When it comes to maintaining and optimizing agricultural equipment, having a clear overview of its components is essential. This knowledge enables operators to ensure their machinery runs smoothly and efficiently, minimizing downtime and enhancing productivity.

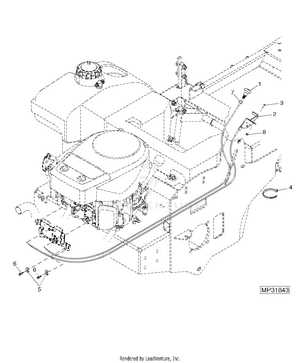

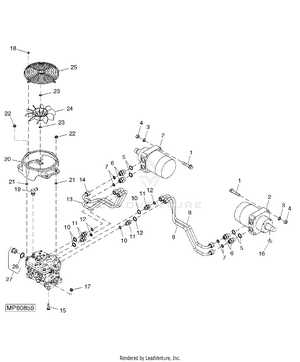

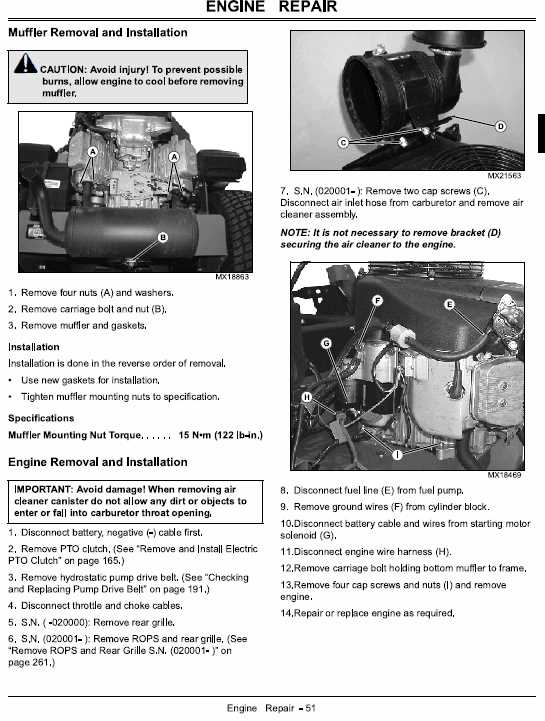

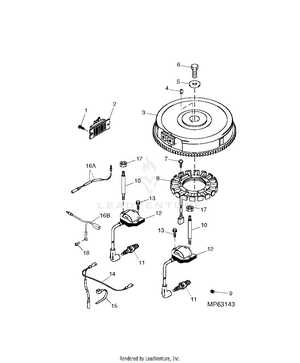

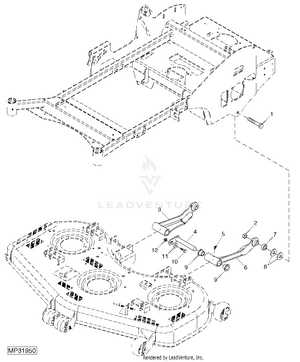

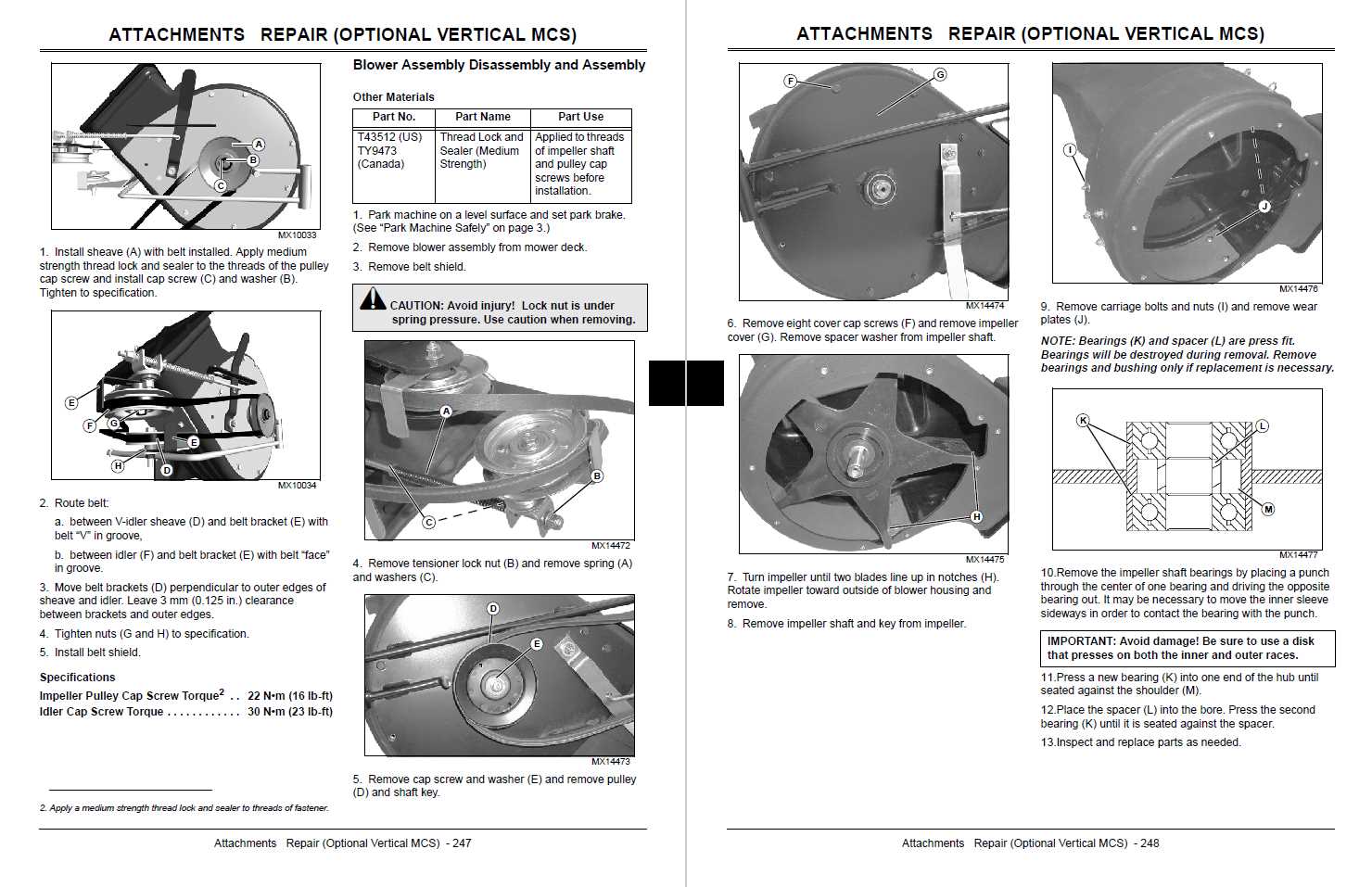

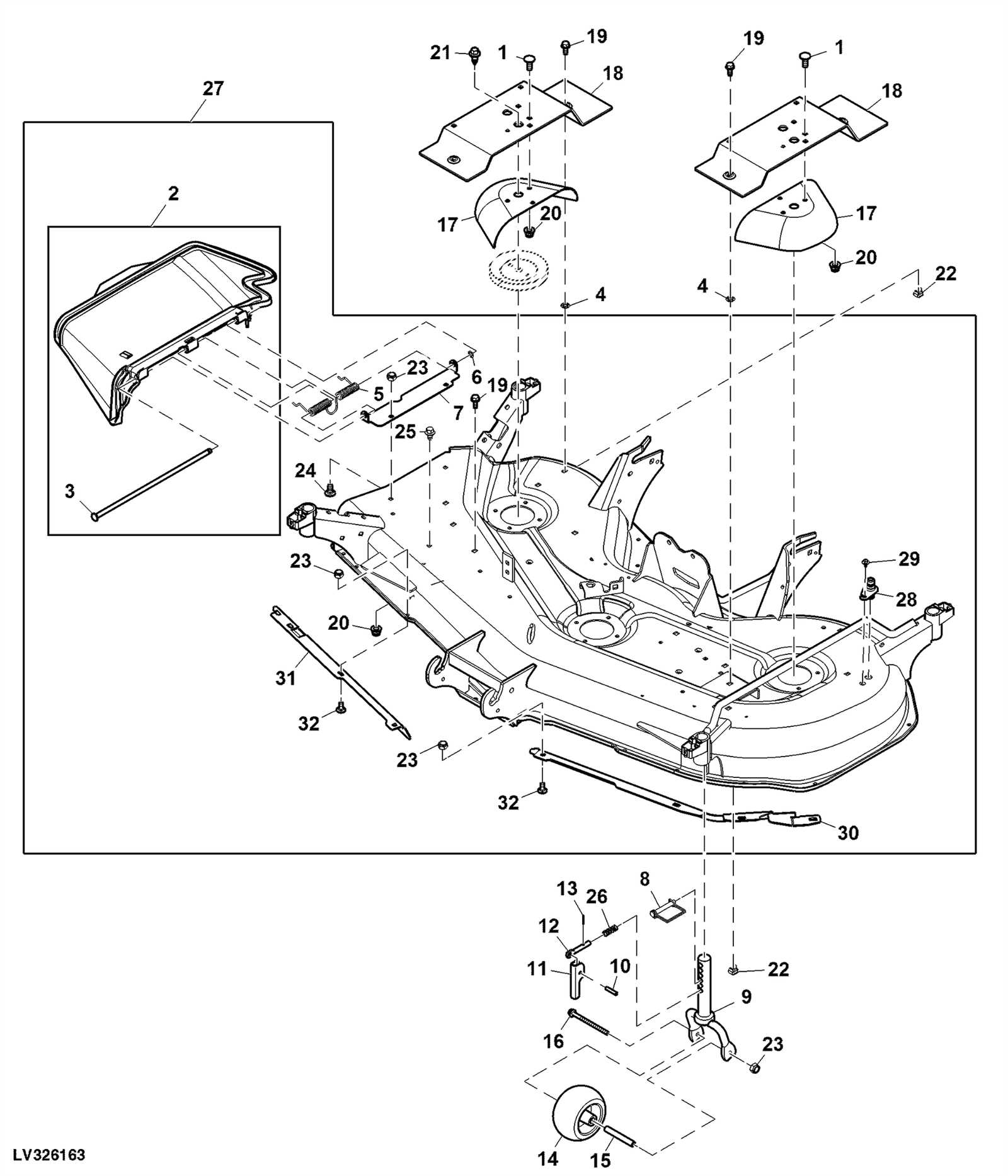

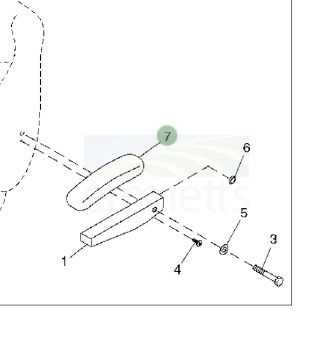

Visual representations of machinery components can significantly aid in identifying and locating necessary elements for repairs or upgrades. By studying these illustrations, users can develop a deeper understanding of the intricate relationships between various parts, making troubleshooting more effective.

Furthermore, being familiar with the structure of the equipment can lead to informed decisions regarding replacements and modifications. A thorough grasp of the machinery’s inner workings ultimately contributes to better performance and longevity.

Understanding the John Deere 727A

The machinery in question is a remarkable piece of equipment widely recognized for its efficiency and reliability in various agricultural applications. This model is designed to tackle demanding tasks, offering a blend of power and precision that enhances productivity in the field.

Key features of this machine include its robust engine, which delivers impressive performance while maintaining fuel efficiency. The intuitive controls are designed for ease of use, allowing operators to maneuver with confidence and tackle even the most challenging terrains.

Moreover, regular maintenance is crucial for ensuring optimal functionality. Understanding the components and their arrangement can significantly aid in troubleshooting and repairs. Familiarity with each part enhances the operator’s ability to keep the equipment in top condition, prolonging its lifespan and effectiveness.

In summary, comprehending the intricate details of this agricultural powerhouse equips users with the knowledge necessary for maximizing its capabilities and ensuring successful operations in the field.

Key Components of the 727A

This section focuses on the essential elements that make up the machinery in question. Understanding these components is crucial for anyone involved in maintenance or repair, as they play a vital role in the overall functionality and performance of the equipment.

Major Elements

Among the primary parts, several are fundamental to ensuring smooth operation. Each element contributes uniquely, and their collective performance determines the efficiency of the entire system.

| Component | Description |

|---|---|

| Engine | Powers the machine and drives its performance. |

| Transmission | Facilitates the transfer of power from the engine to the wheels. |

| Hydraulic System | Controls various functions and enhances operational capabilities. |

| Chassis | Serves as the framework that supports the entire structure. |

Additional Features

Further components enhance usability and comfort. These features are designed to improve user experience, making the equipment easier to operate and more efficient in its tasks.

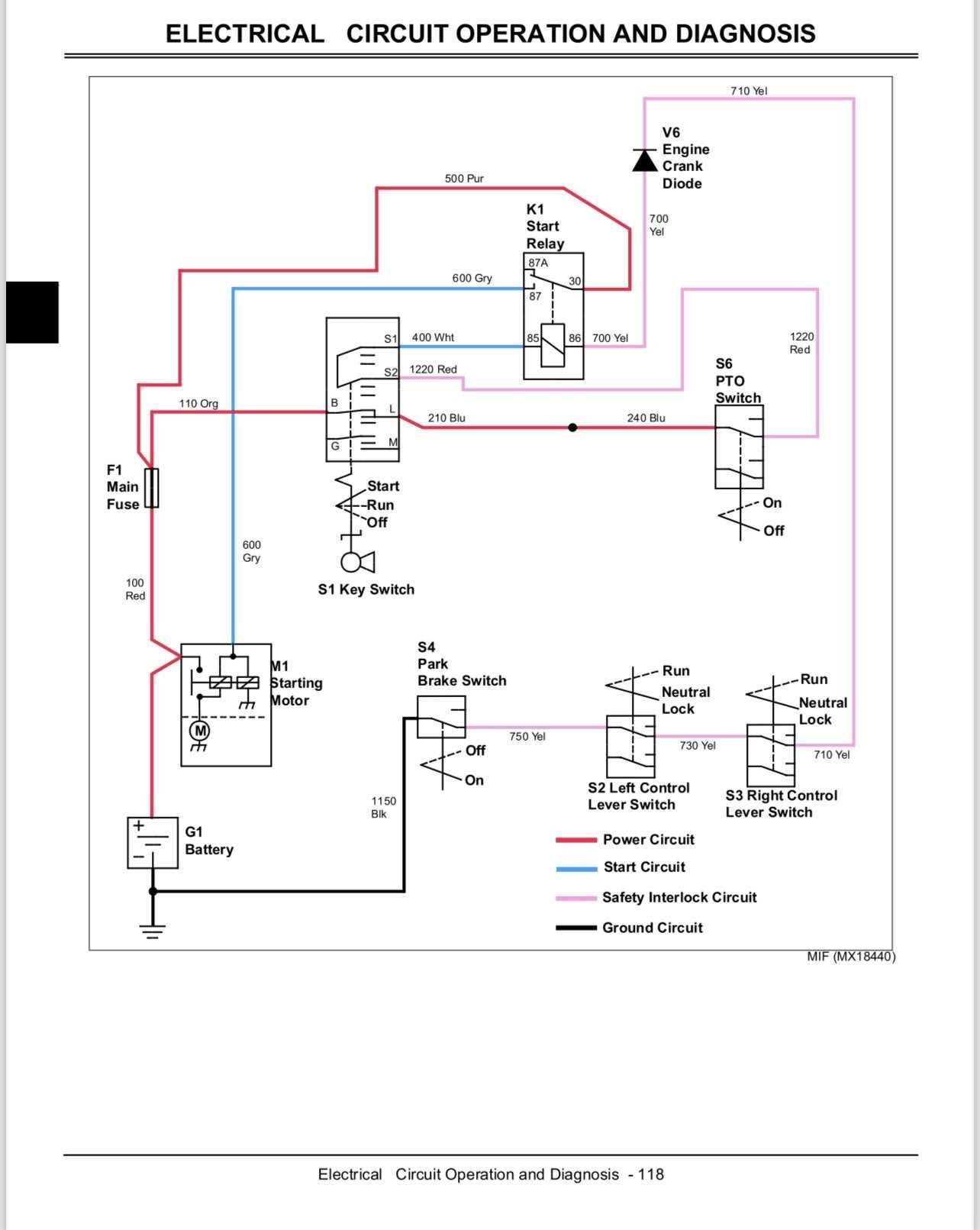

Importance of Parts Diagrams

Understanding the intricacies of machinery requires a clear visual representation of its components. Such illustrations play a crucial role in maintenance and repair, enabling users to identify specific elements easily.

Enhanced Efficiency: These visual guides streamline the repair process, allowing technicians to quickly locate and replace faulty items, ultimately saving time and reducing downtime.

Improved Communication: When collaborating with others, having a visual reference fosters better discussions and helps ensure that everyone is on the same page regarding repairs and replacements.

Accurate Repairs: Access to these visuals minimizes the risk of errors, ensuring that the right components are addressed, which enhances the overall functionality and longevity of the equipment.

Knowledge Expansion: By studying these illustrations, users can deepen their understanding of the machine’s design and operation, fostering a more comprehensive grasp of its workings.

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair. This guide will help you interpret these illustrations, ensuring you can identify and locate each element with ease.

Start by familiarizing yourself with the layout. Components are often numbered or labeled, providing a key to understanding their relationships. Pay attention to the scale, as it helps in estimating sizes accurately.

| Element | Description |

|---|---|

| Reference Number | Indicates specific parts in the accompanying list. |

| Connector Lines | Show how elements interact or are linked. |

| Legends | Explain symbols used in the illustration. |

By mastering these aspects, you can delve deeper into understanding how each component functions within the overall system, leading to more informed decisions during repairs or replacements.

Common Issues with 727A Parts

Many users encounter a variety of challenges when dealing with components of this specific model. Understanding these common concerns can greatly assist in maintenance and repairs, ultimately extending the lifespan of the equipment.

| Issue | Description | Potential Solutions |

|---|---|---|

| Wear and Tear | Components may exhibit signs of deterioration over time due to regular use. | Regular inspections and timely replacements can mitigate this issue. |

| Overheating | Excessive heat can affect performance and lead to breakdowns. | Ensure proper lubrication and cooling systems are functioning optimally. |

| Compatibility Issues | Not all replacements fit perfectly, which can lead to malfunction. | Always verify compatibility before purchasing new components. |

| Corrosion | Exposure to moisture can cause rust and degradation. | Regular cleaning and protective coatings can help prevent corrosion. |

| Loose Connections | Vibrations can cause bolts and fittings to loosen over time. | Routine checks and tightening of connections are advisable. |

Where to Find Replacement Parts

Locating components for machinery maintenance can be a daunting task, but various resources make the process more manageable. Whether you are a seasoned technician or a casual user, understanding where to seek these essentials is crucial for keeping equipment in optimal condition.

Online Retailers are among the most convenient options available. Numerous websites specialize in equipment components, offering extensive catalogs that can be searched by model or category. These platforms often provide detailed descriptions and customer reviews, ensuring informed purchasing decisions.

Local Dealers also serve as reliable sources. Authorized distributors typically stock a wide range of components and can provide expert advice on compatibility and installation. Establishing a relationship with a nearby dealer can lead to valuable insights and access to specialized items.

Salvage Yards represent another viable avenue. Many yards stock used components at a fraction of the new price, allowing for cost-effective repairs. While the condition may vary, a careful inspection can yield valuable finds that extend the life of your machinery.

Online Marketplaces such as auction sites and classified ads offer a platform where individuals can buy and sell used components. While these options may require more diligence to ensure quality, they can lead to significant savings.

By exploring these diverse avenues, you can efficiently find the necessary components to keep your machinery operating smoothly and effectively.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the extended lifespan and optimal performance of your machinery. By implementing a structured maintenance routine, you can prevent issues before they arise, thus enhancing the reliability and efficiency of your equipment.

Routine Inspections

Conducting regular inspections is crucial to identifying wear and tear. Checking fluid levels, filters, and moving parts can help catch potential problems early on. Create a checklist to make the process efficient and thorough.

Proper Storage

Storing machinery in a dry and protected environment can significantly reduce the risk of rust and corrosion. Make sure to clean the equipment before storage and cover it appropriately to shield it from the elements.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Fluid Level Check | Weekly | Ensure all fluids are at recommended levels. |

| Filter Replacement | Every 100 hours | Use manufacturer-recommended filters. |

| Visual Inspection | Daily | Look for signs of wear, leaks, or damage. |

| Thorough Cleaning | Monthly | Remove dirt and debris to improve performance. |

Comparing with Other John Deere Models

When evaluating different machinery from the same manufacturer, it’s essential to understand the unique features and specifications that set each model apart. This comparison not only highlights the strengths and weaknesses of each variant but also helps users make informed decisions based on their specific needs and operational requirements.

For instance, some models may excel in fuel efficiency, while others might prioritize power output or versatility in various tasks. Examining the dimensions, weight, and operational capabilities reveals how each machine fits into various agricultural or industrial applications.

Additionally, understanding the compatibility of components across different models can enhance maintenance efficiency and reduce downtime. Some machinery offers interchangeable elements that simplify repairs and upgrades, making them a practical choice for users who require flexibility.

Ultimately, the decision on which model to choose will depend on a careful assessment of these factors, tailored to the individual’s or organization’s operational goals and environment.

Resources for John Deere Owners

Owning machinery comes with the responsibility of maintenance and repair. Access to reliable resources can make all the difference in ensuring your equipment runs smoothly and efficiently. Whether you’re seeking guidance on routine upkeep, looking for specific components, or needing expert advice, a variety of tools and platforms are available to support you.

Online forums and communities provide a wealth of information shared by fellow enthusiasts and experienced operators. These platforms allow for the exchange of tips, troubleshooting advice, and best practices, fostering a collaborative environment for all owners. Additionally, many manufacturers offer comprehensive online manuals that detail specifications, maintenance schedules, and repair instructions tailored to specific models.

Local dealerships often serve as invaluable resources, providing not only original components but also expert service and recommendations. Regular visits to these establishments can keep you updated on the latest enhancements and offers, ensuring you have the best options for your machinery.

Furthermore, instructional videos and tutorials available on various online platforms can be a game changer, offering step-by-step guidance for repairs and maintenance tasks. These visual aids can simplify complex processes, making it easier for owners to tackle issues with confidence.

By leveraging these diverse resources, operators can enhance their ownership experience, ensuring their equipment remains in peak condition for years to come.