In the world of woodworking and construction, having a clear grasp of the vital elements that make up precision cutting instruments is paramount. These tools, designed for accuracy and efficiency, rely on various integral components that work in harmony to achieve the ultimate results. By examining these elements, users can enhance their understanding and improve their performance.

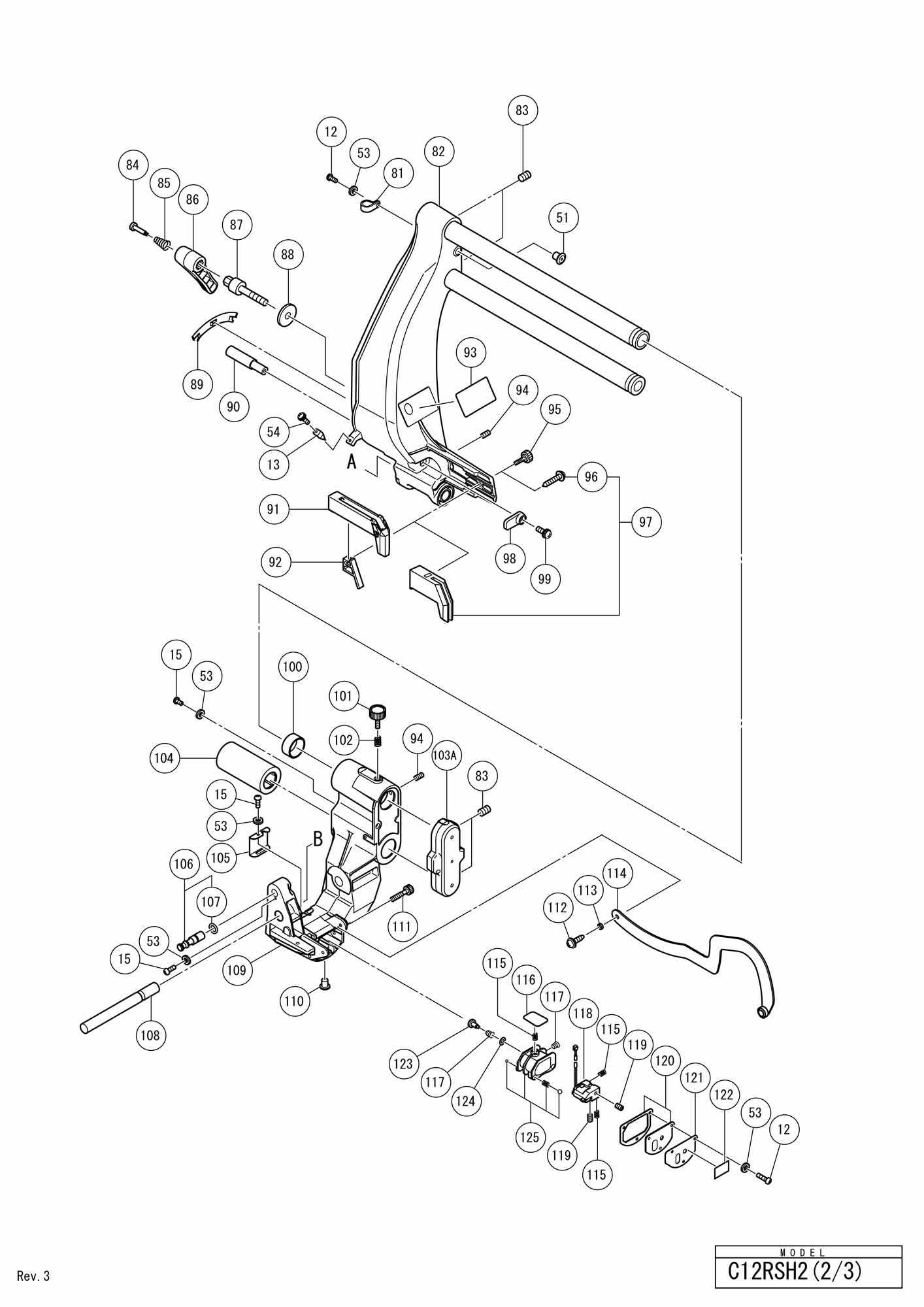

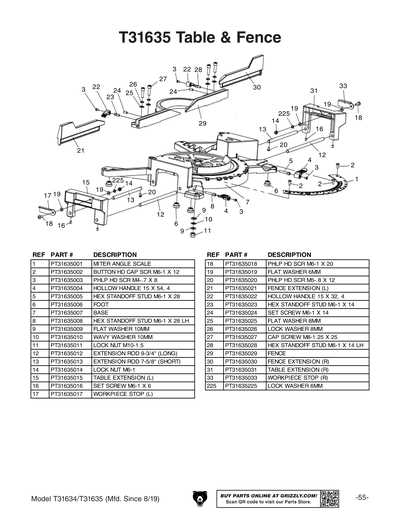

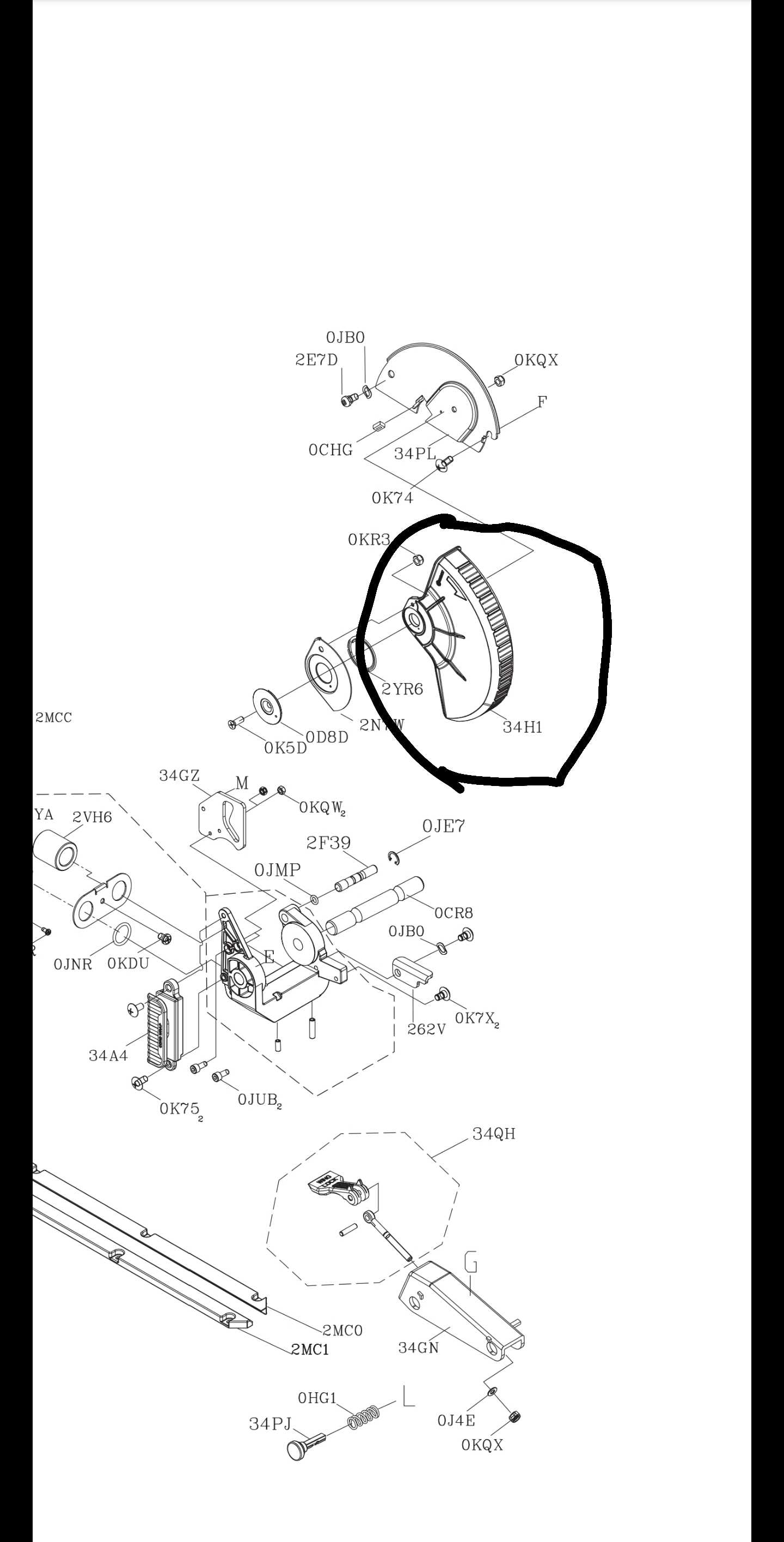

Detailed visual aids play a crucial role in demystifying the inner workings of these instruments. By exploring the configurations and functions of each segment, users can better appreciate how to maintain and troubleshoot their equipment effectively. This knowledge not only fosters better care but also maximizes the lifespan of the tools.

Furthermore, diving into the specifics of each component enables users to make informed decisions when purchasing replacements or upgrades. Understanding what each part does empowers individuals to select the best options tailored to their specific cutting needs, ultimately elevating their craftsmanship.

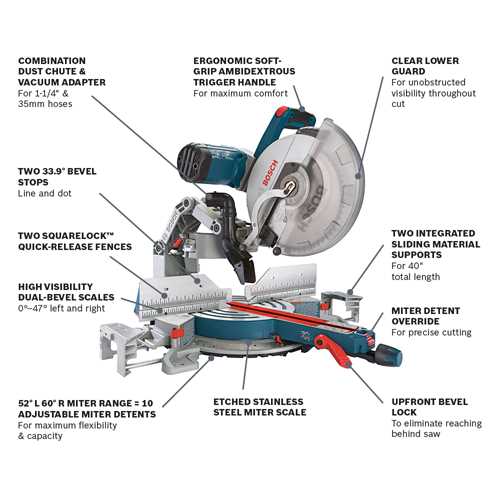

Kobalt Miter Saw Overview

This section provides a comprehensive look at a versatile cutting tool designed for precision and efficiency. Ideal for both DIY enthusiasts and professional tradespeople, it allows users to make accurate angled cuts with ease. The construction and functionality of this equipment make it an essential addition to any workshop or job site.

Key Features

Among the standout characteristics are its robust motor, adjustable settings for different angles, and ergonomic design. These features not only enhance performance but also improve user experience, ensuring safety and comfort during operation.

Specifications

| Specification | Details |

|---|---|

| Motor Power | 15 Amp |

| Blade Size | 10 inches |

| Cutting Capacity | Up to 2×12 at 90 degrees |

| Weight | 50 lbs |

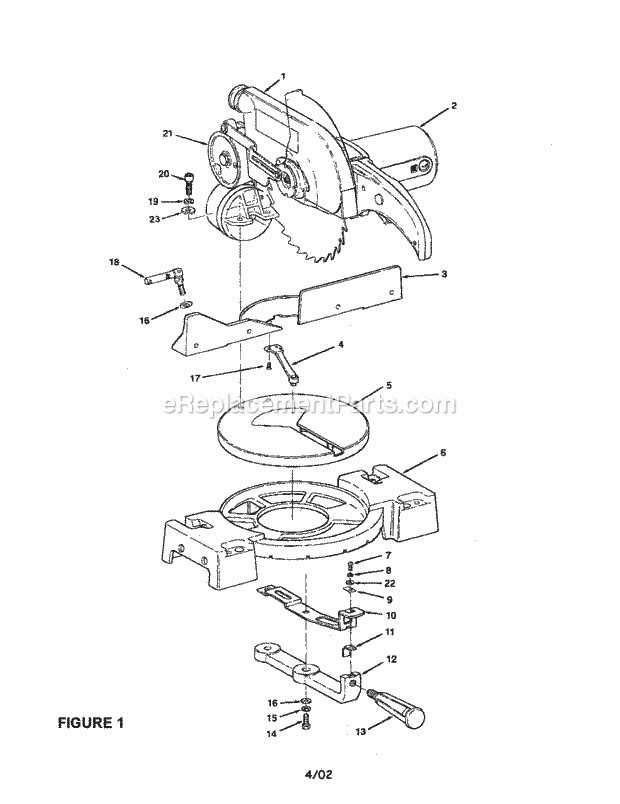

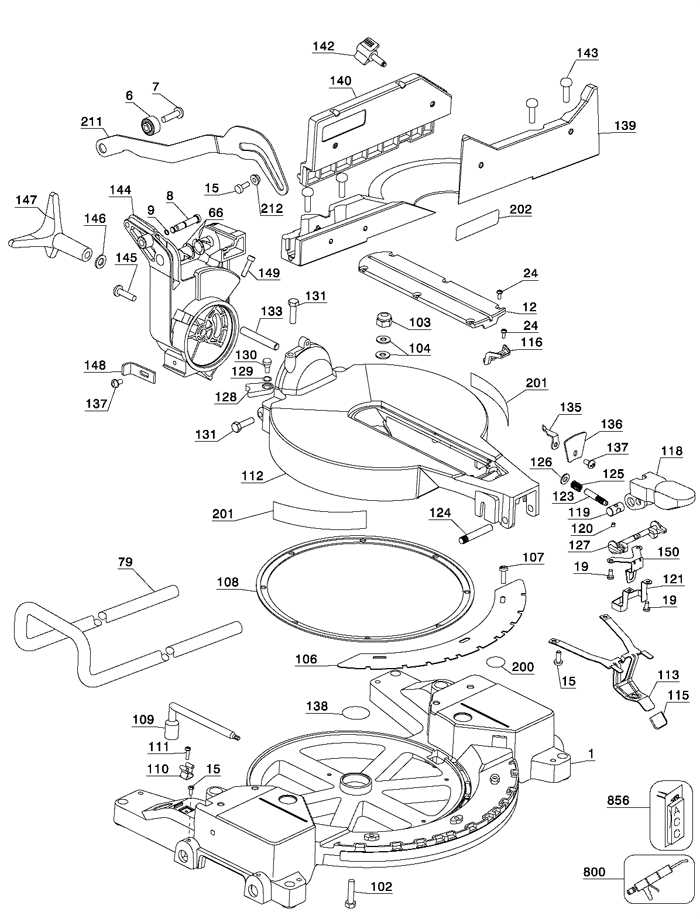

Understanding Miter Saw Components

Exploring the essential elements of a cutting tool reveals a fascinating interplay of functionality and design. Each component plays a crucial role in ensuring precision and efficiency during operation. A comprehensive grasp of these elements enhances not only the user experience but also the effectiveness of tasks at hand.

Below is a breakdown of key components typically found in this type of equipment:

| Component | Description |

|---|---|

| Base | The sturdy foundation that supports the entire apparatus and provides stability. |

| Arm | The pivoting part that allows the blade to tilt and make angled cuts. |

| Blade | The sharp circular tool that performs the cutting action. |

| Fence | A straight edge that helps guide materials for accurate cuts. |

| Trigger | The control mechanism that activates the blade. |

| Dust Collection | A system designed to minimize debris and keep the workspace clean. |

Understanding these components is vital for effective usage and maintenance, ensuring that every project is executed with precision and safety in mind.

Importance of Proper Maintenance

Regular upkeep of your tools is essential for ensuring their longevity and optimal performance. Neglecting maintenance can lead to decreased efficiency, potential hazards, and costly repairs. By prioritizing care, you enhance both safety and productivity in your projects.

| Benefits of Maintenance | Consequences of Neglect |

|---|---|

| Increased tool lifespan | Shortened lifespan |

| Enhanced precision and accuracy | Reduced performance |

| Improved safety | Increased risk of accidents |

| Cost savings on repairs | Higher repair expenses |

Common Issues with Kobalt Saws

Users often encounter various challenges when operating their cutting tools. Understanding these common problems can help in troubleshooting and maintaining optimal performance. Below are some frequent issues that may arise:

- Inaccurate Cuts:

Misalignment of the blade can lead to uneven results. Regular calibration and checking the setup can mitigate this issue.

- Overheating:

Extended use or improper blade selection may cause overheating. Ensuring proper ventilation and taking breaks can help manage this.

- Blade Dullness:

A dull blade can compromise performance and safety. Regular sharpening or replacing blades is essential for maintaining cutting efficiency.

- Electrical Problems:

Issues such as tripped breakers or faulty cords can disrupt operation. Regular inspection of electrical components is crucial for reliable use.

- Vibration:

Excessive vibration can indicate loose components or an unbalanced blade. Tightening screws and checking for damage can alleviate this problem.

Addressing these challenges promptly ensures longevity and enhances the overall user experience with cutting equipment.

Replacement Parts: What You Need

When it comes to maintaining your cutting equipment, understanding the essential components that may require replacement is crucial. Keeping your tools in optimal condition ensures safety, efficiency, and longevity. Knowing what elements to look for can help you make informed decisions when it’s time for a refresh.

Common Components That May Need Replacement

Several key elements are prone to wear and tear over time. These include the blade, which can become dull, and various accessories that may suffer from regular use. Additionally, bearings and motor brushes often require attention to keep the equipment running smoothly. Identifying these components will help you assess the maintenance needs of your device effectively.

Choosing Quality Replacements

When selecting replacements, prioritize quality over cost. High-quality components not only improve performance but also enhance safety. Look for reputable brands and consider reviews to gauge reliability. Investing in durable items can save you money in the long run by reducing the frequency of replacements.

Tools for Miter Saw Repair

Maintaining and fixing your cutting equipment requires a variety of essential implements. Having the right tools on hand not only simplifies the process but also enhances the quality of repairs, ensuring your device operates smoothly.

Essential Tools

- Wrenches and Sockets

- Phillips and Flathead Screwdrivers

- Replacement Blades

- Calipers for Precision Measurements

- Lubricants for Moving Parts

Additional Equipment

- Work Gloves for Safety

- Safety Goggles to Protect Eyes

- Dust Mask to Avoid Inhalation

- Workbench for Stability

- Multimeter for Electrical Checks

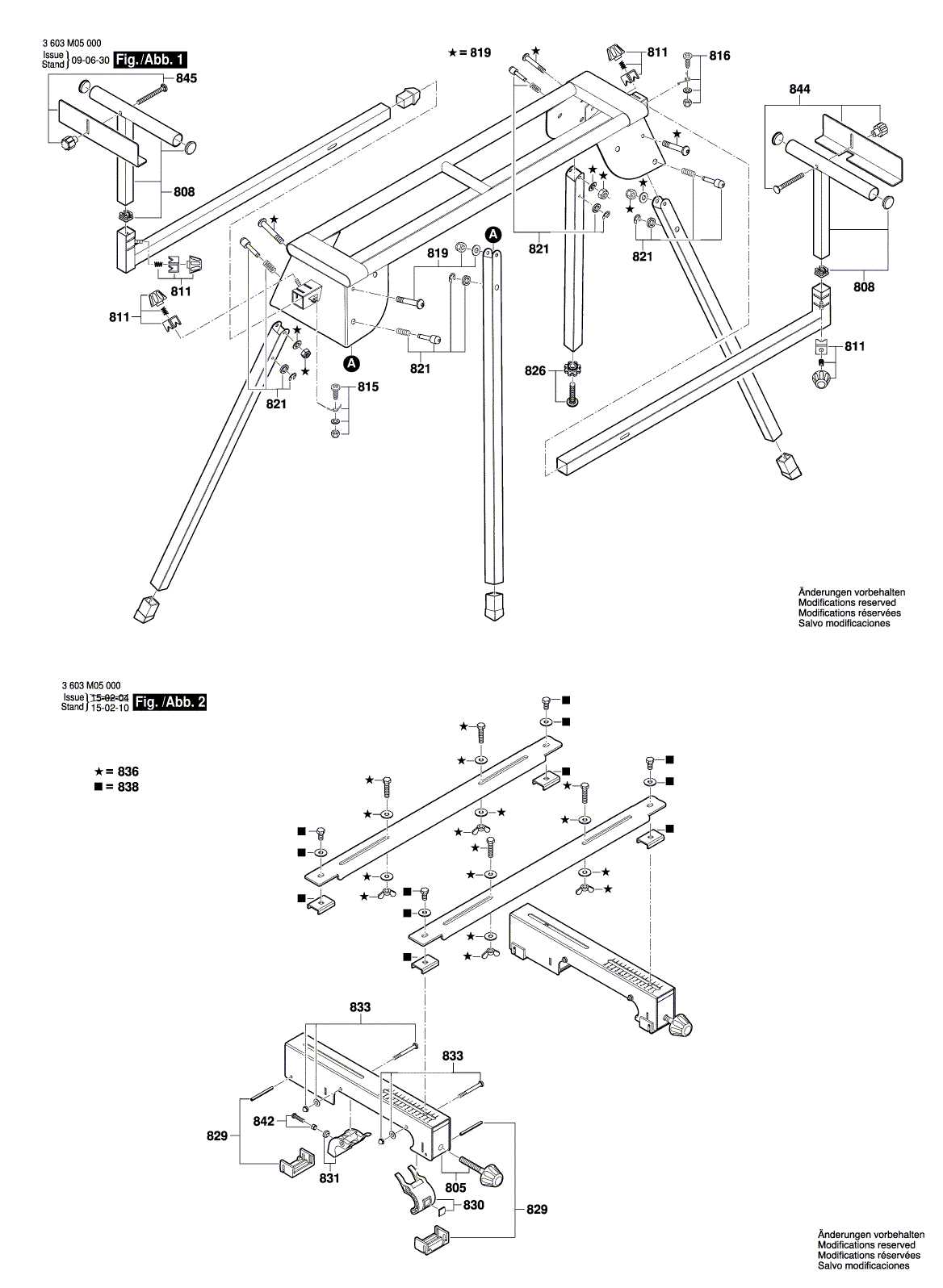

Assembly Instructions for Kobalt Models

This section provides essential guidelines for the effective assembly of your tool, ensuring optimal performance and safety. Following these instructions will facilitate a smooth setup process, allowing you to utilize your equipment efficiently.

Required Tools

Before beginning assembly, ensure you have the following tools available:

| Tool | Purpose |

|---|---|

| Screwdriver | For tightening screws |

| Wrench | For securing bolts |

| Allen Key | For adjusting specific components |

Assembly Steps

To begin assembly, follow these step-by-step instructions. Start by connecting the base to the main body, ensuring all alignment marks match. Secure the components using the appropriate fasteners and verify their tightness. Continue by attaching any additional accessories, referring to the user manual for detailed specifications. Regularly check for stability throughout the process to guarantee safety during operation.

Upgrading Your Miter Saw Performance

Enhancing the efficiency and precision of your cutting tool can significantly improve your projects. By exploring various upgrades, you can transform your equipment into a more reliable and powerful asset. This not only boosts productivity but also elevates the quality of your work.

Investing in Quality Blades: One of the most impactful upgrades involves switching to high-quality blades. These can provide cleaner cuts and longer lifespan, ensuring optimal performance.

Improving Stability: A solid base is crucial. Consider adding a robust stand or enhancing your workstation to reduce vibrations, which can lead to inaccuracies.

Precision Adjustments: Upgrading adjustment mechanisms can offer finer tuning. Look for features that allow for quick and accurate angle changes, making your cuts more precise.

Power Enhancements: If possible, consider modifications that boost the power of your tool. A more powerful motor can handle tougher materials with ease, expanding your capabilities.

In summary, by strategically investing in upgrades, you can achieve ultimate performance enhancements, making your cutting tasks smoother and more efficient.

Safety Tips for Using Miter Saws

Ensuring a secure working environment is essential when operating cutting tools. Adhering to safety protocols not only protects the user but also enhances the quality of the work. Here are key precautions to keep in mind.

Before You Start

- Always wear appropriate personal protective equipment, including goggles and gloves.

- Inspect the tool for any damage or wear before use.

- Ensure that the work area is clean and free of obstacles.

- Check that the material is securely clamped before cutting.

During Operation

- Keep hands and fingers at a safe distance from the cutting area.

- Maintain a firm grip on the tool and workpiece throughout the operation.

- Be aware of the tool’s motion and always cut away from your body.

- Turn off the tool and unplug it when making adjustments or changing blades.