In the realm of outdoor machinery, a comprehensive understanding of the various elements that make up your equipment is essential for effective maintenance and operation. Knowledge of how different components interact can significantly enhance both performance and longevity. Whether you are a seasoned user or a newcomer to lawn care, familiarizing yourself with these intricate layouts can be highly beneficial.

Visual representations of these mechanical assemblies serve as invaluable tools for troubleshooting and repairs. By studying the configuration of each segment, one can easily identify potential issues and address them proactively. Moreover, these illustrations simplify the process of sourcing replacements, ensuring that you always have the right items on hand to keep your machinery running smoothly.

Equipped with an understanding of these layouts, users can approach maintenance tasks with confidence. This knowledge empowers you to tackle challenges head-on, promoting a more enjoyable and efficient experience in your outdoor endeavors. Embracing this resource not only enhances your skill set but also ensures that your equipment remains in optimal condition for years to come.

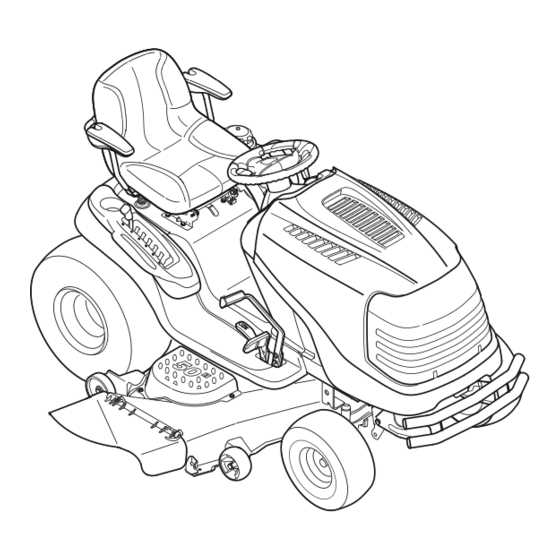

Overview of the Lawn Tractor

This exceptional piece of machinery is designed to provide efficiency and reliability for various lawn care tasks. With a blend of innovative features and user-friendly controls, it has become a favorite among homeowners and landscaping professionals alike. Its robust design ensures durability while delivering a smooth and powerful performance on a range of terrains.

Key Features

Equipped with a powerful engine, this model offers impressive torque and speed, allowing for quick mowing and effortless navigation across large areas. The ergonomic seating and intuitive dashboard enhance the user experience, making it easy to operate even for those new to lawn maintenance. Additionally, its versatile attachments expand functionality, enabling tasks beyond mere grass cutting.

Maintenance and Care

Regular upkeep is crucial to maintaining optimal performance. This machine is designed for straightforward maintenance procedures, ensuring that users can easily access components for inspection and servicing. Following a routine maintenance schedule will extend the life of the equipment and preserve its efficiency, allowing it to continue delivering excellent results season after season.

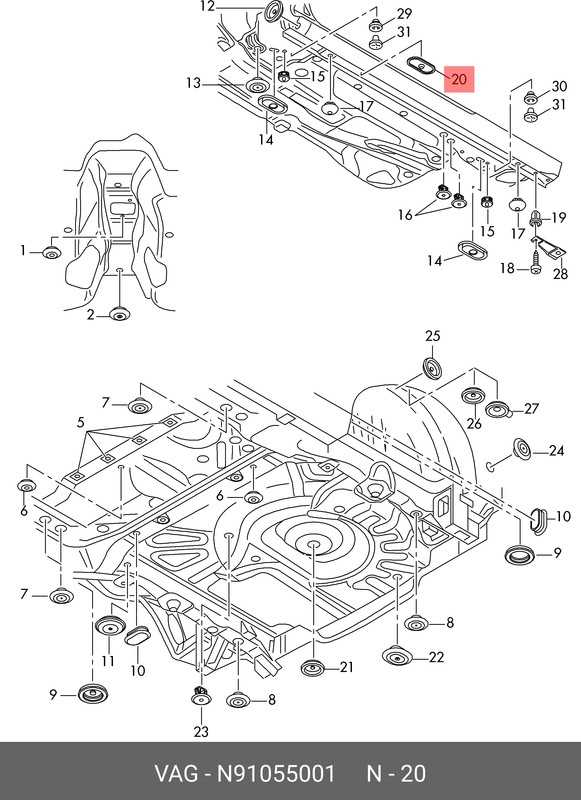

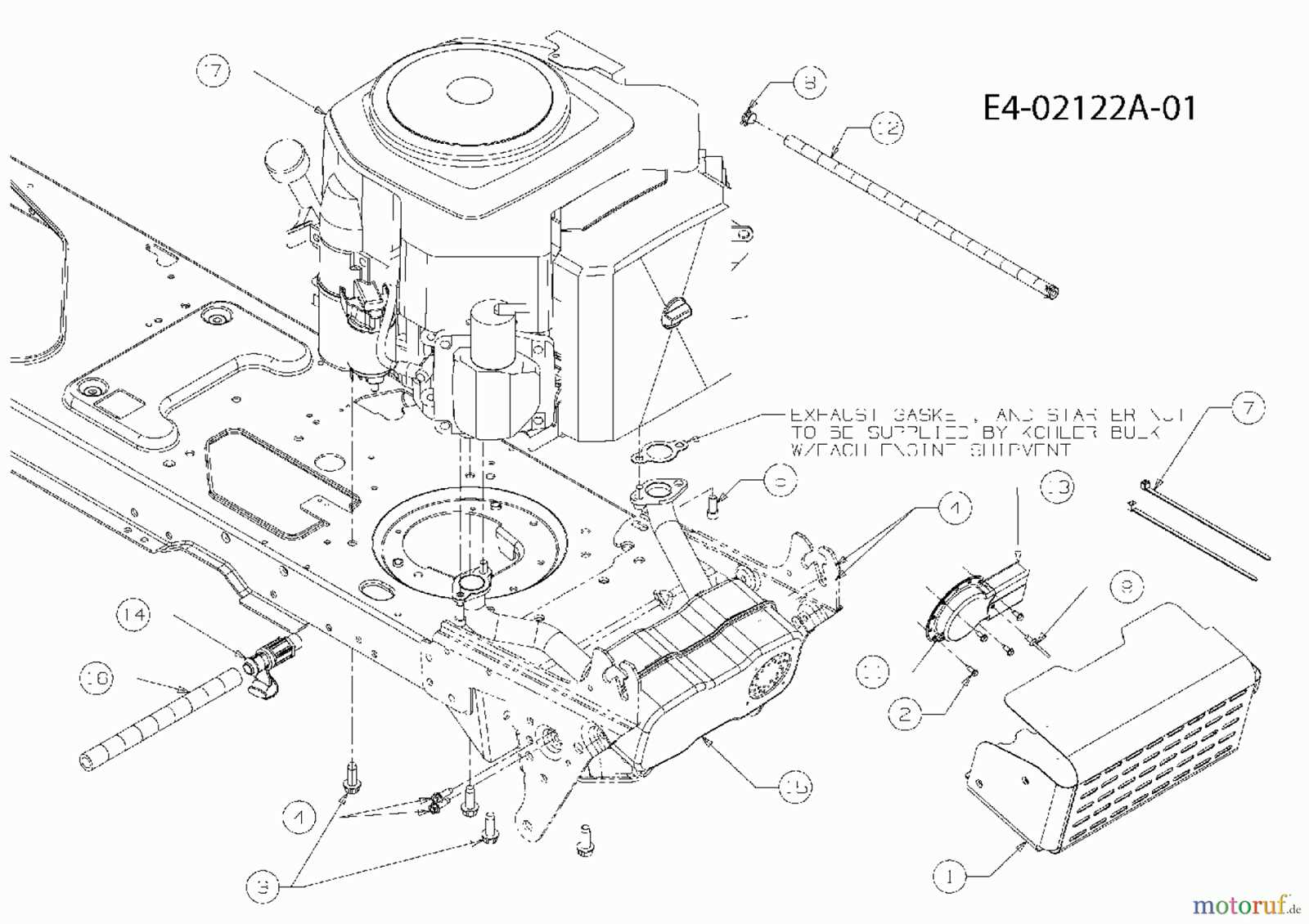

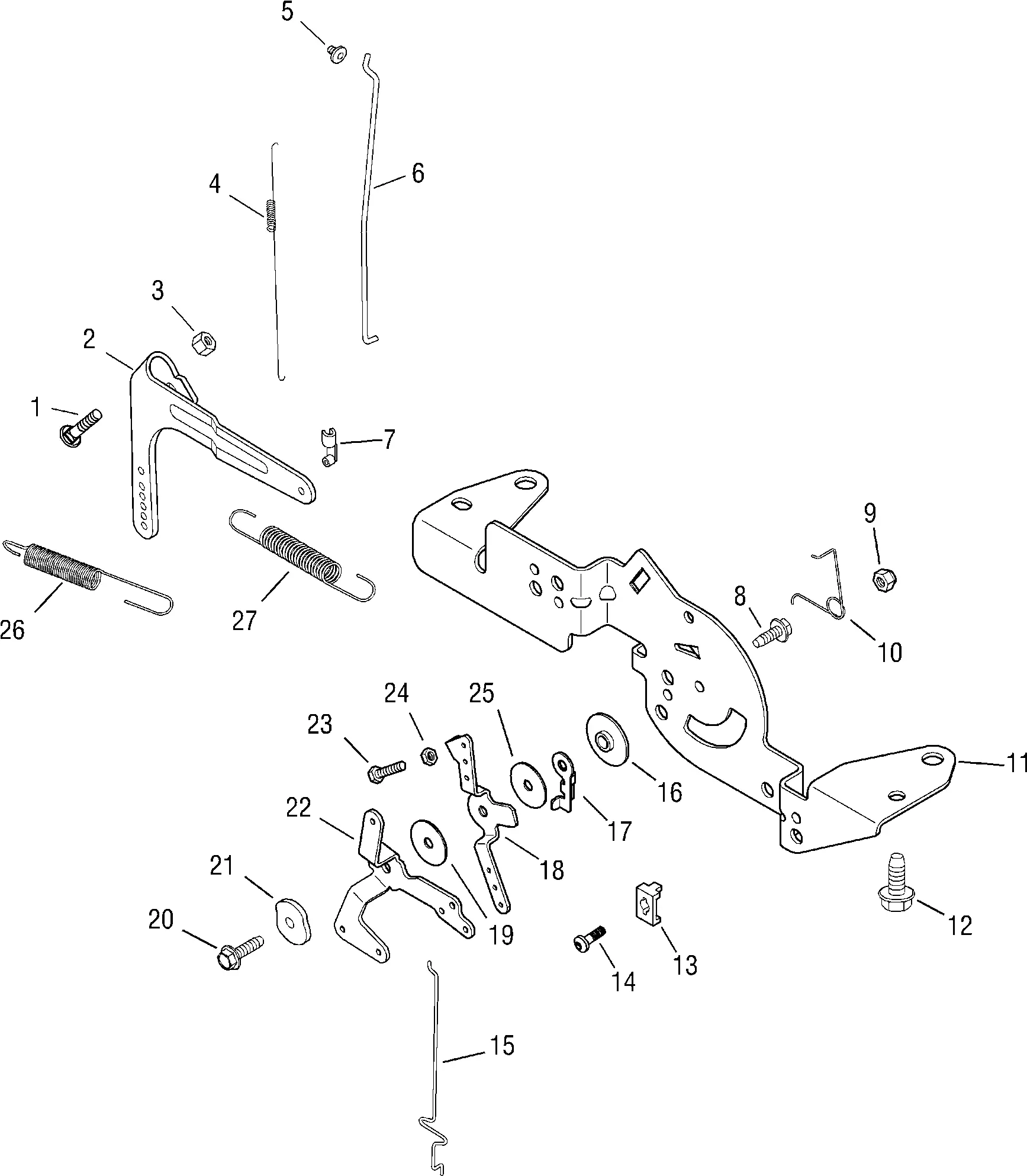

Understanding Parts Diagrams

Visual representations of components play a crucial role in maintenance and repair processes. These illustrations provide detailed insights into the structure and functionality of machinery, allowing users to identify individual elements easily. By grasping the significance of these visuals, users can enhance their understanding and improve their ability to perform necessary tasks effectively.

Benefits of Using Visual Representations

- Clarifies complex assemblies

- Facilitates accurate identification of components

- Simplifies the ordering process for replacements

- Enhances troubleshooting efficiency

Key Elements to Consider

- Labeling: Each element is usually marked clearly, indicating its function and location.

- Organization: Components are arranged systematically, often grouped by their roles within the assembly.

- Detailing: High-quality visuals may include additional information, such as dimensions and specifications.

Understanding these representations empowers individuals to tackle repairs with confidence and precision, ensuring optimal performance of their machinery.

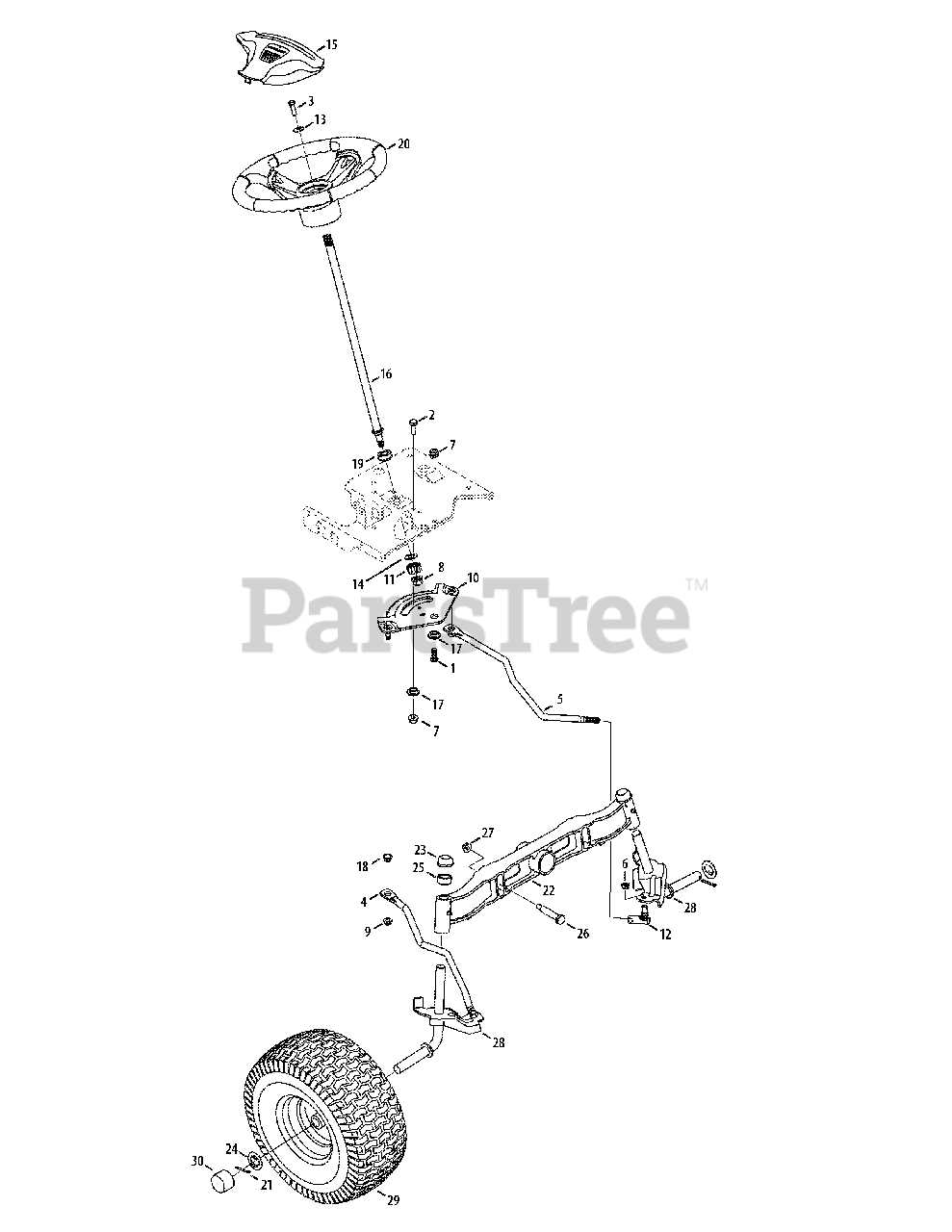

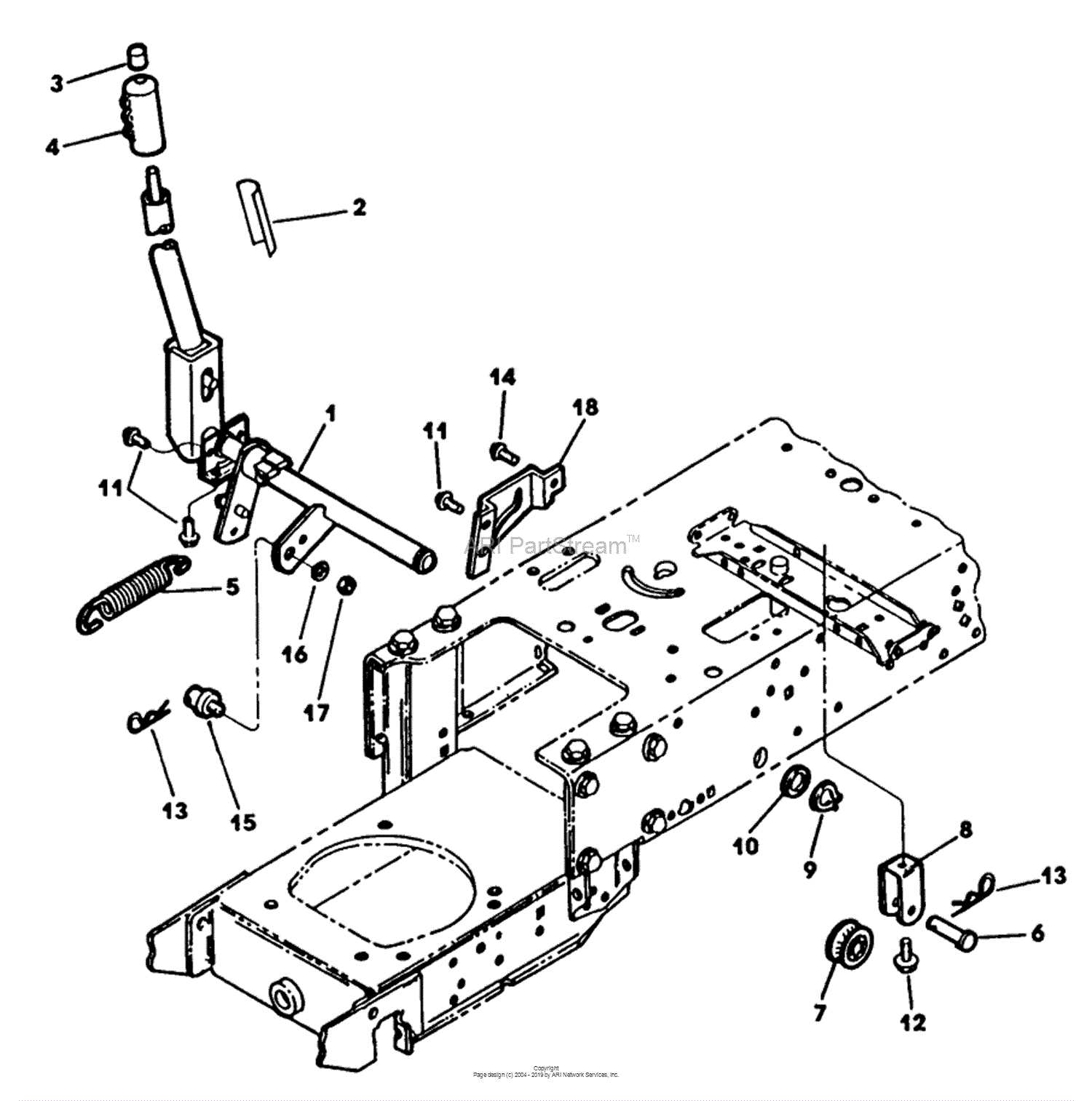

Key Components of the Cub Cadet

This section explores the essential elements of a popular lawn maintenance machine. Understanding these components is crucial for effective operation and maintenance, ensuring longevity and performance.

| Component | Description |

|---|---|

| Engine | The powerhouse that drives the machine, providing the necessary energy for operation. |

| Transmission | A vital system that transfers power from the engine to the wheels, allowing for speed control and movement. |

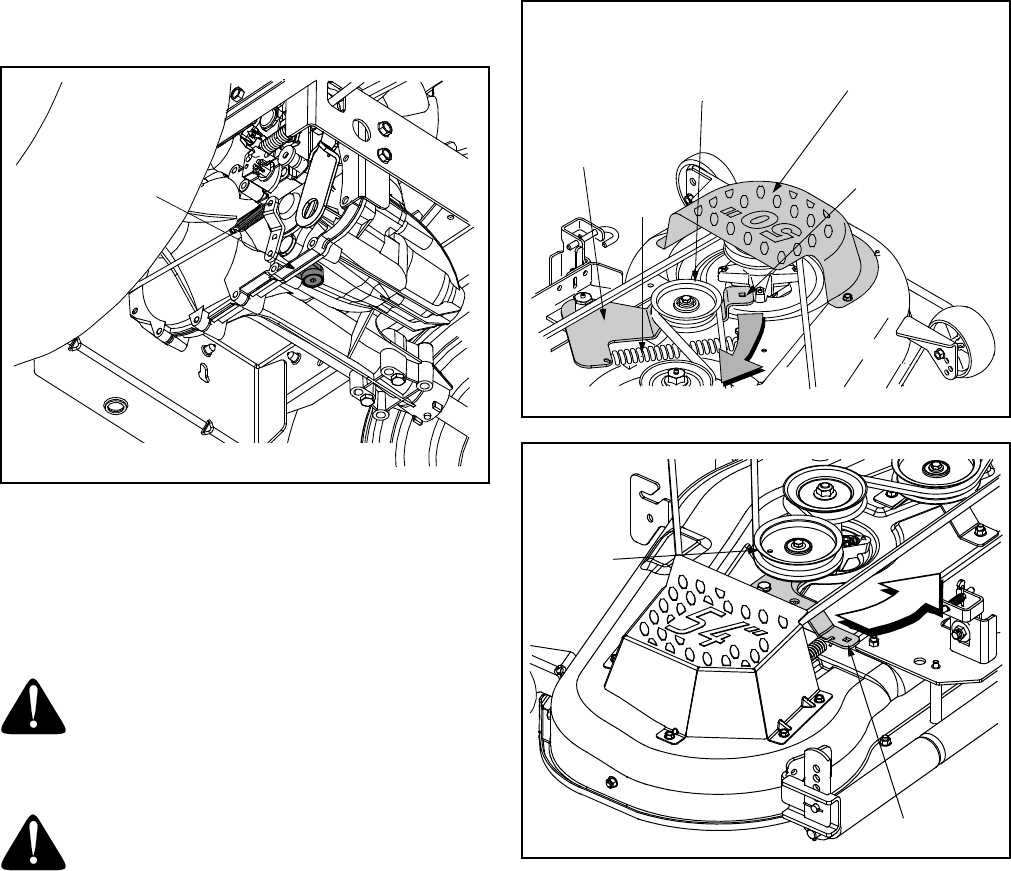

| Deck | The cutting surface that houses the blades, crucial for achieving a precise and clean cut. |

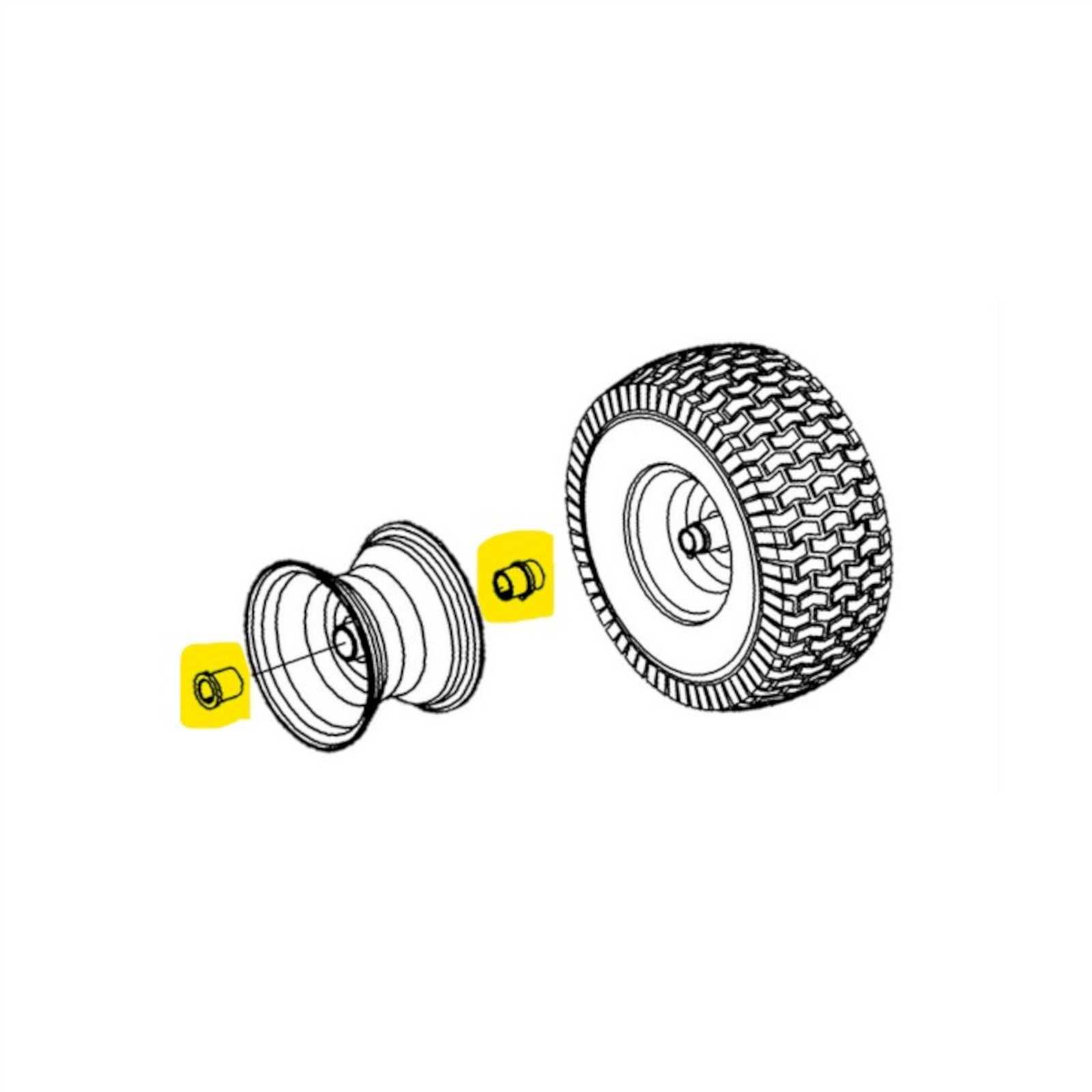

| Wheels | Designed for traction and maneuverability, ensuring smooth navigation across various terrains. |

| Steering System | Enables precise control and direction, enhancing the operator’s ability to navigate around obstacles. |

| Fuel System | Houses the fuel tank and lines, delivering the necessary energy to the engine for operation. |

Benefits of Using Official Diagrams

Utilizing authorized schematics for machinery and equipment offers numerous advantages that enhance the repair and maintenance process. These resources provide clarity and precision, ensuring that users can effectively understand complex systems.

- Accuracy: Official resources are developed by the manufacturer, ensuring that the information is precise and reliable.

- Comprehensive Details: These schematics typically include all components, making it easier to identify and locate specific parts.

- Time Efficiency: With clear visual aids, technicians can quickly find solutions, reducing the time spent troubleshooting issues.

- Enhanced Safety: Accurate diagrams can help prevent mistakes during repairs, promoting safer handling of equipment.

- Cost-Effectiveness: Using official documentation minimizes the risk of purchasing incorrect components, ultimately saving money on unnecessary expenses.

In summary, relying on sanctioned illustrations not only simplifies the repair process but also ensures that the work is performed correctly and efficiently. This leads to prolonged equipment lifespan and improved performance.

Common Issues and Solutions

This section explores frequent challenges encountered with garden machinery and offers practical solutions to enhance performance and longevity. Understanding these common issues can help users maintain their equipment more effectively.

Engine Performance Problems

- Hard starting: Check the fuel level and ensure the choke is set correctly. Inspect the spark plug for wear.

- Loss of power: Clean or replace the air filter and ensure the fuel system is free from debris.

- Excessive vibration: Examine the blades for damage and ensure they are properly balanced.

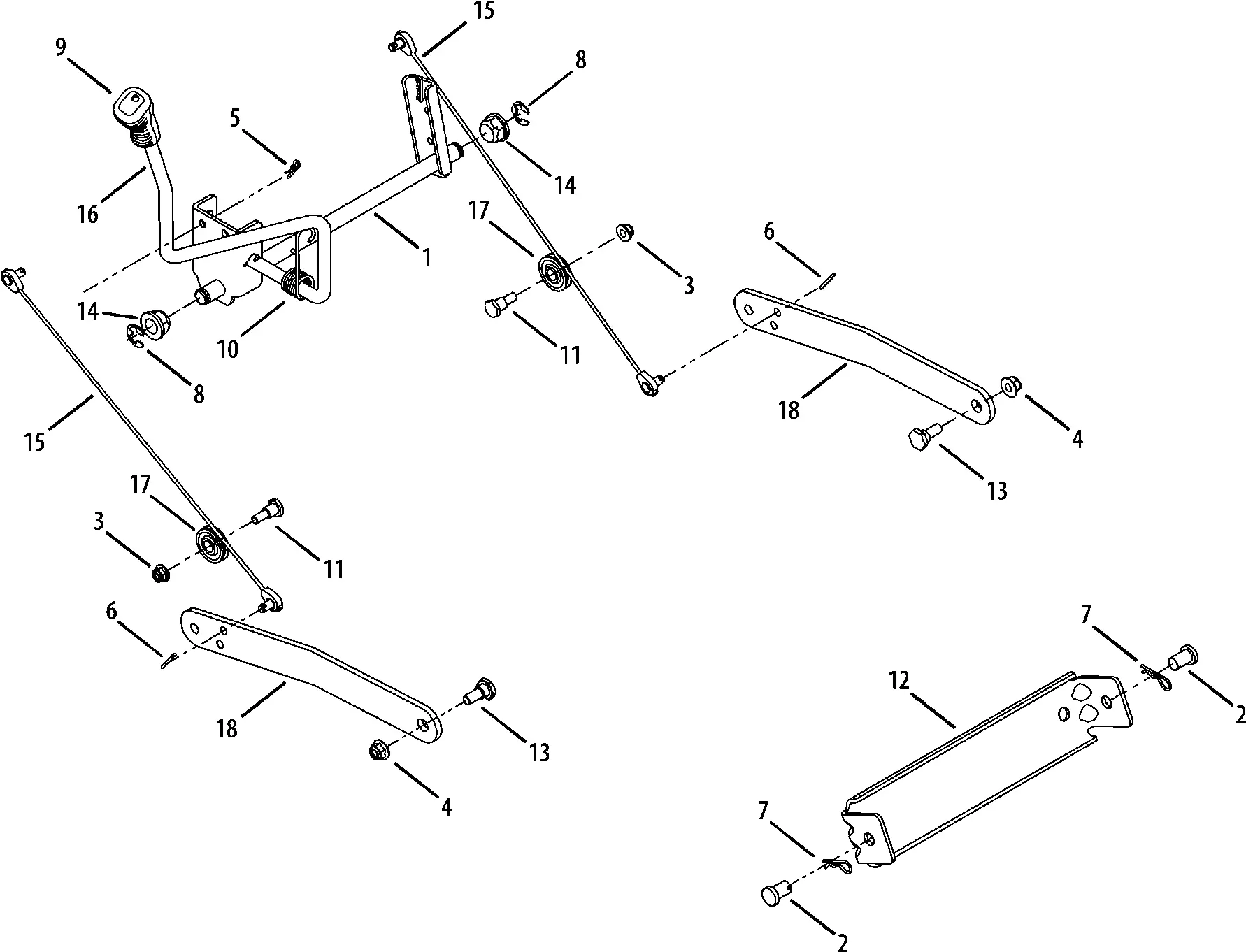

Transmission Issues

- Slipping gears: Inspect the linkage for adjustments and ensure the fluid levels are adequate.

- No movement: Check the drive belt for wear or breakage and replace if necessary.

- Unusual noises: Look for loose parts or worn components within the transmission system.

Where to Find Replacement Parts

When your equipment requires maintenance or repair, locating suitable components can be crucial for its longevity and performance. There are several reliable sources for obtaining the necessary items, ensuring your machinery operates at its best.

- Authorized Dealers: Visiting a certified dealer guarantees that you receive genuine components designed specifically for your model.

- Online Retailers: Numerous websites specialize in outdoor equipment, providing a wide range of options and competitive prices.

- Local Repair Shops: These establishments often have access to various components and can offer advice on what you might need.

- Manufacturer’s Website: Directly checking the official site may yield helpful resources, including part numbers and ordering information.

- Forums and Online Communities: Engaging with fellow enthusiasts can provide insights and recommendations on where to source specific components.

Considering these avenues will help you find the right items efficiently, ensuring your machinery remains in excellent condition.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your outdoor equipment requires regular care and attention. By implementing a few key maintenance practices, you can significantly extend the lifespan of your machinery while enhancing its performance. Consistent upkeep not only prevents breakdowns but also improves overall functionality, making your investment more worthwhile.

Start by regularly checking and changing the oil to keep the engine running smoothly. Clean or replace air filters to ensure optimal airflow and performance. Additionally, inspecting and sharpening blades helps maintain cutting efficiency and reduces strain on the motor.

It’s also essential to keep all moving parts well-lubricated to minimize friction and wear. Pay attention to the tires, ensuring they are properly inflated to avoid unnecessary drag. Lastly, store your equipment in a dry, sheltered area to protect it from the elements, which can cause rust and corrosion.

DIY Repairs for the 1554 Model

Taking on repairs yourself can save both time and money, allowing you to gain a deeper understanding of your equipment. Whether it’s routine maintenance or fixing specific issues, hands-on work can enhance your skills and ensure optimal performance. With a little patience and the right guidance, tackling common repairs becomes an achievable goal.

Essential Tools for Your Repairs

Before diving into any repairs, it’s important to gather the necessary tools. A reliable set of wrenches, screwdrivers, and pliers will be your best friends. Additionally, having a multimeter on hand can help troubleshoot electrical problems, while a jack and jack stands are essential for safely lifting the unit.

Common Issues and Solutions

Many users encounter issues like starting difficulties or cutting inconsistencies. For starting problems, check the battery and ignition components; replacing a worn spark plug can often resolve the issue. If the cutting height is uneven, inspect the blades for wear and ensure they are properly sharpened and balanced. Regular upkeep can significantly prolong the lifespan of your machine.