Maintaining a well-kept yard is essential for any homeowner, and the right tools can make all the difference in achieving a pristine landscape. Familiarizing oneself with the various elements of a cutting device is crucial for effective upkeep. Knowing how these components work together not only enhances performance but also prolongs the life of the equipment.

In this section, we delve into the intricate design of a typical grass-cutting tool, breaking down its essential features. Each segment plays a significant role in the overall functionality, ensuring that the equipment operates efficiently and effectively. Whether you are a seasoned gardener or a novice in outdoor maintenance, understanding these components will empower you to tackle repairs and improvements with confidence.

Additionally, having a clear visual representation of each section can aid in identifying potential issues and making informed decisions regarding maintenance. With the right knowledge, you can optimize your lawn care routine and enjoy the rewards of a beautifully manicured outdoor space.

Understanding Yard Machines Push Mower

This section delves into the essential components and functionality of a common lawn care device, highlighting its operational efficiency and design intricacies. A thorough comprehension of its structure can significantly enhance maintenance practices and overall performance.

Key Components

Familiarizing oneself with the various elements of this lawn care tool allows for better troubleshooting and repair. Each segment plays a vital role in the effective operation of the machine, ensuring a smooth cutting experience.

| Component | Function |

|---|---|

| Engine | Powers the device, enabling it to cut grass. |

| Blade | Responsible for cutting the grass to a desired height. |

| Handle | Provides control and maneuverability for the operator. |

| Deck | Houses the blade and protects the engine components. |

Maintenance Tips

Regular upkeep is crucial for prolonging the lifespan of this device. Simple tasks such as cleaning, oil changes, and blade sharpening can significantly improve performance and reliability.

Key Components of a Push Mower

Understanding the essential elements of a grass-cutting tool is crucial for effective maintenance and operation. Each part plays a significant role in ensuring the equipment functions smoothly, providing optimal performance during use. Familiarity with these components can enhance the longevity of the machine and improve the overall mowing experience.

Blades and Cutting Deck

The blades are perhaps the most critical element, responsible for the actual cutting of the grass. They are typically made of durable steel, designed to withstand the rigors of regular use. The cutting deck houses the blades and dictates the height at which the grass is trimmed. A well-designed deck not only enhances cutting efficiency but also influences the overall maneuverability of the tool.

Engine and Drive System

The engine provides the necessary power to operate the blades and propel the tool forward. There are various types of engines, each offering different levels of power and efficiency. Coupled with the engine is the drive system, which facilitates movement. This system can be either self-propelled or manual, impacting the user’s experience and the effort required to navigate through different terrains.

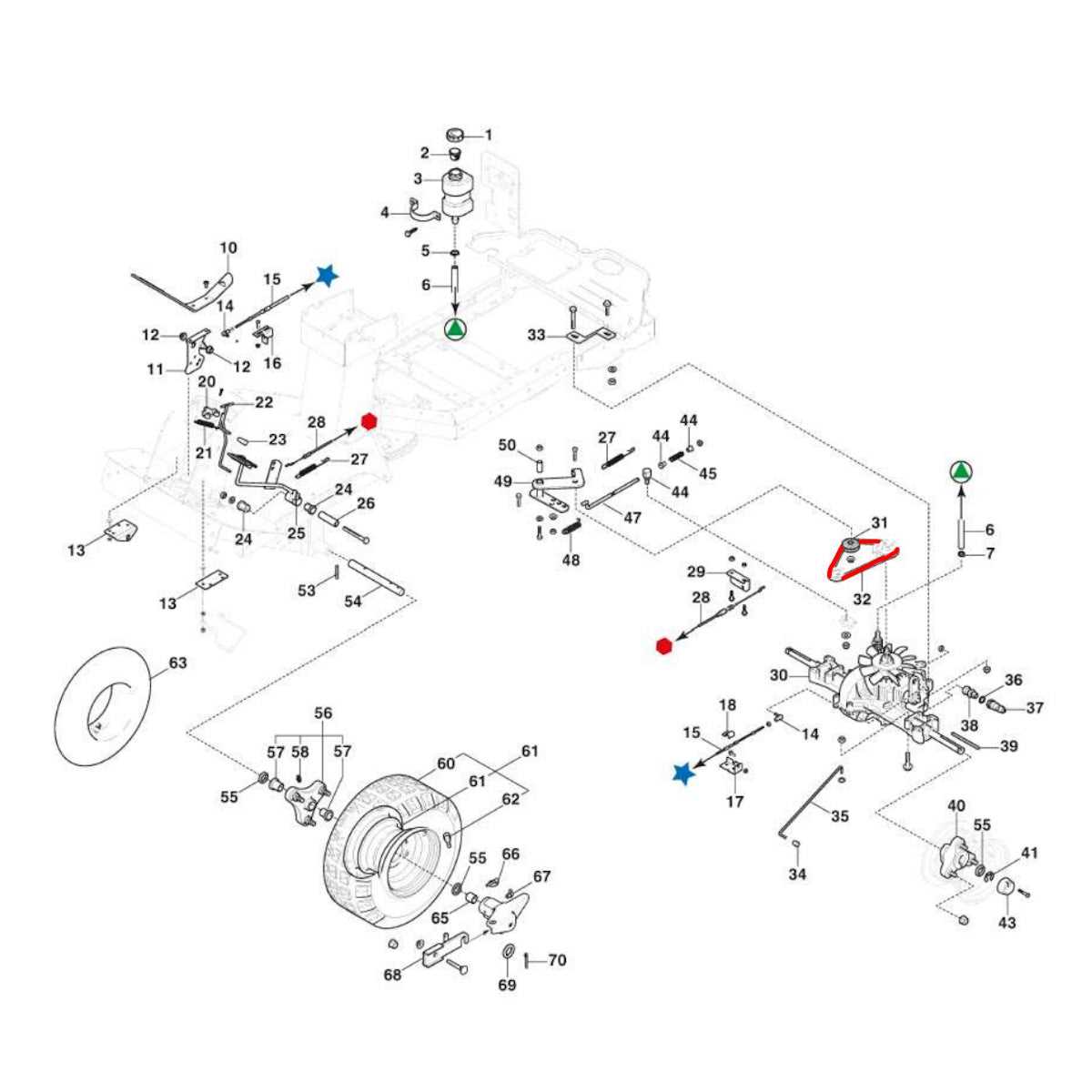

How to Read Parts Diagrams

Understanding the visual representations of components is essential for efficient assembly, repair, or maintenance. These illustrations serve as guides, providing a clear view of how various elements fit together and interact. Grasping the layout and annotations within these visuals can significantly enhance your ability to tackle any task related to equipment upkeep.

To begin, familiarize yourself with the key symbols and notations used in these illustrations. Each element is typically labeled with a unique identifier, which corresponds to a list detailing specifications and descriptions. This allows you to easily locate the necessary components and understand their roles in the overall structure.

Next, pay attention to the arrangement of the items in the visual. Often, they are depicted in a logical order that mirrors their installation sequence or functional relationship. By following this order, you can streamline your process and minimize the chance of errors during assembly or repairs.

Moreover, look for any notes or highlighted sections that may indicate specific instructions or precautions. These annotations can provide crucial insights into the handling or compatibility of certain elements, ensuring that your maintenance tasks are performed safely and effectively.

Finally, practice makes perfect. The more you work with these visuals, the more intuitive they will become. Over time, you will develop a keen eye for recognizing different components and their connections, empowering you to approach any maintenance project with confidence and skill.

Common Issues with Yard Machines

Every mechanical device can encounter challenges that affect its performance and longevity. Understanding these frequent problems is crucial for effective maintenance and optimal operation. This section will explore some of the typical complications associated with these outdoor tools.

Starting Difficulties: One of the most prevalent issues is trouble initiating the engine. This can stem from various factors, such as fuel quality, spark plug condition, or carburetor blockages. Regular checks can mitigate these problems.

Uneven Cutting: Another common challenge is inconsistent cutting performance. This may be caused by dull blades, improper height settings, or uneven terrain. Maintaining sharp blades and adjusting settings as needed can improve results.

Overheating: Machines may experience overheating, leading to potential damage. This can occur due to blocked air filters or insufficient lubrication. Keeping these components clean and well-maintained is essential for preventing overheating.

Vibration Issues: Excessive vibrations can indicate imbalances or loose parts. Identifying and tightening any loose components can help restore smooth operation.

Fuel Leaks: Lastly, fuel leaks are a serious concern that can arise from damaged lines or seals. Regular inspections can help detect leaks early, ensuring safety and efficiency.

Maintaining Your Push Mower Parts

Ensuring the longevity and efficiency of your outdoor cutting equipment requires regular attention and care. By focusing on specific components, you can enhance performance, reduce the likelihood of breakdowns, and promote a healthier environment for your greenery. Proper upkeep not only prolongs the life of your equipment but also improves its overall functionality.

Regular Inspections

Frequent evaluations of the different elements are essential. Check for any signs of wear or damage, including cracks, rust, or corrosion. Cleaning these components after each use will help prevent buildup that can hinder operation. Make it a habit to inspect the blades for sharpness and integrity, as well-maintained blades ensure cleaner cuts and less stress on the machine.

Lubrication and Storage

Applying appropriate lubricants to moving parts is vital for smooth operation. Ensure that all joints and pivot points are well-greased to avoid friction and wear. During the off-season, store your equipment in a dry, sheltered location to protect it from the elements. Covering it with a tarp or dedicated cover can further shield it from dust and moisture, extending its lifespan.

Where to Find Replacement Parts

Locating suitable components for your outdoor equipment can be a straightforward process if you know where to look. Several reliable sources provide a wide variety of options, ensuring that you can find the right item to keep your tools functioning optimally.

Here are some of the best places to consider when searching for suitable replacements:

| Source | Description | Advantages |

|---|---|---|

| Manufacturer’s Website | The official site often offers the latest models and genuine replacements. | Guaranteed compatibility and quality. |

| Local Retail Stores | Brick-and-mortar shops may stock commonly needed components. | Immediate availability and personal assistance. |

| Online Marketplaces | Websites like Amazon or eBay provide a vast selection from various sellers. | Competitive pricing and customer reviews. |

| Specialty Repair Shops | Stores focused on repair services may carry specific components. | Expert advice and potential installation services. |

| Salvage Yards | Places that sell used items may have rare or discontinued components. | Cost-effective solutions for hard-to-find items. |

By exploring these options, you can efficiently find the necessary components to maintain and enhance the performance of your outdoor equipment.

Step-by-Step Repair Guide

Maintaining your outdoor equipment is crucial for ensuring optimal performance and longevity. This guide will provide a clear, structured approach to help you troubleshoot and fix common issues effectively. By following these steps, you can enhance your knowledge and skills in repairing your tools.

Identifying the Problem

Before starting any repair, it’s essential to determine the specific issue. Observe the machine’s performance: does it struggle to start, produce unusual noises, or fail to operate efficiently? Documenting these symptoms will guide you in diagnosing the root cause.

Gathering Tools and Supplies

Once you’ve identified the problem, the next step is to collect the necessary tools and materials. Ensure you have a screwdriver, wrench, and any replacement components required for the repair. Having everything ready beforehand will streamline the process and minimize downtime.

Upgrading Your Mower’s Performance

Enhancing the efficiency and functionality of your cutting equipment can lead to a more enjoyable experience and improved results. Whether you’re looking to increase power, achieve a finer cut, or improve fuel efficiency, various modifications can significantly impact performance. Understanding which upgrades to consider is essential for maximizing your tool’s capabilities.

Several key areas can be targeted for improvements. Upgrading the engine, enhancing the blade quality, and fine-tuning the wheel system are all effective strategies. Below is a comparison of popular upgrades and their benefits.

| Upgrade Type | Description | Benefits |

|---|---|---|

| Engine Enhancement | Replace or modify the engine for increased horsepower. | Higher torque, faster cutting speed, better performance on uneven terrain. |

| Blade Upgrade | Install high-quality or specialized blades. | Cleaner cuts, reduced mowing time, improved durability. |

| Wheel System Improvement | Upgrade wheels for better traction and maneuverability. | Enhanced stability, easier navigation around obstacles, improved overall handling. |

By carefully selecting and implementing these enhancements, you can significantly boost the efficiency of your cutting tool, making maintenance tasks quicker and more effective. Prioritize upgrades that align with your specific needs and preferences to achieve the best results.

Tips for Long-Lasting Equipment

Ensuring the durability of your tools and devices requires careful attention and regular maintenance. By adopting certain practices, you can extend the lifespan of your equipment and enhance its performance over time.

Regular Cleaning: Keeping your equipment clean is crucial. Remove debris, dirt, and grass clippings after each use. This prevents buildup that can cause corrosion and malfunction.

Routine Inspections: Conduct frequent checks to identify any signs of wear or damage. Early detection of issues allows for timely repairs, minimizing the risk of more significant problems.

Proper Storage: Store your equipment in a dry, sheltered place to protect it from harsh weather conditions. Use covers if necessary to further shield against dust and moisture.

Use Quality Fuel: Always use high-quality fuel and lubricants recommended by the manufacturer. This not only optimizes performance but also reduces the likelihood of engine problems.

Follow Manufacturer Guidelines: Adhere to the maintenance schedule provided by the manufacturer. Regular oil changes, blade sharpening, and other specified tasks are vital for longevity.

Invest in Spare Parts: Keep essential spare components on hand to facilitate quick repairs. Having these items readily available can prevent downtime during the peak usage season.

By incorporating these practices into your routine, you can ensure that your tools remain effective and reliable for many seasons to come.