Understanding how various mechanical elements are organized and interconnected is crucial for maintaining and servicing complex machinery. Every piece has a specific role, and knowing where each element fits within the larger system ensures smoother operations and quicker repairs.

In this section, we will explore the detailed arrangement of various technical components, offering a clear and structured breakdown. Whether you’re performing routine maintenance or addressing an issue, having a clear understanding of how everything is connected will greatly enhance your efficiency.

Identifying key sections and visualizing their positioning can prevent costly errors and unnecessary delays. This guide is designed to help you familiarize yourself with the overall configuration, making it easier to tackle

Comprehensive Overview of John Deere Z915B Components

The following section provides a detailed analysis of the core elements that make up this particular machinery model. Understanding how each component interacts within the system is essential for proper maintenance and efficient operation. This overview highlights key features of the equipment’s design, focusing on the mechanical structures and functional assemblies that drive its performance.

Below is a table summarizing the primary systems and their respective functions:

| Component | Function |

|---|---|

| Engine Assembly | Powers the equipment, delivering the necessary force for all operations. |

| Transmission System | Transfers power from the engine to the wheels, ensuring

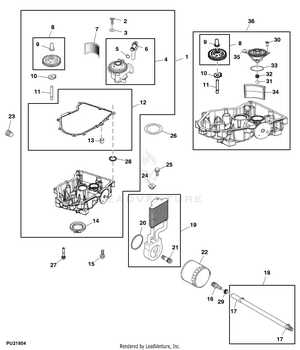

Exploring Key Engine Parts and Functionality

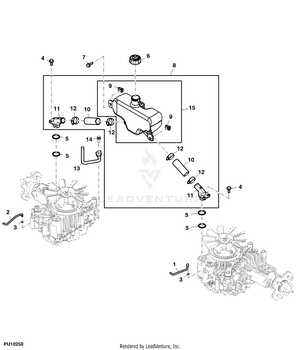

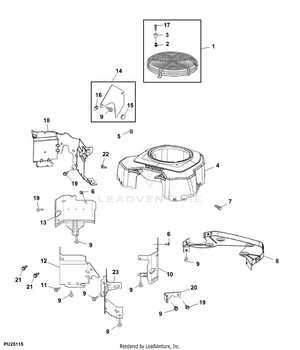

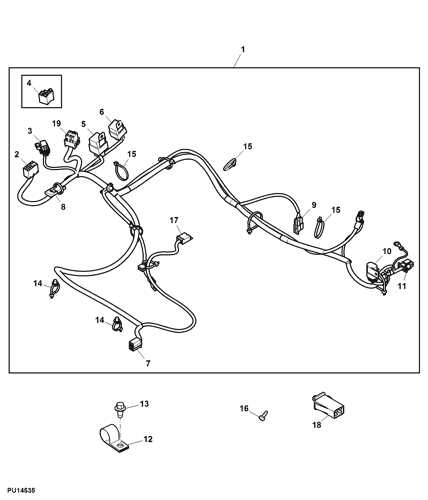

Understanding the essential elements of an engine and how they interact is crucial for maintaining and optimizing performance. Each component plays a unique role in ensuring smooth operation and efficiency. By examining the core mechanical elements, we can better appreciate the intricate balance between power generation, control, and overall functionality. Engine Block and Cylinders form the foundation of any motor. The block houses the cylinders where combustion occurs, converting fuel into mechanical energy. The precision and durability of these components are vital for stable performance over time. Pistons and Crankshaft work together to translate the force Understanding the Electrical System LayoutThe electrical system is a critical component that ensures the smooth operation of various functions. It integrates a variety of wiring, circuits, and connectors to provide power and control to essential mechanisms. Understanding its structure can help in troubleshooting and maintaining the system effectively. Main Power Distribution

The primary power source is distributed through a network of wires and relays, connecting to key areas of the equipment. This ensures that all components receive the necessary electricity for efficient performance. By understanding how the power is routed, you can quickly identify potential issues and address them before they cause more significant problems. Control Circuits and SensorsVarious control circuits manage different functions, from engine ignition to operational sensors. These circuits play a crucial role in monitoring and adjusting performance based on real-time conditions. Familiarity with Guide to the Cutting Deck Mechanism

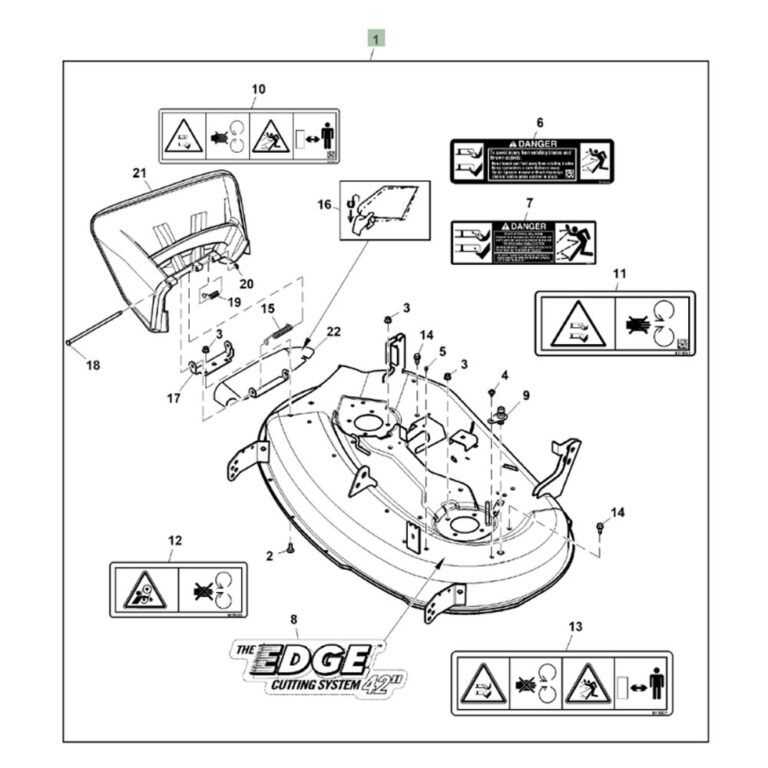

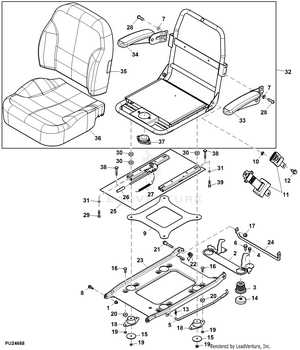

The cutting deck is a crucial component responsible for efficient and precise trimming of grass. Understanding its mechanism is essential for maintaining optimal performance and ensuring a smooth operation. In this section, we will explore the structure, functionality, and key aspects of maintaining this vital system, focusing on its role in delivering clean and even cuts. The cutting deck operates through a series of interconnected elements, including blades, belts, and pulleys. These parts work in harmony to deliver the desired results, with the blades doing the actual trimming, while the belts transfer the power necessary for the system to function. Ensuring that these components are regularly inspected and properly adjusted is vital to preventing uneven cuts and ensuring consistent performance. Maintenance of the cutting deck involves routine cleaning, sharpening of the blades, and checking the alignment of key parts. Regularly removing debris and buildup helps prevent potential damage and enhances the longevity of the mechanism. Proper care ensures not only a smooth and efficient operation but also a longer lifespan of the Steering and Control Assembly BreakdownThe steering and control assembly plays a vital role in ensuring smooth operation and handling. Understanding the layout and the interaction between its components is key to maintaining precision and responsiveness. This section provides a clear breakdown of the main elements involved, offering insights into the inner workings of the system. Main Control Mechanisms

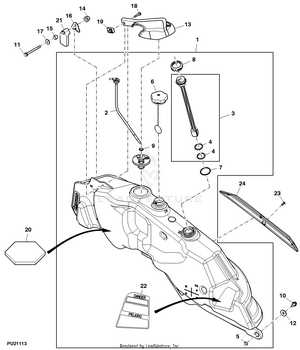

The primary control mechanisms are designed to ensure accurate steering and efficient management of directional changes. These include various levers, rods, and connectors that work together to provide seamless control over movement. Each component is interconnected to create a cohesive unit that responds instantly to user inputs. Key Steering ComponentsThe steering setup consists of several essential parts, such as linkages, pivots, and control arms. These elements are designed to distribute force evenly across the assembly, allowing for balanced and reliable navigation. Proper alignment and maintenance of these components are crucial for ensuring optimal performance and longevity. Analyzing the Fuel System ComponentsIn this section, we will explore the essential elements of the fuel delivery mechanism in small engine machinery. These components work together to ensure the proper flow and regulation of fuel, providing the power needed for efficient operation. Understanding how each part contributes to the system’s functionality is crucial for maintenance and troubleshooting. Key Components of the Fuel Delivery Mechanism

Proper Maintenance for Optimal Performance

Maintaining the fuel system is vital for the overall performance of the machinery. Regular inspection and cleaning of components like the fuel filter, fuel lines, and carburetor can prevent blockages and ensure smooth fuel flow. Additionally, replacing worn-out parts before they fail can save time and costly repairs in the long run. Drive System and Transmission Structure

The drive system and transmission structure play a crucial role in ensuring smooth operation and optimal performance of the machinery. These components work together to transfer power from the engine to the wheels or other operational mechanisms. The design of these systems is fundamental to maintaining the efficiency, durability, and responsiveness of the equipment during use. Power Transfer Mechanisms in the drive system typically involve a series of gears, pulleys, and belts that regulate the distribution of energy. The transmission helps in adjusting the speed and torque, enabling the vehicle to handle various operational demands, such as starting, stopping, or changing directions smoothly. Each part of the transmission system is designed to withstand significant stress and wear while offering minimal maintenance needs. Proper integration of these components ensures a well-functioning drive system capable of handling various terrains and conditions without compromising performance. Maintenance Essentials for the Hydraulic System

Proper upkeep of the hydraulic system is crucial to ensure smooth operation and longevity of your machinery. Regular inspection and maintenance of key components help avoid unexpected breakdowns, enhance efficiency, and prevent costly repairs. Focusing on fluid levels, filters, and connections is essential for optimal performance. Fluid Level and Quality CheckMaintaining the correct hydraulic fluid level is the first step in preserving system integrity. Low or contaminated fluid can lead to poor performance or system failure. Regularly check the fluid level and replace it if it shows signs of contamination, such as discoloration or the presence of particles. Use the manufacturer-recommended fluid to ensure compatibility and proper function. Inspecting Hoses and ConnectionsLeaking hoses or loose connections can significantly affect the hydraulic system’s performance. Regularly inspect all hydraulic lines for signs of wear, leaks, or cracks. Tighten any loose connections and replace damaged hoses to prevent system failures. Proper hose maintenance ensures that pressure is maintained, and components operate smoothly. Commonly Replaced Parts and Their LocationsIn any mechanical system, certain components are more likely to require replacement due to wear, environmental factors, or regular use. Understanding where these frequently changed elements are located can save time and effort during maintenance tasks. By knowing which parts are prone to failure, owners can take proactive measures to ensure their equipment remains operational. Critical Components in the Engine AreaThe engine is the heart of the machine, and several key components within this area often need replacing. Commonly, the air filter, spark plugs, and fuel lines are subject to wear and tear. These parts are easily accessible in the engine compartment and should be checked regularly for signs of damage or clogging. Wear-Prone Parts in the Drive and Cutting MechanismIn addition to the engine, the drive system and cutting mechanism experience high stress and can wear out quickly. Components like belts, blades, and pulleys are typically replaced after prolonged use. These parts are strategically positioned to ensure smooth operation, but their constant exposure to friction makes them susceptible to degradation. |