The efficient functioning of any landscaping apparatus relies on the intricate relationship between its various components. Each segment plays a crucial role in ensuring optimal performance, durability, and maintenance ease. A comprehensive understanding of these elements is essential for anyone looking to enhance their lawn care experience.

In this section, we will explore the key elements that constitute the mechanism of a popular grass-cutting machine. By breaking down the individual components, we can gain insights into their specific functions and how they interconnect. This knowledge not only aids in proper maintenance but also empowers users to troubleshoot issues effectively.

Whether you are a seasoned user or new to the world of lawn management, familiarizing yourself with the layout and function of these essential features can lead to better care practices. With a clear visualization of how everything fits together, you’ll be better prepared to ensure your equipment remains in top condition throughout its lifespan.

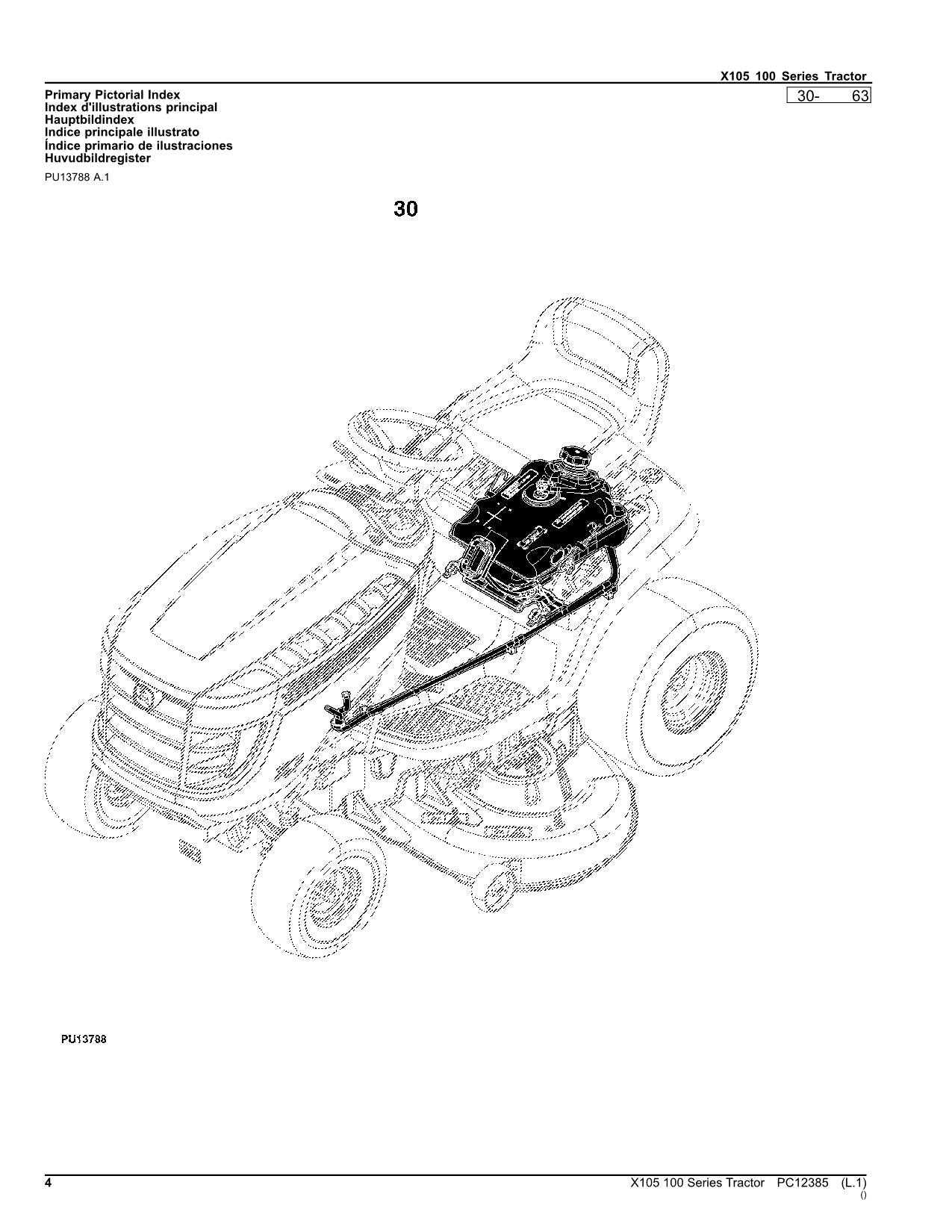

Understanding the John Deere X500 Mower

This section explores the key features and functionalities of a popular lawn care machine, designed for efficiency and ease of use. By examining its components, users can gain insights into maintaining and optimizing performance for optimal results.

Key Features

- Powerful engine for robust performance

- Intuitive controls for user-friendly operation

- Durable construction ensuring longevity

- Versatile attachments for various landscaping tasks

Maintenance Tips

- Regularly check and change the oil to ensure smooth operation.

- Inspect the blades frequently for sharpness and damage.

- Clean the chassis to prevent debris buildup.

- Store in a dry place during off-seasons to prolong lifespan.

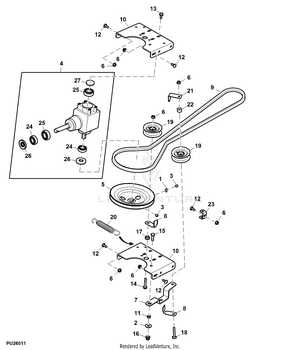

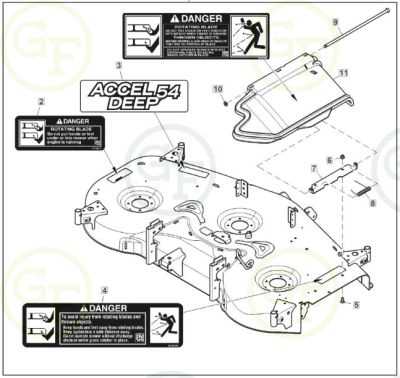

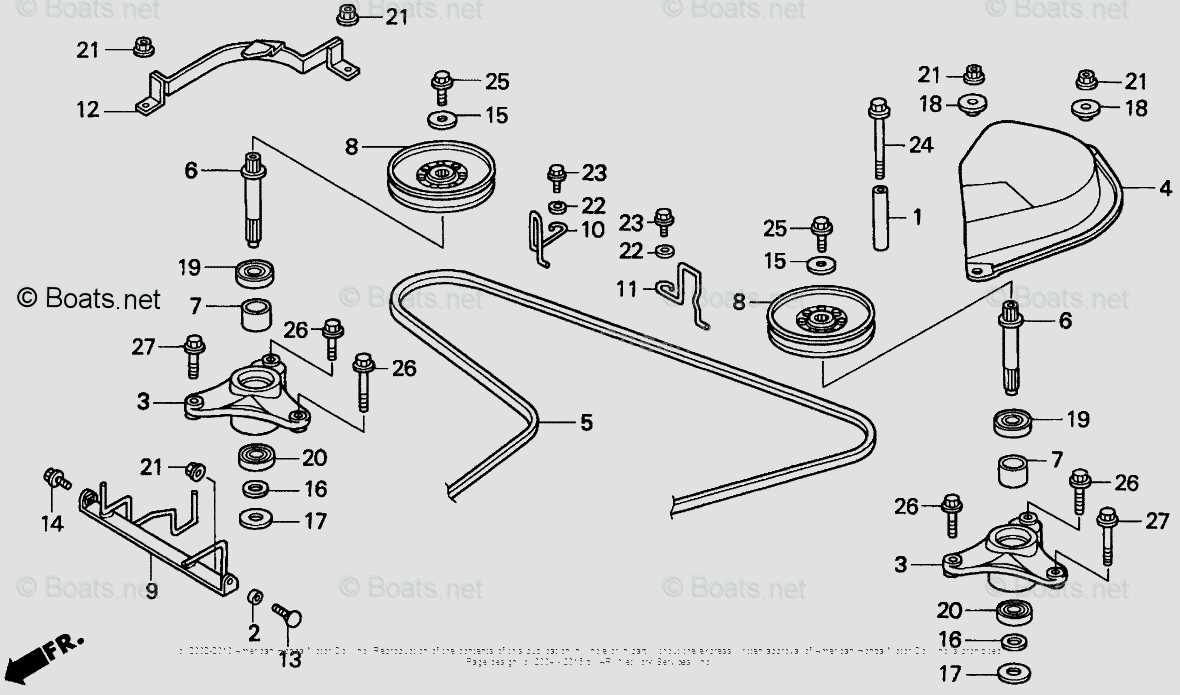

Components of the Mower Deck

The structure of a cutting apparatus consists of various essential elements that work in unison to ensure effective grass management. Understanding these components is vital for maintenance and optimal performance.

Cutting Blades: These are the primary tools responsible for the actual trimming of grass. They vary in shape and size, depending on the desired cut.

Spindles: These cylindrical units house the blades and facilitate their rotation, ensuring a smooth cutting action.

Chassis: This framework supports all components, providing stability and durability during operation.

Anti-Scalp Wheels: These small wheels help prevent the cutting mechanism from digging into the ground, promoting a clean and even finish.

Drive Belts: These flexible connectors transfer power from the engine to the cutting assembly, allowing for efficient operation.

Height Adjustment Mechanism: This feature enables the user to modify the cutting height, accommodating different grass types and lengths.

Importance of Proper Maintenance

Regular upkeep is crucial for ensuring optimal performance and longevity of equipment. Neglecting routine checks can lead to significant issues that affect efficiency and safety. Implementing a maintenance schedule can prevent minor problems from escalating into costly repairs.

Benefits of Regular Upkeep

- Enhanced performance and reliability.

- Increased lifespan of machinery.

- Improved safety for users.

- Cost savings over time through reduced repairs.

Key Maintenance Practices

- Regular cleaning of components to remove debris.

- Checking and replacing worn-out elements as necessary.

- Lubricating moving parts to reduce friction.

- Inspecting belts and blades for signs of wear.

Identifying Common Issues

Recognizing frequent problems can significantly enhance the performance and longevity of your equipment. Various components can experience wear and tear over time, leading to inefficiencies or operational failures. Understanding these issues helps in timely maintenance and repairs.

One common concern is uneven cutting, often caused by dull blades or improper leveling. Inspecting the sharpness and alignment of cutting elements can rectify this issue quickly. Another prevalent problem is poor engine performance, which may stem from fuel quality, air filter blockages, or spark plug wear. Regular checks can prevent these issues from escalating.

Additionally, unusual noises during operation can indicate mechanical failures or loose components. Monitoring these sounds and addressing them promptly can prevent more significant damage. Lastly, difficulty in starting the machine can be linked to battery issues or electrical system faults. Routine inspections of these systems are essential for reliable functionality.

Replacement Parts Availability

Access to suitable components is essential for maintaining the efficiency and longevity of your equipment. When the time comes for replacements, knowing where to find reliable sources can make all the difference. Whether you need to replace worn items or upgrade for improved performance, a variety of options exist to ensure your machinery remains in optimal condition.

Authorized Dealers and Service Centers

One of the best places to seek genuine components is through authorized dealers and service centers. These establishments typically offer a comprehensive inventory of original equipment, ensuring compatibility and quality. Additionally, they often have knowledgeable staff who can assist with installation and maintenance advice.

Online Retailers and Marketplaces

The internet has transformed the way we procure machinery components. Numerous online retailers provide a wide selection of aftermarket and original components, often at competitive prices. However, it is crucial to verify the reputation of the seller and read reviews to ensure you receive high-quality items that meet your needs.

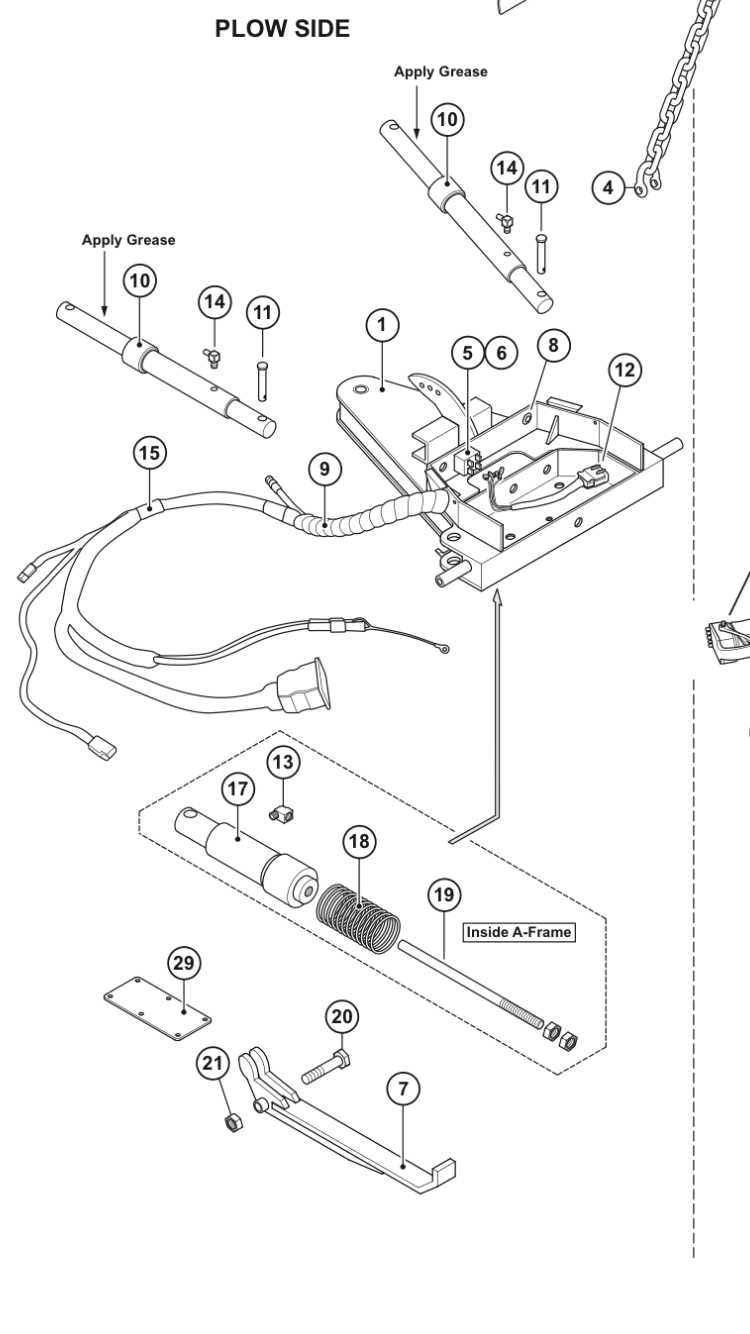

How to Access the Diagram

Understanding the layout and components of your equipment is essential for maintenance and repairs. Accessing the visual representation of these elements can significantly enhance your ability to diagnose issues and perform necessary tasks. Here’s how to efficiently obtain and utilize this valuable information.

Online Resources

One of the quickest ways to find the visual guide is through the official website of the manufacturer. Most brands offer downloadable resources that include schematics and exploded views. Simply navigate to the support or resources section and search for your specific model. Additionally, various forums and community websites may have shared diagrams that can be beneficial.

Manuals and Guides

Physical manuals often contain detailed illustrations and breakdowns of your equipment’s components. If you own a printed copy, consult the table of contents or index to locate the relevant section. Alternatively, many companies provide digital versions of these manuals, which can be accessed on their websites or through customer service.

Using these approaches will enable you to effectively visualize and understand the intricate details of your machinery, leading to more informed maintenance decisions.

Steps for Deck Assembly

Assembling the cutting platform requires careful attention to detail and adherence to the recommended procedures. Following the correct sequence will ensure optimal performance and longevity of the equipment. This guide outlines the necessary steps to efficiently put together the various components.

Preparation and Tools

Before starting the assembly, gather all essential tools and components. Ensure that you have a suitable workspace free from distractions. The primary tools you may need include a wrench set, screwdriver, and pliers. Reviewing the manual for specific requirements and safety instructions is also advisable.

Assembly Procedure

Begin by aligning the main sections according to the specifications outlined in the instruction manual. Secure each piece with the appropriate fasteners, making sure they are tightened but not overtightened, which could cause damage. After the initial assembly, double-check all connections for stability. Finally, perform a visual inspection to ensure everything is correctly positioned before use.

Maintenance Tip: Regularly inspect and maintain the assembled components to ensure they remain in optimal condition for efficient operation.

Safety Precautions During Repairs

When undertaking maintenance or repairs on machinery, ensuring personal safety and preventing accidents should be the top priority. Proper precautions can significantly reduce the risk of injury, making the process smoother and more efficient. Familiarizing oneself with essential safety measures is crucial before starting any repair work.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is essential. This includes safety goggles to protect your eyes from debris, gloves to shield your hands, and sturdy footwear to prevent injuries from heavy objects. Additionally, ear protection may be necessary when working with loud machinery.

Work Environment and Tools

Maintaining a clean and organized workspace is vital for safety. Ensure that tools are in good condition and stored properly when not in use. Always disconnect the power source before beginning any repairs to avoid accidental starts. Being mindful of your surroundings and having a clear exit path can help you respond quickly in case of an emergency.

Tips for Long-lasting Performance

Maintaining the efficiency and longevity of your outdoor equipment requires attention to detail and proactive care. Implementing the right strategies can significantly enhance the performance and durability of your machine, ensuring it operates optimally for years to come.

Here are some essential tips to consider:

| Tip | Description |

|---|---|

| Regular Cleaning | Remove debris and grass clippings after each use to prevent build-up that can cause rust and reduce efficiency. |

| Routine Inspections | Check all components regularly for signs of wear or damage. Addressing issues early can prevent costly repairs. |

| Proper Lubrication | Ensure all moving parts are adequately lubricated to reduce friction and wear, enhancing overall performance. |

| Fuel Quality | Use high-quality fuel to avoid engine issues and improve performance. Regularly replace stale fuel. |

| Sharpen Blades | Keep blades sharp to ensure clean cuts, which promotes healthier grass and reduces stress on the engine. |

| Store Properly | During off-seasons, store equipment in a dry, sheltered location to protect it from the elements. |