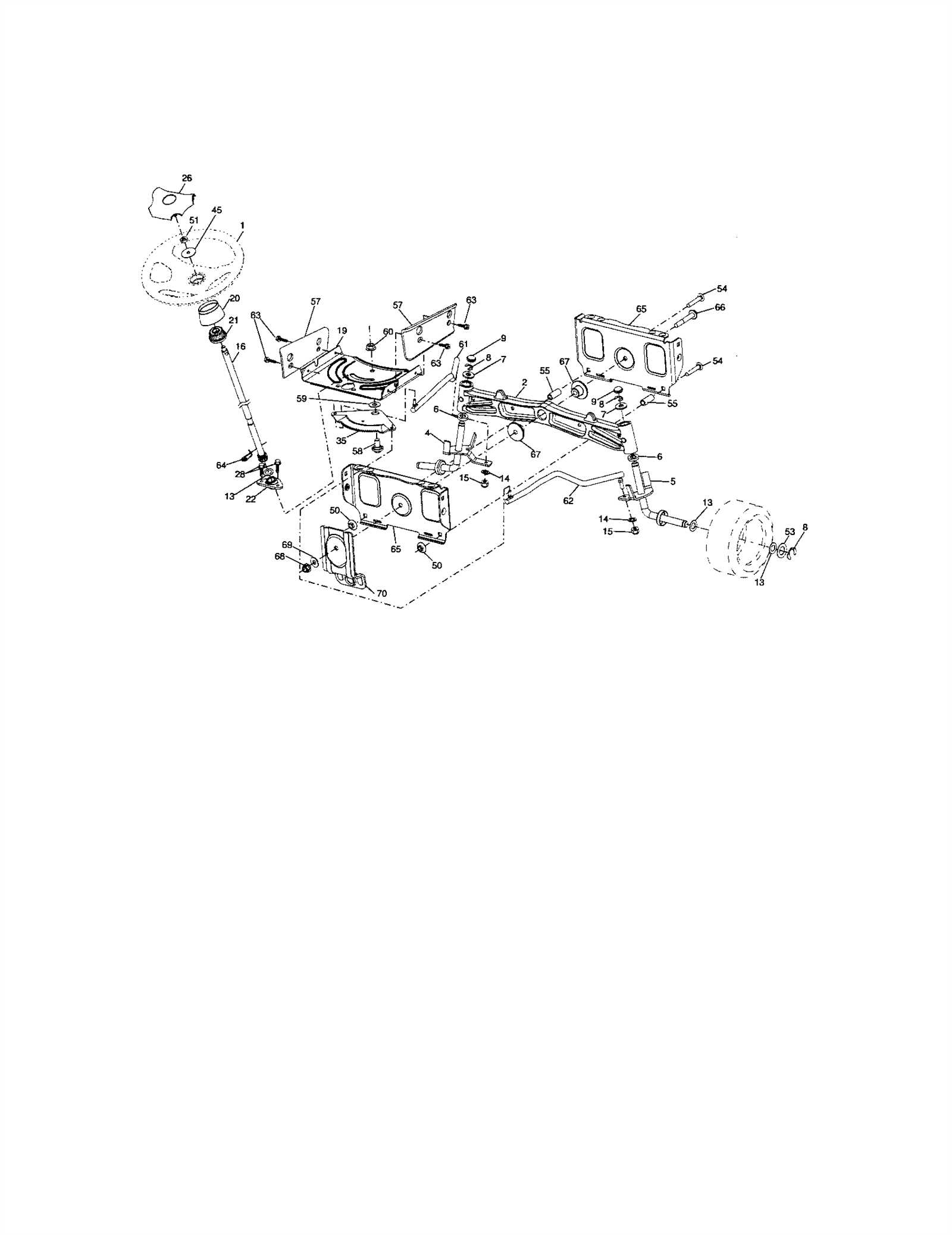

When maintaining a lawnmower, having a clear understanding of its internal structure is essential for effective troubleshooting and repair. Whether you’re replacing a broken piece or simply conducting routine maintenance, recognizing the layout of the machine helps in identifying the correct parts. Knowing where each component fits ensures that the device runs smoothly and efficiently.

Detailed visuals of a lawnmower’s configuration provide a roadmap for users, highlighting the relationship between the different sections. These visual representations offer insight into the placement and functionality of key elements, making it easier to spot potential issues.

Efficient upkeep relies on the ability to quickly locate the right components and tools. This section will guide you through the essential parts and their roles, ensuring that you can navigate any repair or upgrade process with confidence.

Essential Components of Cub Cadet LTX 1042

When maintaining or repairing a lawn tractor, it’s crucial to understand the primary elements that keep the machine functioning smoothly. Each component plays a specific role in ensuring optimal performance, efficiency, and longevity. Familiarizing yourself with these elements helps in troubleshooting and upgrading your equipment effectively.

- Engine: The heart of the machine, responsible for powering the tractor and driving the movement of various attachments.

- Transmission: Allows the operator to control the speed and direction, essential for maneuverability in different terrains.

- Steering Mechanism: Provides the necessary control for precise direction changes and ease of handling during operation.

- Deck Assembly: This structure holds the blades and is vital for cutting grass evenly and efficiently.

- Wheels and Tires: Designed for traction, these are essential for stability and mobility on different surfaces.

- Electrical System: Powers all the lights, indicators, and starting mechanisms, ensuring the tractor operates smoothly and safely.

Each of these elements requires regular inspection and maintenance to ensure they function at their best. Understanding their purpose and how they interconnect can significantly enhance the machine’s performance and durability.

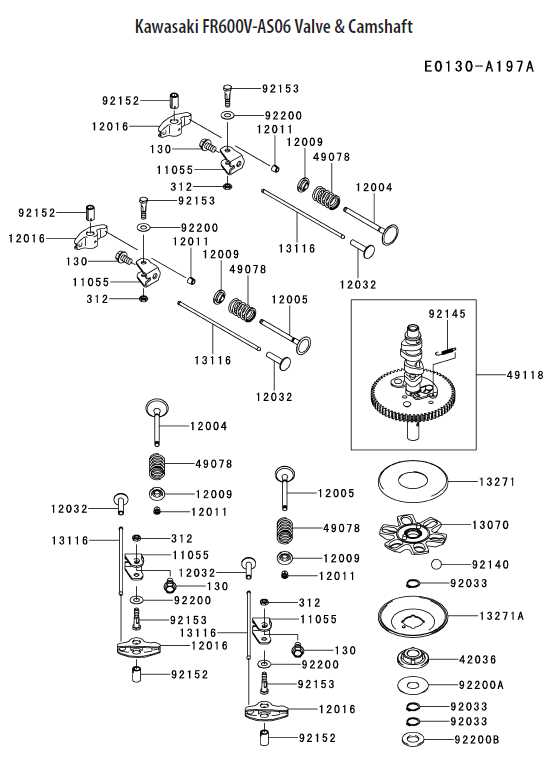

Understanding the Engine Assembly Layout

In this section, we will explore the components that make up the engine’s structure, providing a comprehensive overview of its key parts and their interconnections. Understanding the arrangement of these elements is crucial for proper maintenance, troubleshooting, and performance optimization.

Key Components of the Engine

The engine assembly consists of several critical parts that work together to generate power. These include the crankshaft, which is responsible for converting the force generated by combustion into mechanical energy, and the cylinder, where the fuel-air mixture is ignited. Additionally, the valve system controls the intake and exhaust processes, ensuring smooth operation.

Understanding the Interconnections

Each component in the engine assembly is interconnected through a series of mechanical linkages. Proper alignment and assembly of these parts are essential for efficient functioning. For instance, the piston moves within the cylinder to compress the air-fuel mixture, while the timing belt ensures that the valves open and close at the correct intervals. Any misalignment or wear can lead to significant performance issues.

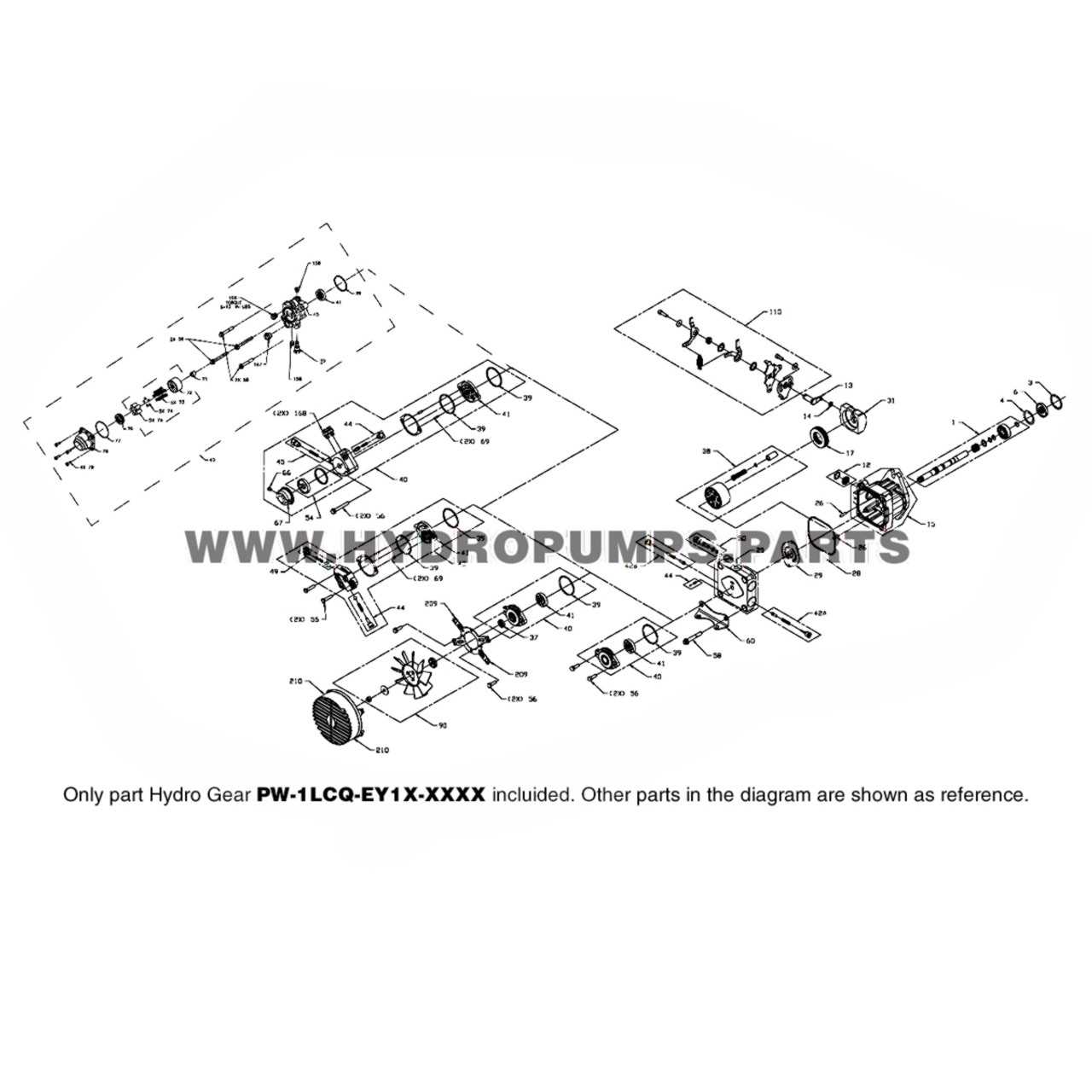

Key Parts of the Transmission System

The transmission system plays a crucial role in the operation of any vehicle, converting power from the engine to the wheels. This system consists of several essential components that ensure smooth and efficient movement. Understanding the key elements involved helps in maintaining and troubleshooting the system effectively.

Drive Belts are one of the most vital parts, transmitting power from the engine to other components. These flexible, yet durable parts ensure that energy flows without interruption, adjusting to the required speed and torque.

Gearbox is another critical element, responsible for adjusting the power output from the engine. It contains various gears that can alter the speed and torque based on the vehicle’s needs. A properly functioning gearbox is essential for smooth transitions between speeds.

Clutch allows for the engagement and disengagement of gears. It prevents the engine from stalling while shifting, making it an indispensable part of the system. A worn-out clutch can lead to difficulty in shifting and reduced overall performance.

Axles transfer the final rotational force to the wheels, enabling movement. These components must withstand high levels of stress and wear, as they support the vehicle’s weight and the torque generated during operation.

Differential helps distribute power evenly to the wheels, especially in turns. By allowing wheels to rotate at different speeds, the differential ensures smoother cornering and overall stability during operation.

Regular maintenance and attention to these key components can prolong the life of the transmission system and improve overall vehicle performance.

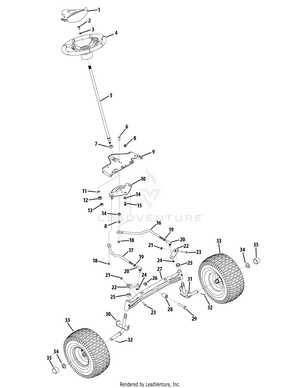

Details on the Steering Mechanism

The steering system of a lawn tractor plays a crucial role in ensuring smooth and responsive control while navigating various terrains. This mechanism consists of several interconnected components that allow the operator to adjust direction with ease and precision. Understanding the different parts involved in this system can help with maintenance and troubleshooting.

The key components of the steering system typically include:

- Steering wheel or tiller

- Steering shaft

- Linkage arms

- Steering gear assembly

- Rack and pinion setup

Each of these elements works together to provide a stable and effective way to maneuver the vehicle. Regular inspection and maintenance are essential to ensure that the steering system remains responsive and free from wear or damage.

Key aspects to consider include:

- Proper lubrication of moving parts to reduce friction

- Checking for loose connections or worn-out components

- Ensuring alignment and balance for precise control

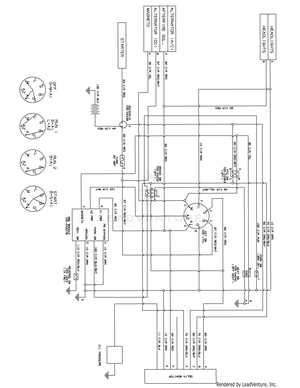

Electrical Wiring and Key Connections

Understanding the electrical system and key connections within machinery is essential for proper operation and maintenance. The network of wires and connectors ensures that power is distributed to various components, allowing for smooth functioning. This section outlines the critical aspects of the electrical network, helping to identify and troubleshoot potential issues.

Power Supply and Distribution

The primary power source is routed through several key connections that distribute electricity to essential systems. Each connection plays a pivotal role in ensuring that power reaches the engine, lighting, and control systems without interruptions. Regular checks of these routes can prevent potential power failures and operational issues.

Control Systems and Connectors

Various connectors link the control systems to the rest of the electrical framework. These connectors are designed for secure, reliable communication between the operator’s commands and the machinery’s responses. It’s crucial to inspect and clean these connections regularly to maintain optimal performance and prevent electrical malfunctions.

Exploring the Cutting Deck Assembly

The cutting deck is a critical component of any lawn care equipment, designed to efficiently trim grass to the desired height. This assembly involves a range of interconnected parts that work together to provide a smooth, consistent cut. Understanding its structure and how each piece contributes to the overall function helps in maintaining optimal performance and ensuring long-term durability.

Key Components of the Assembly

The cutting deck consists of several essential elements, including blades, spindles, pulleys, and the deck itself. Each component plays a vital role in achieving precise cuts while maintaining stability during operation. Regular maintenance is crucial to prevent wear and tear on these parts, as they are exposed to continuous stress and various environmental factors.

| Component | Function |

|---|---|

| Blades | Responsible for cutting the grass at a uniform height |

| Spindles | Support the rotation of the blades |

| Pulleys | Transmit power from the engine to the cutting blades |

| Deck | Houses and protects the blades while allowing for smooth operation |

Maintenance Tips for Longevity

To ensure that the cutting deck operates efficiently, it is important to check the components regularly. Blade sharpening, cleaning, and ensuring that the deck is free from debris can greatly extend its lifespan. Additionally, proper lubrication of moving parts like pulleys and spindles prevents premature wear.

Fuel System: Key Components Explained

The fuel system is an essential part of any engine, responsible for delivering the proper amount of fuel to the combustion chamber. Understanding the main components of this system helps in ensuring efficient operation and long-term performance. The system is designed to work seamlessly, with each part playing a critical role in fuel management, from storage to combustion.

Fuel Tank: The fuel tank stores the fuel until it is needed for combustion. It is designed to hold a sufficient amount of fuel and supply it to the system on demand. Proper maintenance of the fuel tank ensures that no contaminants enter the fuel lines.

Fuel Pump: The fuel pump moves fuel from the tank to the engine. It maintains the necessary pressure to ensure a consistent fuel flow, regardless of engine load or speed. A malfunctioning fuel pump can result in inconsistent fuel delivery, affecting engine performance.

Fuel Filter: The fuel filter cleans the fuel before it enters the engine. It removes dirt, debris, and other contaminants that could cause damage to internal engine components. Regularly replacing the filter helps maintain a smooth and efficient fuel flow.

Fuel Injectors: Fuel injectors are responsible for spraying fuel into the engine’s combustion chamber in precise amounts. They work in conjunction with the engine control unit (ECU) to optimize fuel delivery based on factors like temperature, load, and speed.

Carburetor (if applicable): In older systems, the carburetor mixes air and fuel in the proper ratio before it enters the combustion chamber. While modern systems often use fuel injectors, some engines still rely on carburetors for fuel management.

Brake and Safety Mechanism Overview

The braking and safety system of any riding mower is designed to ensure the operator’s security while the machine is in use. These mechanisms work together to prevent accidents, control movement, and guarantee smooth operation. By integrating safety features, these systems play a crucial role in maintaining stability and preventing unwanted motion during operation.

Key components of the braking and safety system include:

- Brake pedal and related linkages

- Safety switches and sensors

- Automatic parking brake engagement

- Emergency stop features

These parts are strategically placed to deliver reliable control, ensuring the mower can stop efficiently when needed, and providing a safe environment for the user.

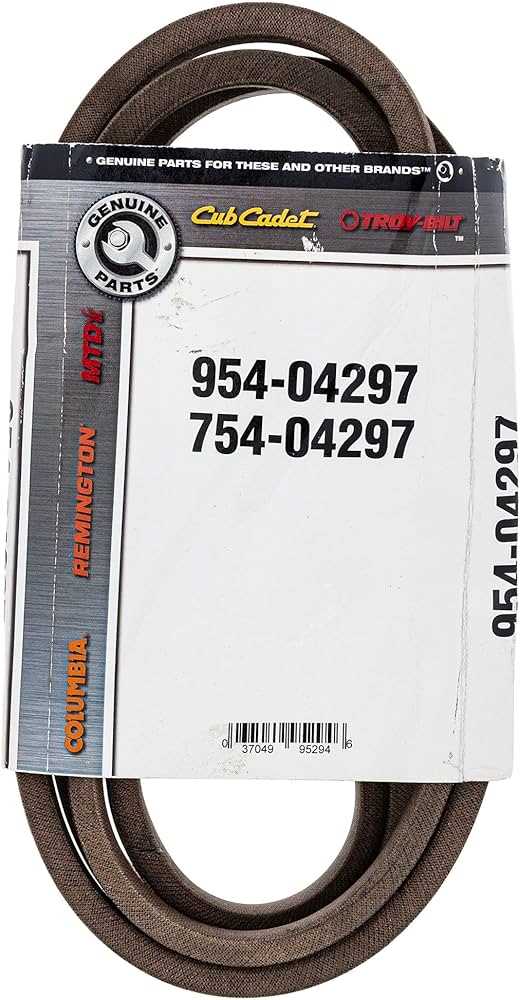

Common Wear and Tear Components

In any mechanical system, certain components are subject to frequent use and natural degradation over time. These elements, often exposed to stress and friction, require periodic inspection and replacement to maintain optimal performance. Identifying these key parts early can help prevent unexpected breakdowns and extend the life of the equipment.

Belts are one of the most commonly worn items. Due to constant movement and tension, they can stretch, crack, or even snap. Regular checks ensure they remain in good condition to avoid performance issues.

Blades endure significant wear as they come into contact with various surfaces. Over time, they may become dull or damaged, reducing cutting efficiency. Replacing or sharpening them regularly is essential for smooth operation.

Wheels and Tires are also subject to frequent wear, especially on uneven or rough terrains. If not maintained, they can become worn down, leading to reduced traction and stability. Keeping them properly inflated and checking for any visible damage can prevent further complications.

Battery life may decrease over time, particularly with frequent usage or extreme weather conditions. It’s important to monitor its charge levels and replace it when necessary to ensure reliable starts and power delivery.

Filters, such as air and fuel filters, often accumulate debris and dirt, reducing the system’s efficiency. Cleaning or replacing these filters regularly ensures optimal engine performance and longevity.