The efficiency of modern farming machinery relies heavily on the intricate design and functionality of its various components. Each element plays a crucial role in ensuring that the overall operation meets the demands of today’s agricultural practices. By gaining insight into these individual pieces, users can enhance maintenance routines and improve performance.

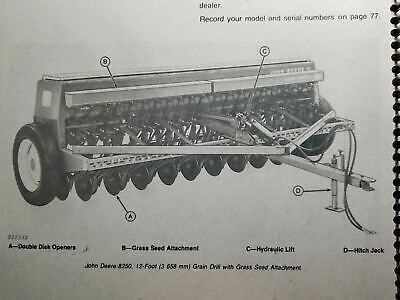

In this section, we will explore the layout of an advanced seeding implement, highlighting its essential mechanisms and how they interact. A comprehensive understanding of these components not only aids in troubleshooting but also empowers operators to maximize the effectiveness of their equipment.

Furthermore, knowing the specific functions of each element facilitates informed decision-making regarding replacements and upgrades. This knowledge can ultimately lead to increased productivity and reduced downtime, making it indispensable for those in the agricultural sector.

Understanding John Deere 8300 Components

Familiarity with the various elements of agricultural machinery is essential for effective operation and maintenance. Each component plays a vital role in ensuring optimal performance and productivity. A thorough comprehension of these elements not only aids in troubleshooting but also enhances overall efficiency in farming practices.

Key components of this specific machine include the frame, which provides structural integrity, and the seed metering system, responsible for accurate seed placement. Additionally, the furrow openers are crucial for creating the right planting depth, while the transport wheels facilitate mobility across fields. Understanding how these elements interact is fundamental for anyone looking to maximize their equipment’s potential.

Regular inspection and maintenance of each part can prevent downtime and extend the lifespan of the equipment. Familiarizing oneself with the layout and functionality of these components will empower operators to make informed decisions regarding repairs and upgrades, ultimately contributing to better crop yields and efficiency.

Importance of Grain Drill Maintenance

Regular upkeep of agricultural implements is crucial for ensuring optimal performance and longevity. Neglecting maintenance can lead to decreased efficiency, increased downtime, and higher operational costs. By dedicating time to proper care, farmers can maximize productivity and safeguard their investment.

Routine inspections help identify potential issues before they escalate into significant problems. Components such as bearings, belts, and blades are subject to wear and tear, and early detection can prevent costly repairs. Additionally, maintaining precise settings enhances the accuracy of planting, leading to better crop yields.

Consistent maintenance practices not only prolong the lifespan of machinery but also contribute to safer operation. Well-maintained equipment reduces the risk of breakdowns, minimizing the chance of accidents on the field. Furthermore, a reliable machine fosters confidence, allowing farmers to focus on other critical aspects of their work.

Investing in maintenance also aligns with sustainable farming practices. Efficiently functioning equipment uses resources more wisely, reducing waste and environmental impact. Ultimately, a commitment to care ensures that agricultural tools remain effective and ready to meet the demands of modern farming.

Key Features of the 8300 Model

This model is renowned for its advanced capabilities, designed to enhance efficiency in various agricultural tasks. Its construction integrates innovative technology to ensure optimal performance, making it a reliable choice for farmers.

Robust Design: The unit features a sturdy build that withstands rigorous field conditions, providing longevity and reducing maintenance needs.

Precision Engineering: Equipped with an accurate seed placement system, this model guarantees even distribution, which is crucial for maximizing crop yield.

User-Friendly Controls: The interface is designed for ease of use, allowing operators to make adjustments quickly, thus saving valuable time during busy seasons.

Versatile Applications: Its adaptability allows it to handle a variety of seeds, catering to different farming requirements, whether for grains or cover crops.

Enhanced Mobility: With improved transport features, this equipment can easily navigate diverse terrains, ensuring productivity across various landscapes.

Common Issues with Grain Drill Parts

When operating seeding equipment, several challenges can arise that affect efficiency and performance. Understanding these common concerns can help in maintaining optimal functionality and prolonging the lifespan of the machine.

Wear and Tear

Over time, components can experience significant wear, leading to diminished effectiveness. Regular inspections are crucial to identify friction points and replace worn parts promptly. Components such as blades and bearings are particularly susceptible to degradation, which can hinder precise seed placement.

Clogging and Blockages

Another prevalent issue is clogging in the delivery system. Debris or residue can accumulate, obstructing the flow of seeds and impacting distribution. Ensuring that all channels are clear and implementing a routine cleaning schedule can mitigate this problem. Additionally, checking for misalignment can prevent future blockages and improve overall efficiency.

Replacement Parts for Optimal Performance

Ensuring the highest level of efficiency in agricultural equipment often hinges on the quality of components used. Regular maintenance and timely replacement of essential elements can significantly enhance functionality and longevity, ultimately leading to improved crop yields. Selecting the right substitutes is crucial for maintaining operational excellence.

Key Components to Consider

Identifying and replacing worn or damaged items is fundamental for peak performance. Below are some critical components that require attention:

| Component | Function | Replacement Frequency |

|---|---|---|

| Seed Box | Holds and distributes seeds evenly | Every season |

| Openers | Creates furrows for planting | As needed, based on wear |

| Drive Chains | Transmits power from the tractor | Check annually |

| Press Wheels | Ensures soil contact for seed germination | Every few seasons |

Benefits of Using Quality Replacements

Utilizing high-quality substitutes enhances the overall performance of agricultural machinery. Reliable components ensure consistent operation, reduce the risk of breakdowns, and ultimately lead to better productivity. Investing in durable replacements is a step towards maximizing efficiency in farming practices.

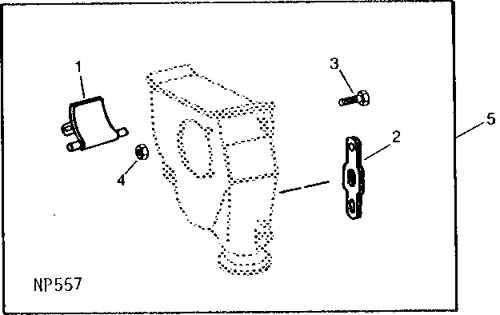

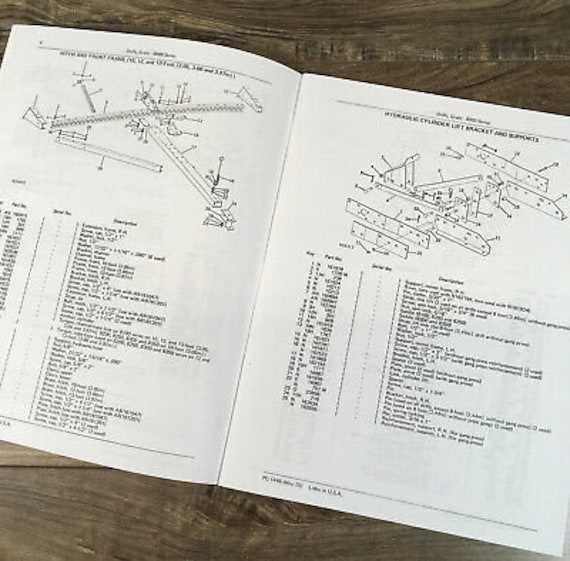

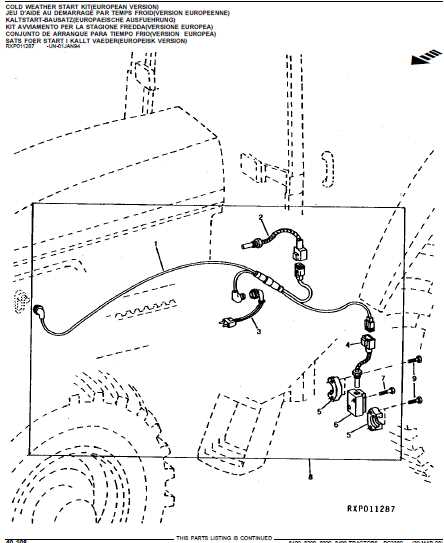

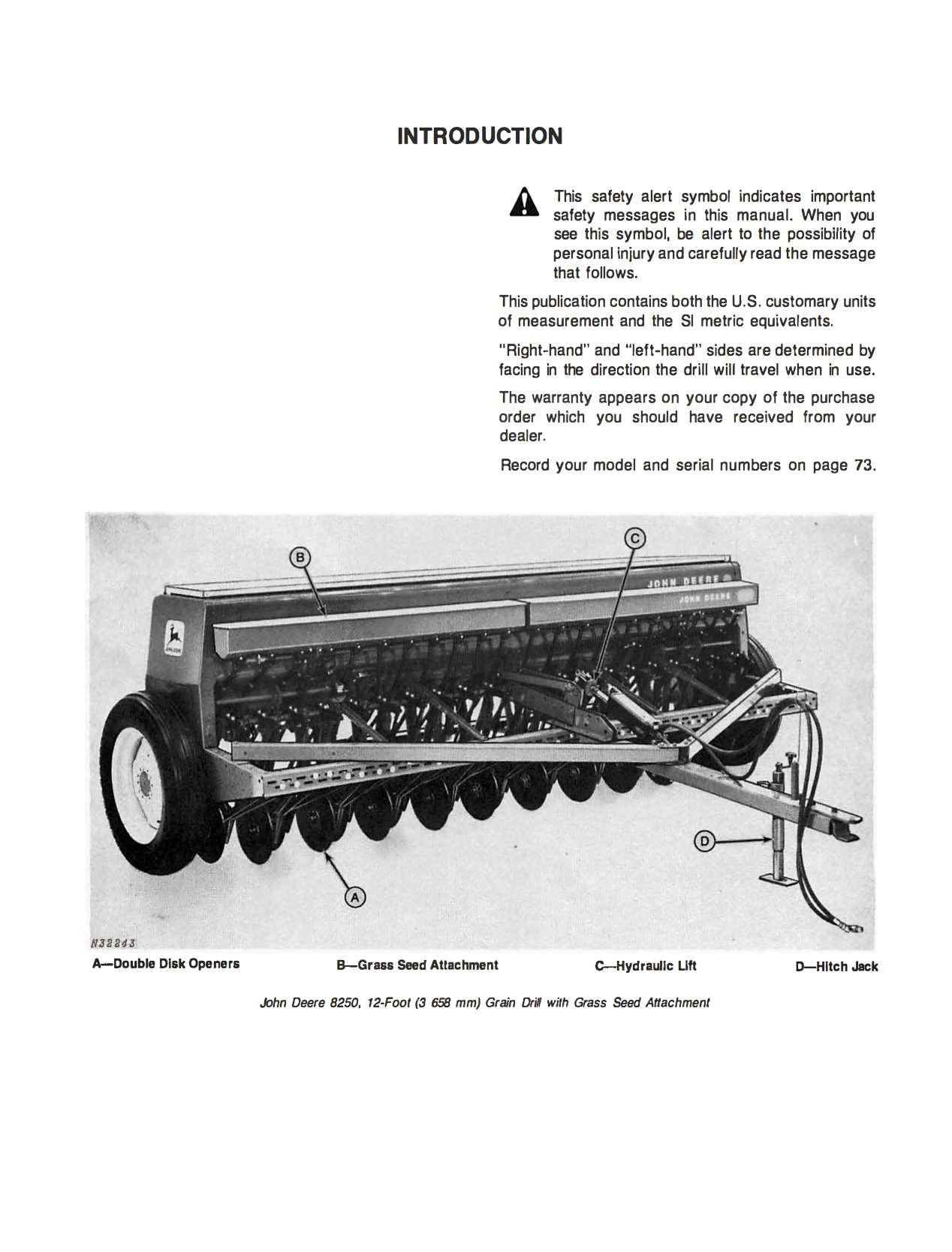

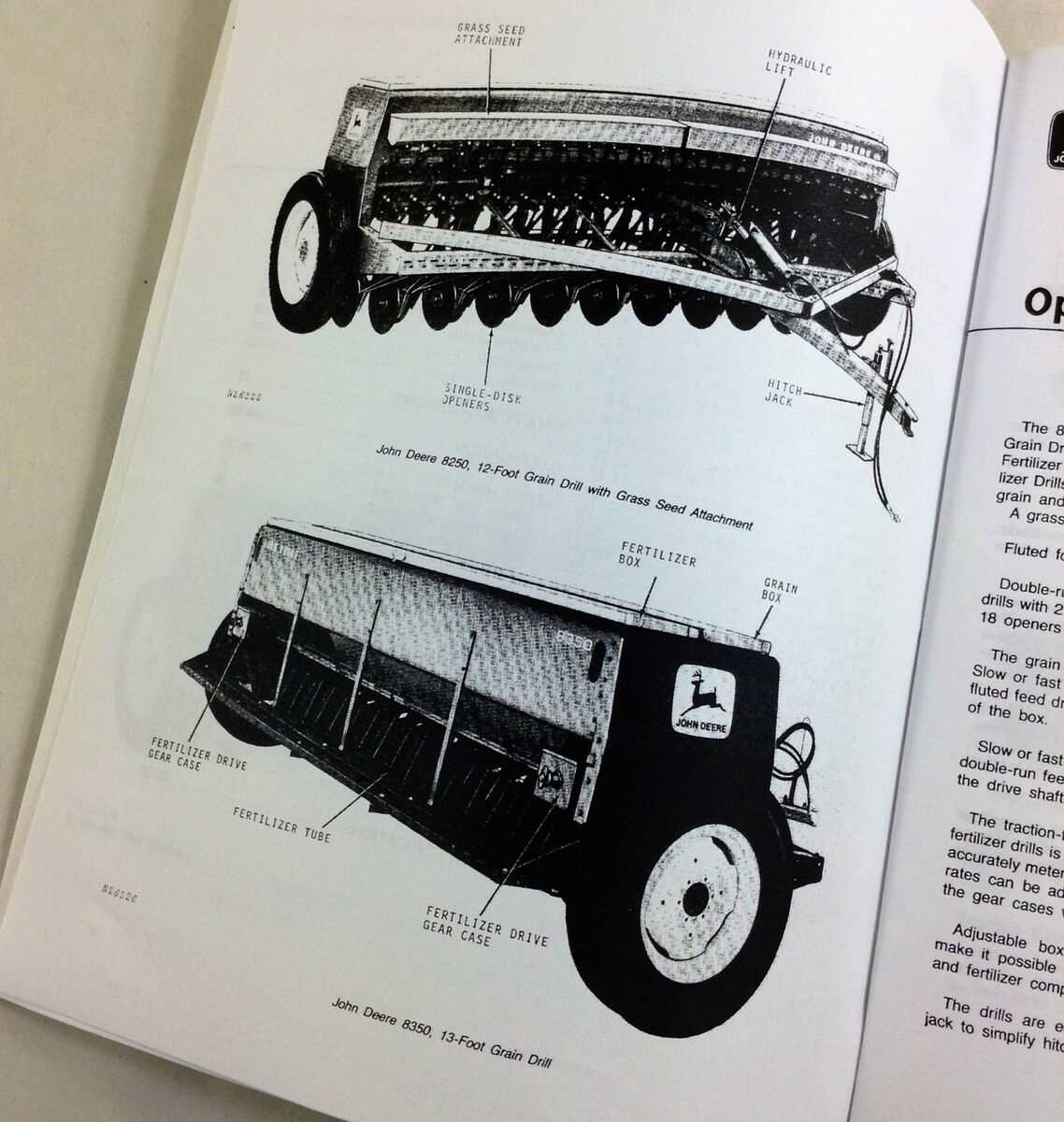

Identifying Parts through Diagrams

Understanding the various components of agricultural machinery can significantly enhance efficiency and maintenance. Visual representations serve as valuable tools in identifying and locating each element, providing clarity and insight into their functions and interconnections.

Benefits of Visual Aids

Utilizing illustrations allows operators to quickly recognize essential elements, streamlining the troubleshooting process. Moreover, these visuals facilitate better communication among team members, ensuring everyone is on the same page when discussing repairs or modifications.

Interpreting the Visuals

When analyzing these representations, it’s crucial to pay attention to labels and legends that indicate specific functionalities. By delving into these details, users can ultimately enhance their understanding and improve overall equipment management.

Tips for Effective Parts Replacement

Replacing components in machinery can enhance performance and extend longevity. Proper techniques and preparation are essential for a smooth process, ensuring that each element functions optimally after installation.

Preparation and Research

Before initiating the replacement, gather all necessary information about the components involved. Consult manuals or online resources to understand the specifications and requirements. This knowledge will facilitate a more efficient and error-free replacement.

Quality and Compatibility

Always choose high-quality replacements that are compatible with your machinery. Investing in reliable components can prevent future issues and maintain operational efficiency. Verify that the selected items meet the manufacturer’s standards for optimal performance.

Resources for John Deere Owners

Maintaining and enhancing your agricultural machinery is crucial for optimal performance. Access to reliable information and resources can significantly aid in ensuring your equipment runs smoothly and efficiently.

- Online Forums: Engage with fellow enthusiasts and professionals to share insights and troubleshooting tips.

- Manufacturer Websites: Official sites often provide manuals, updates, and specifications essential for upkeep.

- Local Dealerships: Authorized dealers can offer personalized advice and genuine components for repairs.

- Instructional Videos: Platforms like YouTube host a variety of tutorials that delve into maintenance and repairs.

Utilizing these resources can lead to the ultimate performance of your equipment, ensuring it meets all your agricultural needs.

Innovations in Grain Drill Technology

Recent advancements in agricultural machinery have significantly enhanced the efficiency and precision of seeding practices. These innovations focus on optimizing planting techniques, improving crop yields, and reducing resource consumption. By integrating modern technology, farmers can achieve greater consistency and effectiveness in their operations.

- Precision Planting: New systems utilize GPS and satellite imagery to ensure accurate seed placement. This technology minimizes overlap and maximizes field coverage.

- Variable Rate Technology: This approach allows for the adjustment of seed quantities based on specific field conditions, promoting better resource management.

- Smart Sensors: Equipped with advanced sensors, modern equipment can monitor soil moisture and nutrient levels, enabling real-time adjustments during the planting process.

- Automated Controls: Automation reduces labor requirements and enhances operational efficiency by allowing for remote monitoring and control of machinery.

These developments not only improve the accuracy of planting but also contribute to sustainable farming practices. By adopting these cutting-edge solutions, agricultural producers can better meet the demands of a growing population while safeguarding natural resources.