Exploring the internal structure of mechanical devices provides valuable insight into how various elements work in harmony to ensure smooth operation. A well-organized schematic can be a powerful tool, offering clarity for maintenance and repair tasks.

This article delves into the detailed layout of key components found in modern power equipment. It emphasizes the importance of each part’s role within the system, ensuring that readers can easily identify, understand, and address potential issues that may arise over time.

By focusing on the interactions between various sections

Craftsman 3000i Generator Parts Overview

This section offers a detailed breakdown of key components essential for ensuring reliable performance and efficient operation. Understanding the primary elements helps with maintenance and troubleshooting, extending the lifespan of the equipment.

- Power Unit: The core mechanism that produces electricity, ensuring smooth functionality during various tasks.

- Control Panel: Provides user-friendly access to essential settings and indicators, such as power output and fuel levels.

- Key Components Inside the Generator

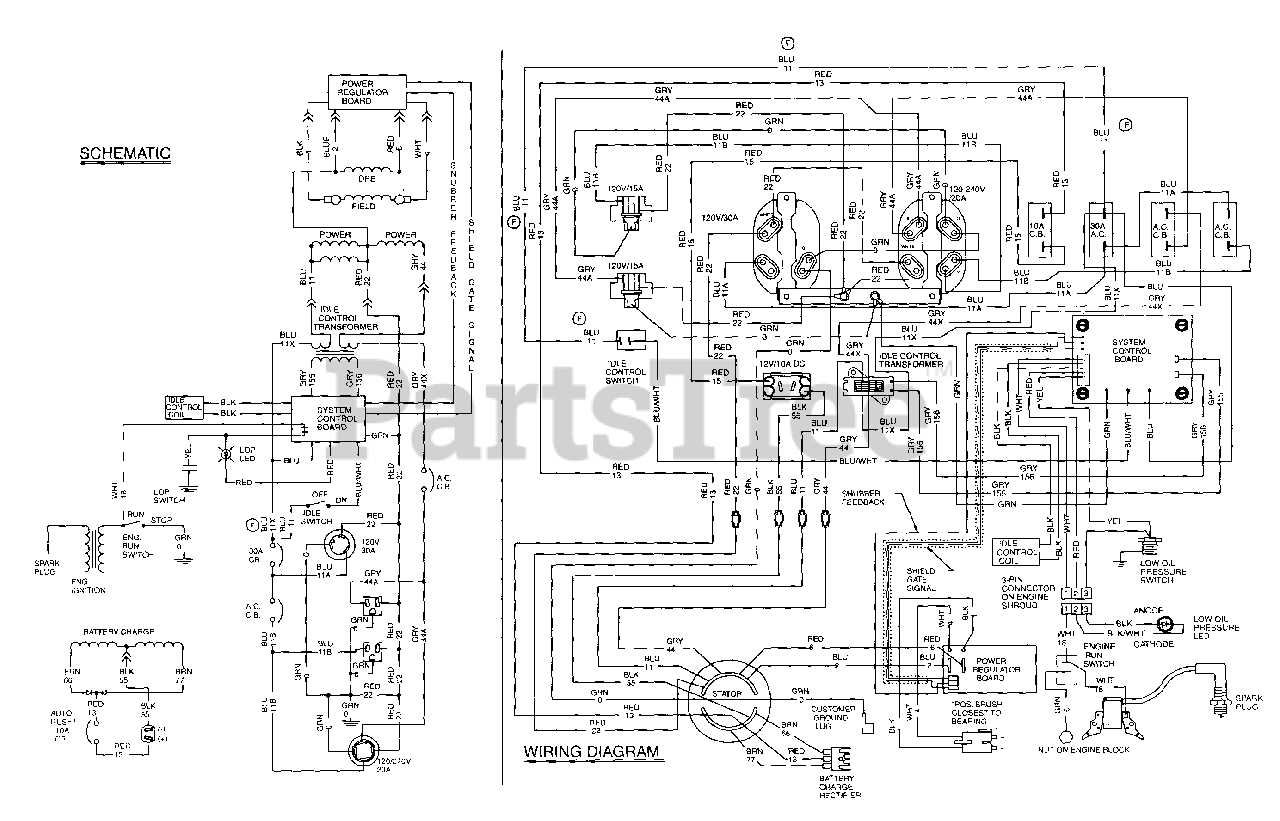

The internal structure of this device consists of several essential systems that work in harmony to produce and regulate electrical energy. Each component plays a specific role, ensuring efficient operation and a stable power output.

Power Generation Unit

The central unit responsible for converting mechanical motion into electrical energy includes a rotor and a stator. These two elements create electromagnetic fields, transforming rotational force into usable electricity.

Control Mechanism and Safety Features

The control board manages voltage and current output, ensuring the electrical flow

Fuel System Elements and Functions

The fuel system plays a critical role in delivering energy to the engine, ensuring smooth operation and consistent performance. It consists of several interconnected components, each contributing to the flow, regulation, and filtration of fuel required for efficient functioning.

- Fuel Tank: Stores the fuel and serves as the primary reservoir, ensuring a steady supply for extended operation.

- Fuel Lines: Transport the

Starting Mechanism Structure and Operation

The starting system relies on a set of coordinated elements that initiate the equipment’s functionality by generating the necessary initial motion. This mechanism ensures smooth activation while minimizing the effort required from the user. Each component works in harmony to create a reliable ignition process, making the operation consistent and efficient.

The structure typically includes a pulling mechanism connected to internal components such as a recoil spring and flywheel. When engaged, these parts generate momentum, transforming manual force into rotational

Maintenance Tips for Engine Parts

Proper upkeep of essential engine components ensures longevity and reliable performance. Regular inspections, cleaning, and timely adjustments help prevent unexpected issues and reduce wear over time.

Check Oil Levels Regularly: Keeping oil at the correct level is crucial to prevent friction between moving elements. Low oil can lead to overheating and long-term damage.

Inspect Air Filters: Clean air filters allow smooth airflow

Electrical Output System Explained

The electrical output system is a crucial component in various power-producing devices, responsible for converting mechanical energy into usable electrical energy. Understanding how this system functions can enhance the user’s ability to operate and maintain the equipment effectively.

This system typically comprises several key elements:

- Alternator: This device plays a vital role in generating electricity by converting mechanical energy into electrical energy through electromagnetic induction.

- Voltage Regulator: It ensures that the output voltage remains stable, preventing fluctuations that could damage connected devices.

- Control Panel: The control panel provides users with important information, including output voltage and current levels, helping to monitor performance.

- Wiring System: This component connects the alternator to the output outlets, enabling the flow of electricity to power various devices.

When these components work together seamlessly, the overall performance of the electrical output system is optimized, ensuring a reliable power source for a range of applications.

Cooling System Parts and Usage

The cooling mechanism of any machine plays a crucial role in maintaining optimal performance and preventing overheating. Understanding the components involved in this system can greatly enhance efficiency and longevity. This section will explore the essential elements of the cooling system and their functionalities, ensuring that the device operates smoothly under various conditions.

Key Components of the Cooling Mechanism

- Radiator: A vital element that dissipates heat from the coolant, allowing the system to maintain a stable temperature.

- Coolant Reservoir: This container holds the coolant fluid, which circulates through the system to absorb and transfer heat.

- Water Pump: Responsible for circulating coolant throughout the system, ensuring that all components remain adequately cooled.

- Thermostat: A regulating device that monitors temperature and controls the flow of coolant based on the device’s heat level.

- Cooling Fan: Assists in airflow across the radiator, enhancing the cooling process, especially during high-load conditions.

Importance of Regular Maintenance

Regular upkeep of the cooling system is essential to prevent overheating and ensure efficient operation. Key maintenance tasks include:

- Checking and replacing coolant as necessary to prevent corrosion and maintain optimal heat transfer.

- Inspecting the radiator for blockages or leaks to ensure effective heat dissipation.

- Testing the water pump functionality to guarantee consistent coolant circulation.

- Monitoring the thermostat for proper operation to avoid temperature fluctuations.

- Cleaning the cooling fan and surrounding areas to ensure unobstructed airflow.

By understanding and maintaining the cooling mechanism, users can enhance the performance and reliability of their equipment, ensuring it operates efficiently for years to come.

Replacing Worn-Out Components Safely

Ensuring the longevity and efficiency of your machinery requires regular maintenance and timely replacement of deteriorated elements. Understanding how to safely handle and replace these components is crucial to maintaining optimal performance and preventing accidents during operation.

Identifying Worn Parts

Before undertaking any replacement, it is essential to recognize which parts need attention. Look for the following signs of wear:

- Visible cracks or fractures

- Excessive rust or corrosion

- Unusual noises during operation

- Decreased performance or efficiency

Safety Precautions

When replacing components, safety should be your top priority. Follow these guidelines to ensure a secure environment:

- Disconnect all power sources before starting any maintenance work.

- Use personal protective equipment, such as gloves and safety goggles.

- Consult the user manual for specific instructions on disassembly and reassembly.

- Keep your workspace clean and organized to avoid accidents.

By carefully identifying worn elements and adhering to safety protocols, you can effectively maintain your equipment and enhance its operational lifespan.

Where to Find Original Spare Parts

Locating authentic components for your equipment is essential to ensure optimal performance and longevity. Various resources can assist you in sourcing these essential items, providing both convenience and reliability.

One of the most effective ways to find genuine components is through authorized dealers. These retailers offer a range of original products that meet the manufacturer’s specifications. Additionally, visiting the official website of the manufacturer can provide a wealth of information, including a catalog of available items and details on how to order them.

Another valuable option is online marketplaces, which often have a wide selection of authentic components. When using these platforms, be sure to check the seller’s ratings and reviews to ensure you are purchasing from a reputable source.

Resource Type Benefits Authorized Dealers Guaranteed authenticity, expert advice, local support Official Manufacturer Website Comprehensive catalog, direct ordering, latest updates Online Marketplaces Diverse selection, competitive pricing, convenience