Maintaining optimal performance for your lawn equipment requires a detailed understanding of its individual components. Each part plays a crucial role in ensuring smooth operation and longevity. This section focuses on exploring the essential elements that form the core of your machine’s cutting system, helping you gain insights into their functionality and importance.

Whether you’re dealing with blade assemblies, drive mechanisms, or other vital elements, understanding how they interconnect is critical for proper maintenance and replacement. This guide provides a breakdown of these components, allowing you to better navigate the structure of your equipment.

In addition to identifying key parts, this article also sheds light on potential issues that may arise from wear and tear. Recognizing the signs of damage or inefficiency early can help you take action to prevent costly repairs down the line, ensuring a longer life for your equipment.

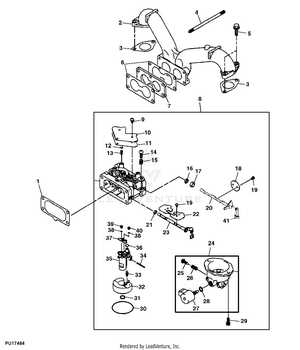

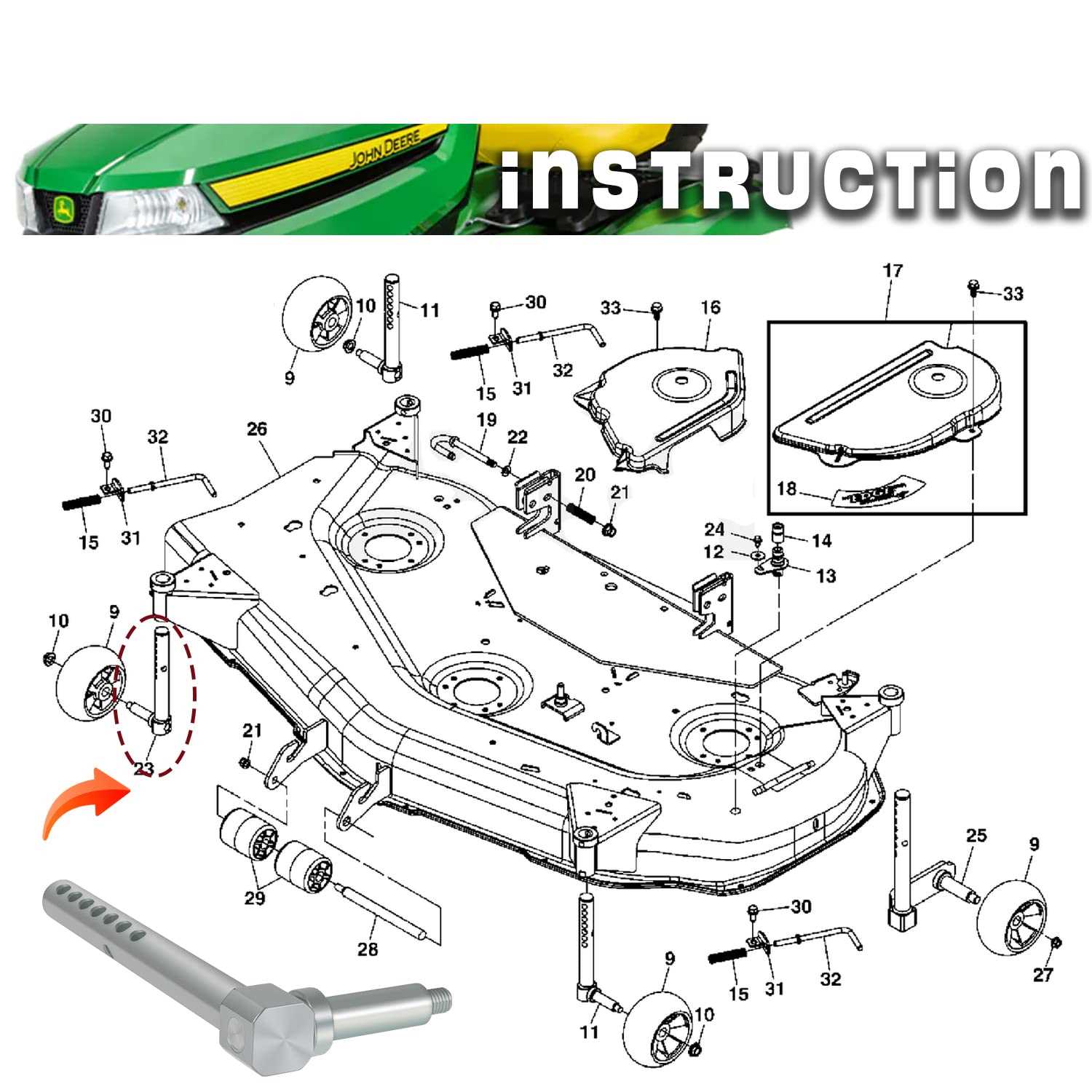

John Deere X320 Mower Deck Overview

The cutting mechanism of this lawn equipment is designed for efficient grass trimming and a smooth finish. Engineered for durability and precision, this feature ensures that your lawn is evenly cut, providing a clean look with minimal effort. Its structure allows for optimal airflow, which contributes to both superior cutting performance and effective grass dispersal. Users can benefit from its reliable build, ensuring consistent results over time.

Key Components include a well-balanced blade system, designed to handle various types of terrain. The adjustment capabilities allow users to fine-tune the height, catering to different preferences and grass conditions. The sturdy design also helps reduce wear and tear, enhancing longevity and reducing maintenance needs.

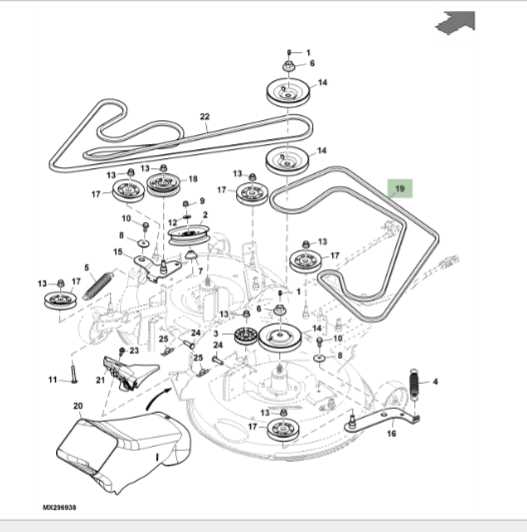

Key Components of the X320 Deck

The cutting platform of this model is designed for efficiency and durability, incorporating several essential elements that contribute to its performance and long-lasting use. Understanding these elements helps in both regular maintenance and ensuring optimal functionality during operation.

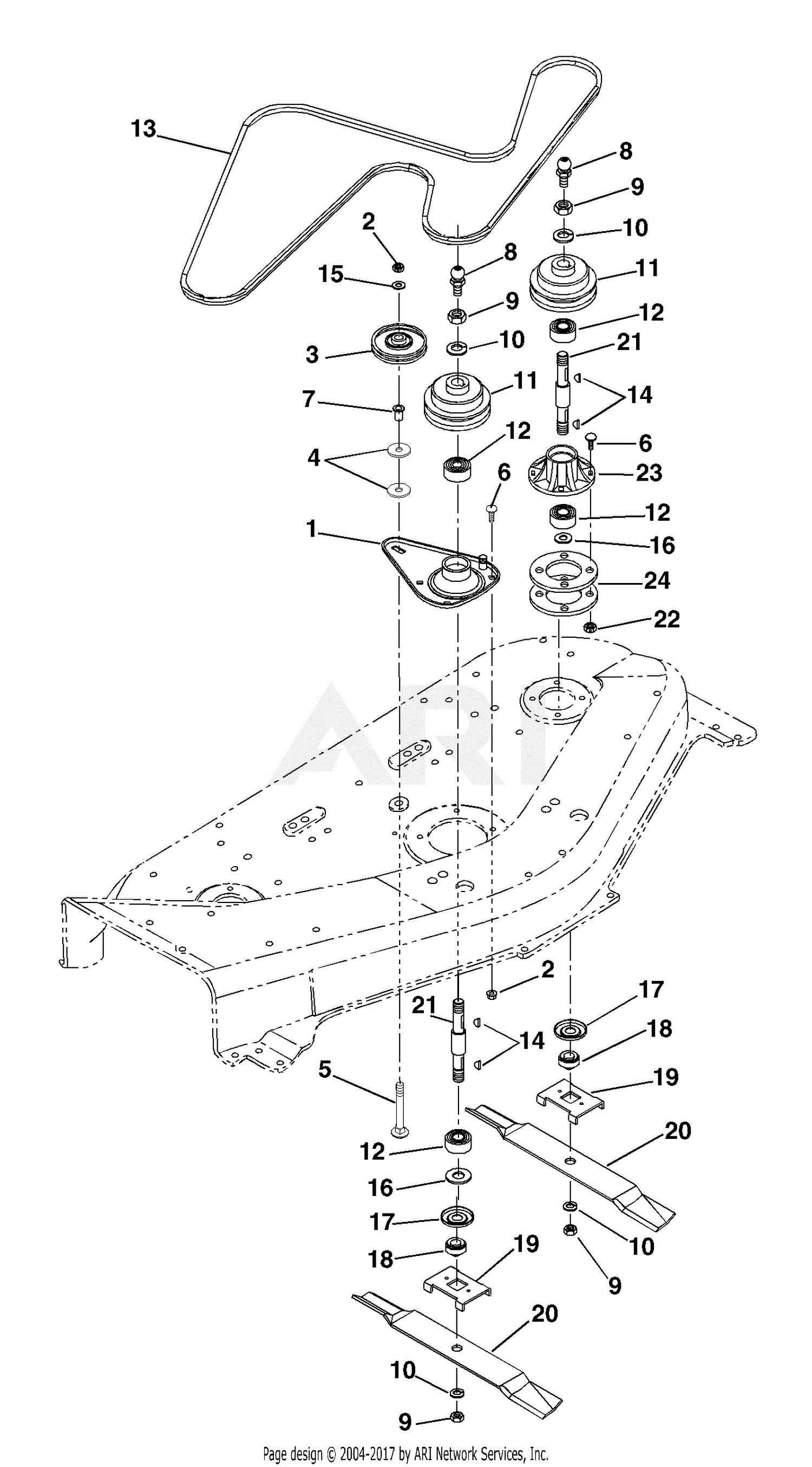

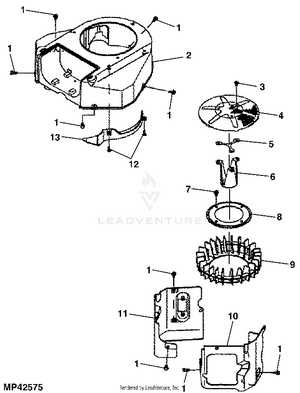

Blade System

The sharp, high-quality cutting edges are a vital part of any lawn maintenance machine. These elements work in tandem to ensure a precise and even trim across the grass surface, making sure that the work is done quickly and effectively.

- High-speed rotation for efficient cutting

- Durable material to withstand wear

- Designed for optimal grass discharge

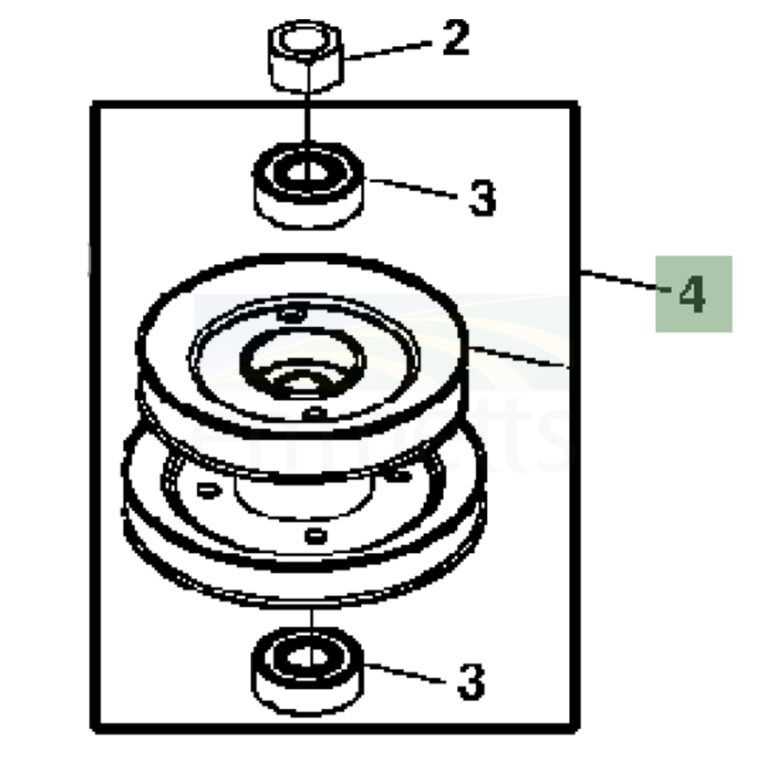

Spindle Assembly

This component is responsible

Common Issues with X320 Deck Parts

Maintenance of cutting equipment often involves dealing with various technical problems. Over time, wear and tear, along with environmental factors, can lead to frequent malfunctions. Understanding the most common issues can help in diagnosing problems early and prolonging the equipment’s lifespan.

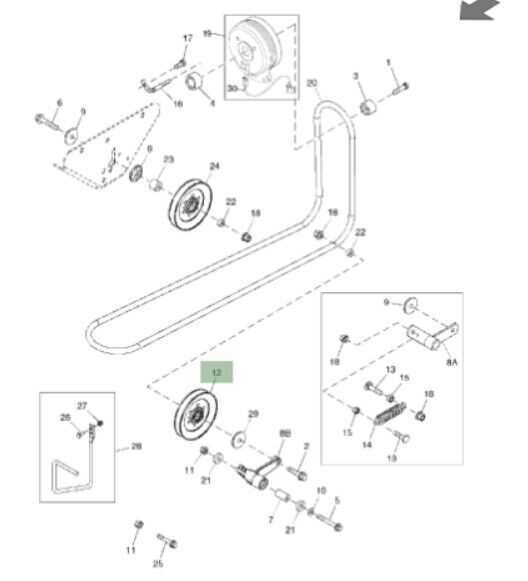

Belt Slippage

One of the frequent concerns users face is the slipping of the drive belt. This can be caused by excessive stretching or debris accumulation. Ensuring proper tension and regularly cleaning the system can mitigate this issue. A worn-out belt might also require replacement to restore optimal functionality.

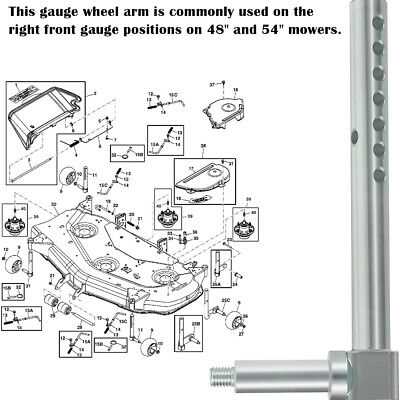

Uneven Cutting

Another prevalent issue is uneven cutting. This can result from blade dullness or improper alignment. Checking for bent or damaged blades and ensuring they are sharpened regularly can help prevent this problem. Additionally, adjusting the height settings and making sure the wheels are balanced can improve cutting consistency.

| Task | Frequency | Details |

|---|---|---|

| Blade Sharpening | Every 20 hours of use | Check the sharpness of the blades regularly to ensure clean cuts

Best Practices for Deck Blade Replacement

Ensuring proper maintenance of your lawn equipment involves regularly replacing the cutting components to maintain efficiency. Over time, these parts can become dull or damaged, affecting performance and leading to uneven cuts. By following a few essential steps, you can ensure a smooth and effective replacement process, prolonging the lifespan of your machine. Safety first: Always disconnect the power source before starting any maintenance work. This is crucial to prevent accidents. Make sure to wear protective gloves to avoid injury from sharp edges. Inspect the cutting area: Before removing the old blades, inspect the area for debris or buildup. Clearing any obstructions will make the replacement easier and safer, and help you assess any additional wear or damage. Proper removal: Use the correct tools to loosen a Compatible Parts for John Deere X320 Deck

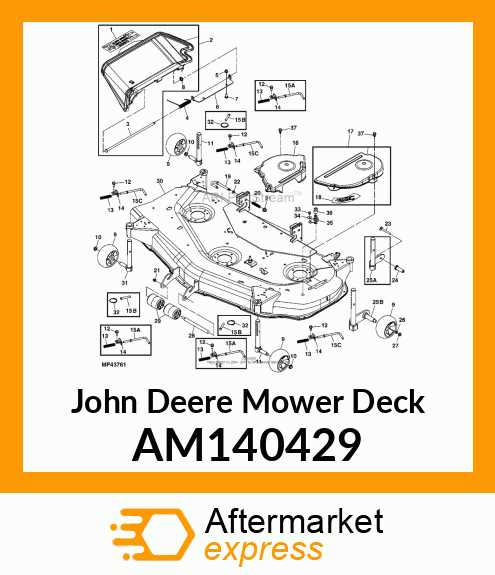

Ensuring the optimal performance of your machine involves understanding the various components that work together seamlessly. Compatibility among these elements is crucial for maintaining efficiency and longevity. This section explores alternative options available for enhancing functionality, enabling owners to make informed decisions regarding replacements and upgrades. Replacement Options

Several alternatives are available to replace worn-out components effectively. These substitutes are designed to meet or exceed original specifications, ensuring a perfect fit and reliable operation. When selecting replacements, consider the quality and durability of materials, as these factors greatly influence performance and lifespan. Maintenance Accessories

In addition to direct substitutes, a range of maintenance accessories can enhance overall functionality. Regular upkeep is essential to prevent premature wear and ensure the machinery operates at peak efficiency. Utilizing high-quality lubricants, filters, and other maintenance tools can significantly extend the lifespan of your equipment. In summary, exploring compatible options for your machinery can lead to improved performance and greater longevity. Prioritize quality and fit when selecting replacements or enhancements to achieve optimal results. Step-by-Step Guide to Deck Removal

Removing the mowing apparatus from your lawn care machine can be an essential task for maintenance and repairs. This process allows for easy access to components that may need cleaning or replacement. Below is a detailed guide that will help you through each stage of the disassembly, ensuring a smooth and efficient operation.

Following these steps will ensure a successful removal of the mowing apparatus, making it easier to perform maintenance and repairs when necessary. |