In the realm of artistic expression and industrial applications, the efficiency of a particular device is paramount. Mastery of this equipment hinges on a deep understanding of its structure and functionality. By exploring the individual elements that comprise this tool, users can enhance their techniques and optimize performance.

Knowledge of the various components not only aids in troubleshooting but also enriches the creative process. Each segment plays a distinct role, contributing to the overall effectiveness of the mechanism. Familiarity with these pieces can empower both novices and seasoned professionals alike.

Furthermore, a comprehensive overview of these integral sections allows for better maintenance and care. Recognizing how each element interacts with others ensures longevity and reliability, making it easier to achieve desired outcomes in diverse projects. By delving into the specifics, one can unlock new possibilities and elevate their craftsmanship.

Understanding Spray Gun Components

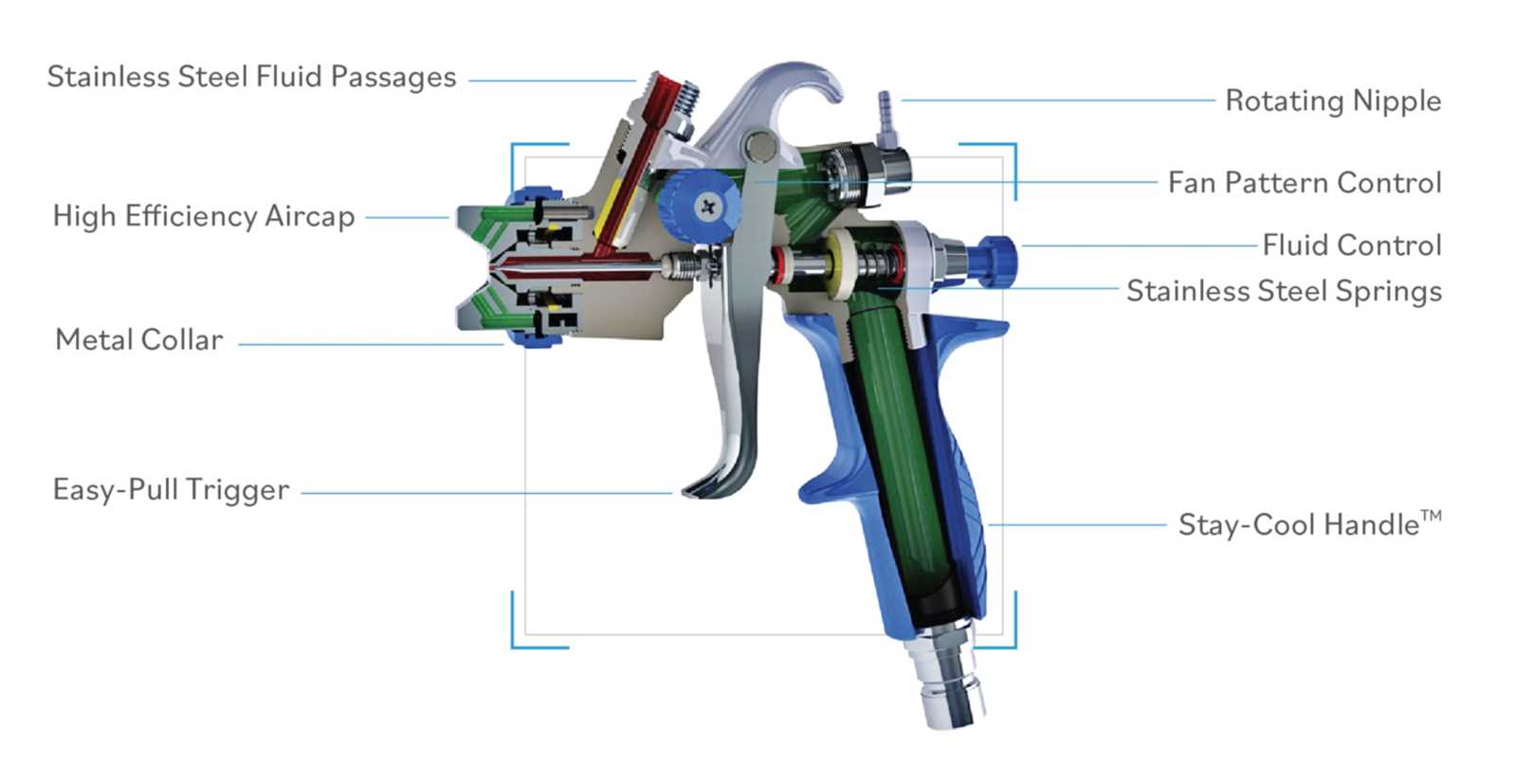

In the realm of fluid application, a clear comprehension of the various elements involved is crucial for achieving optimal results. Each component plays a significant role in the functionality and efficiency of the tool, impacting the quality of the output and the user experience.

Key Elements of the Device

Among the main elements, the nozzle serves as the crucial interface for material delivery, influencing the spray pattern and flow rate. Additionally, the trigger mechanism allows for precise control, enabling users to adjust the flow according to their needs.

Importance of Maintenance

Regular upkeep of these components is essential to ensure longevity and performance. Neglecting this aspect can lead to diminished results and increased wear, emphasizing the need for thorough knowledge of each element’s function and care.

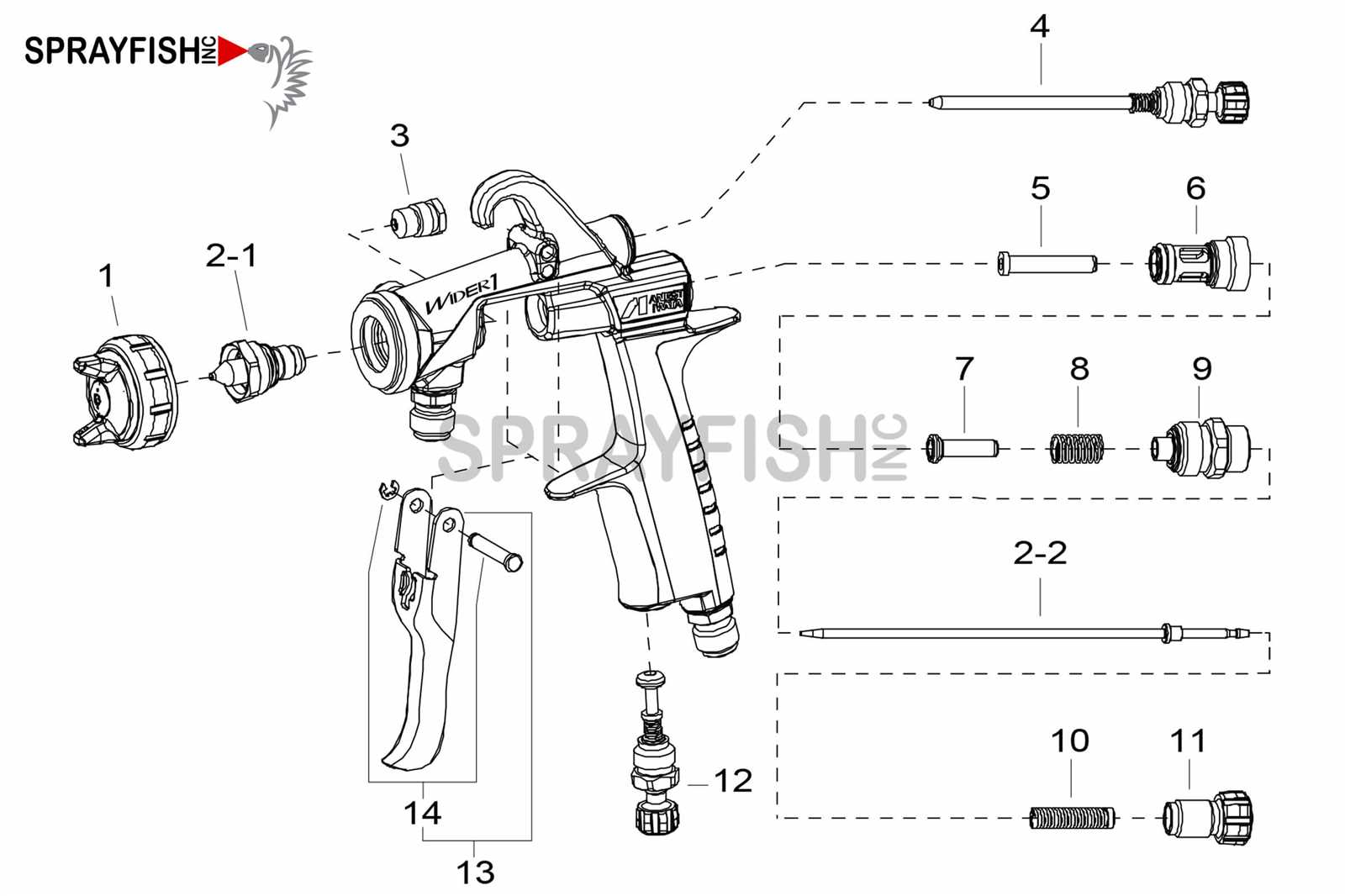

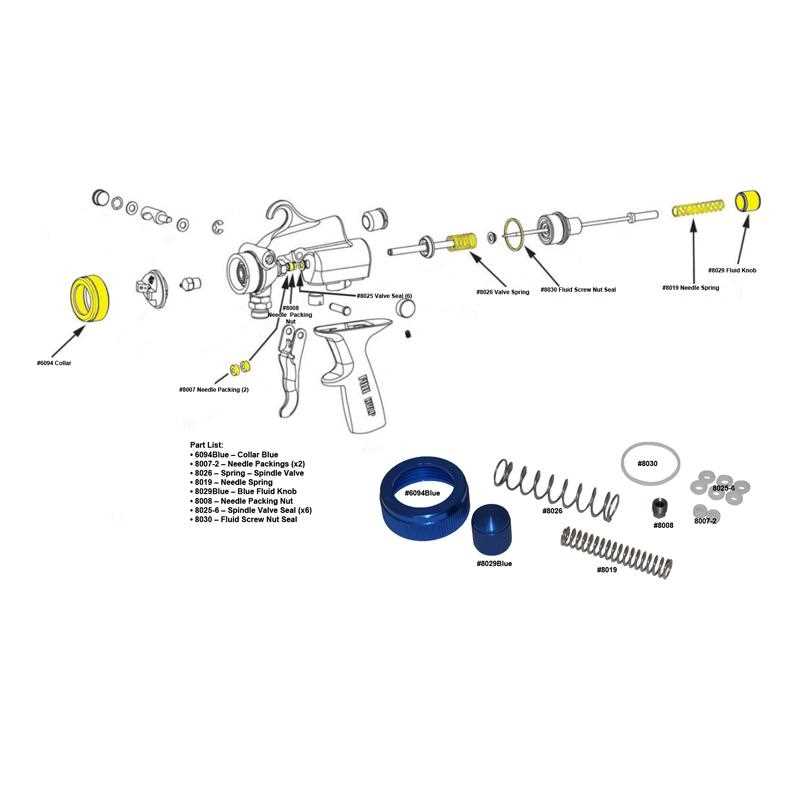

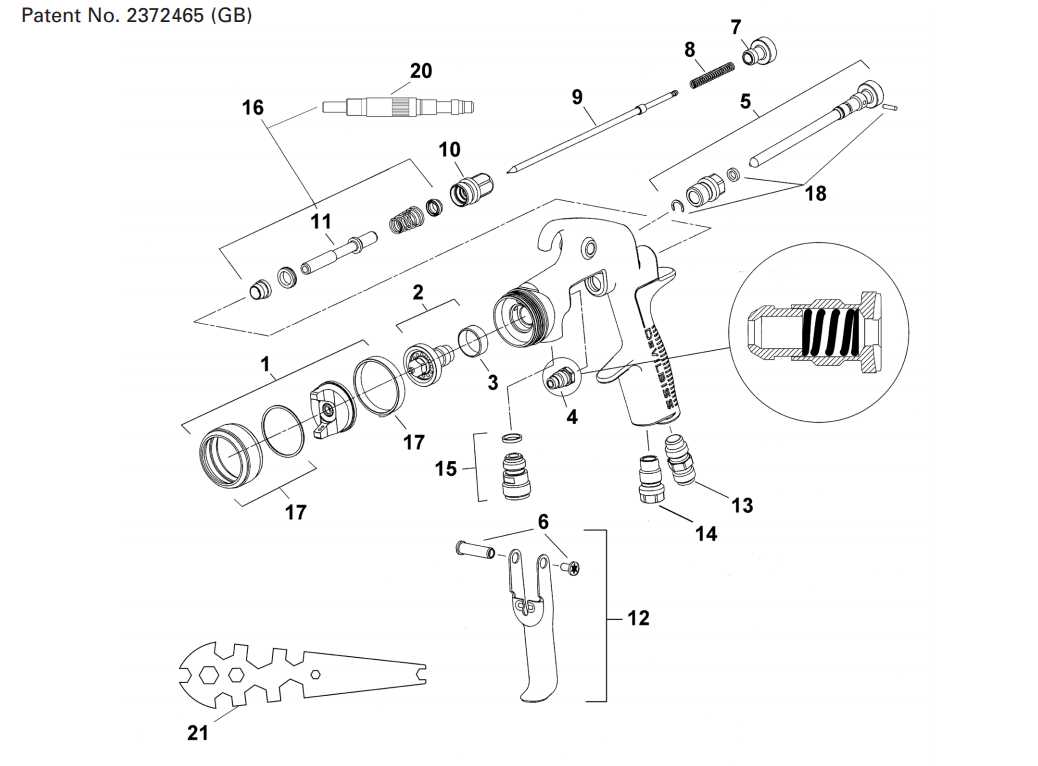

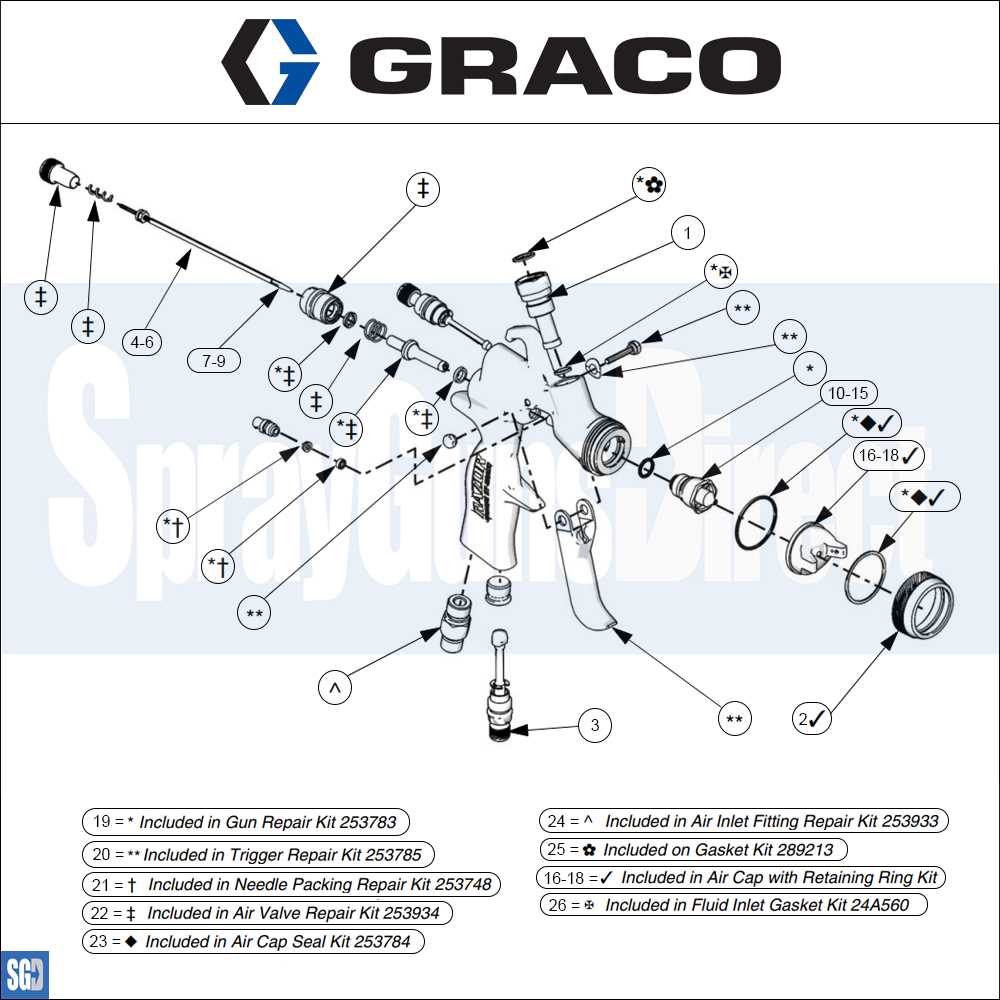

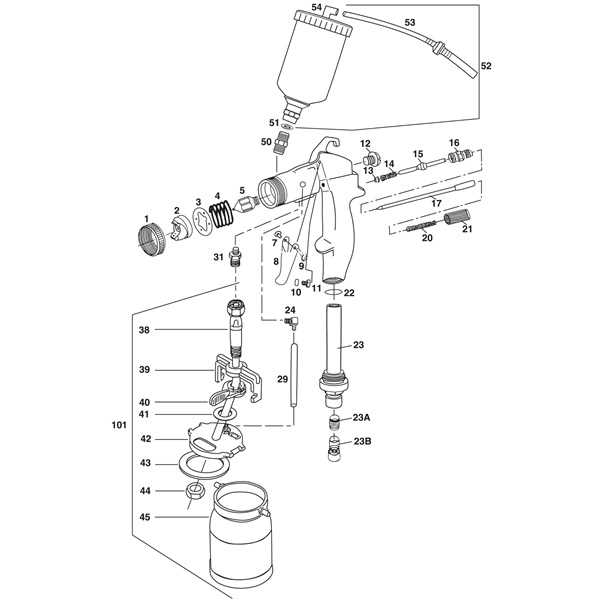

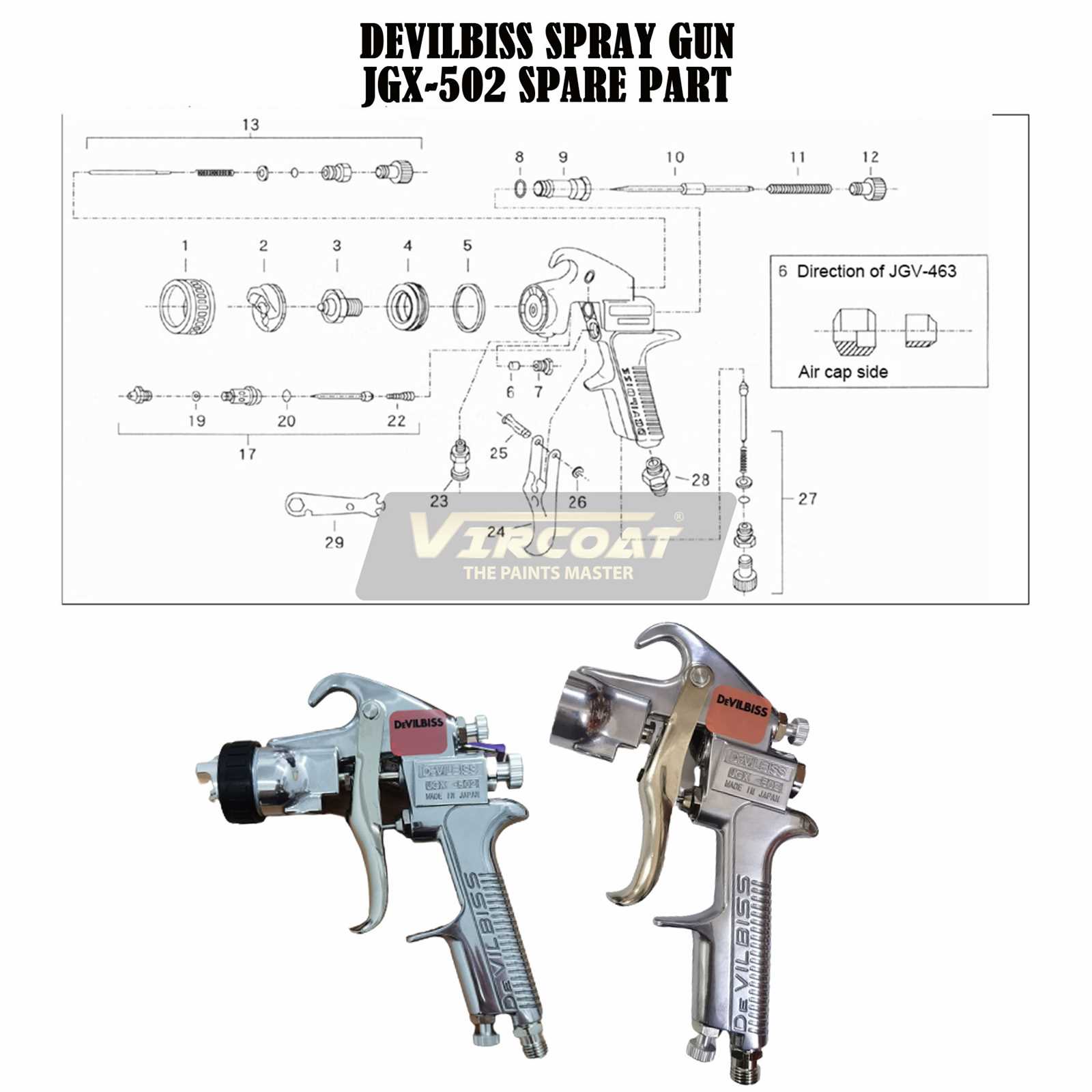

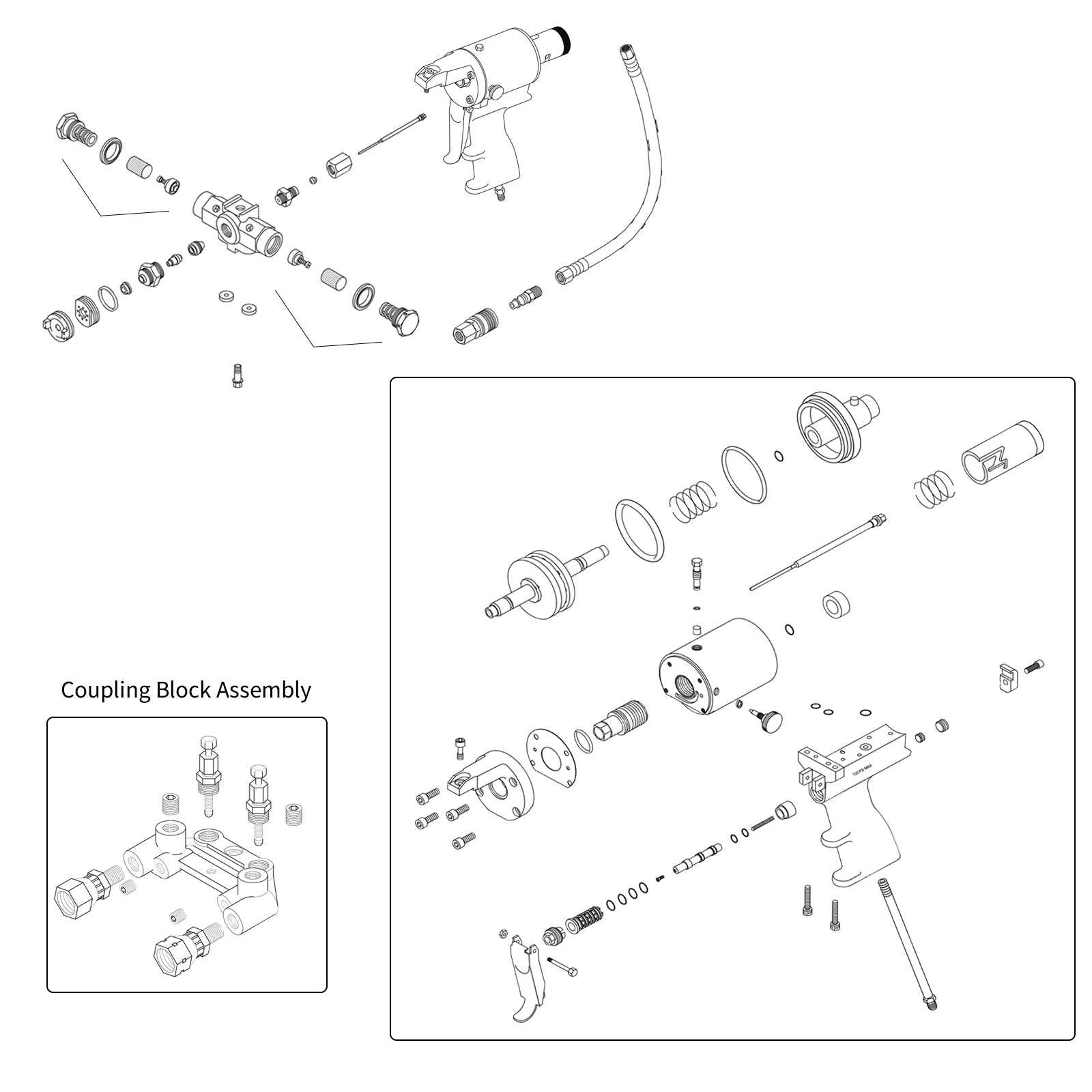

Essential Parts of a Spray Gun

Understanding the fundamental components of a spraying device is crucial for effective operation and maintenance. Each element plays a significant role in delivering optimal performance, ensuring that the material is applied uniformly and efficiently. This section will explore the key elements that contribute to the functionality of such equipment.

Key Components

The primary structure typically includes a housing that supports various functionalities. Within this framework, you’ll find a nozzle, responsible for shaping the spray pattern and controlling the flow of the material. The trigger mechanism allows for precise control over the release, enabling the user to manage the application effortlessly. Additionally, an air cap is crucial for atomizing the liquid, ensuring a fine mist is produced for an even finish.

Additional Features

Another important element is the fluid needle, which works in conjunction with the nozzle to regulate the amount of material being dispensed. The pressure regulator also plays a vital role by maintaining consistent air pressure, crucial for achieving desired results. Finally, the cup holds the liquid to be applied, and its design can influence both capacity and ease of cleaning.

Types of Spray Gun Mechanisms

Understanding the various mechanisms used in painting equipment is essential for selecting the right tool for specific applications. Each type operates differently, influencing factors like paint flow, atomization, and control. Below are the primary mechanisms utilized in these devices.

-

Gravity Feed:

This design allows the coating material to flow from a container situated above the nozzle, using gravity to aid in the process. It is ideal for fine details and precise applications.

-

Suction Feed:

In this mechanism, the fluid is drawn from a container located below the nozzle. This type is often used for larger projects and thicker materials, as it can accommodate higher volumes.

-

Pressure Feed:

This method involves pressurizing the fluid container, allowing for a steady flow of material. It is particularly useful for high-volume applications and professional settings.

-

Airless:

Using high pressure to atomize the fluid, this system eliminates the need for compressed air. It is effective for large surfaces and offers a smooth finish with less overspray.

-

Electrostatic:

This advanced technique uses an electric charge to attract the coating material to the surface, reducing waste and improving coverage. It is commonly employed in industrial applications.

Selecting the right mechanism greatly impacts the efficiency and quality of the application, making it crucial to understand the distinct features of each type.

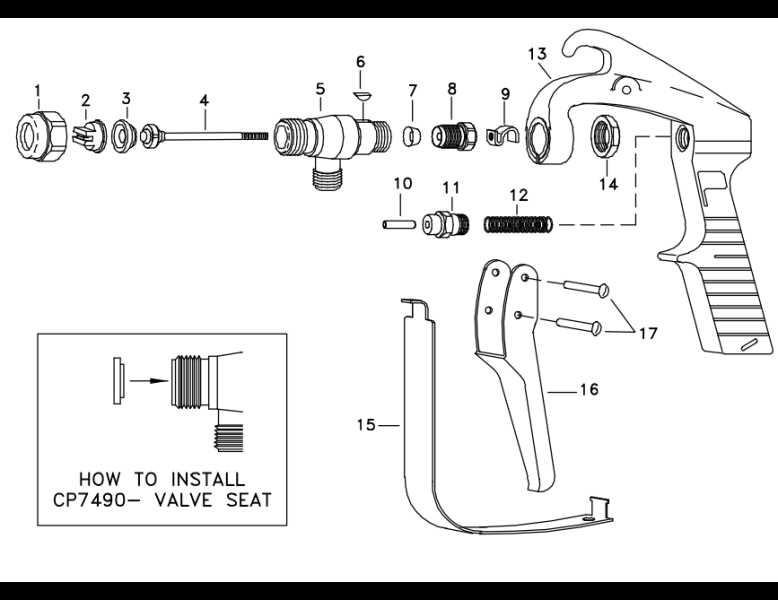

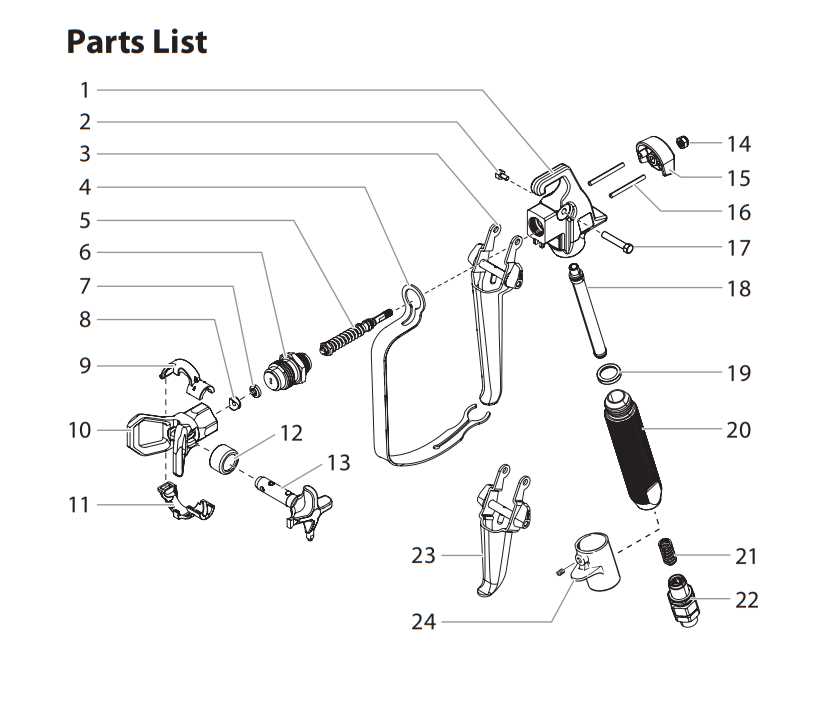

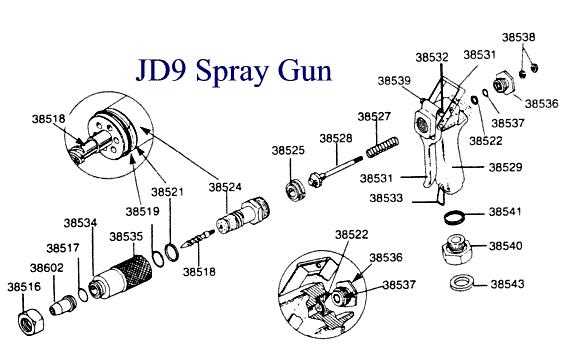

How to Identify Key Elements

Understanding the fundamental components of a spraying device is crucial for effective operation and maintenance. Recognizing these essential elements allows users to troubleshoot issues, optimize performance, and ensure safety during use.

To begin, familiarize yourself with the main assembly features. Typically, devices include a trigger mechanism, a fluid reservoir, and a nozzle. The trigger regulates the flow, while the reservoir holds the material. The nozzle plays a vital role in shaping the spray pattern and controlling the dispersion of the substance.

Next, pay attention to the adjustments available. Many devices offer settings for pressure and flow rate, which can significantly impact the application results. Knowing how to modify these settings according to your project needs is essential for achieving the desired finish.

Finally, inspect the maintenance elements such as filters and seals. These components are critical for preventing clogs and ensuring a consistent output. Regular checks and replacements of these parts will enhance the longevity and efficiency of the equipment.

Importance of Proper Maintenance

Regular upkeep of equipment is crucial for ensuring optimal performance and longevity. Neglecting maintenance can lead to a range of issues, from decreased efficiency to complete operational failure. By dedicating time to proper care, users can enhance functionality and reduce the likelihood of costly repairs.

Enhancing Performance

Routine maintenance allows for the identification and resolution of minor problems before they escalate. This proactive approach helps maintain peak performance levels, ensuring that tools operate smoothly and deliver consistent results. Regular checks and cleanings can prevent clogs and buildup, which can hinder effectiveness.

Extending Lifespan

Investing in maintenance extends the life of equipment significantly. By adhering to recommended service intervals and replacing worn components, users can avoid premature replacements and maximize their investment. A well-maintained device not only performs better but also retains its value over time.

Common Issues and Solutions

In the realm of equipment operation, encountering challenges is not uncommon. Understanding these obstacles and their resolutions is crucial for maintaining efficiency and performance. Here, we explore prevalent problems and their corresponding solutions to enhance the user experience.

Common Challenges

| Issue | Description |

|---|---|

| Clogs | Blockages that hinder fluid flow can lead to inconsistent results. |

| Uneven Application | Inconsistent coverage may result from improper technique or equipment malfunction. |

Solutions

| Issue | Solution |

|---|---|

| Clogs | Regular cleaning and maintenance of components can prevent this issue. |

| Uneven Application | Adjusting pressure settings and ensuring a steady hand can improve results. |

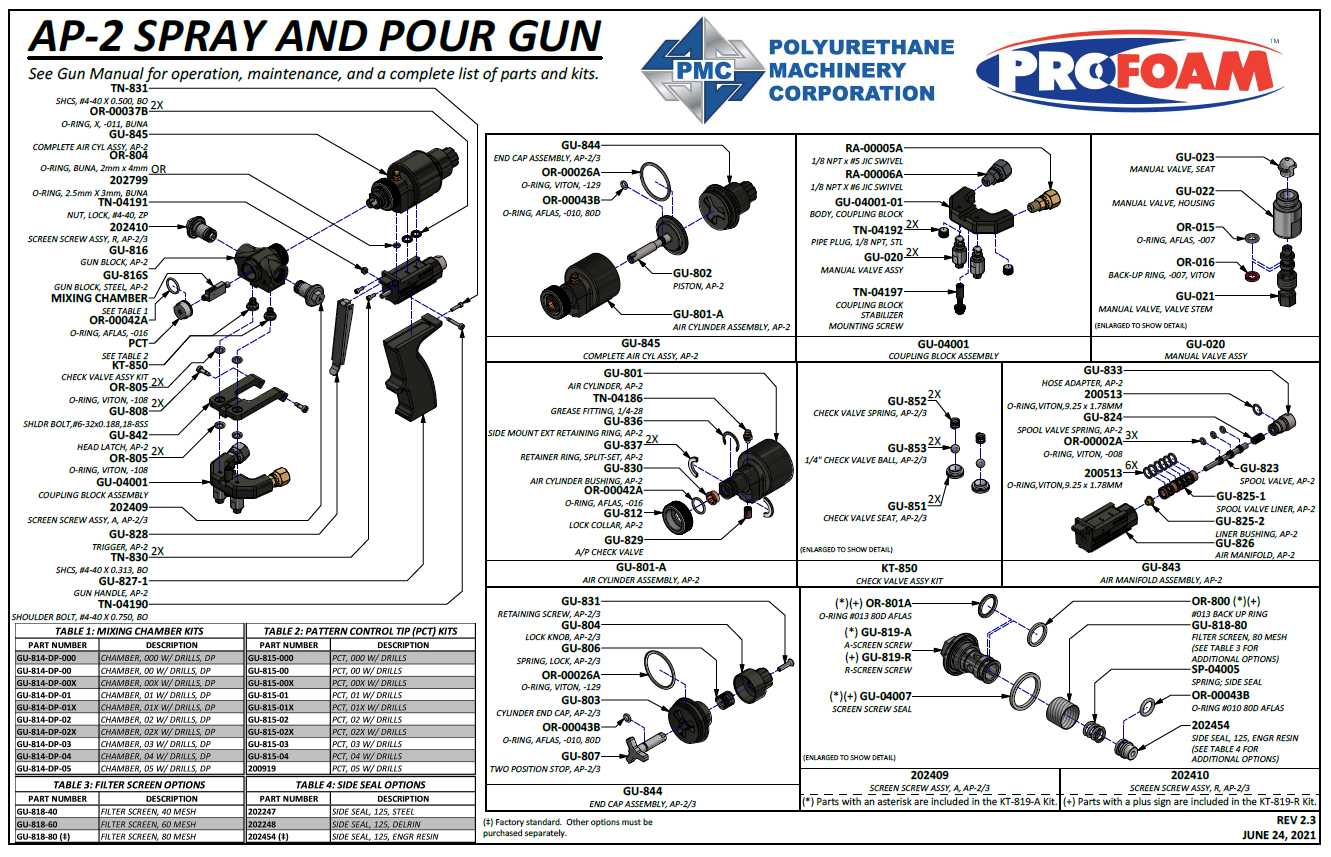

Choosing the Right Accessories

Selecting appropriate tools and components is crucial for achieving optimal results in any project. The right enhancements can significantly influence performance, efficiency, and the overall outcome of your work. Whether you’re aiming for precision or speed, understanding the available options will help you make informed decisions.

Understanding Compatibility

Before investing in additional components, it’s essential to ensure they are compatible with your existing equipment. Different models and brands may require specific attachments or fittings. Review the specifications and recommendations provided by the manufacturer to avoid potential issues.

Assessing Your Needs

Consider the type of tasks you will be performing. Different projects may require varying features, such as different nozzle sizes or pressure settings. Evaluating your requirements will guide you in selecting the most suitable enhancements, ensuring that you achieve the desired results effectively.

Safety Precautions When Using Spray Guns

Ensuring safety during the application of coatings is crucial to prevent accidents and health hazards. Proper precautions help protect both the operator and the surrounding environment from potential risks associated with the equipment and materials used.

Before starting your work, consider the following essential guidelines:

- Always wear appropriate personal protective equipment (PPE), including masks, goggles, and gloves.

- Ensure adequate ventilation in the workspace to minimize exposure to harmful fumes.

- Read and understand the manufacturer’s instructions and safety data sheets for all materials used.

- Keep a fire extinguisher nearby, as flammable substances may be involved.

- Avoid working near open flames or sparks to reduce the risk of ignition.

During the application process, adhere to these practices:

- Maintain a safe distance from flammable materials and surfaces.

- Use the equipment according to the specified pressure settings to prevent overspray and accidents.

- Regularly inspect and maintain the tools to ensure they are in good working condition.

- Be cautious of your surroundings and ensure that others are at a safe distance while working.

By following these safety measures, you can create a safer working environment and achieve better results in your coating projects.