In the world of agricultural machinery, it’s crucial to have a clear understanding of the layout and structure of various components. This knowledge not only helps in routine maintenance but also allows for efficient troubleshooting and repairs. An accurate visual guide can be an essential resource for anyone working with such equipment, ensuring that all elements are correctly identified and positioned.

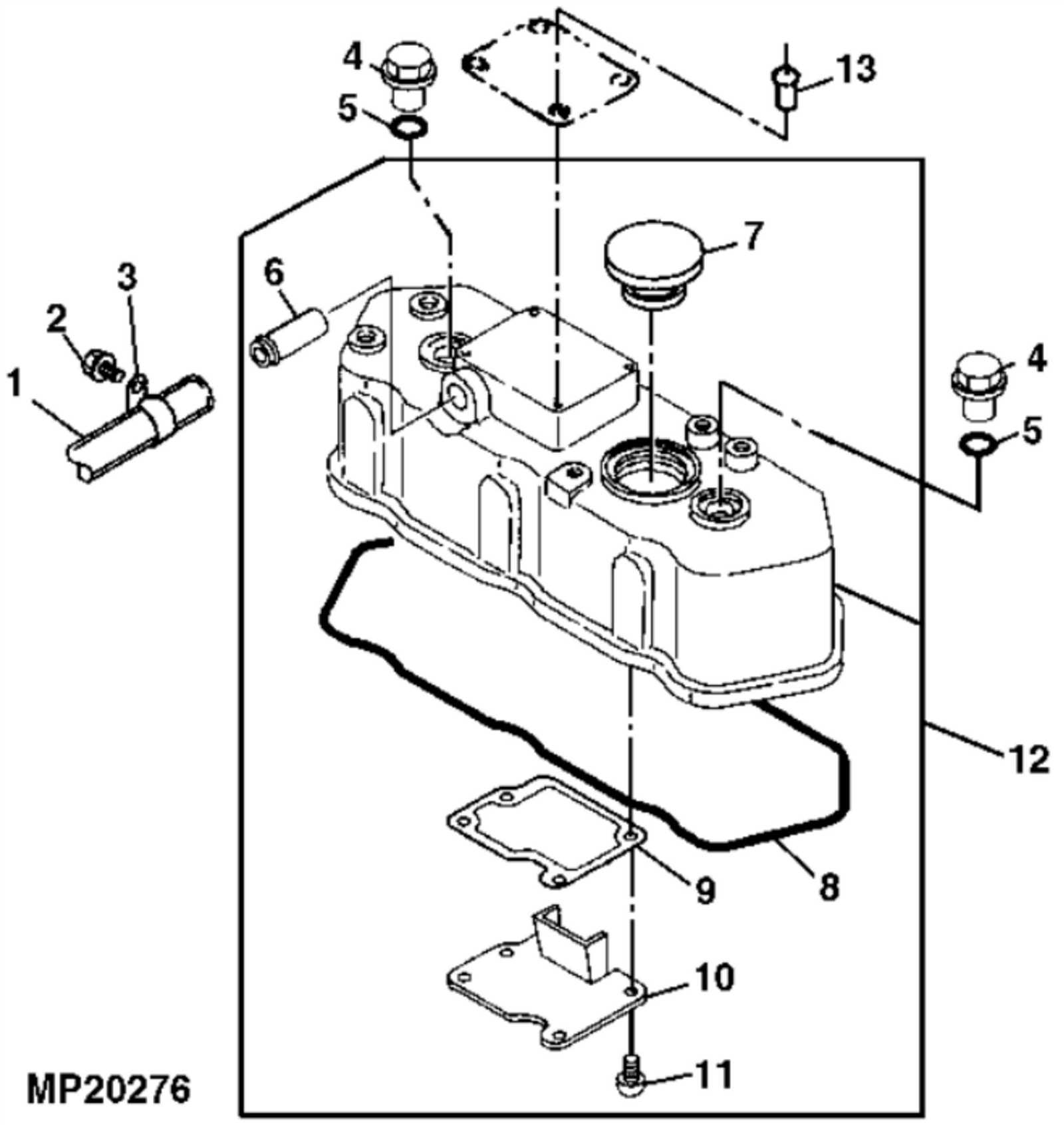

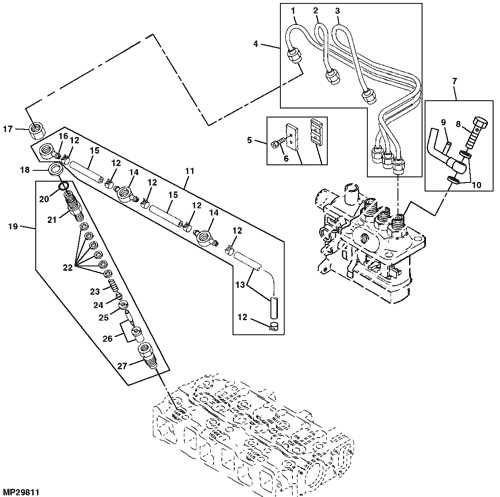

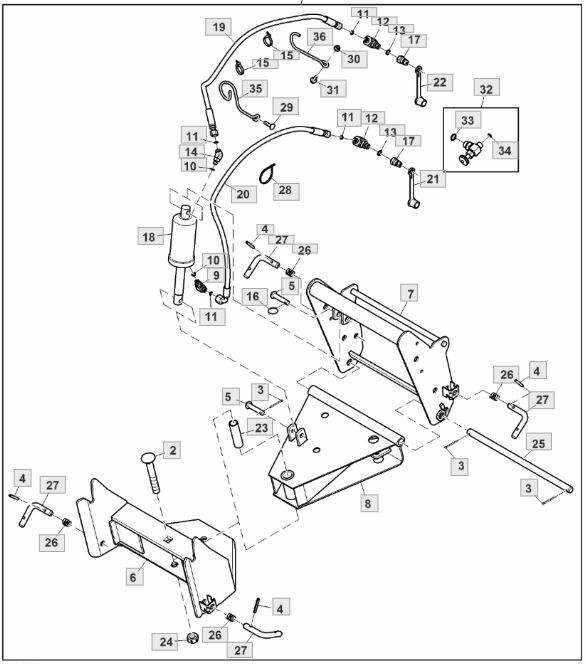

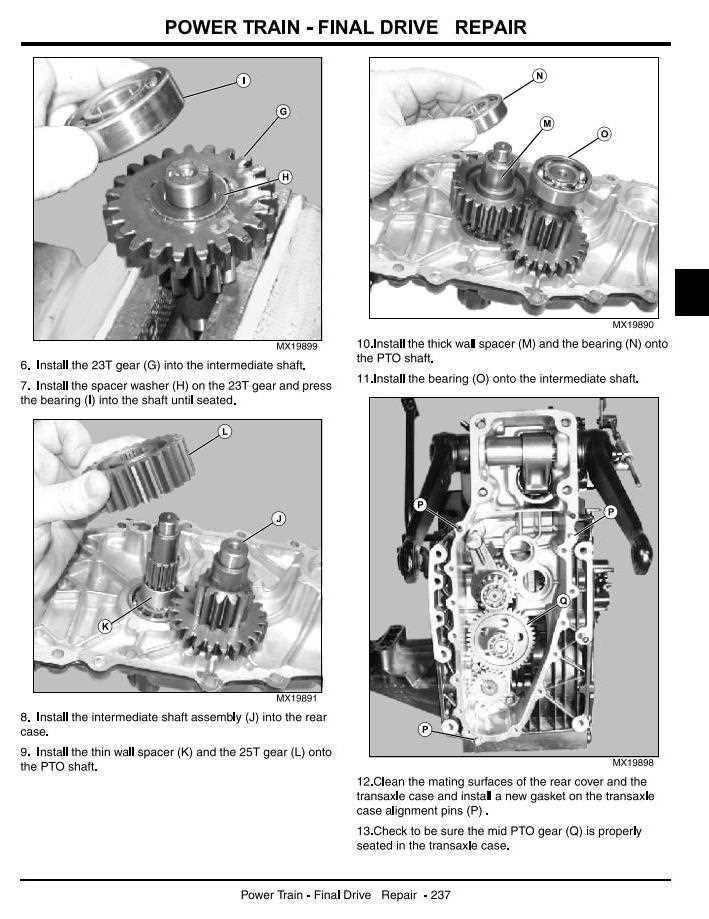

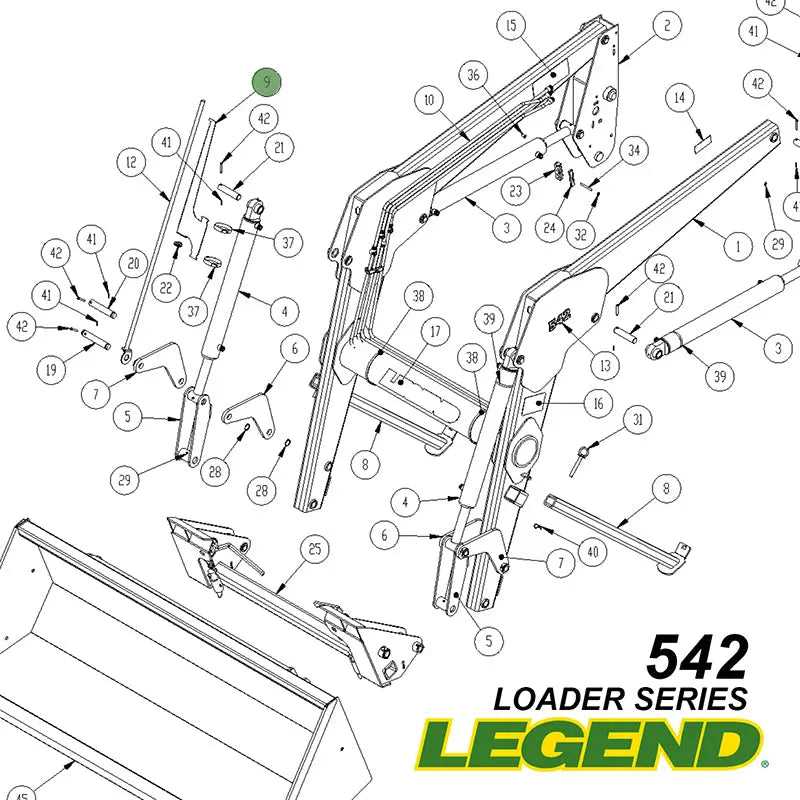

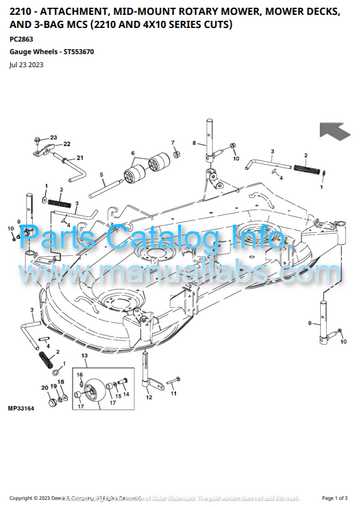

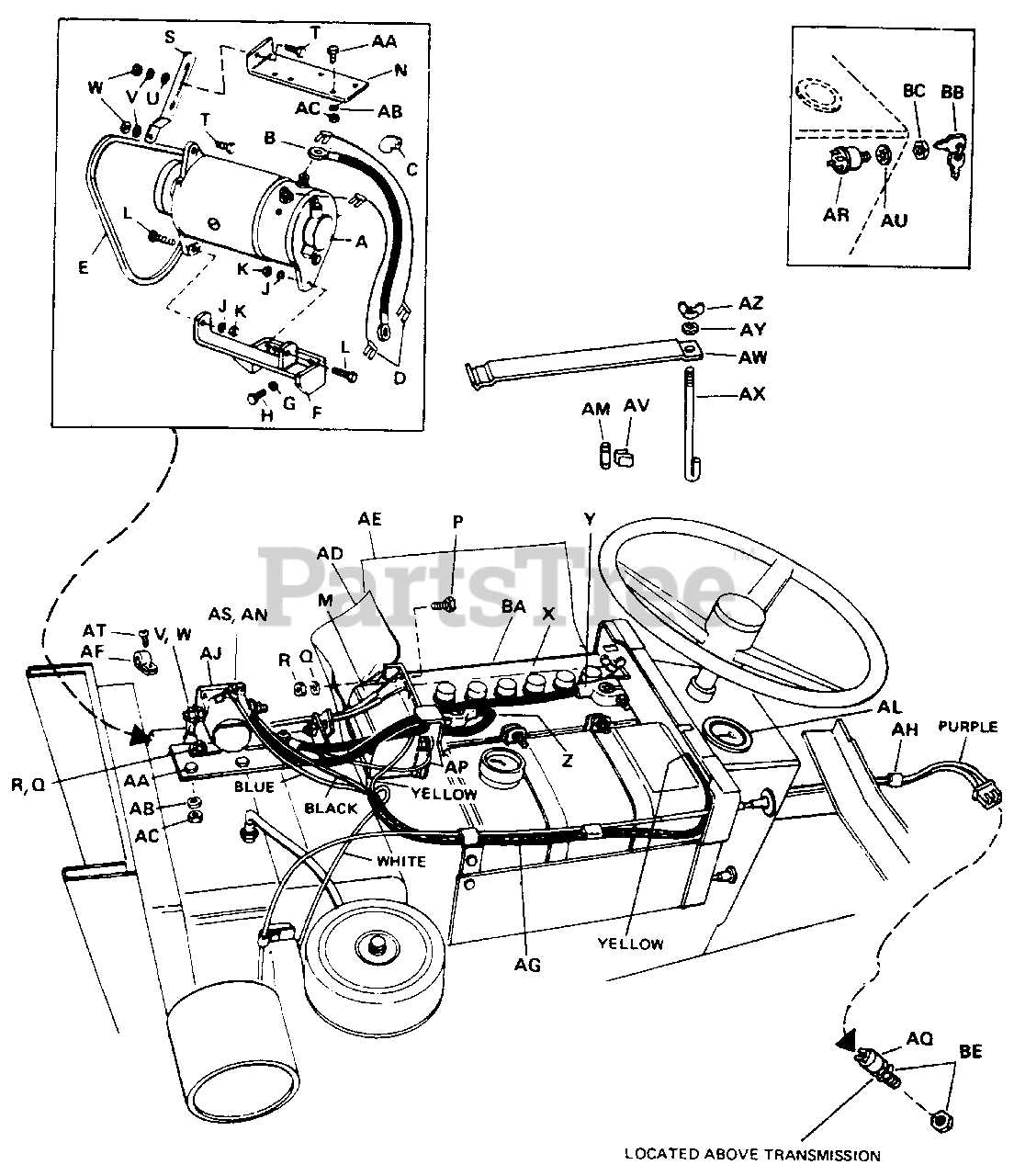

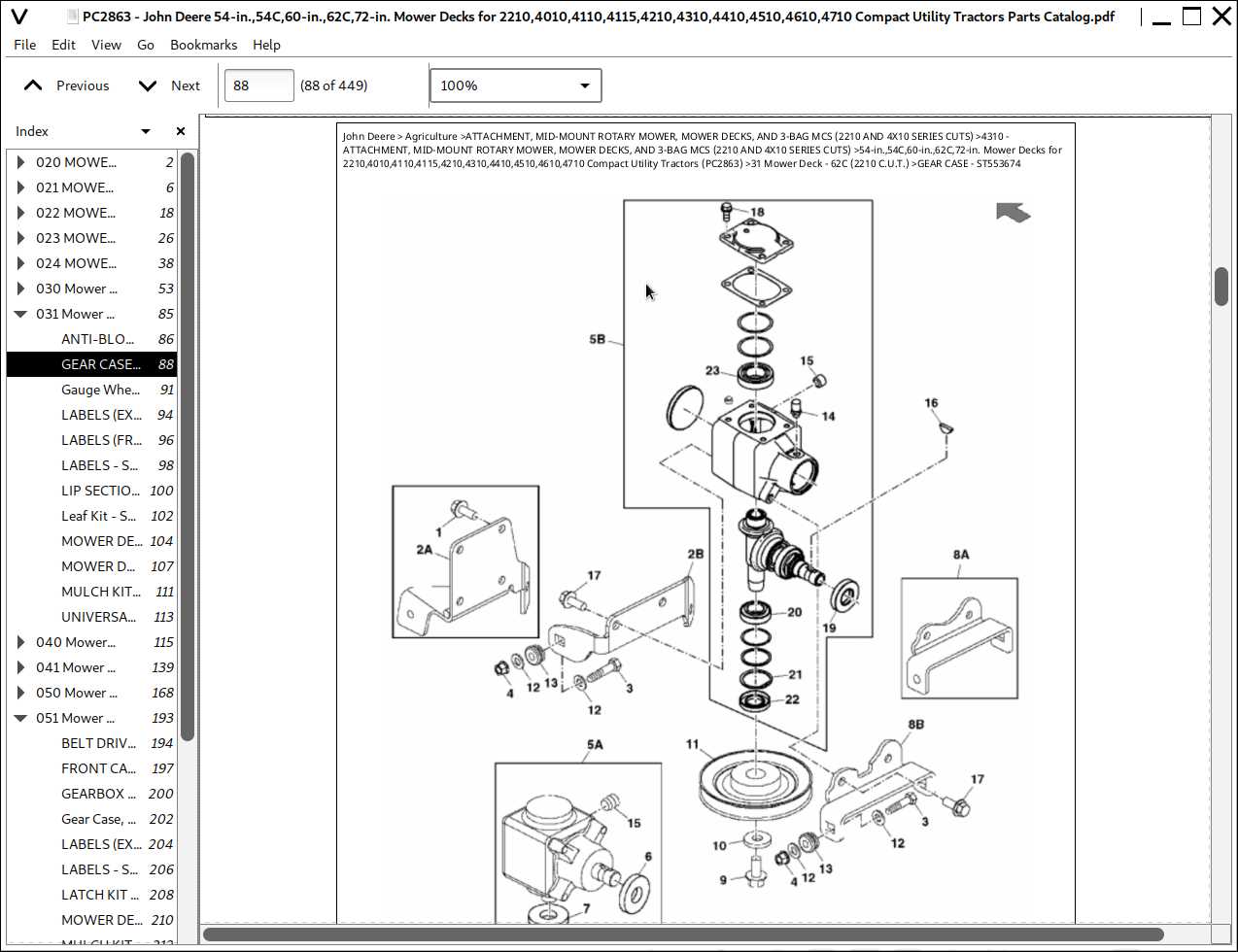

Detailed schematics provide an in-depth look into the assembly and placement of various mechanical and electrical elements. These visual aids offer a comprehensive view of the entire system, making it easier to locate specific elements and understand their interactions. Whether you’re an experienced technician or a new owner, these diagrams can be valuable tools for maintaining and enhancing the performance of your machinery.

Additionally

Comprehensive Guide to John Deere 2210 Parts

This section provides an in-depth overview of the components and essential elements found in compact machinery designed for versatile field tasks. It aims to help users identify and understand various mechanical and structural elements that contribute to optimal performance.

Engine Components: The power source is the heart of any agricultural equipment. Maintaining the integrity of its elements such as fuel injectors, cooling systems, and filtration units is crucial for longevity and efficiency. Ensuring regular upkeep of these components helps prevent potential issues.

Transmission System: A well-functioning gear mechanism is vital for the smooth operation of equipment. It includes gears, clutches, and axles that work together to provide the necessary power and control. Proper inspec

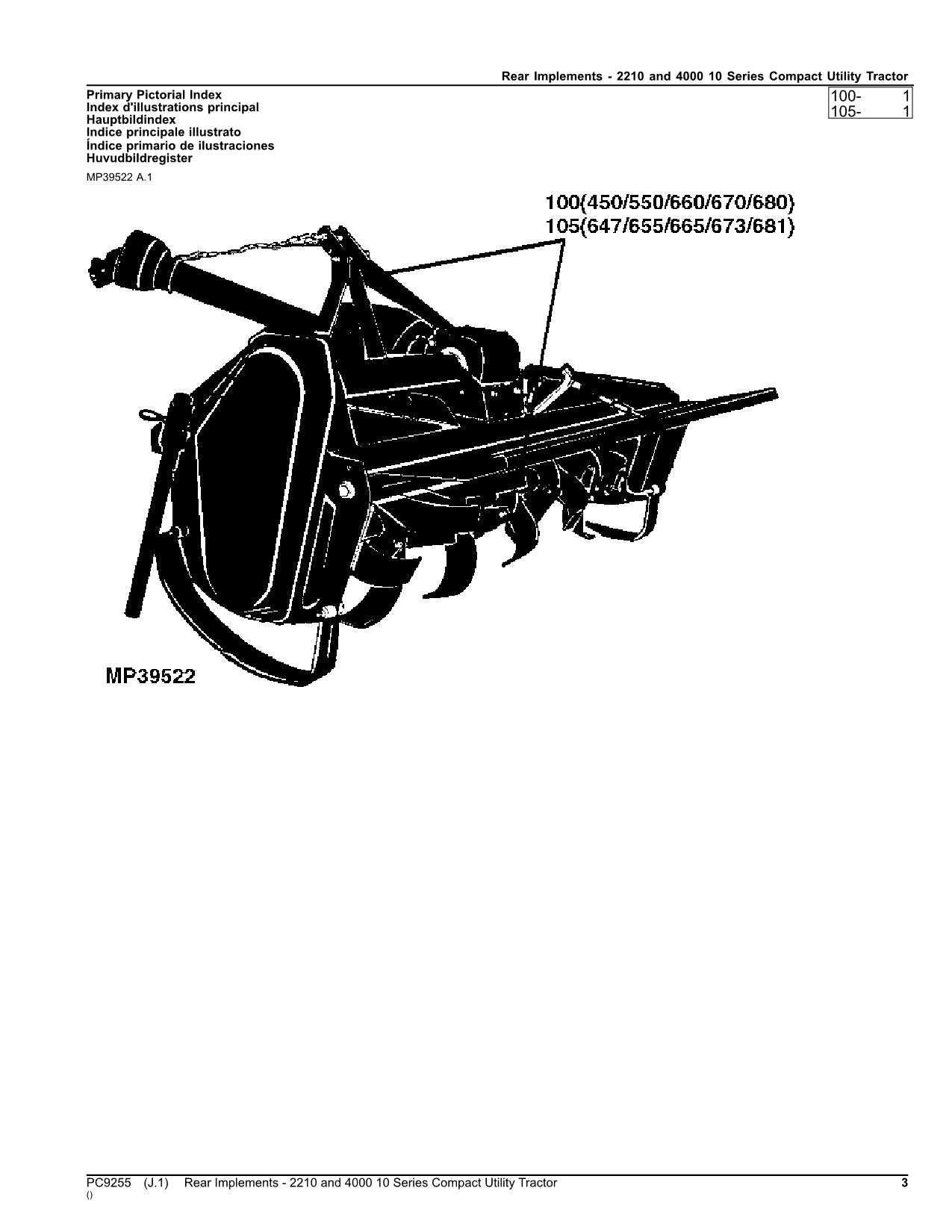

Understanding the Compact Utility Structure

In this section, we will explore the overall framework of a versatile compact utility machine. This vehicle is designed for diverse applications, offering efficiency and flexibility in various agricultural and maintenance tasks. The structure combines strength and adaptability, ensuring reliable performance across different terrains and conditions.

The utility vehicle is built with several essential components that work together to deliver functionality and maneuverability. Below is an overview of these elements:

| Component | Description | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine Block | The power source, providing the necessary energy for various operations. | ||||||||||||

Key Components of the John Deere 2210

Understanding the essential elements of this compact machine is crucial for maintaining its performance and ensuring longevity. This section provides an overview of the primary systems and features that work together to deliver optimal efficiency and versatility in various tasks. Engine and TransmissionThe power unit is the heart of the equipment, delivering consistent output for various applications. Coupled with an efficient transmission system, it ensures smooth operation and adaptability across different terrains. Proper maintenance of these systems is vital for reliable functionality and prolonged service life. Hydraulics and Control Systems

The hydraulics play a critical role in the operation of attachments and lifting mechanisms, offering flexibility and control. Alongside the hydraulics, the control systems provide precise maneuverability, Maintenance Tips for Agricultural Compact Tractor ComponentsEnsuring the longevity and performance of your agricultural equipment relies on regular upkeep and attention to detail. Proper care of machinery components helps prevent unexpected breakdowns and optimizes efficiency during use. Below are some essential tips for maintaining various elements of your compact tractor, ensuring it stays in top working condition.

How to Identify Machinery Component Illustrations

Understanding component illustrations is crucial for proper maintenance and repair. These visual representations help users locate and identify various elements, ensuring that replacements and adjustments are performed accurately. This section provides guidance on recognizing and interpreting these technical illustrations. Key Features of Component Illustrations

Component illustrations typically include labels, numbers, and arrows to indicate specific elements. By learning to match these features with actual parts, users can efficiently locate components. Diagrams often have a legend or key explaining the symbols used, making them easier to understand. Using Reference Tables

Tables are essential for quickly finding details about components in the illustrations. They offer information on part numbers, descriptions, and locations, allowing for straightforward identification.

|