When it comes to maintaining outdoor machinery, having a clear understanding of its various elements is essential. Every unit comprises a multitude of interconnected sections, each playing a crucial role in its overall performance. Recognizing how these components fit together not only aids in troubleshooting but also streamlines the repair process.

In this section, we delve into the intricate assembly of your winter clearing device, providing valuable insights into each segment’s functionality. By examining the layout and relationships between these individual pieces, users can enhance their familiarity with the equipment, leading to more effective maintenance and longer lifespan.

Whether you are preparing for seasonal changes or addressing an unexpected issue, a comprehensive overview of the internal workings will empower you to make informed decisions. Understanding the configuration of these elements is the first step toward efficient operation and care.

Overview of the Snow Removal Equipment

This section provides an insight into a popular brand known for its robust machines designed for efficient winter maintenance. These devices are engineered to tackle the challenges posed by heavy snowfall, ensuring that driveways, walkways, and other surfaces remain clear and safe during winter months.

Key Features and Benefits

These machines often come equipped with powerful engines, advanced auger systems, and user-friendly controls, making them suitable for both residential and commercial use. Their durability ensures they can withstand harsh conditions while delivering optimal performance. Additionally, various models offer features such as adjustable chute angles and heated handles, enhancing user convenience.

Maintenance and Upkeep

Regular maintenance is essential for the longevity of these machines. This includes checking fluid levels, inspecting belts and cables, and ensuring that the auger and impeller are in good condition. Familiarity with the internal components can greatly assist in troubleshooting and repairs, making it easier to keep the equipment running smoothly throughout the winter season.

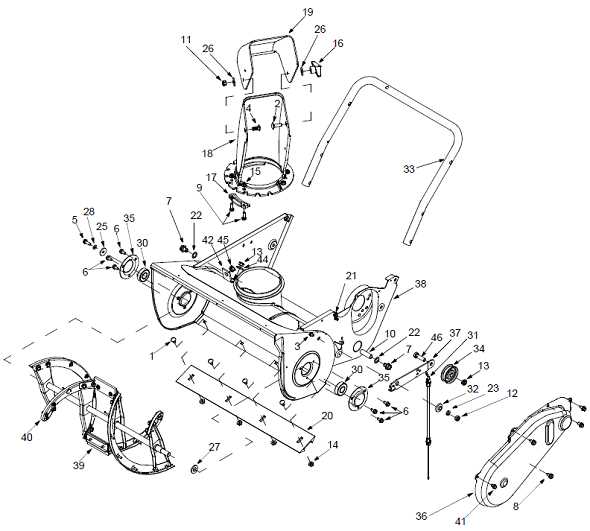

Importance of Snowblower Parts Diagram

Understanding the components of a snow-clearing machine is crucial for effective maintenance and repairs. A visual representation of these elements aids users in identifying each piece and its function, ensuring efficient troubleshooting and replacement when necessary.

Enhanced Maintenance

Having a clear overview of the machine’s assembly allows for better upkeep. It simplifies the process of inspecting individual components, ensuring that each part operates optimally, ultimately extending the lifespan of the equipment.

Efficient Repairs

A detailed illustration not only assists in locating faulty items but also provides insight into the assembly process. This knowledge empowers users to perform repairs confidently, reducing reliance on professional services and saving time and money.

Identifying Key Components of Snowblowers

Understanding the essential elements of a snow-clearing machine is crucial for effective maintenance and operation. Each part plays a significant role in ensuring optimal performance during harsh winter conditions. By recognizing these key components, operators can troubleshoot issues more efficiently and enhance the overall functionality of their equipment.

Major Elements

Among the primary components are the engine, which powers the unit, and the auger, responsible for gathering snow. The impeller then propels the collected snow out of the discharge chute. These interconnected parts work in harmony to clear pathways swiftly and effectively.

Maintenance and Care

Regular inspection of these crucial elements is essential for longevity and reliability. Lubrication of moving parts, replacement of worn-out components, and ensuring proper fuel quality are vital steps to maintain peak performance. Understanding how each section functions can help users address problems before they escalate.

Common Issues with Cub Cadet Models

When it comes to winter machines, users often encounter various challenges that can hinder performance and efficiency. Understanding these frequent problems can help in effective troubleshooting and maintenance, ensuring reliable operation during the snowy months.

Starting Difficulties

Many users report issues with ignition, which may stem from a variety of factors such as a weak battery, stale fuel, or dirty spark plugs. Regular checks and replacements can prevent these starting problems from arising.

Clogging and Inefficiency

Another prevalent issue is the accumulation of snow and debris in the chute, which can reduce efficiency and lead to operational frustration. Regular cleaning and inspection can mitigate this issue and ensure smooth performance.

How to Use Parts Diagrams Effectively

Understanding technical illustrations can greatly enhance your ability to repair and maintain machinery. These visual aids provide a clear representation of components, making it easier to identify parts and their functions. By leveraging these resources, you can streamline your repair process and avoid common pitfalls.

Identifying Components

The first step in utilizing these illustrations is to familiarize yourself with the various elements depicted. Pay attention to labels, numbers, and symbols that indicate the specific role of each item. This knowledge enables you to pinpoint the exact piece you need to replace or inspect.

Following Assembly Instructions

Once you have identified the necessary components, refer to the accompanying instructions for assembly or disassembly. These guides often include step-by-step procedures that correlate with the visual representation, ensuring that you can reassemble everything correctly. Keeping track of your progress through each stage can help prevent confusion.

| Step | Action |

|---|---|

| 1 | Review the illustration carefully. |

| 2 | Identify all required components. |

| 3 | Follow the assembly or disassembly steps. |

| 4 | Ensure all pieces are securely in place. |

Maintenance Tips for Snowblower Longevity

Proper upkeep is essential for ensuring your winter equipment remains efficient and durable throughout its lifespan. By following a few simple practices, you can enhance performance and extend the machine’s operational years.

- Regularly inspect and replace worn components to prevent breakdowns.

- Keep the blades sharp and free from debris for optimal snow clearing.

- Change the oil at recommended intervals to maintain engine health.

- Store the equipment in a dry place to avoid rust and corrosion.

- Check and adjust belts for proper tension and wear.

Implementing these strategies will not only improve efficiency but also save you money on repairs in the long run.

Where to Find Replacement Parts

Finding components for your equipment can be straightforward if you know where to look. Various resources are available, including online retailers, local dealers, and specialized forums, making it easier to locate what you need.

Online Retailers

Numerous websites offer a vast selection of components, often with detailed descriptions and images. Shopping online allows for easy price comparisons and access to user reviews.

Local Dealers

Your nearby dealership may carry an assortment of components and provide expert assistance. Establishing a relationship with local suppliers can lead to personalized support and quicker access to necessary items.

| Source Type | Benefits |

|---|---|

| Online Retailers | Wide selection, competitive pricing, customer reviews |

| Local Dealers | Personalized service, immediate availability, expert advice |

| Specialized Forums | Community support, shared experiences, advice on hard-to-find items |

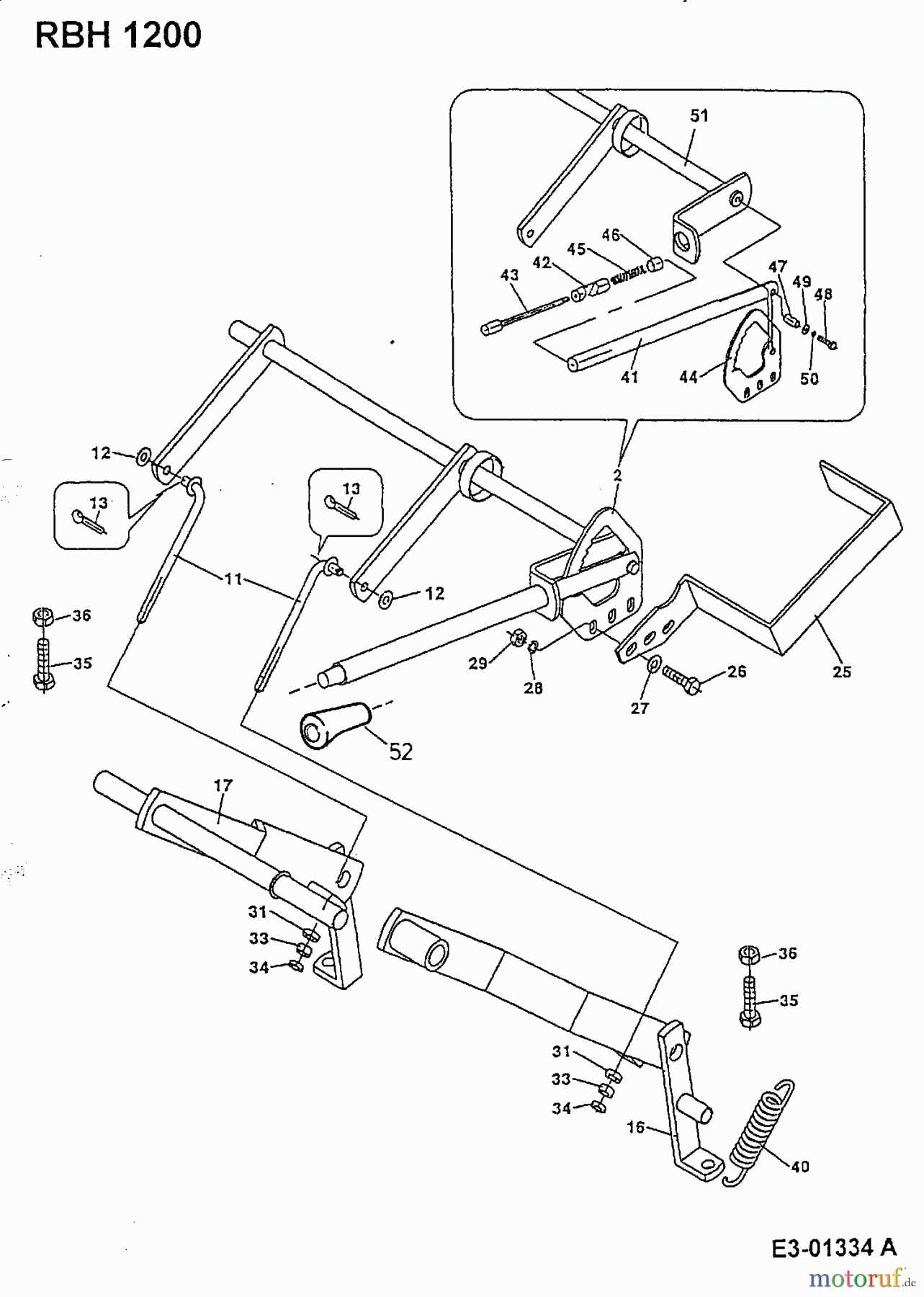

Understanding Assembly and Disassembly

Mastering the process of assembling and disassembling machinery is essential for efficient maintenance and repair. This section will guide you through the fundamental steps and considerations necessary for handling these tasks effectively, ensuring both safety and precision.

Key Considerations

- Familiarize yourself with the structure and function of each component.

- Gather the appropriate tools before beginning the process.

- Ensure a clean and organized workspace to prevent loss of small pieces.

Steps for Assembly

- Review the component layout to understand how each part interacts.

- Start by connecting larger elements before moving on to smaller components.

- Secure each piece tightly to avoid future malfunctions.

- Double-check connections to ensure everything is aligned correctly.

By following these guidelines, you can simplify the process and enhance the longevity of your equipment. Understanding these procedures is key to successful management and upkeep.