In the world of machinery, having a clear understanding of the layout and organization of essential elements is crucial for maintenance and repair. A detailed visual representation can greatly assist enthusiasts and professionals alike in identifying specific sections and components. This not only streamlines the process of troubleshooting but also enhances the overall efficiency of any task at hand.

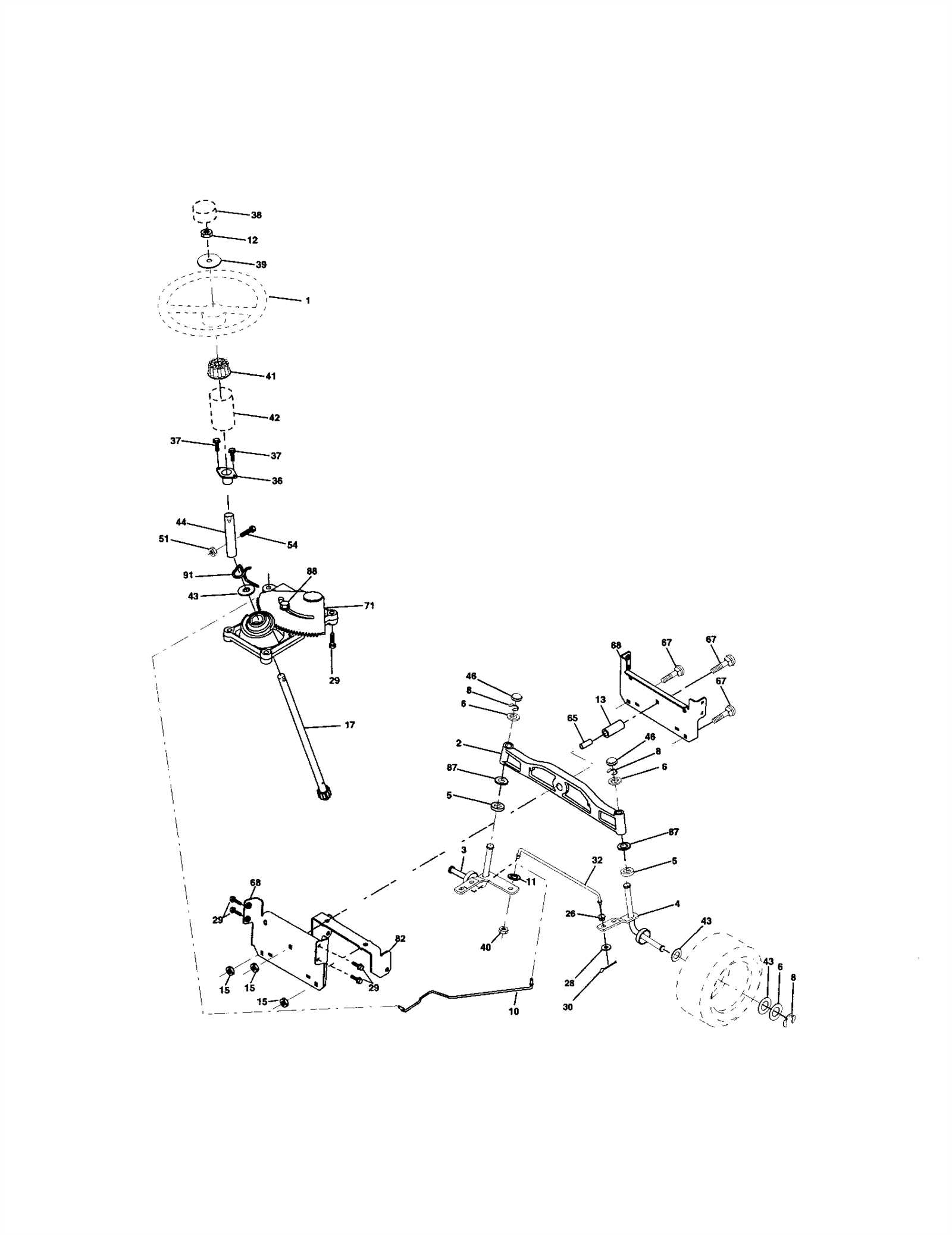

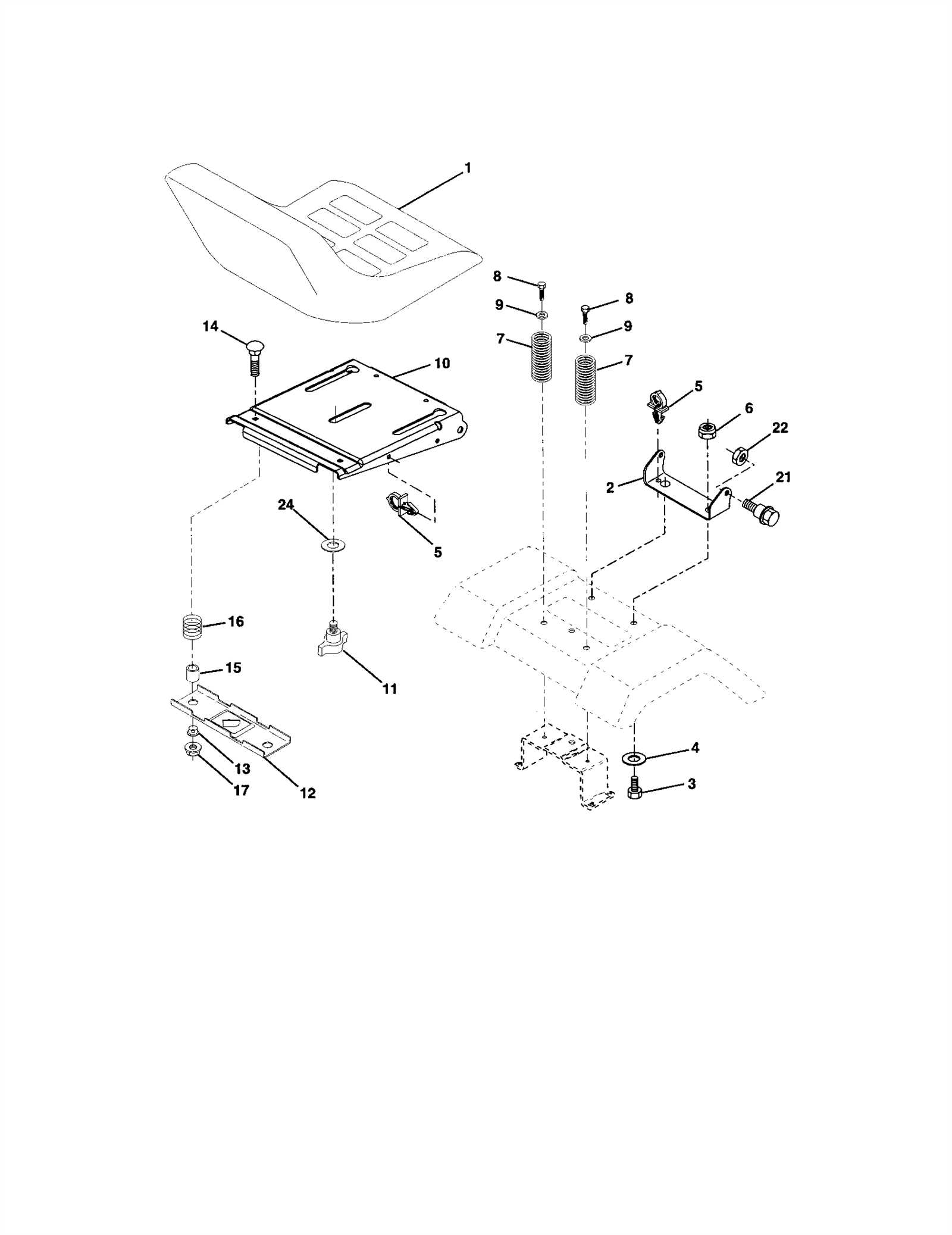

Detailed illustrations serve as invaluable tools, allowing users to navigate complex systems with ease. By providing an overview of individual sections, these visuals help in pinpointing exact locations and understanding the interrelationships between different components. Whether you’re an expert or a novice, familiarity with these layouts can significantly improve your hands-on experience.

Moreover, possessing a comprehensive reference can lead to informed decision-making when it comes to repairs or upgrades. Recognizing each element’s purpose within the larger framework empowers users to maintain their equipment more effectively. This knowledge ultimately translates to better performance and longevity of the machinery in question.

Understanding Craftsman DLT 2000 Parts

Gaining insight into the components of a specific machinery model is essential for effective maintenance and troubleshooting. Each element plays a crucial role in ensuring optimal performance and longevity of the equipment. Familiarity with these individual segments allows users to identify issues quickly and implement appropriate solutions.

Key Components: The various segments are typically categorized into structural, mechanical, and electrical elements. Structural components provide the framework and support, while mechanical parts are responsible for the movement and functionality of the machinery. Electrical elements facilitate operation and control, ensuring everything works seamlessly.

Maintenance Tips: Regular inspection and replacement of worn-out or damaged components can prevent significant breakdowns. Understanding the function of each part aids in recognizing when a specific element may require attention, thereby enhancing the overall efficiency of the machine.

In conclusion, an in-depth understanding of the various components associated with your machinery not only empowers you to perform necessary maintenance but also enhances your ability to make informed decisions regarding repairs and upgrades.

Importance of Parts Diagrams

Understanding the intricacies of machinery is essential for effective maintenance and repair. Visual representations of components play a crucial role in this process, offering clarity and guidance. By depicting each element and its function, these illustrations facilitate a comprehensive approach to troubleshooting and assembly.

First and foremost, such visual aids enable users to identify individual pieces quickly. This is particularly beneficial when dealing with complex devices, where the relationship between various components may not be immediately apparent. Clear visuals enhance the user’s ability to locate and replace malfunctioning elements efficiently.

Additionally, these representations serve as educational tools, especially for those new to the field. They provide a foundational understanding of how devices operate, fostering confidence in both repair and assembly tasks. Users can gain insights into the functionality and interconnectivity of components, leading to more informed decisions during maintenance.

Moreover, visual guides can improve communication among team members. When working collaboratively, having a common reference point minimizes misunderstandings and ensures everyone is on the same page regarding procedures. This alignment can significantly enhance workflow efficiency and reduce the risk of errors.

In conclusion, visual schematics are invaluable assets for anyone involved in the upkeep of mechanical devices. They not only simplify the identification and replacement of components but also empower users with knowledge, improving overall operational effectiveness.

Key Components of the DLT 2000

This section explores the essential elements that contribute to the functionality and efficiency of the tool in question. Understanding these components is crucial for effective operation and maintenance.

- Motor: Powers the device, providing the necessary torque and speed.

- Blade: The primary cutting element, critical for achieving precise results.

- Handle: Ensures user comfort and control during operation.

- Base Plate: Stabilizes the tool, allowing for accurate and steady cutting.

- Switch: Facilitates easy operation and safety control.

Familiarity with these parts enhances overall performance and longevity.

How to Read the Parts Diagram

Understanding the visual representation of components is essential for effective maintenance and repair. This guide will provide insights into deciphering the layout, ensuring that you can identify and locate each element easily.

Identifying Components

Begin by examining the key features of the illustration. Look for labels and numbers that correspond to specific items. Familiarizing yourself with the symbols used can greatly enhance your comprehension.

Utilizing Reference Materials

Consult the accompanying documentation for additional context. Often, these materials include descriptions and specifications that clarify the role of each component. Cross-referencing this information with the visual can lead to a deeper understanding of assembly and functionality.

Common Issues with DLT 2000 Parts

When working with machinery, certain challenges can arise that may affect performance and functionality. Understanding these common problems is essential for maintaining efficiency and ensuring longevity. Various components may experience wear and tear over time, leading to operational difficulties that users need to address promptly.

Wear and Tear

One of the most frequent issues involves the gradual deterioration of key components. Over time, constant usage can lead to a reduction in efficiency, causing parts to function improperly. Regular inspections can help identify these wear patterns early, allowing for timely replacements and repairs.

Compatibility Problems

Another significant concern is the compatibility of various elements within the system. Using mismatched components can lead to malfunctions or even damage to the machinery. It’s crucial to ensure that all parts are suitable for the specific model to maintain optimal performance and safety.

Where to Find Replacement Parts

Finding suitable components for your equipment can be a straightforward process when you know where to look. Numerous resources are available, from online retailers to local shops, ensuring you can restore your machinery to optimal working condition.

Online Retailers

The internet offers a plethora of options for sourcing components. Websites dedicated to tools and equipment often have extensive inventories. Major e-commerce platforms also stock a wide variety of items, making it easy to compare prices and availability. Always check customer reviews to gauge the reliability of sellers.

Local Supply Stores

Visiting local hardware or specialized tool shops can be beneficial as well. Staff members are often knowledgeable and can assist in locating the specific items you need. Additionally, you can inspect products in person, ensuring they meet your requirements before purchasing. Networking with fellow enthusiasts can also lead to valuable recommendations for trustworthy local suppliers.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment requires regular attention and care. By implementing a few essential practices, you can significantly extend the lifespan and efficiency of your tools, allowing them to perform at their best for years to come.

Regular Cleaning

Keep your tools clean to prevent dust and debris from affecting their functionality. Use a soft brush or cloth to remove any buildup, especially in moving parts. This simple step can make a significant difference in performance.

Routine Inspections

Conduct periodic checks for wear and tear. Look for any loose components or signs of damage. Addressing minor issues early can prevent more serious problems later, ensuring your equipment remains in excellent condition.

Comparing DLT 2000 with Other Models

When evaluating different equipment options, it’s essential to consider how various models stack up against one another. Each variant offers distinct features and capabilities that cater to specific needs. By examining these differences, users can make informed choices tailored to their requirements.

Performance and Efficiency

One of the primary factors to compare is the performance and efficiency of each model. Some variants may excel in power output, while others prioritize energy consumption. Analyzing these attributes can highlight which equipment is best suited for particular tasks.

Durability and Maintenance

Another critical aspect is the durability and maintenance requirements of each option. Certain models may be built with sturdier materials, reducing wear over time, whereas others might necessitate more frequent upkeep. Understanding these elements helps ensure long-term satisfaction and functionality.

User Experiences and Reviews

This section aims to capture the diverse perspectives of individuals who have engaged with a specific tool, sharing insights that highlight both advantages and challenges encountered during use. User feedback serves as a valuable resource for prospective buyers, providing real-world implications of product performance.

| Reviewer | Rating | Comments |

|---|---|---|

| John D. | 5/5 | Excellent performance! It exceeded my expectations in precision. |

| Sarah K. | 4/5 | Very reliable, but I faced some minor issues with the setup. |

| Mike T. | 3/5 | Decent quality, but not as durable as I hoped. |

| Emily R. | 4.5/5 | Great value for money! It has made my projects much easier. |