In the realm of farming equipment, comprehending the intricate arrangement of various elements is crucial for optimal performance and maintenance. Each machine is a complex assembly of interconnected parts that work harmoniously to achieve efficient operation. A clear visualization of these components can significantly enhance the understanding of how to care for and troubleshoot machinery.

By exploring the layout and functionality of essential elements, operators can gain valuable insights into their equipment’s mechanics. This knowledge not only aids in identifying specific components but also facilitates timely repairs and replacements. Having access to detailed representations of these configurations empowers users to make informed decisions regarding upkeep and modifications.

Furthermore, a comprehensive overview of the machinery’s structure fosters a deeper appreciation for its design and engineering. As users become more familiar with the intricacies of their tools, they can better navigate the challenges associated with maintenance and operation. Ultimately, this understanding paves the way for a more efficient and productive farming experience.

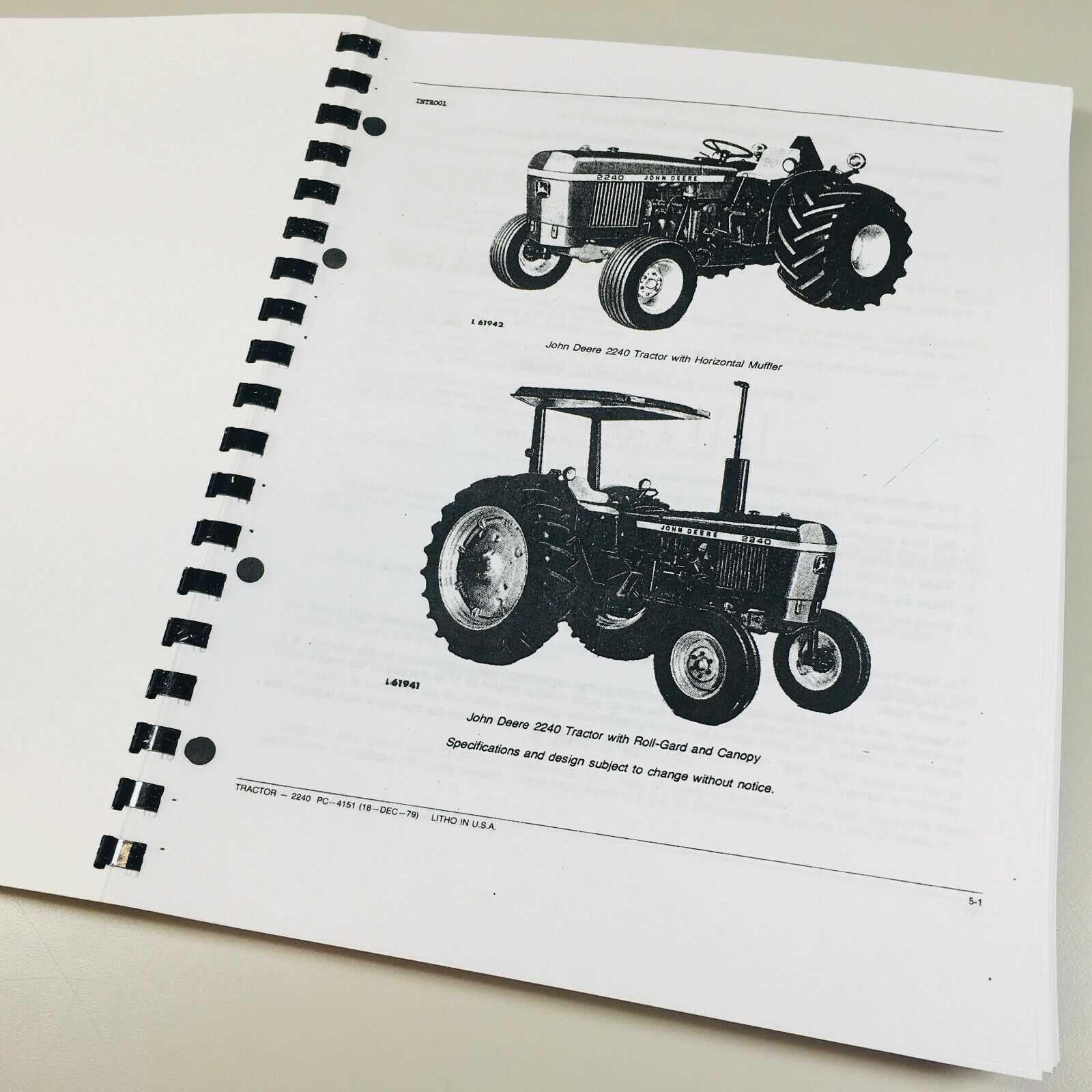

Understanding the John Deere 2240

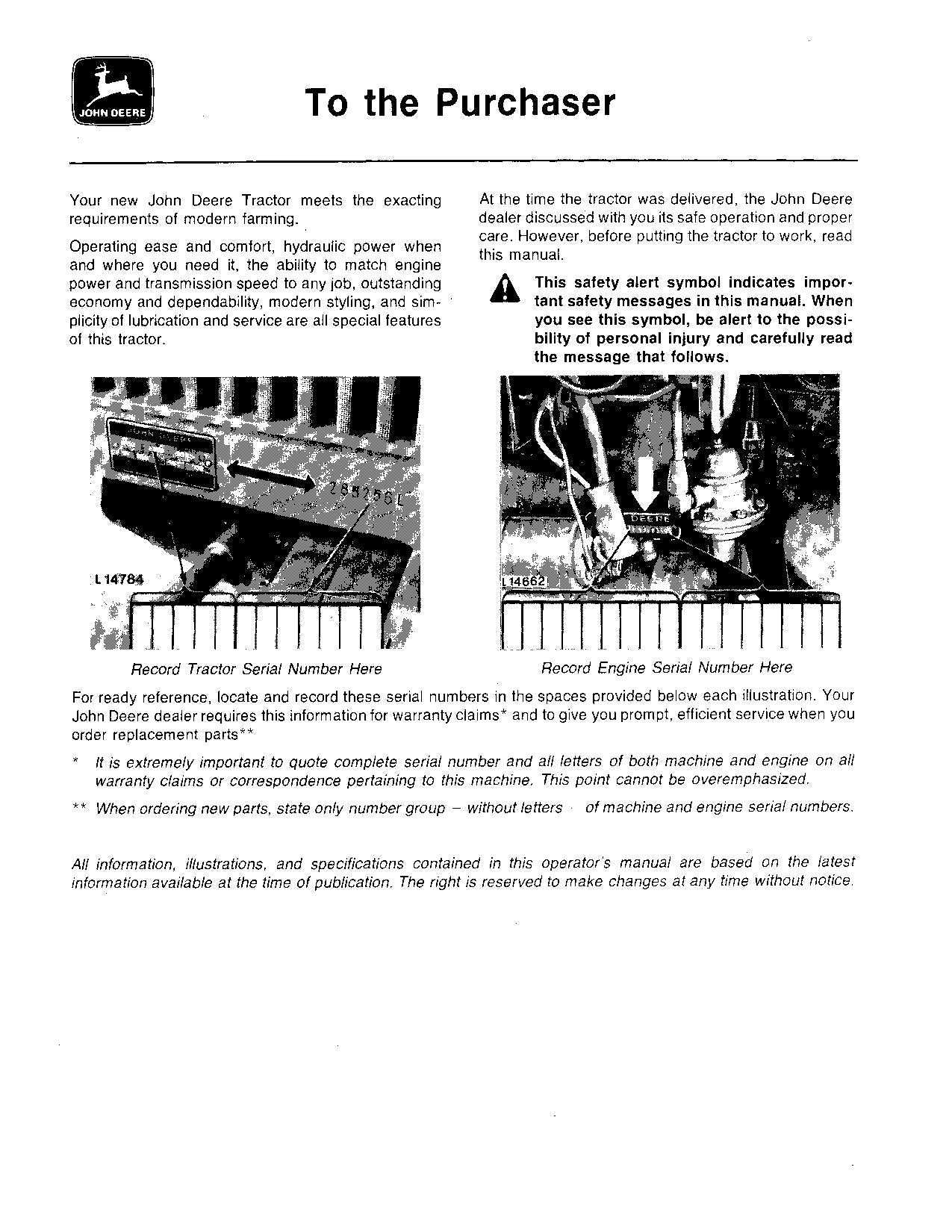

This section provides insight into a popular agricultural machine known for its reliability and efficiency. Designed for diverse farming tasks, it has become a staple for many in the agricultural sector. A thorough understanding of its components and functionality is essential for optimal performance and maintenance.

Key features of this machine include a robust engine, user-friendly controls, and versatile attachments, allowing operators to tackle various tasks with ease. Familiarity with the essential elements enhances operational effectiveness and extends the lifespan of the equipment.

| Component | Description |

|---|---|

| Engine | Provides power and performance for heavy-duty tasks. |

| Transmission | Facilitates smooth shifting and control over speed and torque. |

| Hydraulics | Enables the operation of attachments and implements. |

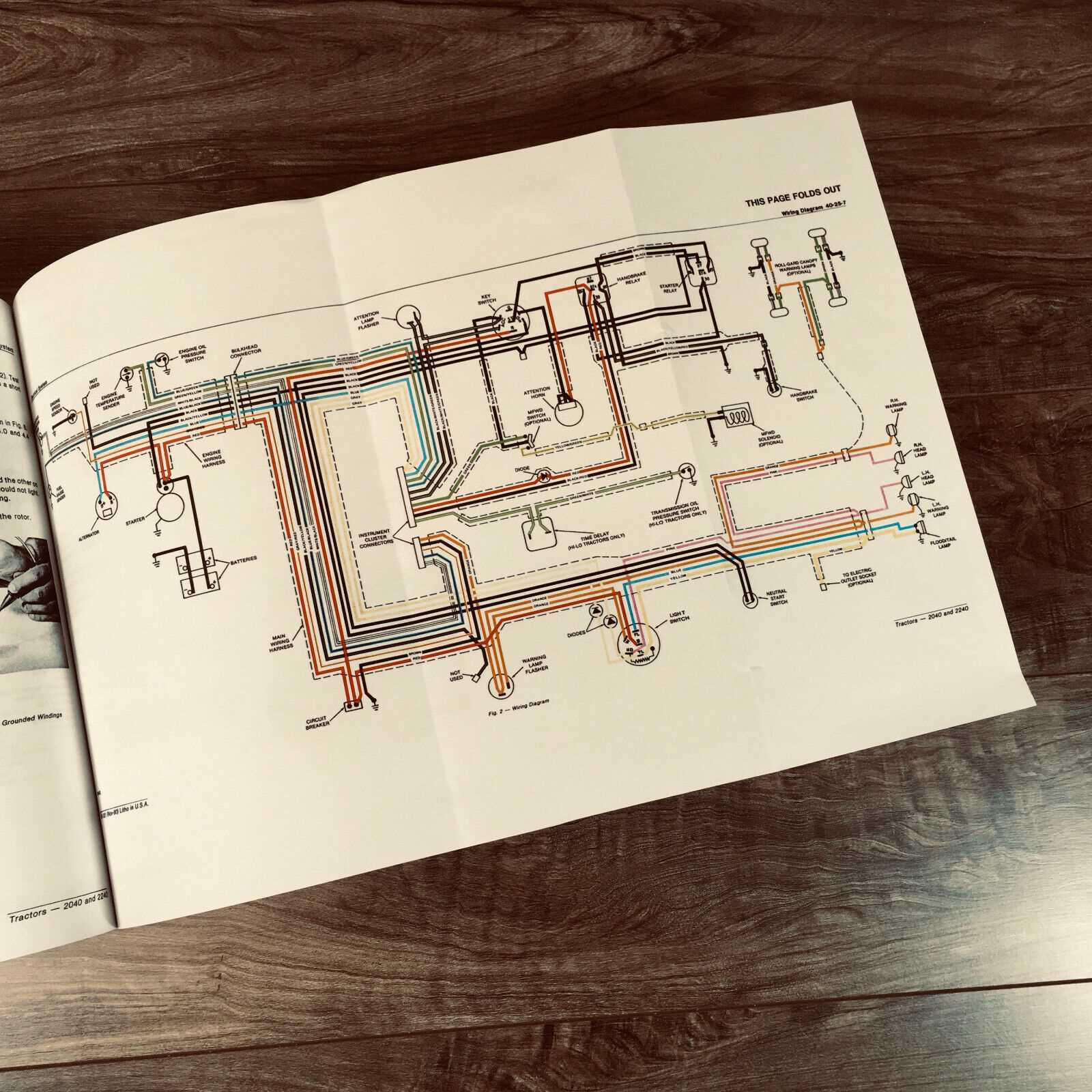

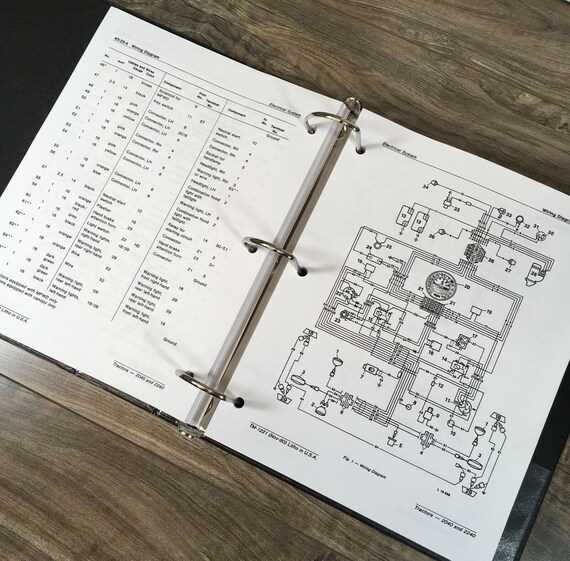

| Electrical System | Supports ignition, lighting, and other electronic functions. |

Regular maintenance and familiarity with each system are crucial for keeping the machine running efficiently. Understanding these aspects can significantly enhance productivity and minimize downtime in the field.

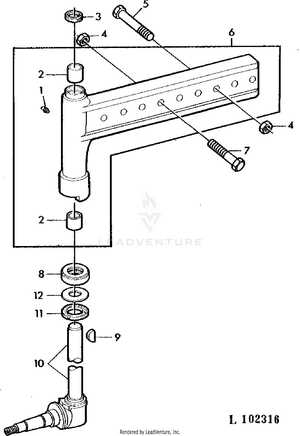

Key Components of the 2240 Model

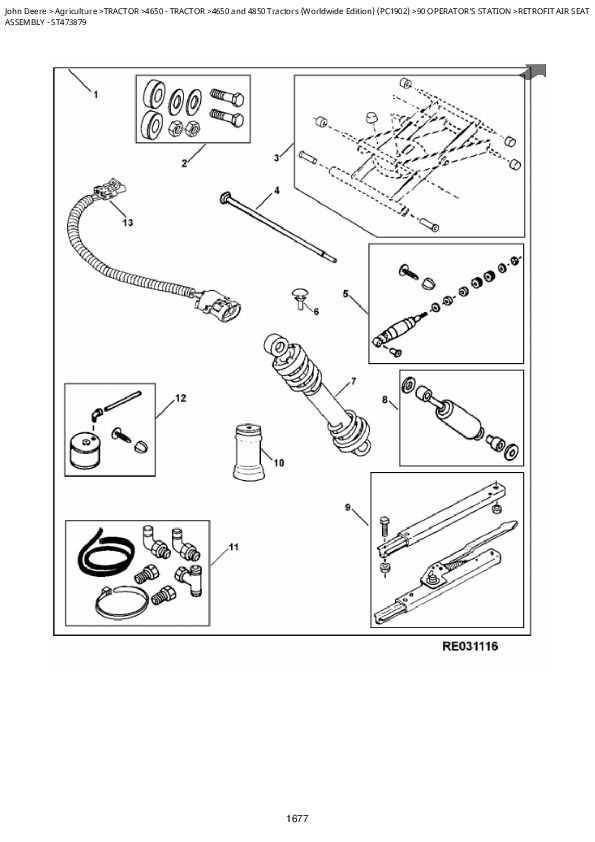

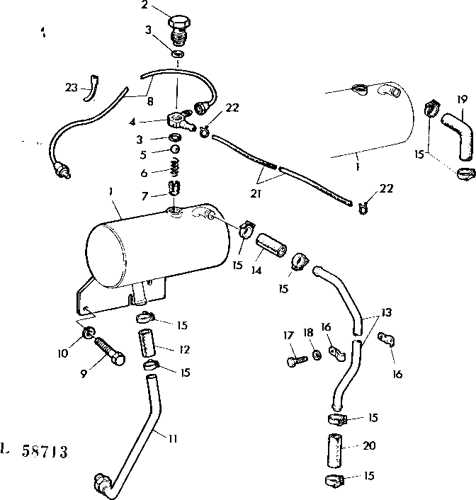

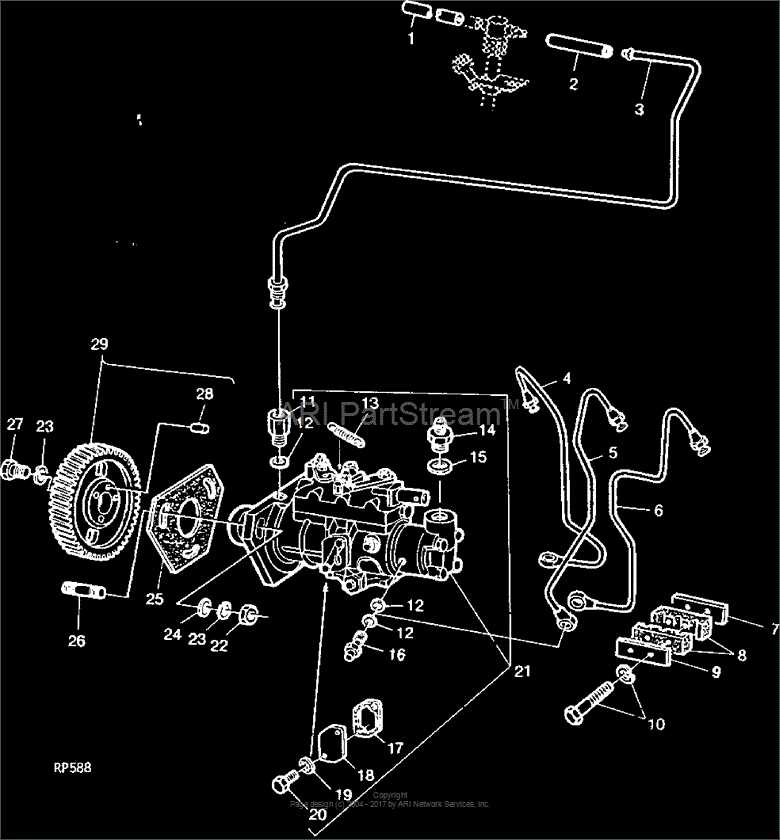

This section delves into the essential elements that contribute to the functionality and efficiency of this agricultural machinery. Understanding these components is crucial for both maintenance and performance optimization. Each part plays a significant role in the overall operation, ensuring reliability and effectiveness in various tasks.

| Component | Description |

|---|---|

| Engine | A powerful unit that drives the entire system, providing the necessary torque and horsepower for demanding tasks. |

| Transmission | This mechanism transfers power from the engine to the wheels, allowing for smooth acceleration and control. |

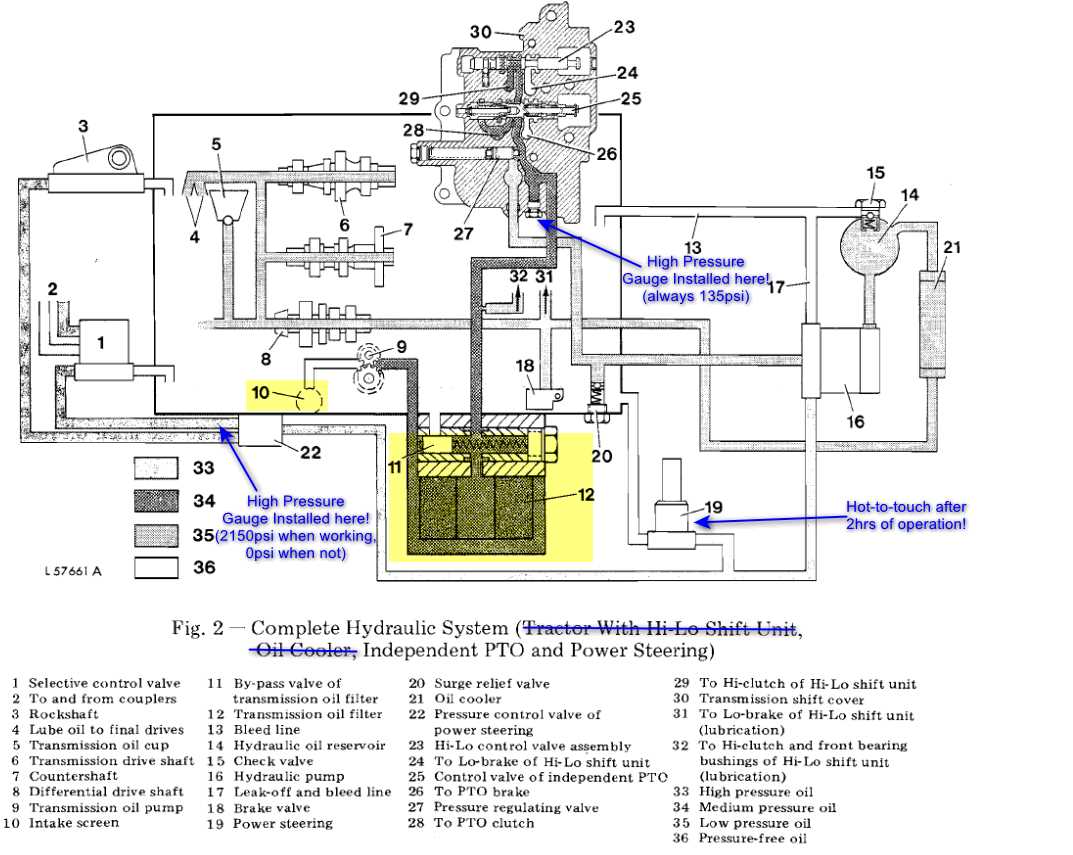

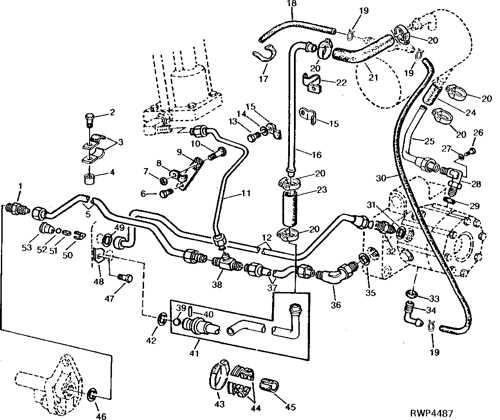

| Hydraulic System | Responsible for powering attachments and implements, this system enhances the machine’s versatility and operational capability. |

| Chassis | The robust framework that supports all components, ensuring stability and durability under various working conditions. |

| Wheels | These are designed to provide optimal traction and maneuverability, making it easier to navigate different terrains. |

Where to Find Parts Diagrams

Locating detailed illustrations of components can greatly simplify the maintenance and repair processes for various machinery. These visual resources provide essential insights into the structure and arrangement of different elements, enabling users to identify what is needed for efficient operation.

Online Resources

Numerous websites cater to enthusiasts and professionals alike, offering extensive libraries of schematics. Here are some popular options:

- Manufacturer’s Official Website: Often the most reliable source, featuring up-to-date resources.

- Specialized Online Retailers: Many sellers provide access to diagrams alongside their inventory.

- Community Forums: Engaging with fellow users can yield helpful links and shared resources.

- Technical Manuals: Digital versions of manuals often include comprehensive illustrations.

Local Resources

Sometimes, physical locations can offer valuable assistance in your search for illustrations:

- Dealerships: Authorized retailers often have access to manufacturer databases.

- Repair Shops: Experienced mechanics may have personal collections of diagrams.

- Library Archives: Local libraries might hold manuals and guides that are not available online.

Common Issues and Solutions

In the world of agricultural machinery, various challenges can arise that impact performance and reliability. Understanding these common problems and their respective solutions can enhance the longevity and efficiency of equipment, ensuring smooth operation during critical tasks.

| Issue | Description | Solution |

|---|---|---|

| Engine Starting Problems | Difficulty in starting the engine can be caused by battery issues or fuel supply problems. | Check battery charge and connections; inspect fuel lines for blockages. |

| Hydraulic System Failures | Loss of power in hydraulic functions may indicate leaks or low fluid levels. | Examine hoses for leaks; ensure hydraulic fluid is at the correct level. |

| Overheating | Excessive heat can lead to engine damage and is often caused by coolant issues. | Check coolant levels and radiator for blockages; replace the thermostat if necessary. |

| Transmission Issues | Difficulty shifting gears may stem from low fluid levels or mechanical failures. | Inspect transmission fluid levels; consult a technician for mechanical repairs. |

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components ensures a higher level of reliability and performance for machinery. These components are specifically designed to fit seamlessly with the equipment, providing optimal functionality and longevity. When opting for such items, users can rest assured that they are maintaining their machinery to the highest standard.

Quality Assurance

OEM components are manufactured under strict quality control measures, ensuring they meet the specifications set by the original creators. This attention to detail translates into enhanced durability and reduced risk of failure, ultimately leading to lower maintenance costs over time.

Compatibility and Performance

Choosing original components guarantees compatibility with existing machinery, reducing the likelihood of operational issues. This ensures that equipment operates at peak performance, enhancing productivity and efficiency. By investing in these parts, users can maximize their equipment’s potential and extend its lifespan.

Aftermarket vs. Original Parts

The choice between replacement components produced by the original manufacturer and those made by third-party companies is a common consideration for equipment owners. Each option presents distinct advantages and potential drawbacks that can impact performance, longevity, and cost-effectiveness.

Original components are typically designed to meet specific standards set by the manufacturer, ensuring compatibility and reliability. Here are some key benefits:

- Quality Assurance: Generally, these items are rigorously tested for durability.

- Exact Fit: They are made to fit seamlessly with existing machinery.

- Warranty Protection: Often, using these components helps maintain warranty coverage.

On the other hand, third-party alternatives can offer appealing benefits that may attract buyers:

- Cost Savings: Usually, these options are more affordable, which can be significant for budget-conscious owners.

- Availability: They may be easier to find, especially for older models.

- Diverse Selection: Some companies provide unique variations or enhancements not found in original offerings.

Ultimately, the decision between these types of components should be based on individual needs, budget constraints, and the specific requirements of the equipment in question.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the long-lasting performance of any machinery. By implementing a structured maintenance routine, owners can significantly extend the lifespan of their equipment and enhance its efficiency. This section outlines practical advice to keep your machine running smoothly for years to come.

Routine Inspections

Conducting frequent checks on various components is crucial. Look for signs of wear and tear, such as leaks or unusual noises. Addressing minor issues promptly can prevent more serious problems from developing. Prioritize areas like the engine, hydraulics, and electrical systems, as these are critical for optimal operation.

Proper Lubrication

Keeping moving parts well-lubricated minimizes friction and reduces the risk of overheating. Use high-quality lubricants recommended for your model. Regularly schedule lubrication as part of your maintenance plan, ensuring all necessary components receive adequate attention. This simple step can lead to enhanced performance and decreased wear over time.

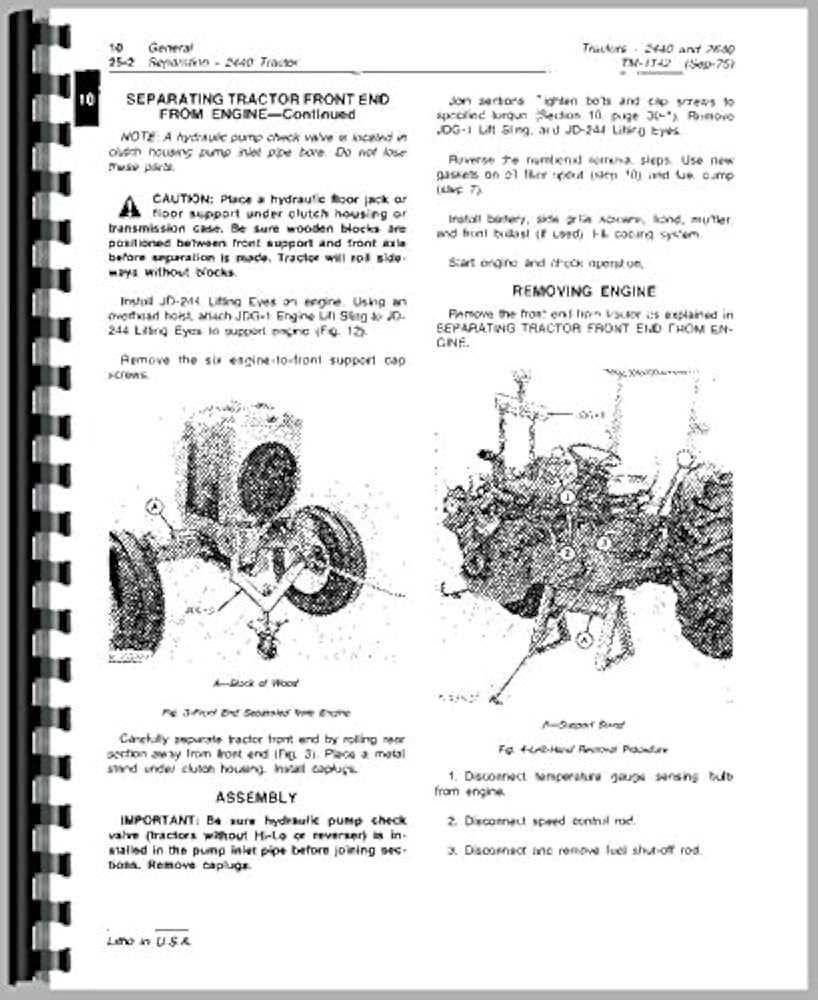

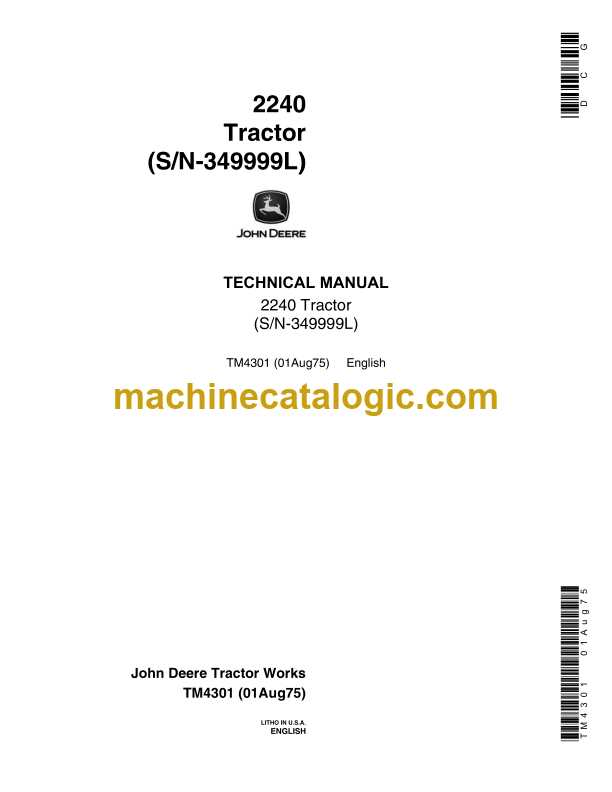

Repair Resources for 2240 Owners

Maintaining and fixing agricultural machinery can be a complex task, but having access to the right resources makes the process more manageable. Owners can benefit from a variety of tools, manuals, and community support to ensure their equipment runs smoothly. This section aims to highlight essential resources available for those seeking assistance in repairs and maintenance.

Manuals and Guides

Comprehensive manuals are invaluable for understanding the intricacies of machinery. These documents often include detailed instructions, troubleshooting tips, and maintenance schedules. Many owners can find printed copies or digital versions online, which provide step-by-step guidance for common issues and preventive care. Investing time in reading these resources can save both time and money in the long run.

Online Forums and Communities

Engaging with fellow enthusiasts through online platforms can provide practical insights and support. Many forums feature experienced users who share their expertise, offer advice, and troubleshoot problems collaboratively. Participating in these communities not only fosters knowledge exchange but also helps owners feel connected to a larger network of individuals who share similar challenges and solutions.

Community Support and Forums

In the world of machinery maintenance and repair, community-driven support platforms play a crucial role. Enthusiasts and professionals alike can benefit from shared experiences, advice, and resources. These forums provide a space for individuals to seek help, exchange knowledge, and connect with others who share similar interests in machinery upkeep.

Engagement and Knowledge Sharing

Active participation in online communities allows users to ask specific questions and receive answers from seasoned experts and fellow hobbyists. Members often post detailed guides, troubleshooting tips, and innovative solutions that can simplify complex tasks. This collaborative environment fosters learning and enhances problem-solving capabilities.

Resources and Networking

Many forums offer a wealth of resources, including manuals, repair tips, and product recommendations. Users can also network with local professionals and enthusiasts, leading to potential partnerships or mentorship opportunities. Engaging in these communities not only aids in individual projects but also contributes to a broader understanding of machinery maintenance and enhancement.