Maintaining outdoor machinery requires an understanding of how its mechanical components function together. When tackling repairs or adjustments, visual guidance proves essential for smooth and effective operation. This section aims to provide clear insights into the inner workings of essential systems used in landscaping tools, ensuring proper maintenance and troubleshooting.

In the following exploration, we break down the core structural elements and their specific roles. Whether you’re performing seasonal maintenance or resolving unexpected issues, familiarizing yourself with the core assembly will streamline the process. Proper alignment and configuration are critical for achieving optimal performance across varying terrain conditions.

We’ll also focus on the importance of correct

Ariens Mower Deck Overview

The equipment responsible for achieving a smooth and even cut plays a vital role in lawn maintenance. Its structure ensures efficient performance, improving the quality of grass trimming with each pass. Understanding how individual components interact can help extend the unit’s lifespan and maintain consistent results.

- Cutting Blades: The sharp tools rotate rapidly to slice through grass, ensuring a uniform appearance.

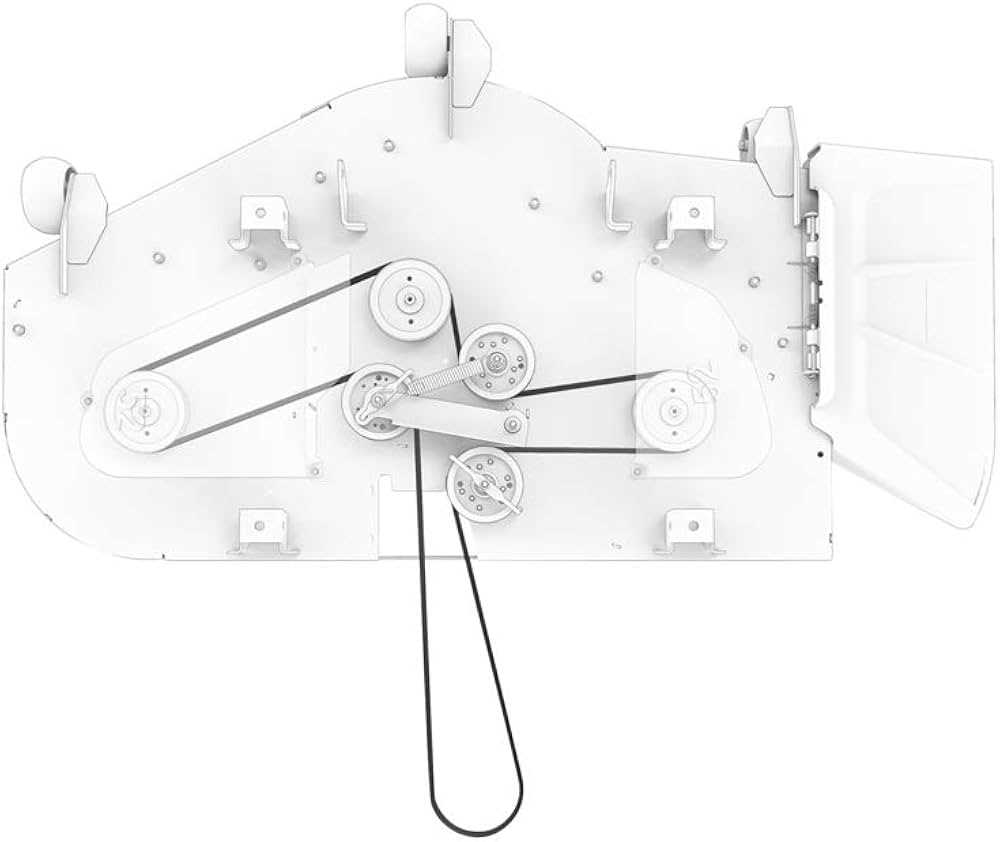

- Belt System: Transfers energy from the engine to the cutting tools, driving the entire operation smoothly.

- Pulleys and Spindles:

Blade Types and Configurations

Understanding the variations in cutting tools and their setups is essential for achieving optimal performance and desired results. Different environments, grass conditions, and user needs call for specialized solutions, each with distinct characteristics.

Standard Blades: These are designed for general-purpose use, offering a balance between precision and durability. They excel in typical conditions, providing consistent cuts across various terrains.

High-Lift Blades: Characterized by an aggressive upward airflow, these are ideal for bagging operations. Their shape promotes better collection of clippings, ensuring a cleaner surface.

Mulching Blades: Equipped with multiple cutting edges, these tools finely chop grass into small pieces. This configuration allows the clippings to decompose naturally, returning nutrients to the soil.

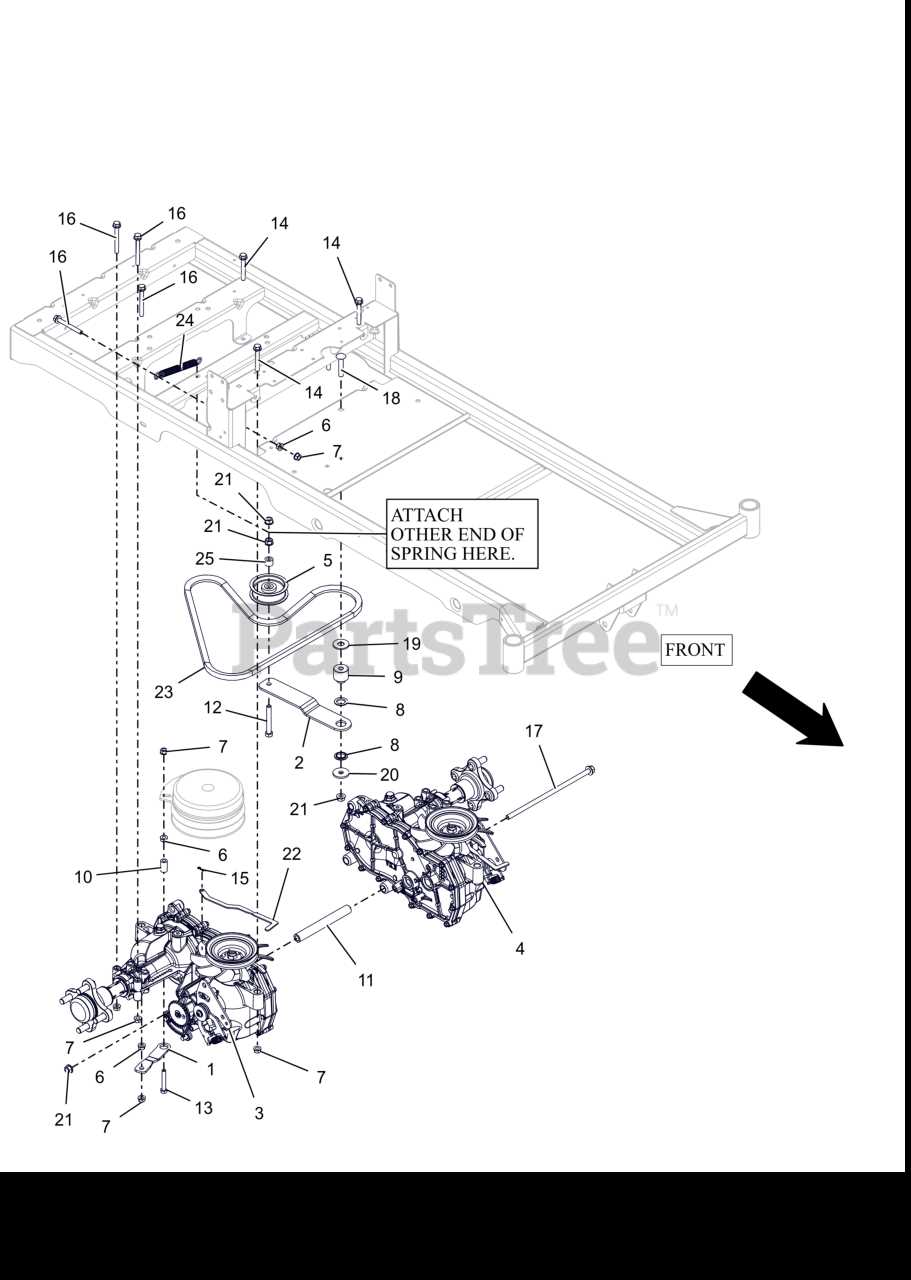

Belt Routing and Adjustments

Proper alignment of the drive belt ensures smooth operation and prevents unnecessary wear. Understanding how to position the belt correctly and make precise adjustments is essential for maintaining peak performance and extending the service life of mechanical systems.

Belt Path Overview

The belt follows a defined path around several pulleys, each designed to redirect movement efficiently. Ensuring that the belt remains seated in the correct grooves is crucial to avoid slippage. Double-check the path after installation to confirm that all guiding components are aligned with the manufacturer’s recommendations.

Tension Adjustments

A well-calibrated belt tension guarantees consistent operation. If the

Spindle Assembly Maintenance Tips

Regular upkeep of rotating shaft components ensures smooth performance and extends the overall lifespan of the system. Proper care minimizes unexpected downtime and prevents premature wear, keeping the mechanism reliable over time.

Signs of Potential Issues

- Unusual vibrations or noise during operation.

- Uneven rotation or wobbling detected upon inspection.

- Increased friction leading to overheating of the bearings.

Steps for Routine Care

- Inspect the fasteners periodically and tighten them if necessary.

- Clean any

Importance of Proper Pulley Alignment

Maintaining precise alignment between pulleys ensures smooth mechanical operation and reduces the likelihood of performance issues. When rotating elements are properly aligned, they minimize unnecessary tension and wear, resulting in improved longevity of the components involved. Correct alignment helps the system function efficiently, limiting friction and potential breakdowns.

Poor alignment can lead to imbalanced movement, causing belts to slip or wear unevenly. This can increase energy consumption, reduce operational efficiency, and cause premature failure of connected parts. Regular inspection and adjustment of pulley alignment are essential to

Deck Leveling Procedures for Smooth Cuts

Achieving an even cutting height is essential for maintaining a pristine appearance in your lawn. Proper adjustment techniques not only enhance the aesthetics but also promote healthy grass growth by ensuring uniform exposure to sunlight and moisture. This section outlines the steps necessary to calibrate your cutting mechanism effectively for optimal performance.

Preparation and Tools Needed

Before starting the leveling process, gather the required tools, including a measuring tape, level, and wrench. Ensure that the machine is on a flat, level surface to facilitate accurate measurements. It is advisable to inspect the cutting mechanism for any wear or damage that might affect performance.

Adjustment Steps

Begin by measuring the height of the blades at various points. Compare the readings to determine if adjustments are necessary. To raise or lower the cutting elements, locate the height adjustment mechanism and make the appropriate changes. After adjusting, recheck the height to ensure consistency across the width. Once satisfied with the alignment, test the equipment in a small area to confirm smooth operation and even cuts before proceeding with larger tasks.

Choosing Compatible Replacement Parts

When it comes to maintaining your outdoor equipment, selecting appropriate substitutes for worn or damaged components is crucial. Using compatible alternatives ensures optimal performance, extends the lifespan of your machinery, and promotes overall efficiency. Understanding the various options available can help you make informed decisions during the replacement process.

Understanding Compatibility

Compatibility is essential when selecting replacements. Not all components are created equal; therefore, it’s important to verify that the substitutes meet the necessary specifications for your specific model. This consideration includes checking dimensions, material quality, and functionality.

Sources for Quality Substitutes

Reliable sources play a significant role in finding suitable replacements. Authorized dealers, reputable online retailers, and specialty stores can provide genuine or high-quality aftermarket alternatives. Always research and compare options to ensure you are making a sound investment.

Source Type Advantages Authorized Dealers Genuine components, warranty support Online Retailers Convenience, often competitive prices Specialty Stores Expert advice, specialized inventory Troubleshooting Common Deck Issues

Maintaining the functionality of a cutting mechanism is essential for achieving optimal performance and results. Over time, various problems may arise that hinder its efficiency. This section aims to address common complications and provide insights into their resolution, ensuring a smooth operation during use.

Uneven Cutting

One frequent issue experienced is uneven cutting, which can lead to an inconsistent appearance in the area being tended. This problem may be attributed to several factors, such as improper height settings, dull blades, or uneven terrain. To rectify this, start by adjusting the height settings to ensure uniformity. Additionally, inspect the blades for sharpness and replace them if necessary. Finally, evaluate the terrain and make any necessary adjustments to maintain level ground.

Clogging and Debris Buildup

Another common challenge involves clogging and accumulation of debris, which can significantly impede performance. This often occurs when grass clippings and other materials obstruct the flow. To resolve this, regularly clean the underside of the cutting mechanism after use. Consider using a pressure washer for thorough cleaning, and ensure that the area remains free from excessive debris. Regular maintenance will help to prevent future blockages and maintain optimal efficiency.

Seasonal Care and Storage Guidelines

Proper maintenance and storage practices are essential to ensure the longevity and efficiency of your equipment. By following these guidelines, you can protect your investment and prepare your machinery for optimal performance in the upcoming seasons.

Maintenance Before Storage

Before placing your equipment in storage, it’s crucial to conduct a thorough inspection. Clean the exterior and remove any debris or grass clippings to prevent rust and deterioration. Check the fluid levels, including oil and fuel, and replace them if necessary. Sharpen or replace blades to ensure readiness for the next use.

Optimal Storage Conditions

Store your machinery in a cool, dry environment to avoid exposure to moisture and extreme temperatures. If possible, elevate the equipment off the ground to prevent contact with potential contaminants. Additionally, consider covering your equipment with a protective tarp or cover to shield it from dust and debris.