The efficiency and longevity of air pressure machinery heavily rely on the intricate relationships between their individual elements. A clear comprehension of these components is essential for both maintenance and effective operation. By exploring these various parts, users can enhance their knowledge and troubleshoot potential issues effectively.

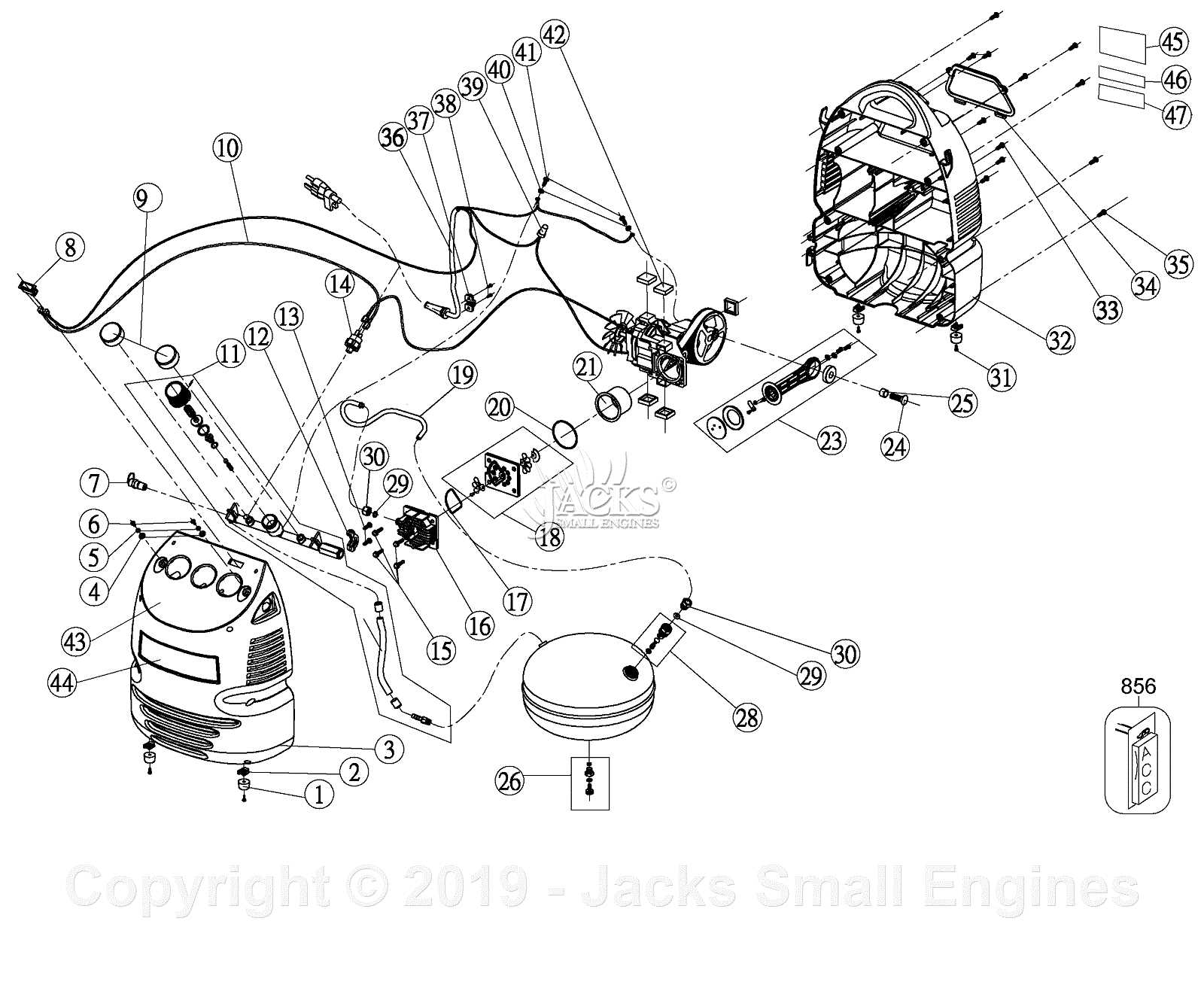

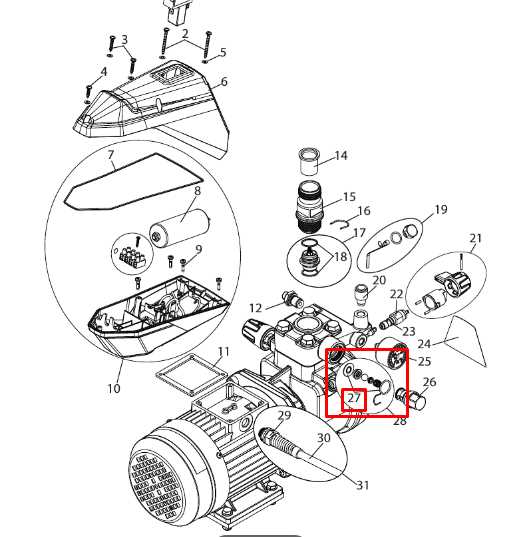

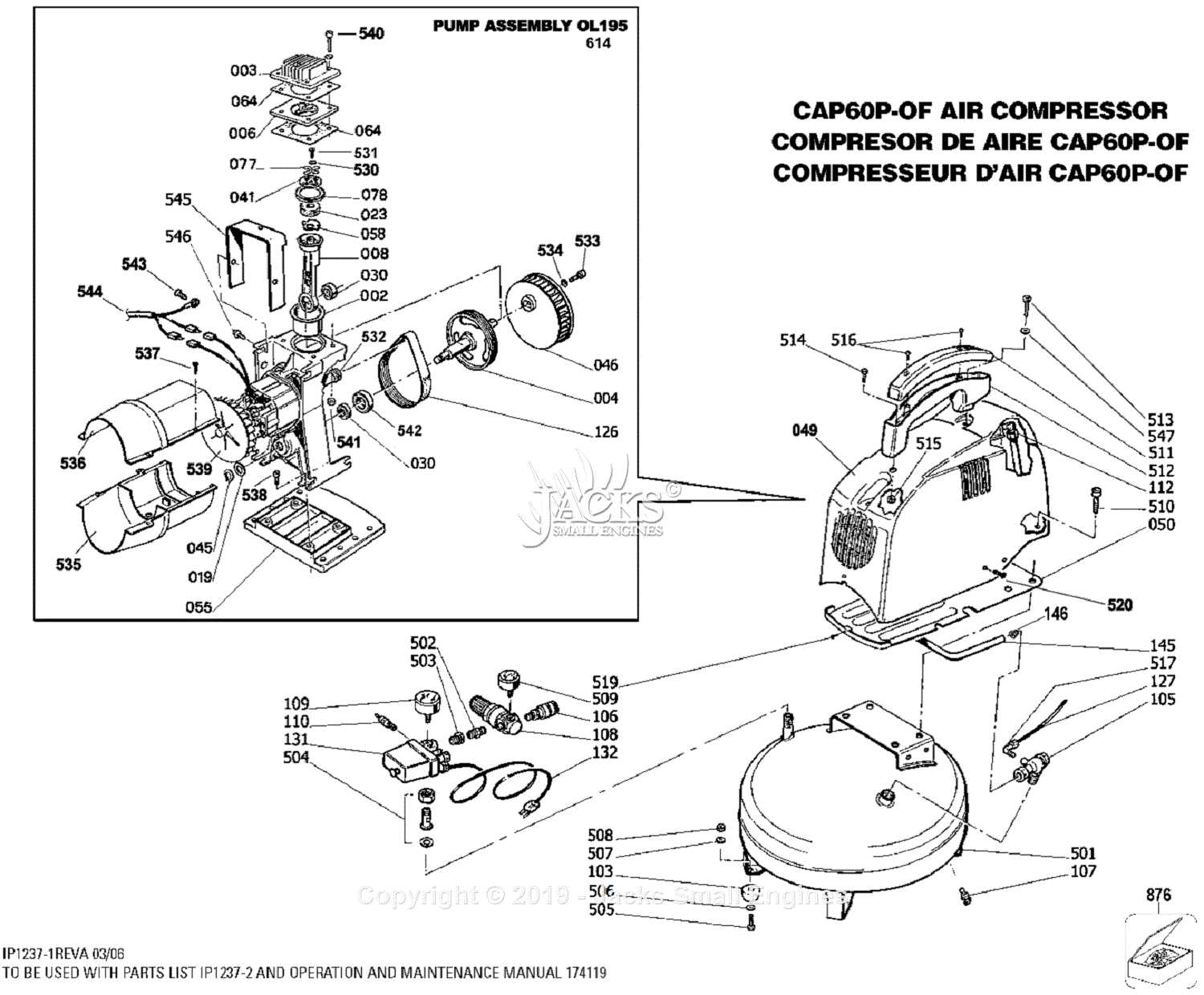

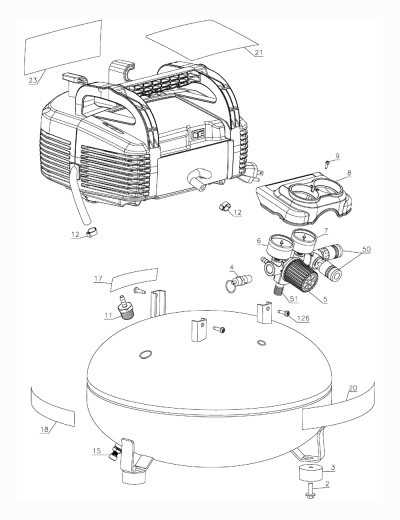

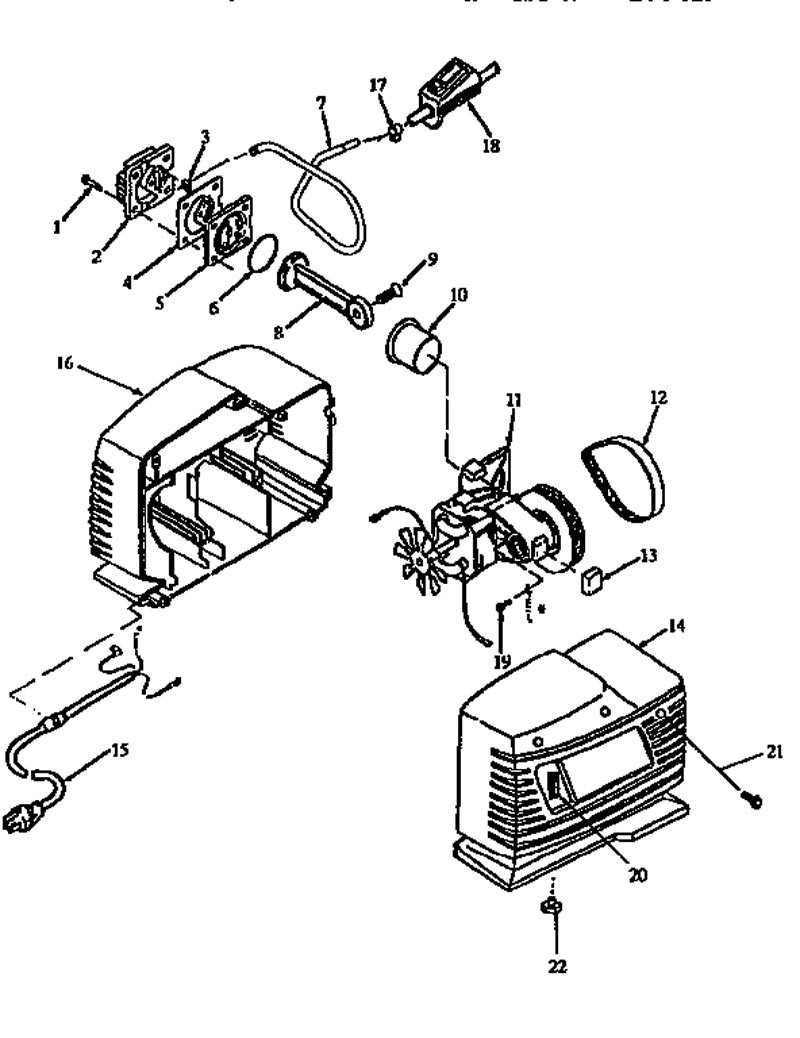

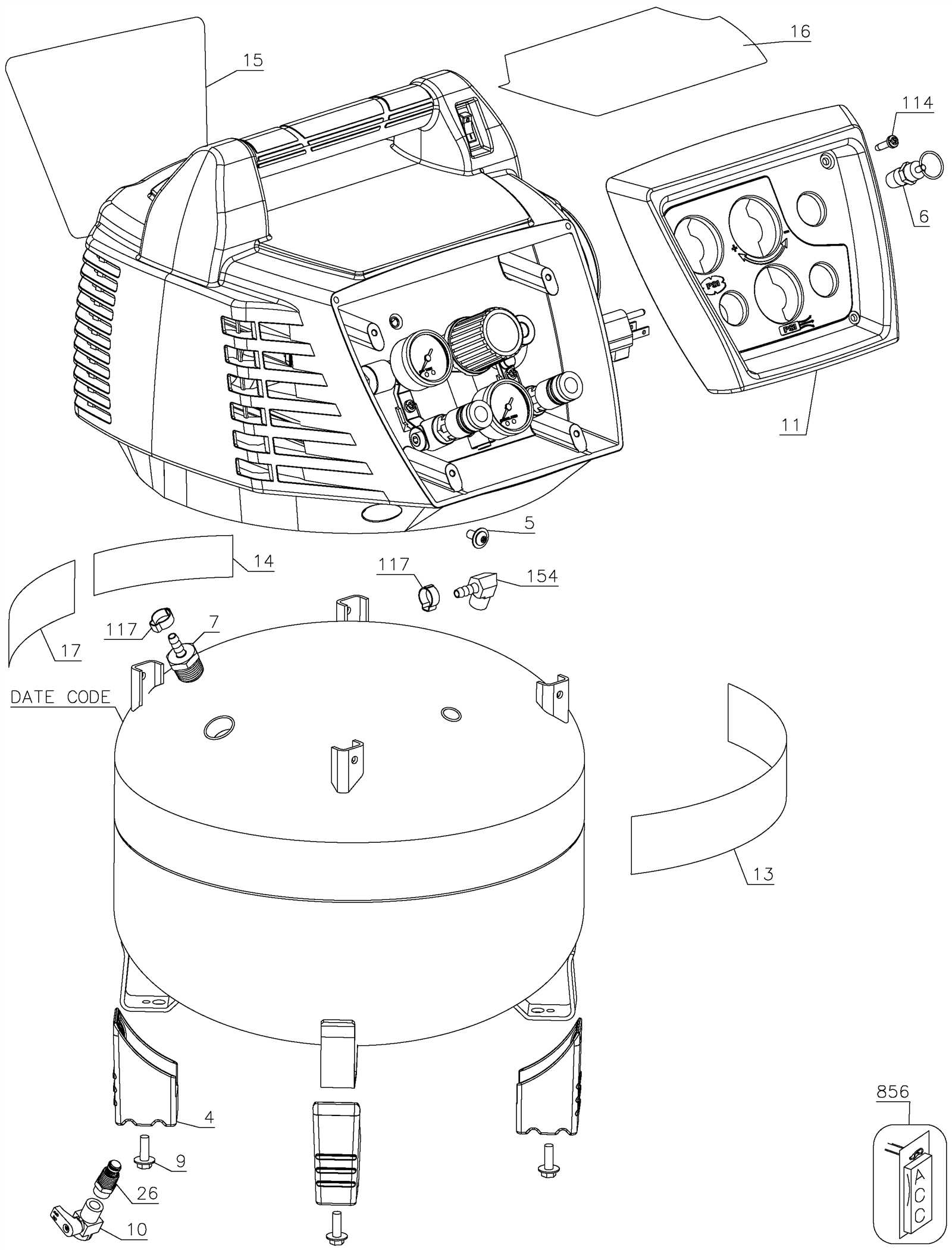

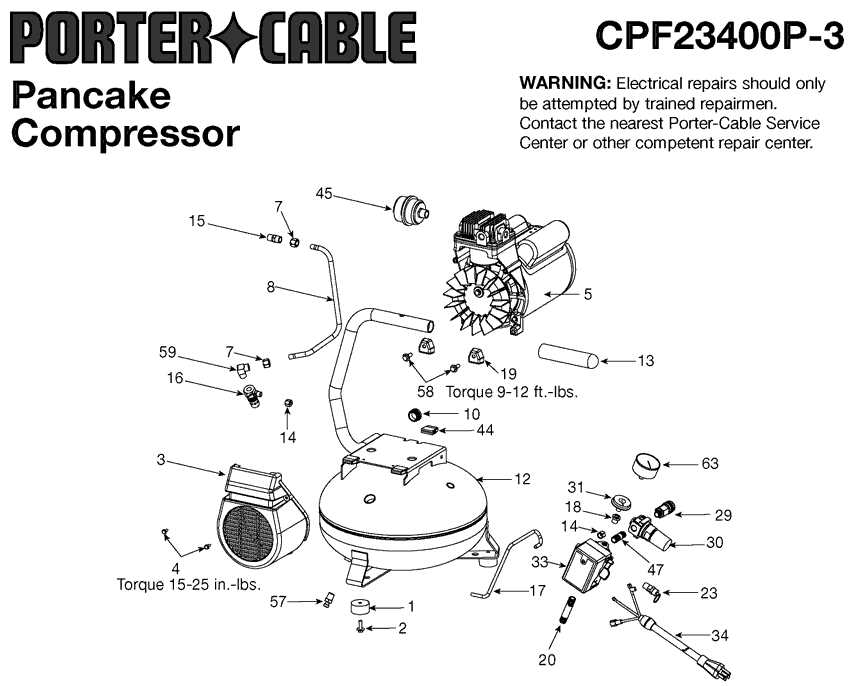

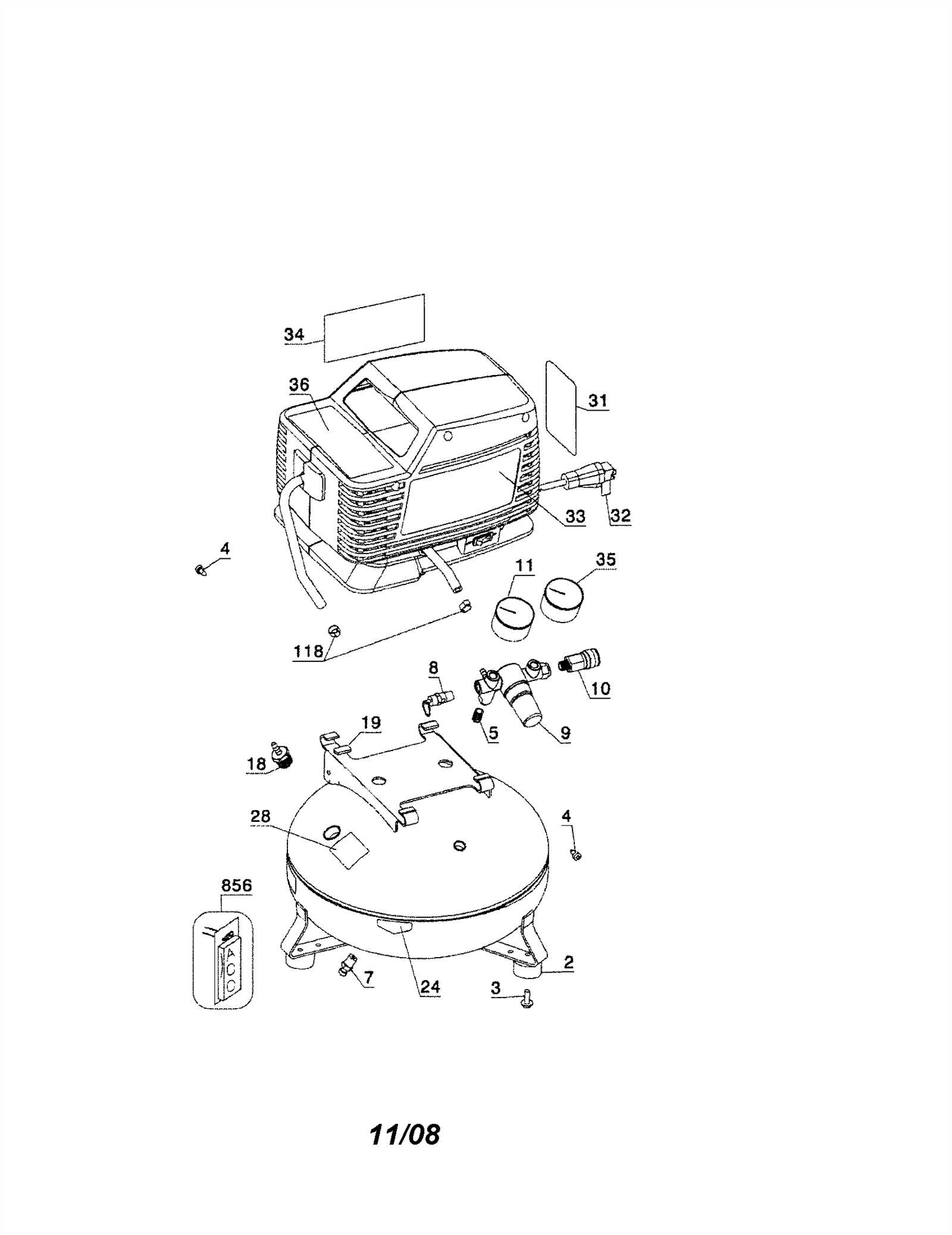

Visual aids play a crucial role in grasping how different segments interact within the system. A well-structured illustration serves as a roadmap, guiding users through each component’s function and positioning. This ultimately facilitates a deeper understanding of the equipment’s overall performance and capabilities.

Whether you are a seasoned professional or a newcomer, delving into the specifics of these assemblies will equip you with the insights necessary for optimizing functionality. Mastering the intricacies of air compression tools ensures not only enhanced productivity but also a safer working environment.

Understanding Porter Cable Pancake Compressors

Air storage devices designed for a variety of tasks offer efficiency and convenience, making them essential tools for both DIY enthusiasts and professionals. Their compact design and portability enhance their usability, allowing users to tackle various projects with ease. This section explores the fundamental aspects of these units, focusing on their functionality, components, and maintenance considerations.

Key Features and Benefits

These compact air units are known for their lightweight structure and quick recovery times. They are ideal for powering air tools, inflating tires, and more. Users appreciate their ability to deliver consistent airflow and pressure, which is critical for achieving optimal results in different applications.

Maintenance and Care

Regular upkeep is vital to ensure longevity and performance. Proper cleaning and periodic inspections help prevent issues that may arise from wear and tear. Understanding the essential elements involved in their operation can facilitate better maintenance practices.

| Component | Function |

|---|---|

| Tank | Stores compressed air for various applications |

| Motor | Powers the compression process |

| Regulator | Controls the output pressure |

| Pressure Gauge | Indicates current pressure levels |

Key Components of the Compressor

The functionality of a pressure generator relies on several essential elements that work in unison. Understanding these components helps users maintain efficiency and performance while ensuring longevity in operation. Each part plays a unique role in the overall mechanism, contributing to effective air compression and delivery.

Main Elements

Here are the primary components commonly found in most air pressure devices:

| Component | Description |

|---|---|

| Motor | Powers the unit, converting electrical energy into mechanical energy to compress air. |

| Tank | Stores compressed air, allowing for a steady supply during operation. |

| Regulator | Controls the output pressure, ensuring that air is delivered at the desired level. |

| Pressure Switch | Automatically turns the motor on and off to maintain the preset pressure in the tank. |

| Air Filter | Prevents contaminants from entering the system, ensuring clean air output. |

Additional Features

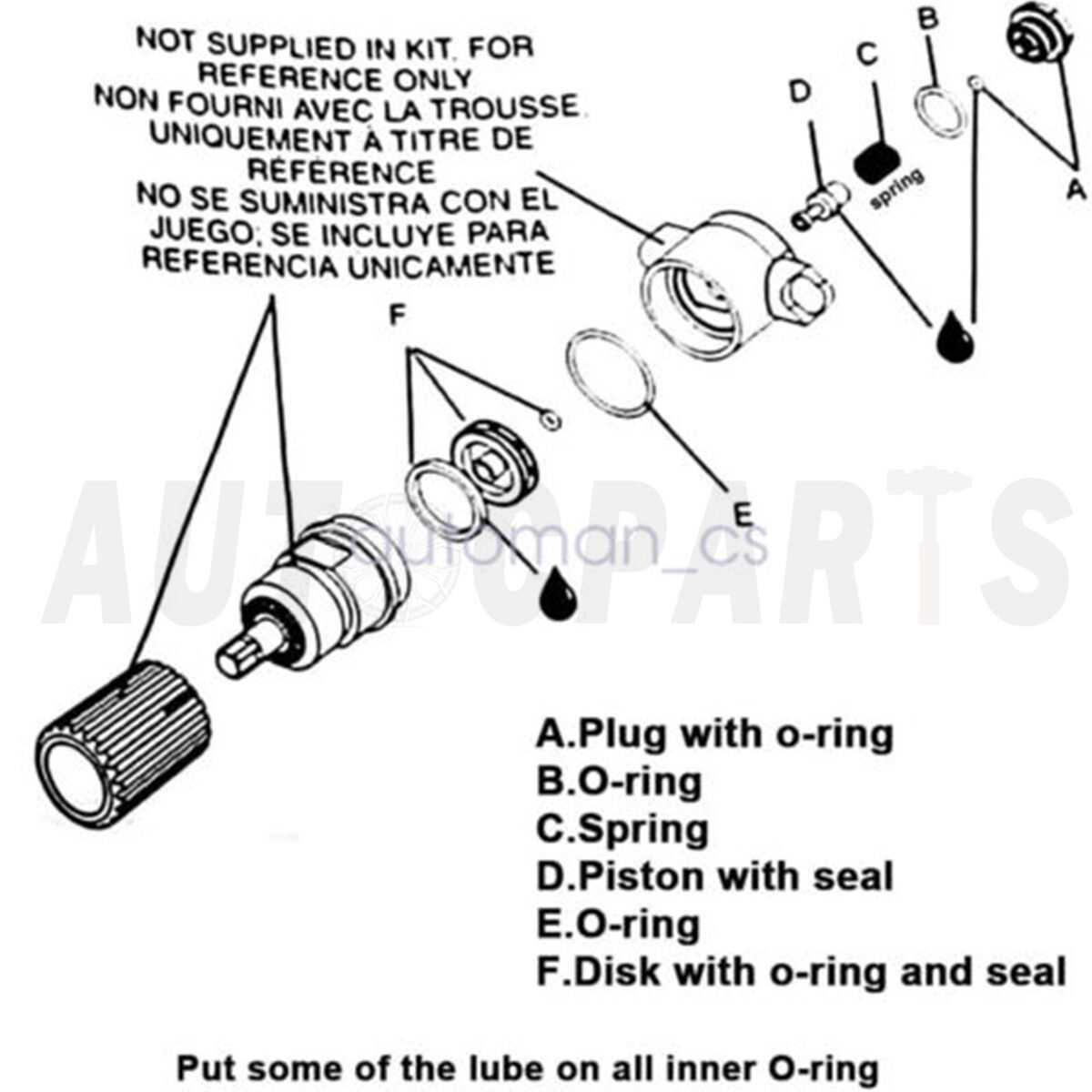

Besides the primary elements, there are various auxiliary features that enhance performance. These may include safety valves, quick-connect fittings, and drain valves, each contributing to the overall efficiency and safety of the operation. Familiarity with these features can help users optimize usage and troubleshooting.

Importance of Each Part Explained

Understanding the significance of each component within a system is essential for optimal functionality and longevity. Each element plays a specific role, contributing to overall performance and efficiency. A detailed examination of these components reveals how they work in harmony to achieve desired results.

Key Components Overview

Every segment within the assembly serves a vital function. Recognizing how these elements interact can enhance maintenance practices and troubleshooting efforts. Below is a breakdown of major components and their responsibilities:

| Component | Function |

|---|---|

| Motor | Drives the system, providing the necessary power to operate. |

| Tank | Holds compressed air, ensuring a steady supply during operation. |

| Regulator | Controls the pressure output, maintaining consistent performance. |

| Gauge | Displays current pressure levels, aiding in monitoring and adjustments. |

| Safety Valve | Prevents overpressure situations, ensuring user safety and equipment integrity. |

Conclusion

Each element of the assembly is crucial for maintaining efficiency and safety. By understanding their roles, users can ensure proper care and enhance the system’s performance.

Common Issues with Compressor Parts

In the realm of air pressurizing devices, various challenges can arise that impact performance and efficiency. Understanding these frequent concerns can aid in proper maintenance and timely repairs, ensuring longevity and reliability.

Leaks are one of the most prevalent issues, often caused by worn-out seals or damaged fittings. These can lead to significant drops in pressure, resulting in reduced functionality.

Overheating is another common problem, typically stemming from insufficient airflow or clogged filters. This can cause components to fail prematurely, leading to costly repairs.

Noise levels can also indicate underlying troubles. Unusual sounds might suggest loose elements or internal wear, necessitating immediate attention to prevent further damage.

Electrical issues, such as tripped breakers or faulty switches, can disrupt operation and should be addressed promptly to avoid hazardous situations.

Regular inspection and maintenance can help identify these challenges early, ensuring optimal performance and extending the life of the equipment.

How to Maintain Your Compressor

Proper upkeep of your air apparatus is essential for optimal performance and longevity. Regular maintenance not only enhances efficiency but also minimizes the risk of unexpected breakdowns. By following a few key practices, you can ensure that your equipment remains in excellent working condition for years to come.

Regular Inspections

Conduct routine checks to identify any signs of wear or damage. Look for leaks, corrosion, and loose connections. Paying attention to these details can prevent minor issues from escalating into significant problems. Additionally, verify that all components are securely fastened and functioning correctly.

Keep It Clean

Cleaning your device regularly is crucial. Dust and debris can accumulate, hindering performance. Use a soft cloth to wipe down exterior surfaces, and ensure that intake vents are free from obstruction. Emphasizing cleanliness helps maintain airflow and prevents overheating.

Following these simple steps will greatly enhance the reliability and efficiency of your air machinery. By being proactive in your maintenance efforts, you can extend the life of your equipment and improve its overall functionality.

Tools Needed for Repairs

When undertaking maintenance or fixing equipment, having the right instruments is crucial for a successful outcome. Proper tools not only facilitate the repair process but also enhance safety and efficiency.

Essential instruments include a reliable wrench set for loosening and tightening fasteners, screwdrivers for removing or securing screws, and a multimeter to check electrical components. Additionally, air hoses and fittings might be necessary to ensure proper airflow during operation.

Investing in high-quality tools can make a significant difference, allowing for seamless repairs and extending the lifespan of your equipment. Always ensure that your toolkit is complete before starting any maintenance work.

Finding Replacement Parts Easily

Locating components for your equipment can be a straightforward process if you know where to look. Understanding the structure of your machinery and the specific elements you need can save you time and frustration. This section provides insights on how to efficiently identify and procure the necessary items for maintenance and repair.

Start by consulting the user manual that accompanies your device. Manuals typically include detailed illustrations and lists of components, making it easier to identify what you need. Additionally, many manufacturers have online resources where you can access diagrams and parts lists.

| Resource Type | Description |

|---|---|

| User Manual | Contains illustrations and specifications of various components. |

| Manufacturer Website | Offers downloadable diagrams and lists of components. |

| Online Retailers | Provide a wide selection of components along with compatibility information. |

| Forums and Communities | Connect with other users who can share experiences and recommendations. |

Utilizing these resources effectively can enhance your ability to find the right components, ensuring your equipment operates smoothly and efficiently.

Using the Parts Diagram Effectively

Understanding the intricate layout of components in any machinery is essential for both maintenance and troubleshooting. A visual representation can greatly aid users in identifying parts, facilitating repairs, and ensuring optimal performance. By leveraging this visual tool, users can enhance their efficiency and minimize downtime.

Identifying Key Components

Start by familiarizing yourself with the main sections of the visual representation. Focus on labeling to understand which parts correspond to various functions. This knowledge allows you to quickly locate any component that may require attention or replacement. Moreover, a clear grasp of the assembly helps prevent mistakes during reassembly.

Streamlining Repairs and Maintenance

Utilizing a visual aid simplifies the process of performing repairs. By referencing the layout, you can ensure that all necessary tools and components are at hand before starting your work. This organized approach not only saves time but also reduces frustration during maintenance tasks. Additionally, it can enhance your confidence in addressing issues as they arise.

Upgrading Your Compressor Parts

Enhancing the components of your air equipment can significantly improve its performance and longevity. By investing in high-quality replacements, you can ensure more efficient operation and reduce downtime.

- Identify the areas that require improvement.

- Research compatible components that offer better efficiency.

- Consider upgrades that enhance durability and reduce wear.

Prioritize the following upgrades for optimal results:

- Air filters for improved airflow.

- Regulators for precise pressure control.

- Hoses with better flexibility and strength.

Regular maintenance paired with thoughtful enhancements can lead to the ultimate performance of your equipment.