leaks: Seals may wear out, resulting in leaks that can affect operational integrity.

Addressing these common problems promptly can enhance the reliability and performance of the equipment. Regular inspections and maintenance routines are recommended to mitigate these issues.

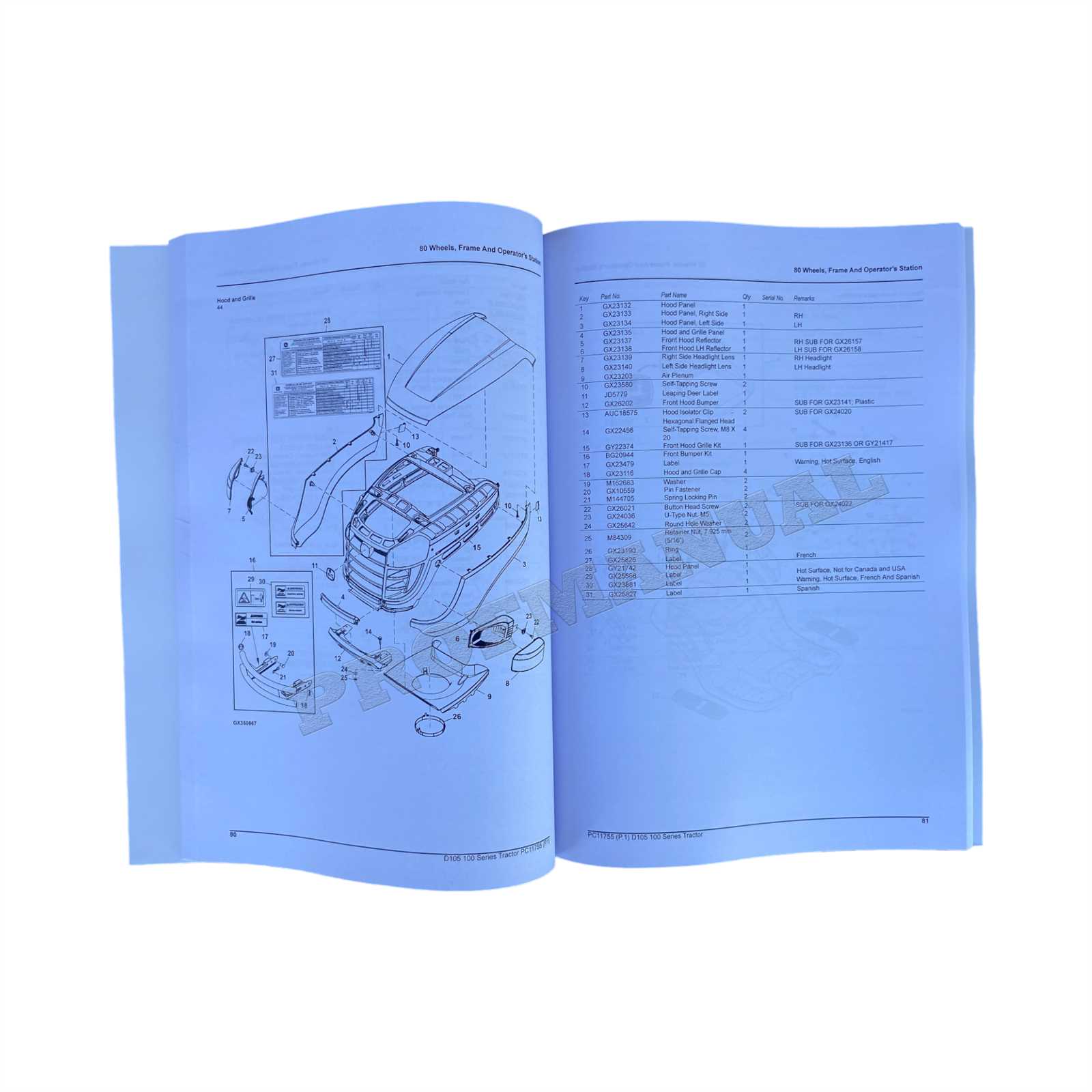

Where to Find Official Diagrams

When seeking detailed illustrations for machinery components, it is essential to access reliable sources that provide accurate and up-to-date information. These resources not only aid in identifying the correct parts but also assist in understanding the assembly and functionality of the equipment.

Manufacturer Websites: The first place to check is the official site of the equipment’s manufacturer. They often offer a dedicated section for manuals and technical resources, which includes comprehensive schematics and illustrations for various models.

Authorized Dealers: Contacting authorized dealers can be beneficial as they typically have access to proprietary documentation and can provide guidance on locating specific illustrations tailored to your model.

Online Forums and Communities: Engaging with online communities or forums dedicated to machinery can yield valuable insights. Enthusiasts and professionals often share resources, including links to official illustrations and user manuals.

Parts Retailers: Reputable retailers that specialize in equipment components may also host sections for technical documentation. These platforms frequently have searchable databases where users can find diagrams related to their machinery.

Library and Archive Resources: For those who prefer physical copies, local libraries or archives may hold manuals and technical documents. Many libraries have interlibrary loan services, allowing you to access a wider range of materials.

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components offers a range of advantages that enhance the performance and longevity of machinery. These high-quality replacements are specifically designed to fit and function seamlessly with your equipment, ensuring optimal efficiency and reliability.

One significant benefit is the assurance of compatibility. Since these components are made to the exact specifications of the original design, they eliminate the risks associated with mismatched alternatives. This compatibility translates to improved performance, allowing machines to operate at their best without unnecessary disruptions.

Another advantage is the durability of OEM components. Crafted from superior materials, they tend to outlast generic options, providing better value in the long run. Investing in these quality parts reduces the frequency of replacements and repairs, leading to lower maintenance costs over time.

Moreover, using original components can help maintain the warranty of the machinery. Many manufacturers stipulate that utilizing non-genuine parts may void warranties, which can lead to unexpected expenses. Sticking with OEM components ensures that the equipment remains protected under its warranty terms.

Finally, sourcing these components often comes with access to exceptional customer support and resources from manufacturers. This support can be invaluable, offering guidance and information that enhances the overall maintenance experience. Overall, opting for original components is a smart choice that pays off through enhanced performance, reliability, and peace of mind.

Maintenance Tips for D105 Owners

Proper upkeep of your equipment is essential to ensure its longevity and optimal performance. Regular maintenance not only enhances efficiency but also prevents unexpected breakdowns, allowing you to complete tasks smoothly and effectively. Below are some vital tips to help you maintain your machine in excellent condition.

Routine Checks

Conducting frequent inspections is crucial. Look for signs of wear and tear, such as leaks or unusual noises. Regularly check the fluid levels, including oil and coolant, to keep everything running smoothly. A clean air filter is also vital for efficient operation, so inspect and replace it as needed.

Cleaning and Storage

Keeping your equipment clean helps prevent rust and deterioration. After each use, remove any dirt and debris to maintain a pristine condition. Additionally, when storing the machine, ensure it is in a dry, sheltered area to protect it from the elements. Covering it with a tarp can provide extra protection against dust and moisture.

By following these maintenance practices, you can enhance the performance and lifespan of your equipment, ensuring it remains a reliable tool for all your projects.

Replacing Parts: Step-by-Step Guide

Maintaining equipment efficiency often requires the replacement of certain components. This guide outlines a systematic approach to facilitate the process, ensuring that each step is clear and manageable. By following these instructions, users can achieve successful replacements with minimal hassle.

Preparation

- Gather necessary tools: screwdrivers, wrenches, and safety gloves.

- Identify the specific components that need replacement.

- Consult the user manual for detailed specifications and recommendations.

Replacement Process

- Ensure the equipment is powered off and disconnected from any power source.

- Carefully remove any covers or protective casings to access the components.

- Take note of the arrangement of parts, using photographs if necessary for reference.

- Remove the damaged or worn-out item, taking care to follow the correct procedure.

- Install the new component, ensuring it fits securely and is aligned properly.

- Replace any covers or casings, ensuring they are fastened correctly.

- Test the equipment to confirm that the new item is functioning as intended.

By following these steps, users can effectively replace essential components and maintain optimal performance in their machinery.