When it comes to maintaining your agricultural or landscaping equipment, having a clear understanding of its various elements is crucial. Each component plays a vital role in ensuring optimal performance and longevity. Knowing how these parts fit together and function can save time and resources in repairs and upkeep.

In this guide, we will explore the intricate layout of these essential mechanisms. From the powertrain to the hydraulic systems, comprehending the relationship between each segment is key to effective maintenance. Whether you’re a seasoned operator or a new enthusiast, familiarity with your machine’s structure will enhance your overall experience.

By delving into the specifics of the assembly, you can not only improve your troubleshooting skills but also make informed decisions about replacements and upgrades. Engaging with this knowledge will empower you to keep your equipment running smoothly, ensuring that you can tackle any task with confidence.

Understanding the John Deere 2025R

This section explores the features and functionalities of a versatile compact tractor designed for various agricultural tasks. Recognizing its components and their roles is essential for effective operation and maintenance. A thorough comprehension of this machinery ensures that users can maximize its capabilities in different settings.

Key Features

- Compact Size: Ideal for small farms and residential properties.

- Powerful Engine: Provides the necessary strength for demanding tasks.

- Hydraulic System: Enhances efficiency in lifting and moving materials.

- Ergonomic Design: Ensures comfort during extended use.

Maintenance Essentials

- Regular Inspections: Check for wear and tear on crucial components.

- Fluid Changes: Keep hydraulic and engine fluids at optimal levels.

- Filter Replacements: Ensure clean air and fuel intake for peak performance.

- Tire Maintenance: Monitor pressure and tread for safety and efficiency.

Key Features of the 2025R Model

The 2025R model stands out in its category due to a combination of advanced engineering and practical design. This machine is tailored to meet diverse agricultural and landscaping needs, offering both power and versatility for various tasks.

- Compact Size: Ideal for maneuvering in tight spaces, making it suitable for residential properties and small farms.

- Powerful Engine: Equipped with a robust engine that delivers efficient performance for demanding jobs.

- Hydrostatic Transmission: Provides smooth and effortless control, enhancing the user experience during operation.

- Versatile Attachments: Compatible with a wide range of implements, allowing for quick transitions between tasks.

- Comfortable Operator Station: Designed for ease of use, featuring an ergonomic seat and intuitive controls for better comfort during long hours of work.

Overall, the unique attributes of this model contribute to its reputation as a reliable choice for both hobbyists and professionals in the field.

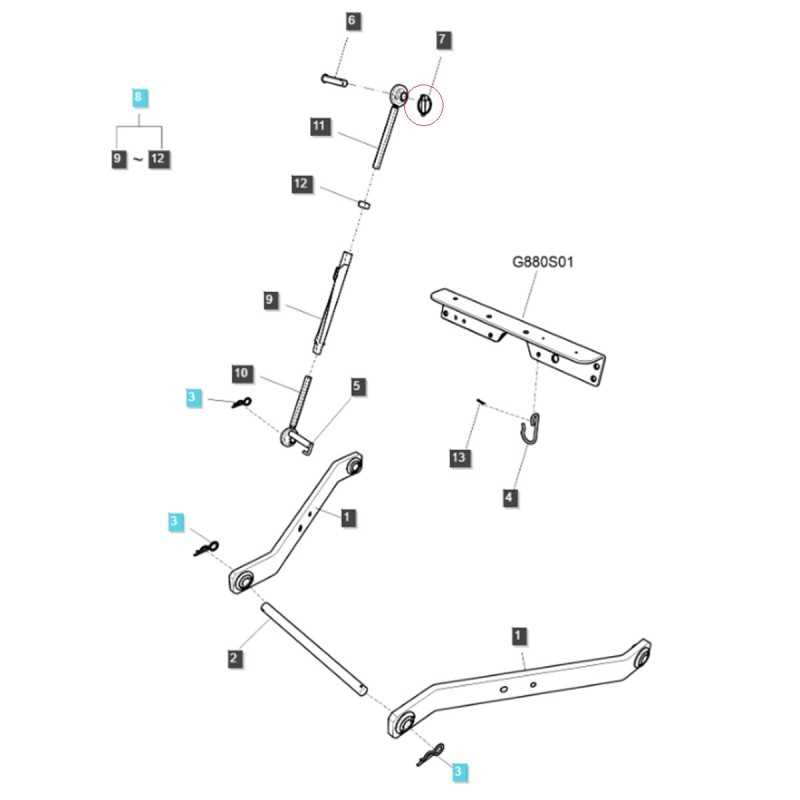

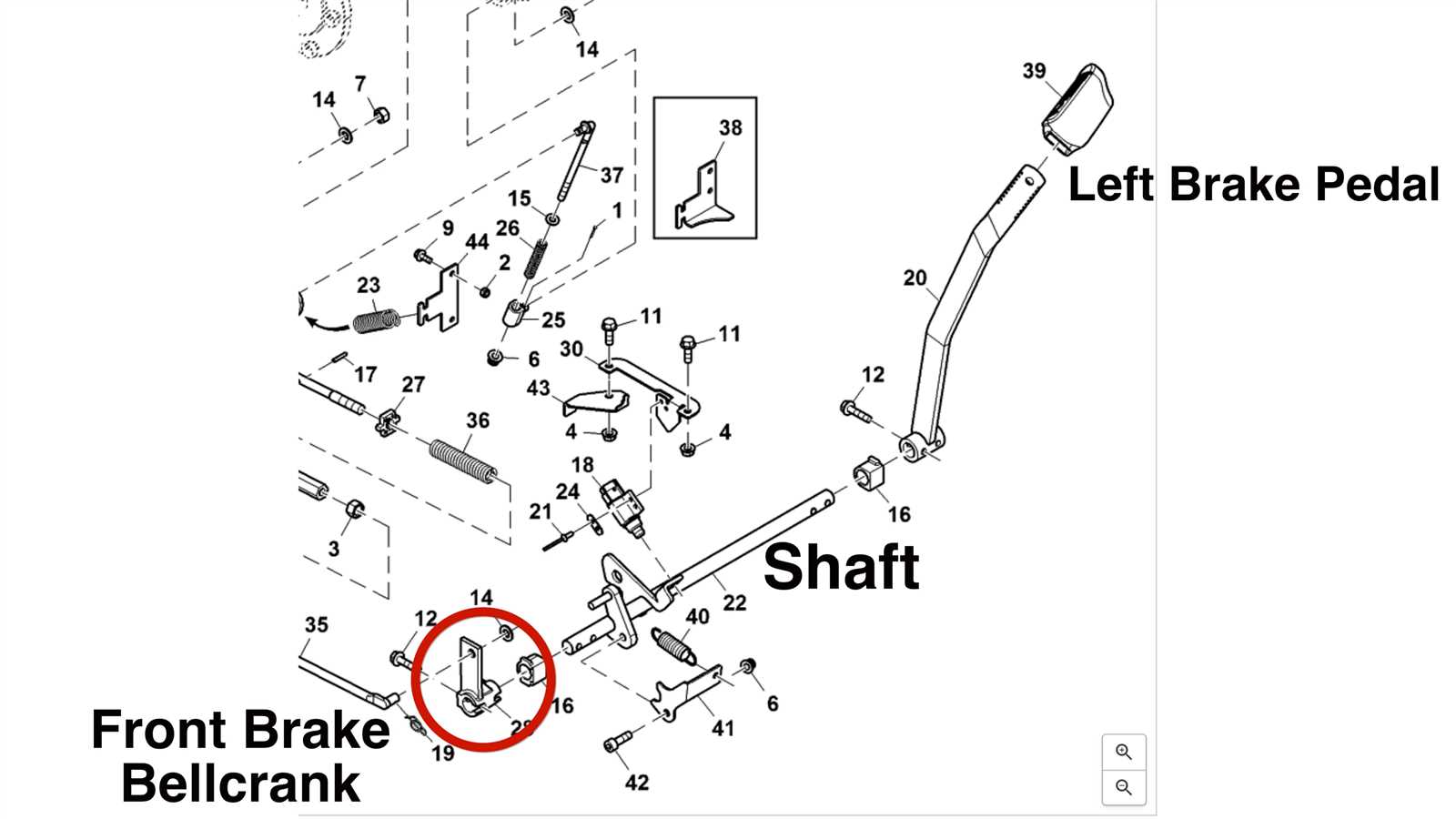

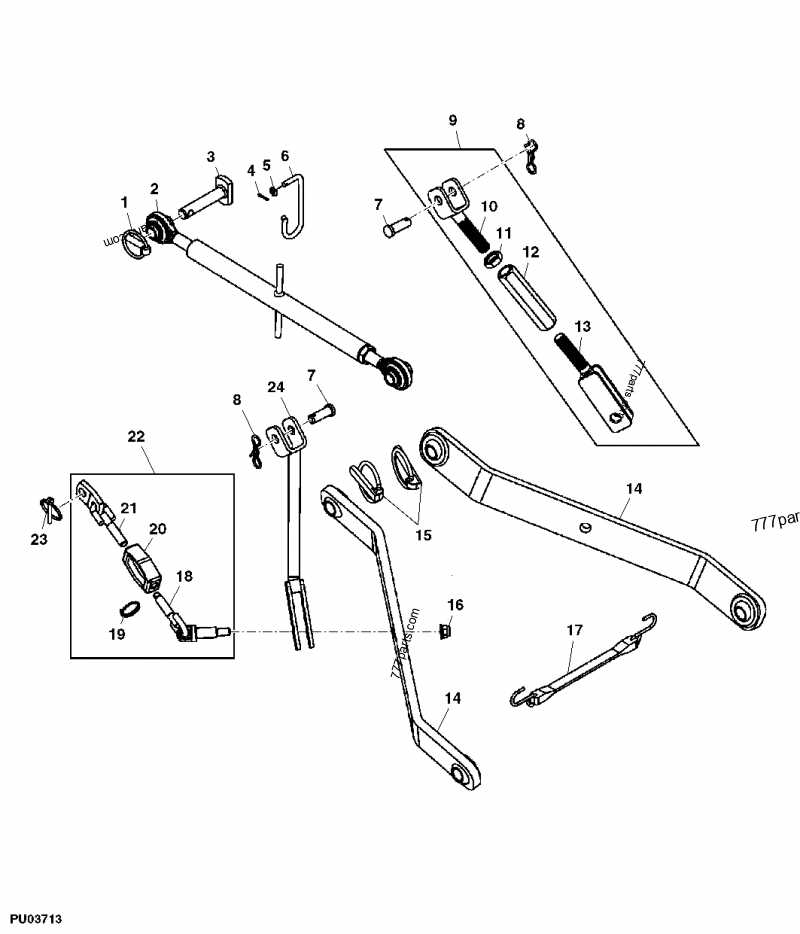

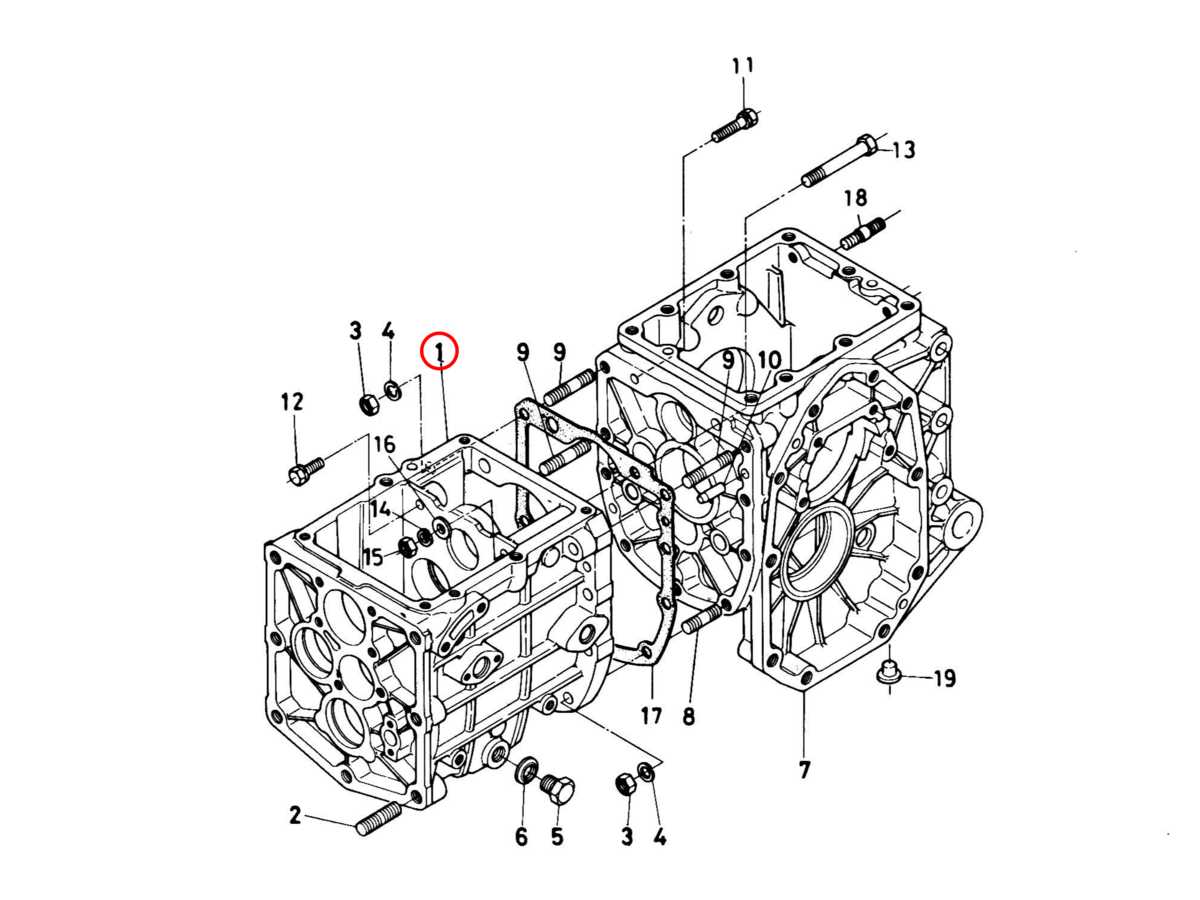

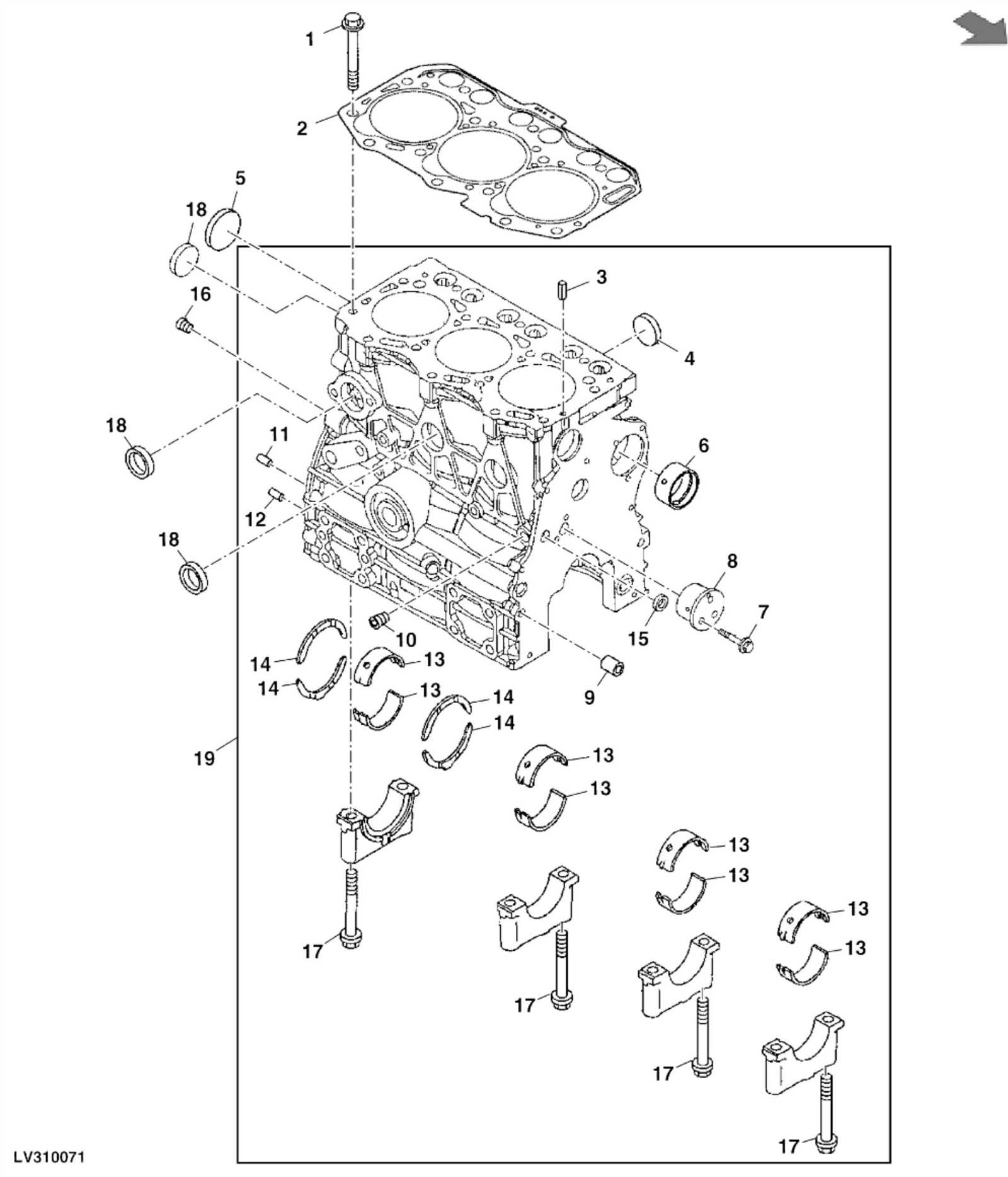

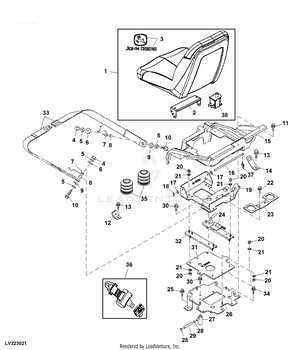

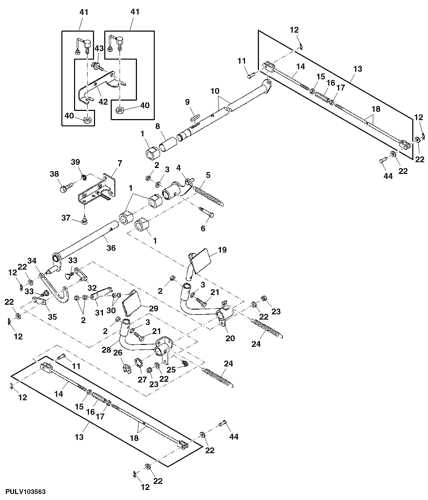

Importance of Accurate Parts Diagrams

Having precise visual representations of components is crucial for effective maintenance and repair. These illustrations serve as essential references, guiding technicians through the intricate assembly and functionality of machinery. When dealing with complex systems, clarity in these visuals minimizes the risk of errors and enhances operational efficiency.

| Benefits | Description |

|---|---|

| Enhanced Understanding | Clear visuals help users grasp the structure and function of various elements. |

| Reduced Errors | Accurate visuals lower the chances of incorrect assembly or part replacement. |

| Time Efficiency | Quick reference aids streamline maintenance processes, saving valuable time. |

| Cost-Effectiveness | Minimized mistakes lead to lower repair costs and prolonged equipment life. |

Common Replacement Parts for 2025R

Maintaining the efficiency and functionality of your equipment requires regular attention to certain key components. Understanding which elements are frequently replaced can help ensure your machine operates smoothly and lasts longer. Here are some commonly needed items for your model that you might consider keeping on hand.

Filters are essential for keeping fluids clean and preventing contaminants from causing damage. Oil, fuel, and air filters should be checked regularly and replaced as needed to maintain optimal performance.

Batteries are vital for reliable operation, especially in colder climates. A high-quality replacement ensures that your machine starts easily and runs efficiently, so it’s wise to monitor battery health closely.

Belts are crucial for power transmission between components. Over time, they can wear out or become damaged, leading to decreased performance. Regular inspections and timely replacements will keep everything running smoothly.

Tires play a significant role in traction and stability. Depending on usage, tire wear can occur, making periodic replacement necessary to ensure safety and effectiveness during operation.

Seals and Gaskets are often overlooked but are essential for preventing leaks in fluid systems. Regularly replacing these components helps maintain pressure and functionality, avoiding costly repairs down the line.

Being proactive about these essential components can greatly enhance the longevity and reliability of your equipment, allowing for efficient operation in various tasks.

Where to Find Parts Diagrams

Locating detailed illustrations for machinery components can significantly enhance maintenance and repair tasks. These resources serve as valuable guides, allowing users to understand the assembly and functionality of various elements within their equipment.

Official Manufacturer Resources

One of the most reliable sources for these visual aids is the official website of the manufacturer. They often provide comprehensive documentation that includes exploded views and lists of components, ensuring accuracy and relevance.

Online Communities and Forums

Engaging with online communities and forums dedicated to machinery enthusiasts can also yield useful resources. Members frequently share links, tips, and even personal insights regarding accessing these valuable illustrations, enriching your understanding.

Tips for Identifying Components

Recognizing various elements of machinery can significantly enhance your understanding and maintenance skills. Familiarity with specific components is crucial for effective troubleshooting and repairs. Here are some strategies to help you pinpoint the necessary parts with confidence.

1. Consult Manuals: Always refer to the manufacturer’s manual. These documents often contain detailed illustrations and descriptions that aid in identifying individual elements. Having a physical or digital copy at hand can save time and reduce frustration.

2. Use Online Resources: Numerous websites and forums are dedicated to equipment enthusiasts. These platforms often feature user-uploaded images, videos, and discussions that can provide valuable insights into component recognition.

3. Label and Organize: When disassembling machinery, label each part clearly. This practice not only helps in identifying components during reassembly but also serves as a reference for future maintenance tasks.

4. Visual Comparison: If possible, compare the parts with online images or diagrams. This method allows you to visually match components and ensure you have the correct item for your needs.

5. Seek Professional Help: If you’re uncertain about identifying a specific element, don’t hesitate to consult a professional. Experienced technicians can offer guidance and clarity that can be invaluable.

By employing these tips, you’ll enhance your ability to identify and understand the components of your machinery, leading to more efficient repairs and maintenance practices.

Maintaining Your John Deere Equipment

Regular upkeep of your machinery is essential for optimal performance and longevity. Proper maintenance not only enhances efficiency but also prevents unexpected breakdowns, ensuring smooth operations throughout the year.

Begin with routine inspections to identify any wear and tear. Check fluid levels, replace filters, and examine belts for signs of damage. Keeping the equipment clean and free of debris will also contribute to its durability.

Consult the owner’s manual for specific maintenance schedules and recommended practices. This guidance will help you stay on track and maximize the lifespan of your valuable investment.

Finally, don’t hesitate to seek professional assistance when needed. Expert technicians can provide insights and services that ensure your machinery remains in top-notch condition.

Common Issues and Solutions

In the realm of compact machinery, operators often encounter a variety of challenges that can hinder performance. Understanding these common problems and their remedies can enhance efficiency and prolong the lifespan of equipment. This section outlines prevalent issues and practical solutions to ensure smooth operation.

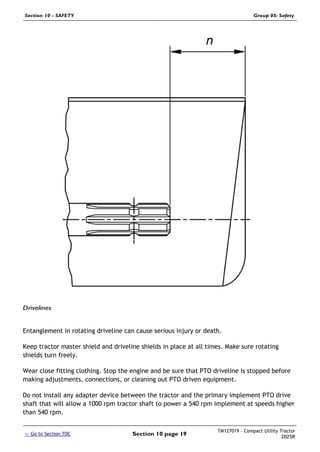

Hydraulic System Problems

Hydraulic systems are vital for the functionality of many machines. Issues such as leaks or reduced pressure can lead to poor performance. Regular maintenance and timely inspections are crucial for identifying and addressing these problems.

| Issue | Solution |

|---|---|

| Fluid leaks | Inspect hoses and connections for wear, and replace damaged components. |

| Low pressure | Check fluid levels and filters, and replace if necessary. |

Electrical System Failures

Electrical malfunctions can lead to operational interruptions. Symptoms may include starting issues or erratic behavior of controls. Understanding the electrical layout can help diagnose and rectify these concerns efficiently.

| Issue | Solution |

|---|---|

| Starting difficulties | Examine the battery connections and test the battery’s charge. |

| Unresponsive controls | Inspect wiring and fuses for damage and replace as needed. |

Benefits of Genuine John Deere Parts

Utilizing authentic components ensures optimal performance and longevity for your machinery. These high-quality elements are designed to fit seamlessly, minimizing the risk of malfunctions and enhancing overall efficiency.

| Advantage | Description |

|---|---|

| Quality Assurance | Manufactured to meet strict standards, ensuring durability and reliability. |

| Perfect Fit | Engineered for compatibility, reducing installation time and effort. |

| Performance | Optimized for superior functionality, leading to improved machine efficiency. |

| Warranty Protection | Many authentic components come with warranties, offering peace of mind. |