In the realm of agricultural equipment, comprehending the intricate assembly of machinery is crucial for optimal performance and maintenance. Familiarity with the various elements and their functions can significantly enhance operational efficiency and prolong the lifespan of the equipment. This section aims to provide insight into the essential components that constitute a specific model of heavy machinery.

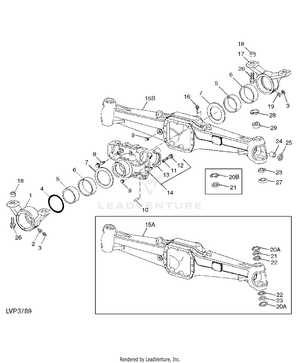

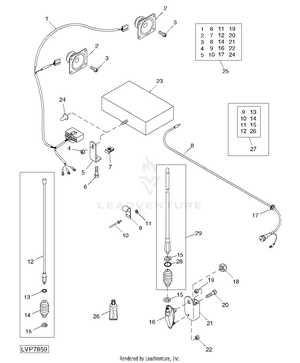

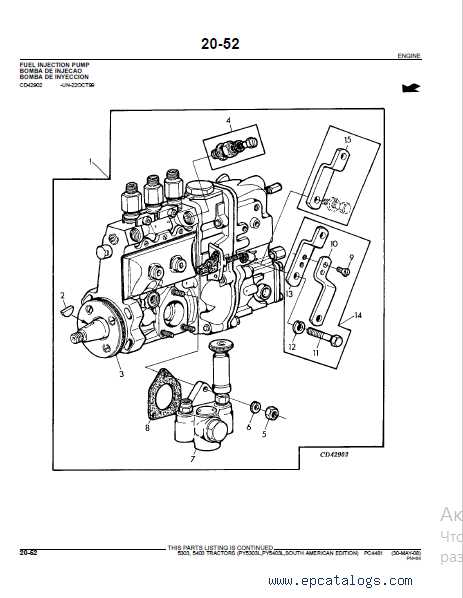

Visual aids play a pivotal role in facilitating a clear understanding of how these components interrelate. By examining detailed representations, users can identify individual parts, their placements, and how they contribute to the overall functionality of the machine. This knowledge empowers operators and technicians alike to address potential issues more effectively.

Furthermore, recognizing the significance of each component not only aids in troubleshooting but also assists in the procurement of replacement items when necessary. A well-informed approach to machinery maintenance ensures that agricultural operations run smoothly, reducing downtime and enhancing productivity in the field.

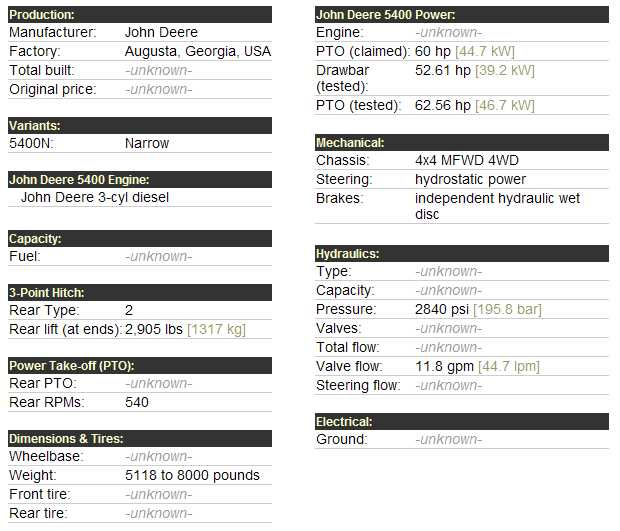

Understanding John Deere 5400 Components

Grasping the intricacies of machinery is essential for effective maintenance and repair. Familiarity with individual elements allows operators and technicians to troubleshoot issues efficiently and enhance the overall performance of the equipment. Each component plays a vital role in ensuring smooth operation and longevity.

When analyzing the structure of such machinery, it is important to consider the following categories of components:

- Engine System: Powers the entire unit and includes various subsystems that manage fuel, air intake, and exhaust.

- Transmission: Facilitates the transfer of power from the engine to the wheels, affecting speed and torque.

- Hydraulic System: Utilizes fluid power to operate attachments and implements, crucial for functionality in various tasks.

- Electrical Components: Encompass wiring, sensors, and control systems that manage and monitor machine operations.

- Chassis and Frame: Provides structural support and stability, ensuring durability under various working conditions.

Understanding these elements not only aids in identifying potential problems but also enhances the operator’s ability to make informed decisions regarding upgrades and modifications. A comprehensive knowledge of machinery components can lead to improved efficiency and reduced downtime in operations.

Importance of Parts Diagrams

Understanding the layout of machinery components is crucial for effective maintenance and repair. Visual representations provide clarity, allowing operators to identify each element’s function and location. This insight ultimately enhances efficiency and prolongs the lifespan of equipment.

Additionally, these illustrations facilitate communication among technicians, ensuring everyone is on the same page during service procedures. This collective understanding minimizes errors and accelerates the troubleshooting process.

| Benefits | Description |

|---|---|

| Clarity | Helps in easily identifying components and their arrangement. |

| Efficiency | Speeds up repair processes by providing quick reference. |

| Collaboration | Enhances teamwork among service personnel. |

| Error Reduction | Minimizes mistakes in assembly and disassembly tasks. |

Common Issues with 5400 Models

The machinery in question often encounters a variety of challenges that can affect performance and reliability. Understanding these common problems is crucial for effective maintenance and longevity. Identifying symptoms early can lead to timely interventions and reduce overall downtime.

One frequent concern is engine performance. Operators may notice a decrease in power output or increased fuel consumption, which could indicate issues such as clogged filters or malfunctioning injectors. Regular inspections and timely replacements can help mitigate these issues.

Another issue involves hydraulic systems. Users might experience leaks or unresponsive controls, which can hinder operational efficiency. Checking seals and connections periodically can prevent more serious complications.

Transmission problems are also reported, where shifts may become rough or unresponsive. This could stem from low fluid levels or worn components. Ensuring proper fluid maintenance is essential to avoid extensive repairs.

Lastly, electrical faults can disrupt functionality, with symptoms like malfunctioning lights or faulty gauges. Regularly inspecting wiring and connections can help maintain electrical integrity and prevent these frustrating issues.

How to Read Parts Diagrams

Understanding visual representations of machinery components is essential for effective maintenance and repair. These illustrations serve as guides, allowing users to identify various elements and their relationships within the system.

To effectively interpret these visual aids, consider the following steps:

- Familiarize Yourself with the Legend:

- Look for symbols and their meanings.

- Check for color coding that indicates specific categories or functions.

- Identify Major Sections:

- Locate the main assemblies and subassemblies.

- Understand how these components interact with each other.

- Follow the Numbering System:

- Numbers typically correspond to individual components.

- Cross-reference these with the accompanying list for further details.

- Pay Attention to Annotations:

- Note any additional notes or instructions provided.

- Look for maintenance tips or troubleshooting information.

By systematically analyzing these elements, you can gain a comprehensive understanding of the machinery, facilitating efficient repairs and ensuring optimal performance.

Where to Find Replacement Parts

Locating suitable components for agricultural machinery can often seem daunting. However, numerous resources are available to assist you in finding the necessary items to keep your equipment running smoothly. From online marketplaces to local dealerships, understanding your options can make the process much easier.

| Resource Type | Description | Benefits |

|---|---|---|

| Online Retailers | Websites dedicated to selling machinery components. | Wide selection, often competitive pricing. |

| Authorized Dealers | Official distributors for specific brands. | Guaranteed compatibility and quality assurance. |

| Local Repair Shops | Businesses that specialize in equipment maintenance. | Expert advice and immediate availability of items. |

| Salvage Yards | Places that offer used machinery parts. | Cost-effective options and rare finds. |

| Online Forums | Communities of equipment enthusiasts and professionals. | Shared experiences and recommendations. |

Maintenance Tips for John Deere 5400

Proper upkeep is essential for maximizing the lifespan and efficiency of your agricultural machinery. Regular attention to key components ensures optimal performance and minimizes the risk of unexpected breakdowns. Here are some effective strategies to keep your equipment running smoothly.

Routine Inspections

Conducting frequent checks on fluid levels, filters, and belts can help identify potential issues before they escalate. Inspect tire pressure and tread wear to enhance stability and traction. Ensure that all connections are secure and free from corrosion to maintain reliable functionality.

Scheduled Servicing

Adhering to a scheduled maintenance plan is crucial. Replace fluids, change filters, and service the engine according to the manufacturer’s recommendations. Invest in quality lubricants and ensure all moving parts are well-greased to reduce friction and wear. Timely maintenance not only enhances performance but also boosts resale value.

Comparing 5400 Parts with Other Models

Understanding the components of different machinery models can provide valuable insights into their compatibility and performance. When examining the elements of one specific model alongside others, it becomes evident how design variations can affect functionality and maintenance. This analysis aids in identifying interchangeable components, enhancing repair efficiency, and optimizing performance across similar units.

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Engine Type | 4-Cylinder | 3-Cylinder | 4-Cylinder |

| Horsepower | 60 HP | 50 HP | 65 HP |

| Transmission | Manual | Hydrostatic | Manual |

| Wheelbase | 85 inches | 80 inches | 90 inches |

| Weight | 3200 lbs | 2800 lbs | 3500 lbs |

This table illustrates key specifications that can differ significantly between various machinery types. Such comparisons enable operators to make informed decisions regarding upgrades or repairs based on their specific operational needs and preferences.

Online Resources for Repair Guides

Accessing reliable online resources can significantly enhance your repair experience. Various platforms provide detailed manuals, troubleshooting tips, and user forums that cater to both novice and experienced individuals. These resources often include step-by-step instructions, diagrams, and videos that facilitate understanding and execution of repairs.

Websites dedicated to agricultural machinery often feature extensive libraries of guides and community support. These platforms allow users to share experiences, seek advice, and exchange valuable insights, creating a collaborative environment. Additionally, some sites offer downloadable content that can be accessed offline, ensuring that assistance is always within reach during repair tasks.

Expert Recommendations for Upgrades

Enhancing the performance and longevity of agricultural machinery can significantly boost productivity and efficiency. Expert insights suggest that strategic upgrades can make a noticeable difference in operation, ultimately leading to better results in the field.

1. Optimize Engine Performance: Consider upgrading the engine’s air intake and exhaust systems. Enhanced airflow can lead to improved combustion, resulting in better power output and fuel efficiency. Regular maintenance of these systems is also crucial to maintain optimal performance.

2. Improve Hydraulics: Upgrading hydraulic components, such as pumps and cylinders, can increase lifting capacity and responsiveness. High-performance hydraulic fluids can also reduce wear and tear, ensuring smoother operations under heavy loads.

3. Upgrade Tires: Selecting high-quality tires designed for specific terrains can enhance traction and stability. This can prevent slippage and increase operational speed, ultimately improving overall efficiency.

4. Implement Precision Agriculture Technology: Integrating GPS and other precision tools can greatly enhance operational accuracy. This technology allows for better planning and execution, reducing waste and increasing yield.

5. Focus on Operator Comfort: Enhancing the operator’s experience with upgraded seating, climate control, and visibility features can lead to improved concentration and productivity. Comfortable operators are more effective in their tasks.

By considering these recommendations, you can ensure your machinery remains competitive and capable of meeting the demands of modern agriculture.