When it comes to maintaining and optimizing agricultural machinery, a thorough comprehension of the various elements involved is crucial. Each piece of equipment consists of numerous components that work in harmony to ensure efficient operation. Recognizing the layout and functionality of these parts can significantly enhance the performance and longevity of your machinery.

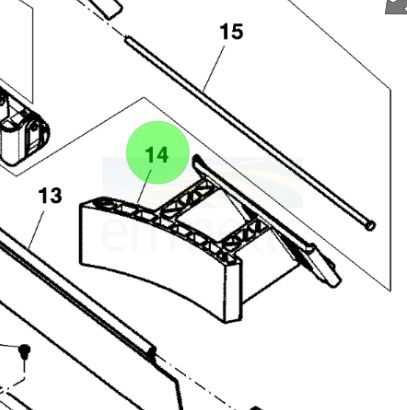

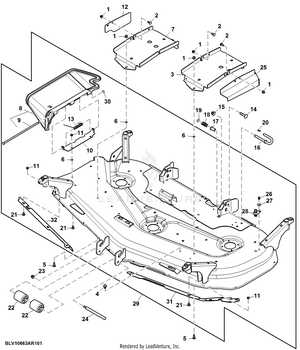

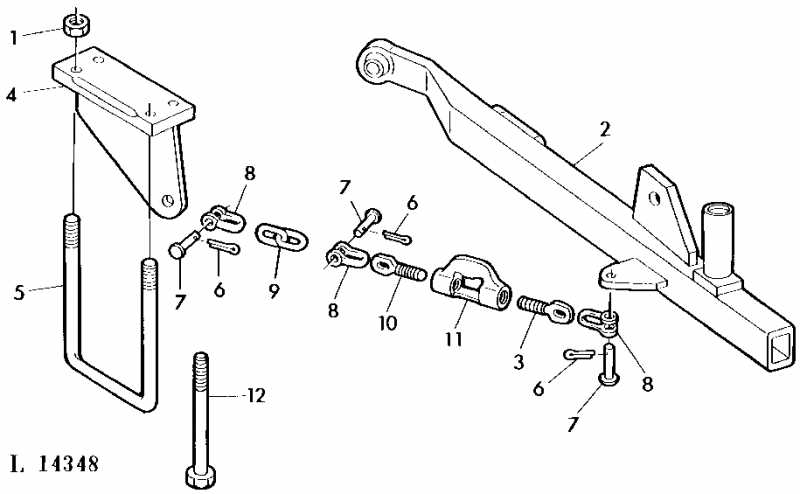

Visual representation of these components plays a pivotal role in facilitating repairs and upgrades. A clear outline can assist operators in identifying the specific areas that require attention or replacement. By having a detailed overview, one can avoid common pitfalls and make informed decisions regarding maintenance.

Furthermore, a comprehensive understanding of these mechanical elements not only aids in troubleshooting but also empowers users to optimize their machines for varying agricultural tasks. Whether it’s enhancing productivity or ensuring safety, grasping the intricacies of the equipment’s construction is essential for any operator aiming for excellence in their field.

Understanding John Deere 2032R Components

Exploring the essential elements of a compact utility machine reveals the intricate relationships between various components that ensure optimal performance and efficiency. Each segment plays a vital role in the overall functionality, enabling operators to achieve their tasks effectively.

Core Elements

The primary components include the engine, transmission, and hydraulic systems, each contributing to power generation and movement. Understanding how these core elements interact is crucial for maintenance and operation, allowing for enhanced productivity.

Maintenance and Upkeep

Regular inspection and servicing of these vital parts can significantly extend the lifespan of the machinery. Familiarity with the specific functions and positions of each component aids in timely repairs and adjustments, ensuring smooth operation.

Importance of Accurate Parts Diagrams

Precision in visual representations of components is crucial for effective maintenance and repair. These illustrations serve as vital tools for technicians, enabling them to identify, locate, and understand the intricate relationships between various elements within machinery. When each piece is accurately depicted, it simplifies the process of troubleshooting and enhances the efficiency of repairs.

Benefits of Detailed Visual Representations

High-quality illustrations provide numerous advantages, including:

| Benefit | Description |

|---|---|

| Enhanced Clarity | Clear images eliminate confusion, making it easier to recognize specific components. |

| Improved Accuracy | Accurate depictions reduce the risk of errors during repairs, saving time and resources. |

| Streamlined Processes | With precise visuals, technicians can quickly assess what is needed, facilitating smoother workflows. |

| Effective Training | Comprehensive illustrations are invaluable for educating new personnel, ensuring they grasp essential concepts. |

Conclusion

In summary, accurate representations of machinery components are indispensable for efficient operation and maintenance. They empower technicians with the knowledge needed to perform their tasks effectively, ultimately contributing to the longevity and reliability of equipment.

Common Issues with 2032R Parts

When working with agricultural machinery, it’s essential to be aware of frequent challenges that can arise with various components. Understanding these issues can help users maintain optimal performance and extend the lifespan of their equipment.

Wear and Tear: One of the most prevalent problems is the natural degradation of parts over time. Regular usage can lead to diminished efficiency, making it crucial to inspect and replace worn components periodically.

Compatibility Problems: Another common concern is the mismatch between different elements. Using non-original replacements can result in improper fit and function, ultimately impacting the machine’s overall performance.

Fluid Leaks: Leaks in hydraulic systems can arise due to degraded seals or damaged connections. These issues not only affect functionality but can also lead to costly repairs if not addressed promptly.

Electrical Failures: Electrical systems are vital for operation, and failures in wiring or connectors can lead to performance issues. Regular checks of electrical components can help prevent unexpected downtime.

Maintenance Oversights: Neglecting routine maintenance can result in numerous problems, including decreased efficiency and increased wear. Following a consistent maintenance schedule is key to avoiding these pitfalls.

Where to Find Replacement Parts

Locating suitable components for your equipment is crucial for maintaining optimal performance and longevity. With a variety of options available, it’s essential to know where to search for reliable items that meet your specific needs.

Online Retailers

The internet offers a plethora of retailers specializing in machinery components. Many websites provide extensive catalogs, complete with specifications and customer reviews, allowing you to make informed decisions. Look for platforms that guarantee authenticity and offer competitive pricing.

Local Dealerships

Your local dealerships are valuable resources for obtaining high-quality components. They often have knowledgeable staff who can assist you in identifying the right items. Additionally, purchasing locally can reduce wait times and shipping costs, ensuring you get back to work quickly.

Maintenance Tips for 2032R Models

Proper upkeep is essential for maximizing the performance and longevity of your compact utility tractor. Regular attention to various components ensures smooth operation and minimizes the risk of breakdowns. Here are some crucial recommendations to keep your machinery in optimal condition.

Regular Fluid Checks: Frequently inspect and replace fluids, including engine oil, coolant, and hydraulic fluid. Clean, fresh fluids help prevent wear and tear on internal parts, enhancing overall efficiency.

Air Filter Maintenance: Keep an eye on the air intake system. A clean air filter is vital for optimal engine performance. Replace it as necessary to ensure proper airflow and reduce fuel consumption.

Tire Inspection: Regularly check tire pressure and tread depth. Maintaining the correct pressure improves fuel efficiency and handling, while adequate tread ensures safety and traction on various surfaces.

Battery Care: Inspect the battery terminals for corrosion and ensure connections are secure. Regularly check the charge level and clean the terminals to prevent starting issues.

Routine Greasing: Lubricate moving parts and joints to minimize friction and wear. Follow the manufacturer’s guidelines for lubrication intervals to keep components functioning smoothly.

Seasonal Checks: Before changing seasons, conduct a thorough inspection of your equipment. Prepare it for cold weather by checking antifreeze levels and ensuring that all systems are functioning properly.

By following these essential maintenance practices, you can ensure that your compact utility tractor remains reliable and efficient for years to come.

Upgrading John Deere 2032R Equipment

Enhancing agricultural machinery can significantly improve efficiency and productivity. Upgrades can range from simple modifications to comprehensive overhauls, ensuring that equipment operates at its best. Investing in high-quality components and modern technology not only boosts performance but also extends the lifespan of the machine.

Identifying Needs is the first step in the enhancement process. Understanding specific tasks and operational challenges allows for tailored improvements. Whether it’s increasing horsepower, improving maneuverability, or enhancing comfort for the operator, a focused approach ensures that every upgrade serves a purpose.

Another crucial aspect is compatibility. When selecting new components, it’s essential to ensure that they integrate seamlessly with existing systems. This can involve consulting with manufacturers or specialists who can provide insights into the best options available. Proper compatibility leads to better performance and reduces the risk of future issues.

Technology Integration plays a vital role in modern upgrades. Features like GPS guidance systems, advanced control interfaces, and automated functions can transform traditional equipment into cutting-edge machinery. These technologies not only simplify operations but also enhance precision, allowing for more effective resource management.

Lastly, maintenance should not be overlooked. Regular checks and servicing of upgraded components will help maintain their efficiency and reliability. Establishing a proactive maintenance schedule ensures that all enhancements continue to deliver optimal performance over time.

Understanding Hydraulic Systems in 2032R

Hydraulic systems play a crucial role in enhancing the efficiency and performance of various machinery. These systems utilize fluid mechanics to transmit power, enabling smooth operation of attachments and implements. A solid grasp of how these systems function can significantly improve maintenance and troubleshooting efforts.

Key Components of Hydraulic Systems

- Pump: Converts mechanical energy into hydraulic energy, providing the necessary pressure.

- Actuator: Transforms hydraulic energy back into mechanical energy to perform work.

- Valves: Control the flow and direction of hydraulic fluid, ensuring proper operation of the system.

- Fluid Reservoir: Stores hydraulic fluid and helps maintain system pressure.

- Filters: Remove contaminants from the fluid to protect components from wear and damage.

Benefits of a Well-Designed Hydraulic System

- Increased efficiency in power transfer, reducing energy losses.

- Improved control over movement and force application, enhancing precision.

- Versatility in operation, allowing for a variety of attachments to be used effectively.

- Enhanced durability and reliability, minimizing downtime and maintenance costs.

Understanding these elements is essential for anyone looking to optimize performance and ensure longevity in machinery that relies on hydraulic power.

Wiring and Electrical Components Explained

Understanding the intricacies of wiring and electrical elements is crucial for maintaining optimal performance in agricultural machinery. These systems not only provide power but also ensure the effective operation of various components, enabling seamless functionality across different tasks.

Wiring Harness: The wiring harness serves as the backbone of the electrical system, connecting various parts while facilitating the flow of electricity. It is essential for distributing power and signals to components such as lights, sensors, and the ignition system.

Fuses and Relays: These protective devices play a significant role in safeguarding electrical circuits. Fuses prevent overcurrent conditions by breaking the circuit when a fault occurs, while relays act as switches that control high-power devices through low-power signals.

Battery and Charging System: The battery is the heart of the electrical system, providing the necessary power to start the engine and run electrical components. A well-functioning charging system ensures the battery remains charged during operation, preventing unexpected failures.

Sensors and Control Units: Sensors monitor various parameters and relay information to control units, which process data and make real-time decisions. These components are vital for enhancing efficiency and ensuring the machinery operates within optimal parameters.

In summary, a thorough understanding of wiring and electrical components is essential for effective maintenance and operation. Knowledge of these elements can significantly enhance the longevity and reliability of agricultural machinery.

Comparative Analysis with Similar Models

This section explores the distinctions and similarities between various compact utility tractors in the same category. By examining their features, performance, and user satisfaction, we aim to provide a comprehensive understanding of how these machines stack up against one another.

When assessing comparable models, several factors come into play:

- Engine Power: Evaluate horsepower ratings to determine operational efficiency.

- Hydraulic System: Compare lift capacities and flow rates for enhanced functionality.

- Attachments Compatibility: Analyze the range of implements each model can accommodate.

- Ease of Maintenance: Consider access to key components for servicing.

- User Feedback: Review customer reviews and ratings for real-world insights.

By delving into these aspects, users can make informed decisions based on their specific needs and preferences.