When it comes to maintaining outdoor machinery, having a clear understanding of its various components is essential for optimal performance and longevity. This section aims to provide a detailed overview of the critical elements that make up your tool, highlighting their functions and how they contribute to overall efficiency.

Recognizing each component’s role not only aids in troubleshooting common issues but also empowers users to perform necessary repairs and upgrades with confidence. By familiarizing yourself with the intricate relationships between these parts, you can ensure that your device remains in peak condition for all your landscaping tasks.

In the following sections, we will explore an illustrative representation of these components, offering insights into their configuration and maintenance. This knowledge will be invaluable whether you’re an experienced user or a newcomer to the world of outdoor equipment.

Poulan Pro 25cc Pole Saw Overview

This section provides a comprehensive look at a versatile tool designed for efficient trimming and cutting. Ideal for both residential and professional use, this equipment combines power and portability, making it an excellent choice for maintaining trees and shrubs.

Key Features

- Lightweight design for easy maneuverability

- Robust engine for reliable performance

- Adjustable length to reach high branches

- User-friendly controls for enhanced handling

- Durable construction for long-lasting use

Benefits of Use

- Increased efficiency in yard maintenance tasks

- Enhanced safety features for user protection

- Ability to handle various types of vegetation

- Reduced fatigue during extended use

- Cost-effective solution for tree care

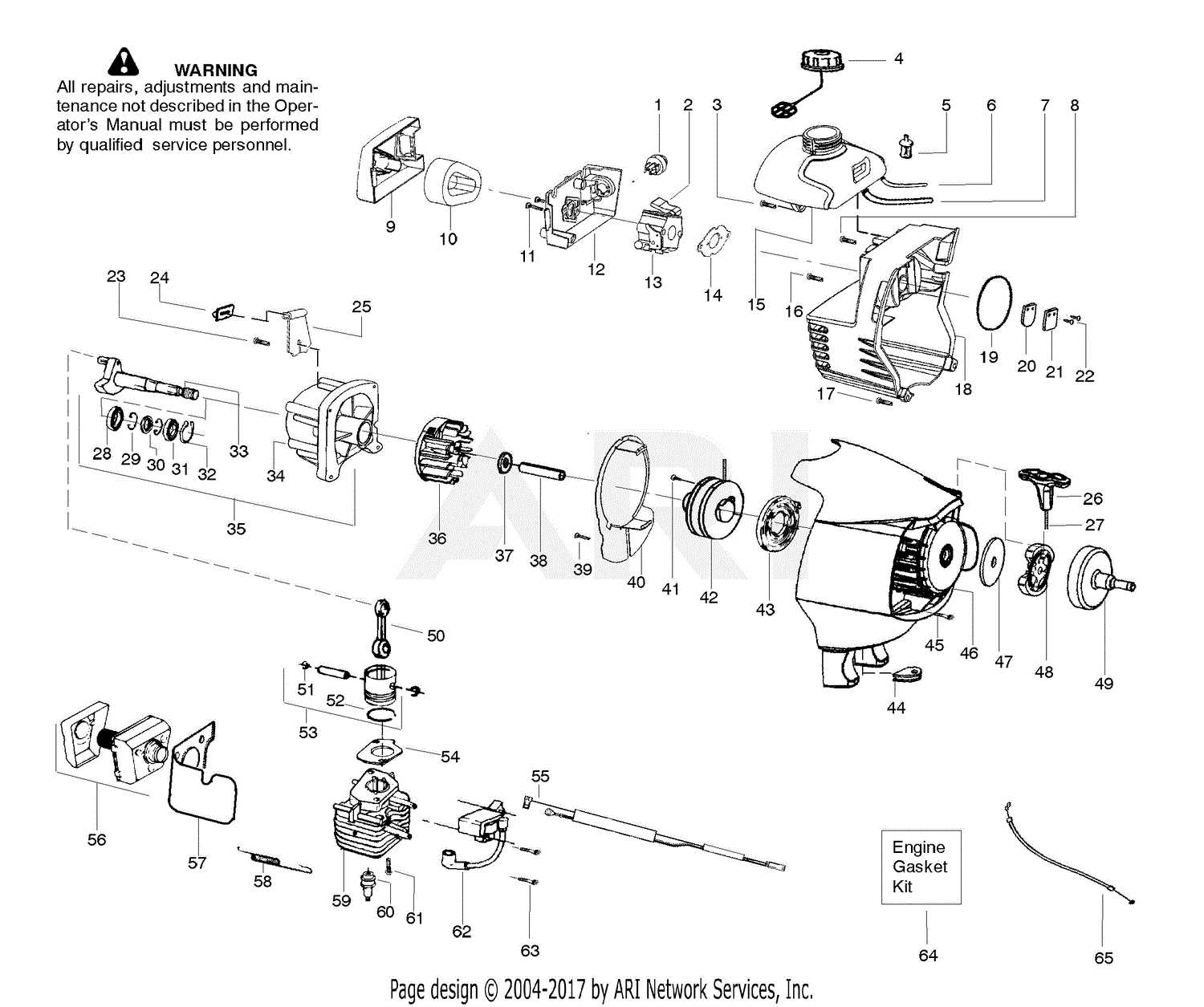

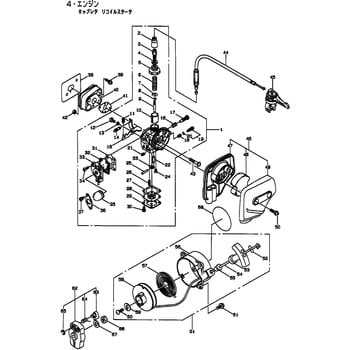

Understanding the Parts Diagram

The illustration of components is a crucial resource for anyone looking to comprehend the assembly of a specific tool. It provides a visual reference that simplifies the identification and function of each element within the machine. Familiarizing oneself with this visual guide can enhance maintenance efforts and facilitate repairs, ultimately extending the lifespan of the equipment.

Key Components and Their Functions

Each segment shown in the visual representation has a unique role in the overall operation of the device. Recognizing these individual functions allows users to troubleshoot effectively when issues arise. For instance, some parts contribute to the power transmission, while others are essential for safety mechanisms. Understanding these distinctions is vital for both novice and experienced operators.

Navigating the Visual Reference

When examining the visual guide, it is important to pay attention to the labels and numbers associated with each component. This notation not only aids in identifying parts during replacement but also assists in ensuring that all necessary tools are available for service. A systematic approach to this resource can greatly streamline the repair process.

Key Components of the Pole Saw

The efficiency of a cutting tool relies heavily on its essential elements, each serving a unique function to enhance performance and ease of use. Understanding these crucial components can help users appreciate the tool’s design and maximize its potential in various tasks.

Motor and Drive System

The motor is the powerhouse, providing the necessary energy to drive the blade. Coupled with the drive system, it ensures seamless power transfer, enabling smooth cutting action. The design and specifications of these parts directly influence the overall strength and longevity of the equipment.

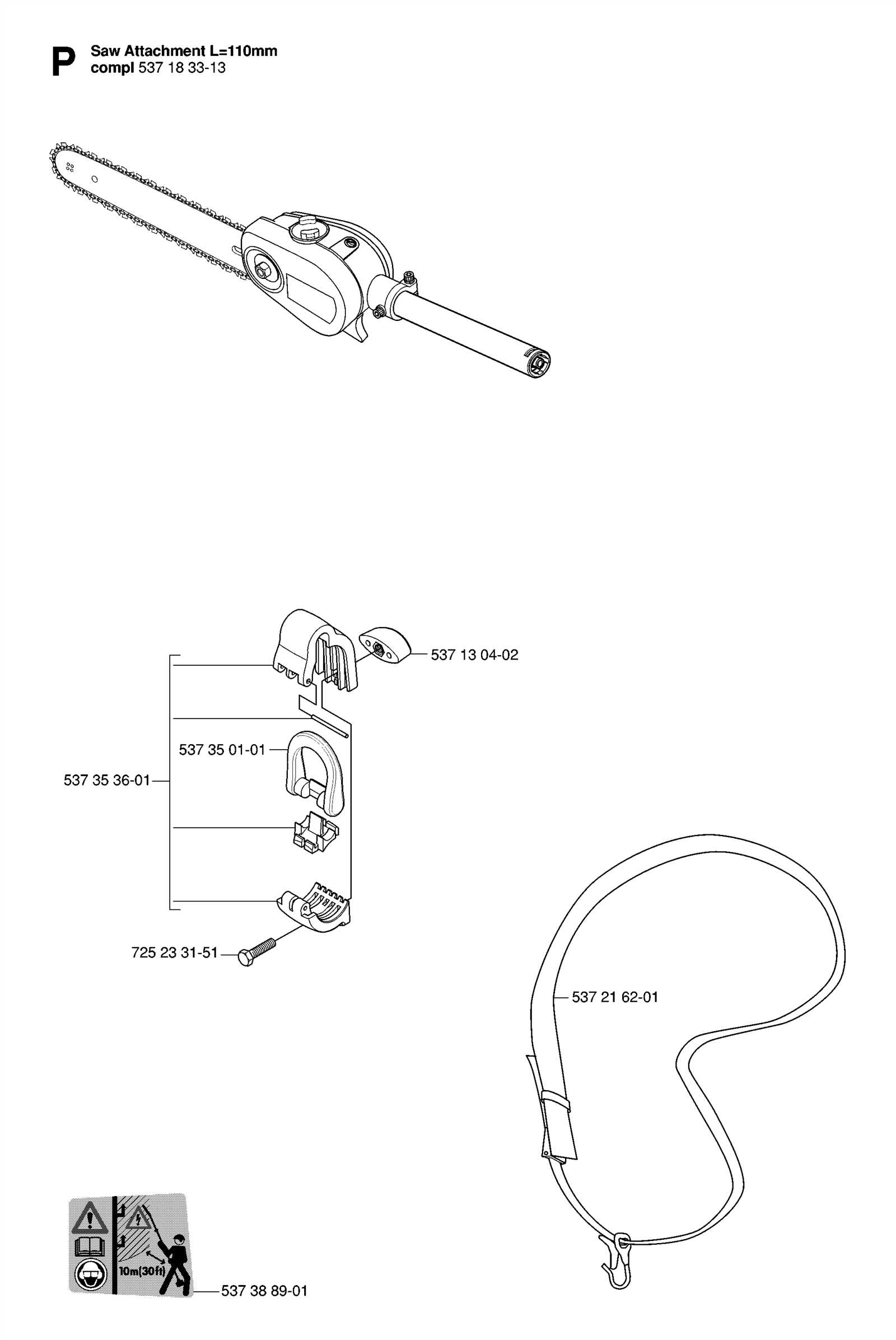

Cutting Mechanism

The cutting mechanism consists of the blade and its attachment system, crucial for achieving precise cuts. Different blade types cater to various applications, while an efficient attachment system allows for quick replacements, enhancing versatility in use.

Maintenance Tips for Longevity

Regular upkeep is essential for extending the lifespan of your equipment. By following a few simple practices, you can ensure that it continues to operate smoothly and efficiently, reducing the need for repairs and replacements. This not only saves you money but also enhances your overall experience when using your tools.

Routine Cleaning

Keeping your equipment clean is crucial. After each use, remove debris and residues that can cause wear and tear. Use a soft brush or cloth to clean the exterior, and ensure that all moving parts are free from dirt and grime. Regular cleaning helps prevent corrosion and prolongs the functionality of your device.

Proper Storage

Storing your tools correctly can significantly impact their longevity. Always place them in a dry, sheltered area away from extreme temperatures and moisture. Use protective covers if available, and ensure that they are not stacked in a way that could cause damage. Proper storage practices contribute to maintaining optimal performance over time.

Common Issues and Troubleshooting

When using outdoor power equipment, users may encounter a range of common problems that can hinder performance. Understanding these issues and knowing how to address them can significantly enhance the efficiency and longevity of your tool. This section provides insights into frequent malfunctions and practical solutions to keep your equipment running smoothly.

Engine Performance Problems

One of the most prevalent issues is engine performance inconsistency. Symptoms may include difficulty starting, stalling during operation, or reduced power output. These problems can often be traced back to fuel quality or contamination. Regularly check the fuel mixture and ensure that you are using fresh, clean fuel. Additionally, inspect the air filter for clogs, as restricted airflow can lead to suboptimal engine function.

Cutting Efficiency Issues

Another common concern is ineffective cutting, which can stem from dull or damaged cutting tools. If you notice that your equipment struggles to cut through materials or requires excessive effort, it may be time to sharpen or replace the cutting components. Also, ensure that all attachments are securely fastened, as loose parts can contribute to poor performance. Regular maintenance and inspection will help maintain optimal cutting efficiency.

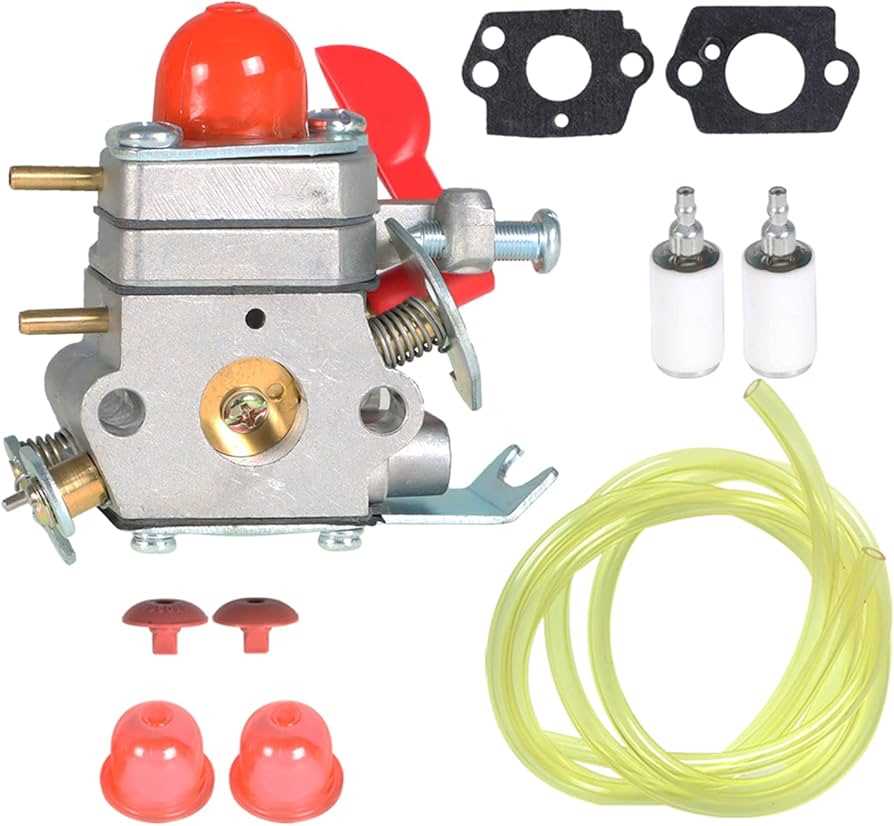

Replacement Parts Availability and Options

When it comes to maintaining outdoor equipment, ensuring access to suitable components is essential for optimal performance and longevity. Availability of replacement items can significantly influence the efficiency of repairs and upkeep, allowing users to easily find what they need to restore functionality.

Various avenues exist for sourcing these components, ranging from authorized retailers to online marketplaces. Users can explore manufacturer websites for direct purchases, where they can find original components that guarantee compatibility. Additionally, third-party suppliers often offer alternatives that may provide a cost-effective solution without sacrificing quality.

It is advisable to consider factors such as warranty, durability, and customer reviews when selecting components. By weighing these elements, individuals can make informed decisions that best suit their needs and ensure the longevity of their equipment.

Tools Needed for Repairs

When it comes to maintaining and fixing your outdoor equipment, having the right instruments at your disposal is essential. Proper tools not only facilitate the repair process but also ensure that the job is done effectively and safely. Being well-equipped can save you time and frustration during your maintenance tasks.

Essential tools include wrenches and screwdrivers, which are crucial for loosening and tightening various components. Additionally, a socket set can provide greater leverage and access to hard-to-reach areas. Cutting tools, such as shears or utility knives, may also be necessary for any adjustments or modifications.

Don’t forget about safety equipment. Protective gloves and eyewear are vital for safeguarding yourself from potential hazards while working. A sturdy workbench can also provide a stable surface, making it easier to handle parts and tools.

By gathering these necessary implements, you can approach your repair tasks with confidence, ensuring that your equipment remains in optimal condition for years to come.

Assembly Instructions for Beginners

Understanding how to put together equipment can seem daunting at first, but with clear guidance, anyone can achieve it successfully. This section provides straightforward steps to assist newcomers in assembling their tools efficiently and safely.

Essential Tools Needed

- Screwdriver

- Wrench

- Safety glasses

- Work gloves

Step-by-Step Assembly Process

- Begin by laying out all components on a flat surface for easy access.

- Refer to the user manual for specific assembly instructions.

- Attach the main body and secure it with screws using a screwdriver.

- Connect any additional sections, ensuring all parts fit snugly.

- Double-check all connections for stability and safety.

- Perform a final inspection before use, confirming everything is properly assembled.