The intricate assembly of a mechanical device often holds the key to its efficient operation and maintenance. Understanding the arrangement and relationship of each element can greatly enhance the user experience, ensuring smoother functionality and ease of repairs. This section delves into the essential configurations that define the structure of this particular model.

Recognizing the roles of various components within the overall system allows users to troubleshoot issues effectively. Whether it’s a simple part replacement or a comprehensive overhaul, a thorough comprehension of how each piece interconnects is invaluable. This exploration emphasizes the significance of familiarity with the internal makeup to maximize performance and longevity.

By providing a detailed visual representation of the assembly, users can identify parts quickly and accurately. This clarity not only aids in repairs but also fosters a deeper appreciation for the engineering behind the machinery. Engaging with the layout enhances the overall understanding and capability to handle any mechanical challenge that may arise.

This section aims to provide a comprehensive understanding of a specific model’s components and their functions. By exploring the various elements, readers will gain insights into how these parts contribute to the overall performance and efficiency of the machine. Knowing the details can help in maintenance and troubleshooting, ensuring optimal operation.

Key Features and Specifications

- Designed for high efficiency and reliability

- Equipped with advanced technology for enhanced performance

- User-friendly interface for ease of operation

- Durable construction to withstand demanding conditions

Common Components and Their Roles

- Engine: Provides the necessary power for operation.

- Control panel: Allows users to adjust settings and monitor performance.

- Hydraulic system: Facilitates movement and operation of attachments.

- Chassis: Offers structural support and stability during use.

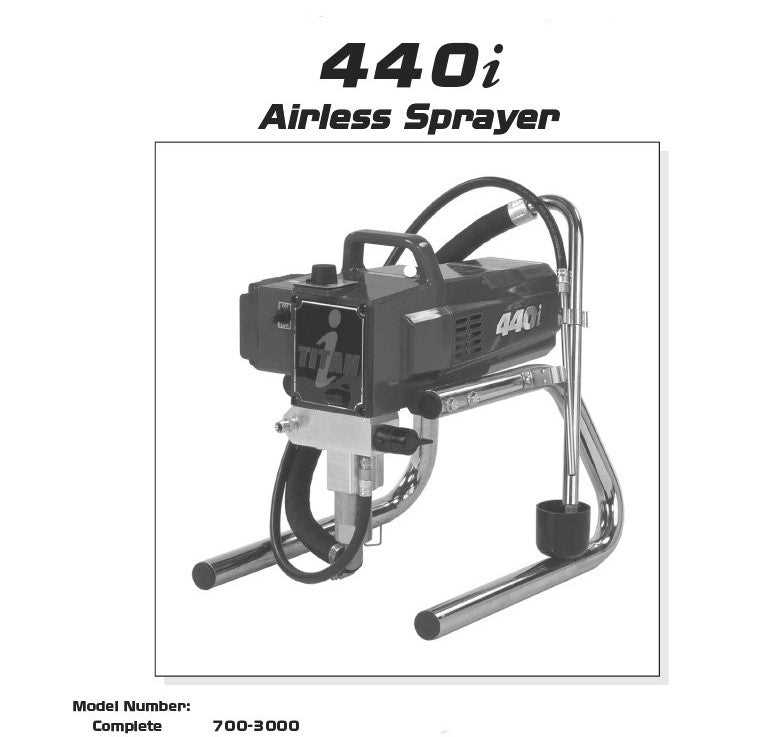

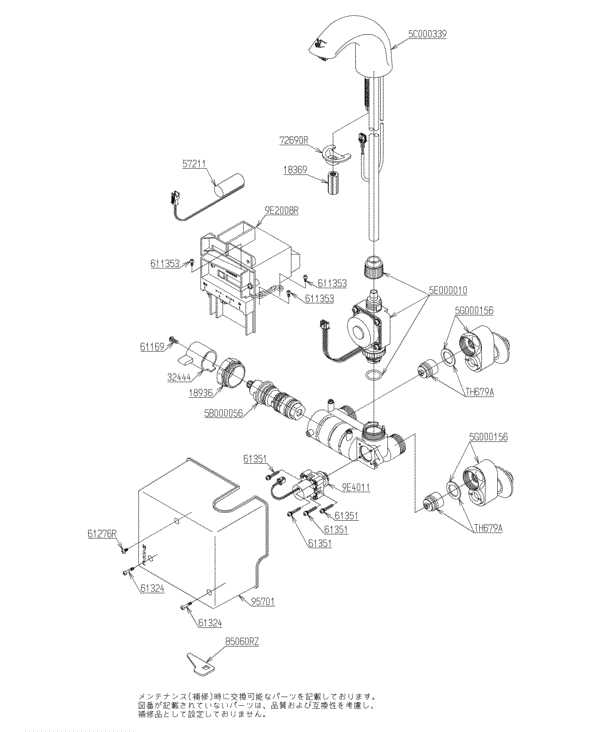

Key Components of Titan 440i

The effective operation of any advanced machinery relies on its fundamental elements, which contribute to overall functionality and performance. Understanding these essential components is crucial for maintenance and troubleshooting, ensuring that the equipment remains in optimal working condition.

Among the critical elements are the engine, which provides the necessary power, and the pump assembly, responsible for fluid movement. Additionally, the nozzle plays a vital role in directing the output effectively, impacting the efficiency of operation. The filter system is equally important, as it ensures that contaminants do not interfere with the machine’s performance.

Another significant component is the control panel, which allows users to monitor and adjust settings easily. Furthermore, the frame serves as the structural backbone, providing stability and support during use. Each of these parts works harmoniously, contributing to the overall efficiency and reliability of the equipment.

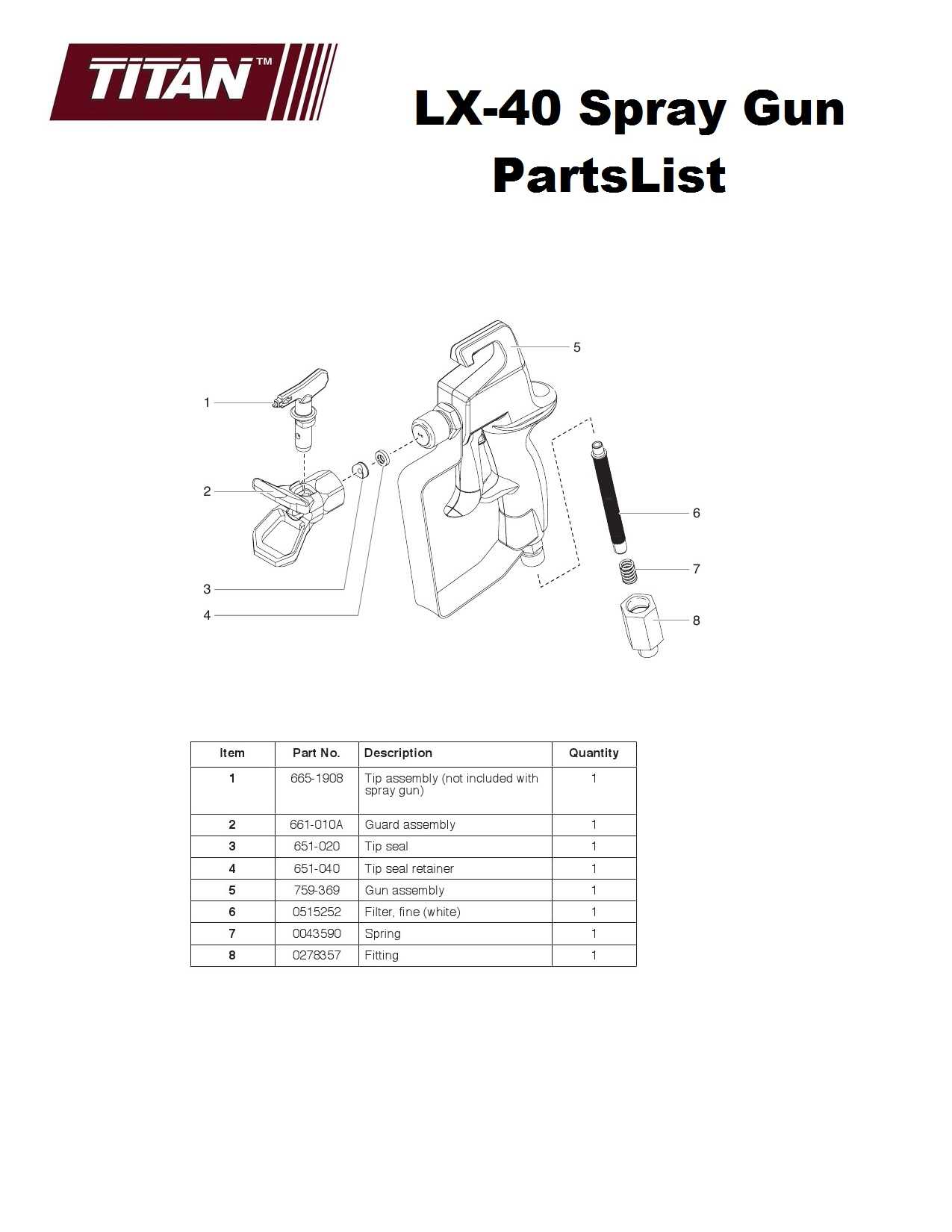

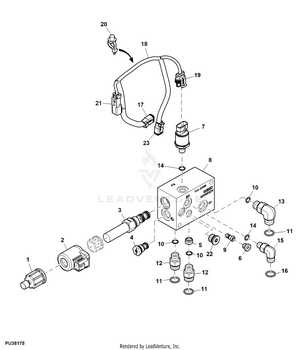

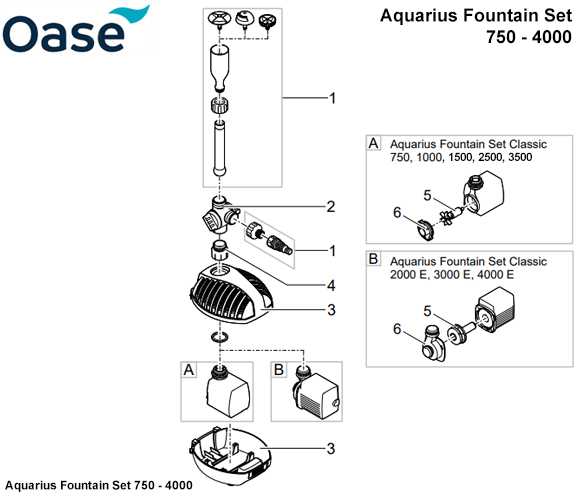

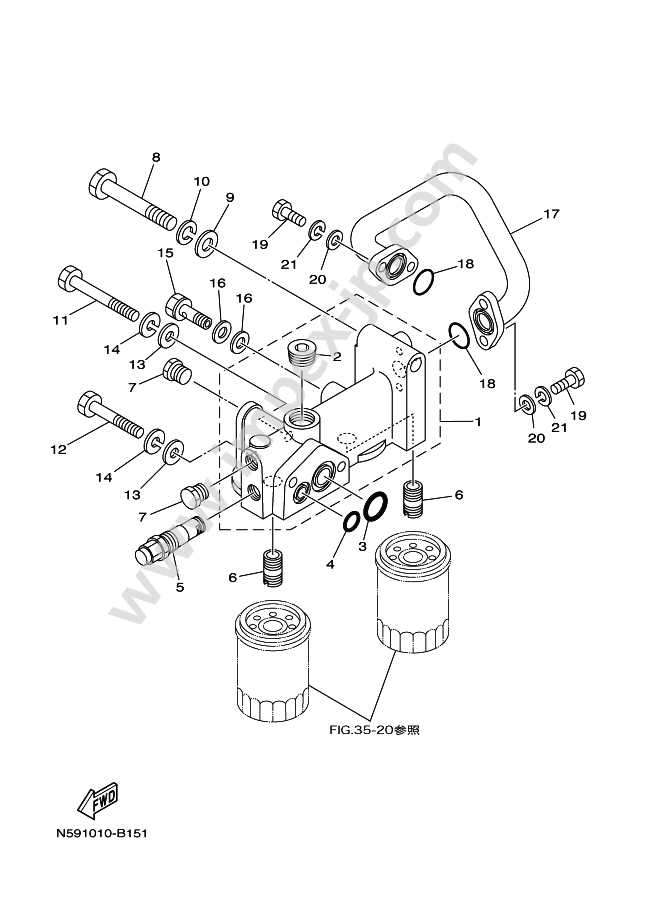

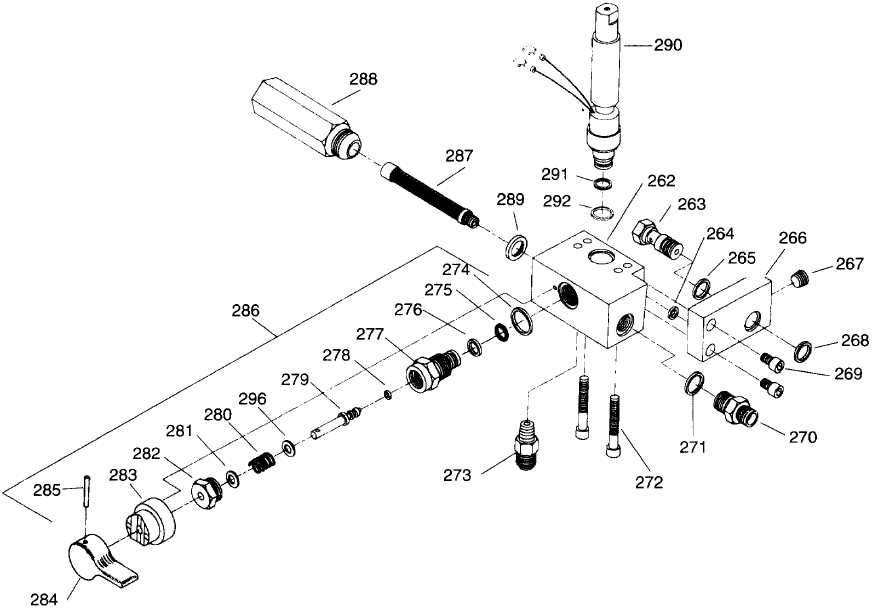

Understanding the Parts Diagram

In order to effectively comprehend the layout of various components, it’s essential to delve into how each element is represented and interconnected. This knowledge allows users to visualize the assembly and functionality of the machinery, facilitating repairs and maintenance.

When examining the layout, several key aspects become apparent:

- Component Identification: Each section typically includes labels or numbers corresponding to specific pieces, aiding in quick identification.

- Arrangement: The positioning of each element reveals how they work together within the system, offering insights into operational efficiency.

- Connections: Understanding how components link and interact helps in troubleshooting and ensuring that all parts function cohesively.

Familiarizing oneself with these representations not only enhances the ability to carry out repairs but also improves overall familiarity with the equipment. A thorough grasp of the structure and arrangement empowers users to address issues confidently and maintain optimal performance.

Importance of Regular Maintenance

Consistent upkeep is essential for the longevity and efficiency of any equipment. By adhering to a regular maintenance schedule, users can significantly enhance the performance and reliability of their machinery. Proactive measures not only prevent unexpected breakdowns but also contribute to safer operation and reduced repair costs.

Enhancing Performance and Longevity

Routine servicing ensures that all components function optimally, thereby maximizing productivity. This practice helps identify wear and tear before it leads to significant failures, allowing for timely replacements and adjustments. Regular checks and cleanings can extend the life span of the equipment, ultimately saving resources and time.

Cost-Effectiveness and Safety

Investing in systematic maintenance is a cost-effective strategy in the long run. By preventing major malfunctions, operators can avoid costly repairs and downtime. Moreover, regular inspections contribute to a safer working environment by minimizing the risk of accidents related to equipment failure.

How to Identify Spare Parts

Identifying the necessary components for repair or maintenance can often be a challenging task. It is crucial to have a systematic approach to ensure that you acquire the right elements for your equipment. Understanding the various components and their functions will significantly streamline this process.

Start by examining your equipment thoroughly. Look for any labels, serial numbers, or model identifiers that can provide valuable information. These details often guide you to the specific elements required for replacement or enhancement.

Utilizing manufacturer resources is also beneficial. Many manufacturers provide catalogs or online platforms where you can find detailed descriptions of components. These resources typically include images and specifications, which can assist in confirming the compatibility of the required items.

Additionally, consulting with professionals or online forums can offer insights into common issues and solutions. Engaging with a community of users may help you identify less common components or alternatives that may not be listed in standard resources.

By taking these steps, you can effectively navigate the process of identifying necessary replacements, ensuring that your equipment remains functional and efficient.

Common Issues and Solutions

This section addresses frequent challenges that users may encounter with their equipment, providing practical solutions to enhance performance and reliability. Understanding these common problems can help users maintain their devices more effectively.

Frequent Problems

- Equipment not starting

- Unusual noises during operation

- Inconsistent performance or output

- Leaks or fluid issues

- Electrical failures

Troubleshooting Tips

- Check Power Supply: Ensure that the unit is properly connected to a functioning power source.

- Inspect for Blockages: Examine hoses and openings for any debris that may hinder performance.

- Examine Connections: Look for loose or damaged electrical connections that could affect operation.

- Regular Maintenance: Follow a scheduled maintenance routine to clean and service the equipment.

- Seek Professional Help: If issues persist, contact a qualified technician for assistance.

Where to Purchase Replacement Parts

When the time comes to find components for your machinery, knowing the right places to look can save you both time and money. A variety of suppliers offer quality items, ensuring that you can keep your equipment running smoothly. It’s essential to explore different options, as each supplier may have unique advantages, including pricing, availability, and customer support.

Online Retailers

Many online platforms provide an extensive selection of components. Websites specializing in machinery supplies often feature detailed descriptions and user reviews, helping you make informed decisions. Additionally, purchasing online can offer competitive pricing and convenient delivery options.

Local Suppliers and Dealers

Visiting local shops or authorized dealers can be beneficial as well. These establishments often carry specific components and can provide expert advice tailored to your needs. Establishing a relationship with a local supplier may also lead to exclusive discounts or offers.

Tips for DIY Repairs

Engaging in do-it-yourself repairs can be a fulfilling experience, allowing individuals to tackle issues with their equipment and potentially save on service costs. Whether addressing minor glitches or more significant malfunctions, having the right approach can make all the difference.

First and foremost, always gather the necessary tools and materials before starting any repair work. This preparation will minimize interruptions and streamline the process. Having everything on hand also reduces the temptation to rush through steps, which can lead to mistakes.

Next, consult available resources such as manuals or online guides to familiarize yourself with the equipment’s components and common problems. These resources can provide valuable insights and troubleshooting tips that may not be immediately apparent.

Additionally, take the time to document the disassembly process. Photographing each step or keeping a written log can help ensure that reassembly is straightforward, preventing confusion and missed pieces.

Finally, practice patience. Repairs can sometimes take longer than expected, especially if unexpected challenges arise. Remaining calm and focused will contribute to a successful outcome and enhance your skills for future projects.

Resources for Further Assistance

When seeking additional guidance for your equipment, a variety of resources are available to help you navigate any challenges. These tools can provide valuable insights and solutions to enhance your understanding and operational efficiency.

- User Manuals: Refer to the official manuals that accompany your device. They often include troubleshooting tips, usage instructions, and maintenance guidelines.

- Online Forums: Participate in community discussions where users share experiences and solutions. Websites dedicated to equipment support can be particularly helpful.

- Manufacturer Support: Contact the customer service department of the manufacturer. They can offer expert advice tailored to your specific model and concerns.

- Tutorial Videos: Explore video platforms for visual demonstrations on common issues and operational tips. These resources can simplify complex processes.

- Local Technicians: If hands-on assistance is required, consider reaching out to certified technicians who can provide repairs and maintenance services.

Utilizing these resources can empower you to effectively manage your equipment and ensure optimal performance over time.