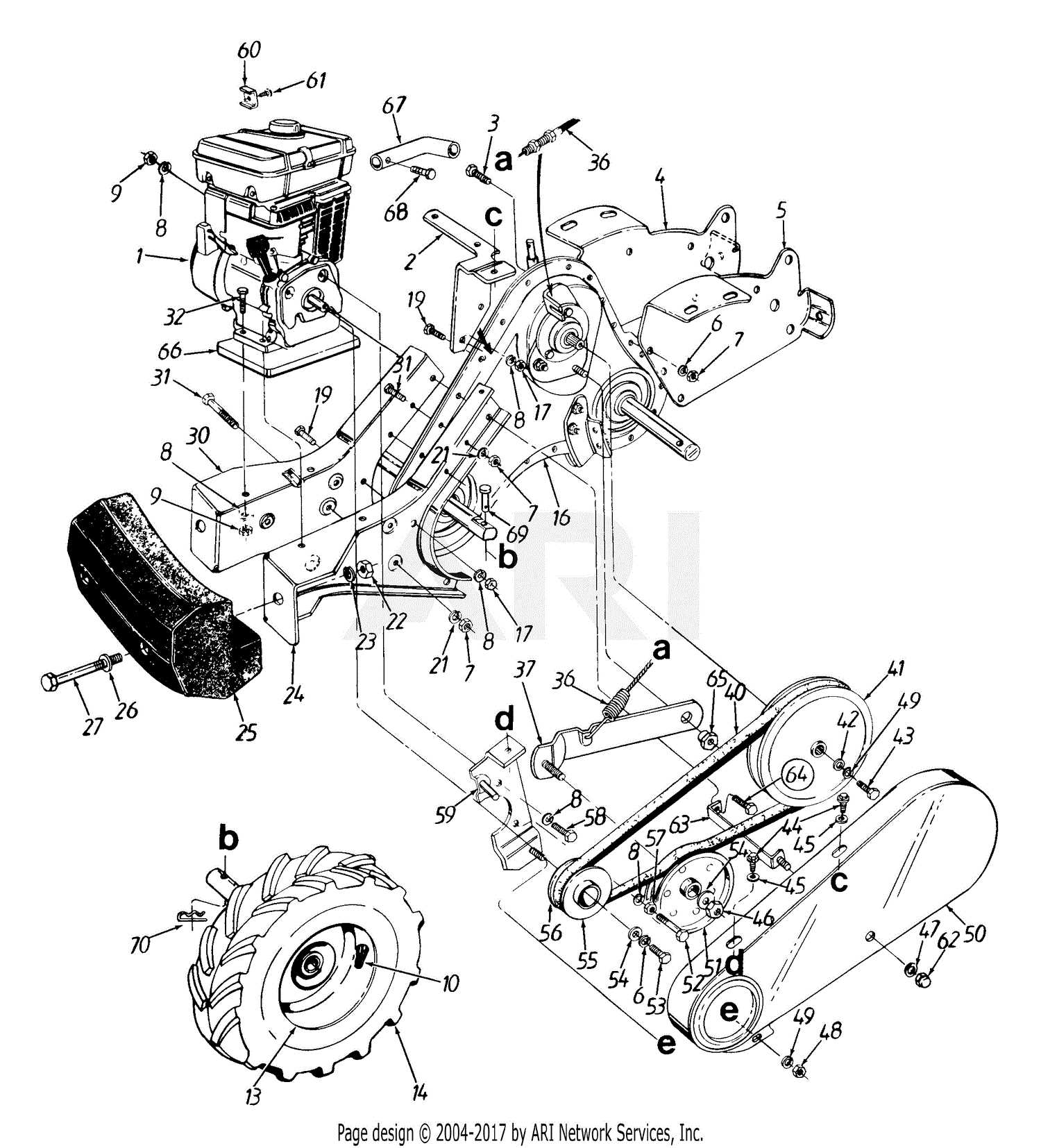

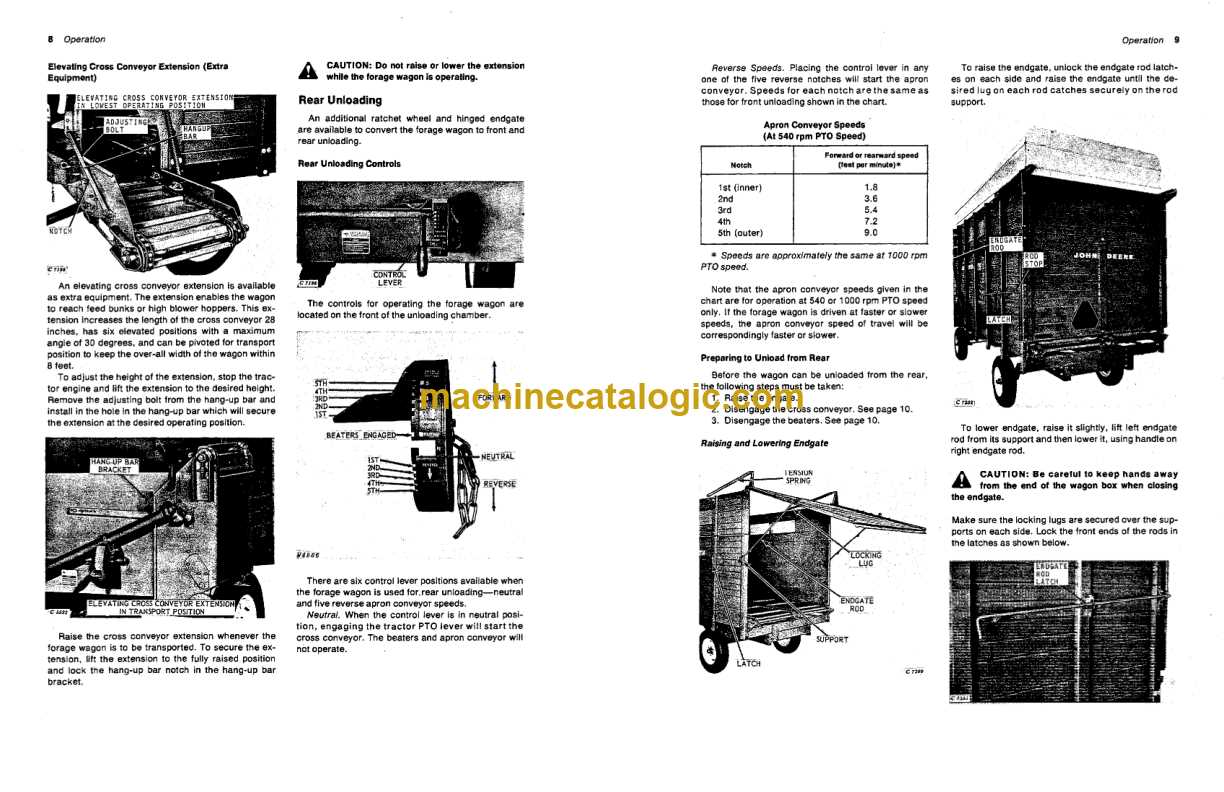

When it comes to maintaining agricultural equipment, understanding the arrangement and configuration of various mechanical elements is crucial. Proper knowledge of how different segments come together not only simplifies repairs but also ensures the long-term functionality of the machinery. Whether you’re dealing with older models or more recent editions, a clear grasp of these components is invaluable.

The layout of these elements can be intricate, with numerous connections and detailed designs playing a role in the machine’s operation. Knowing how everything fits together provides the user with the confidence to approach both routine maintenance and more complex overhauls. This guide delves into the specifics of the assembly, helping users identify and comprehend each section with precision.

By breaking down the inner workings of such

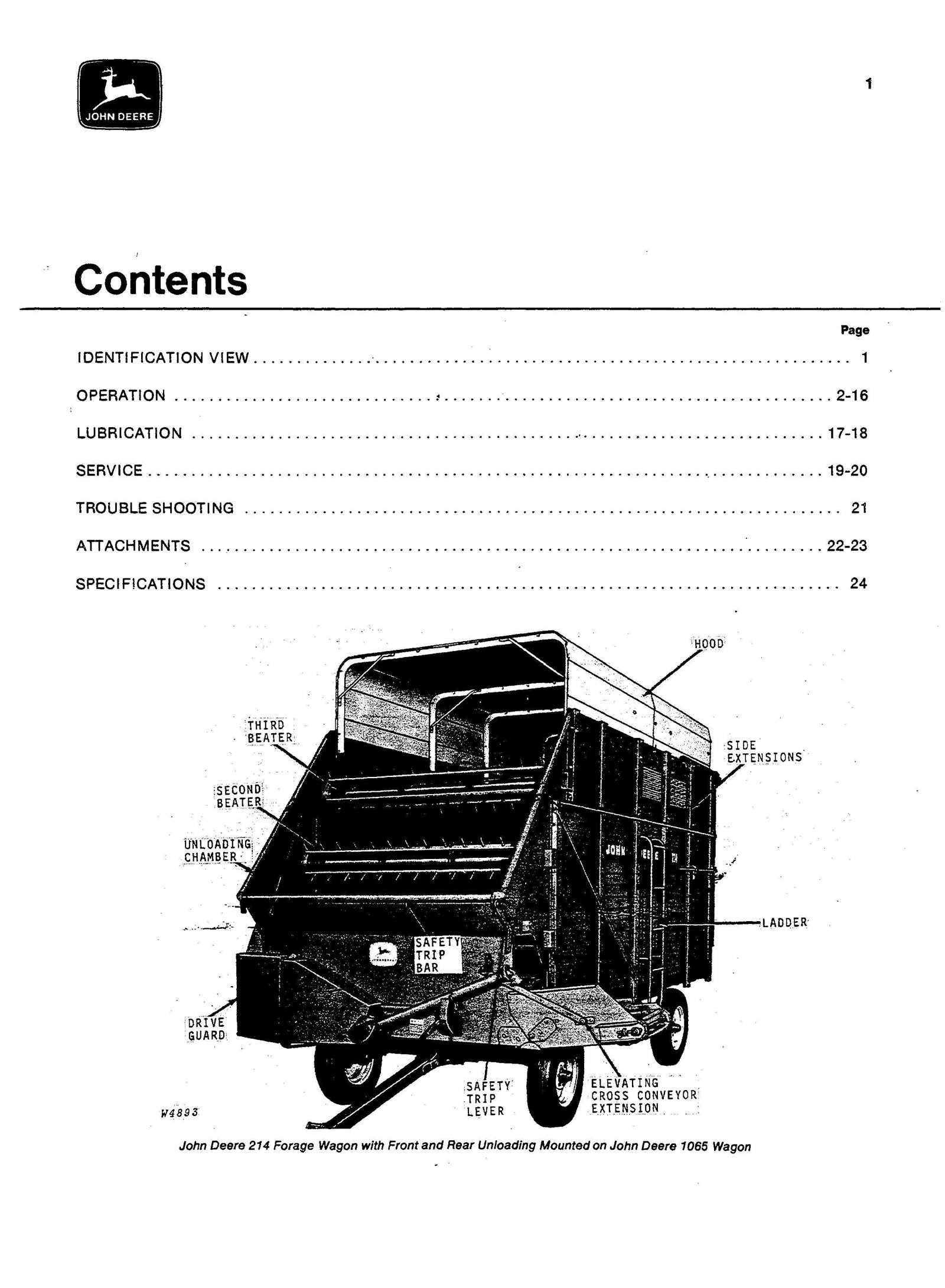

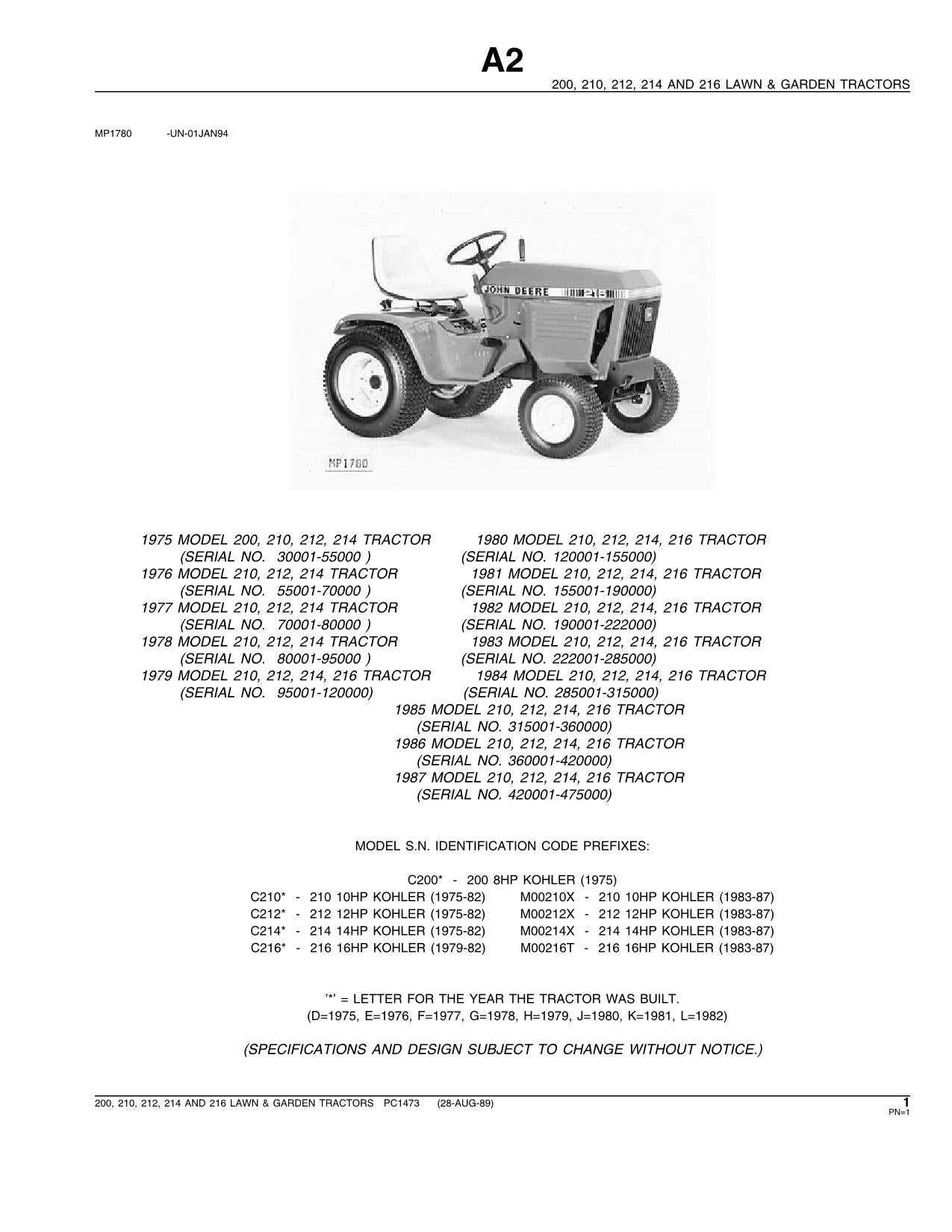

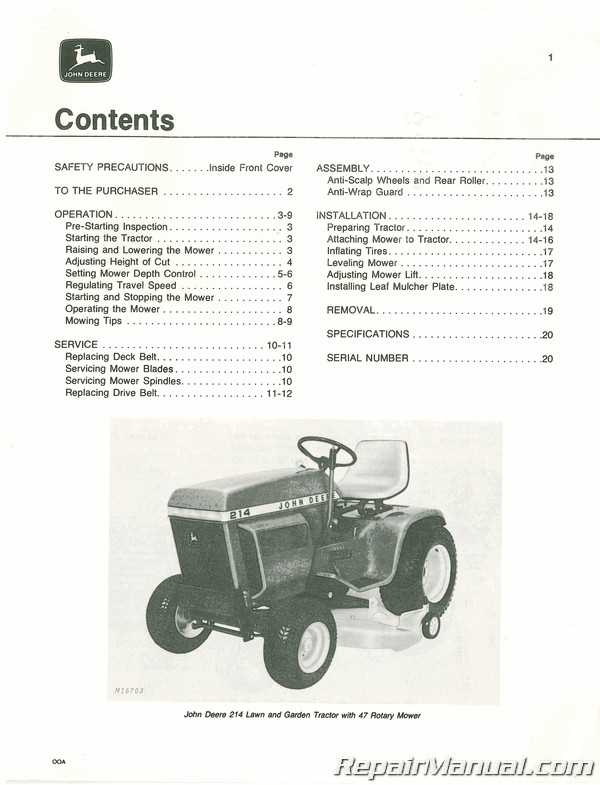

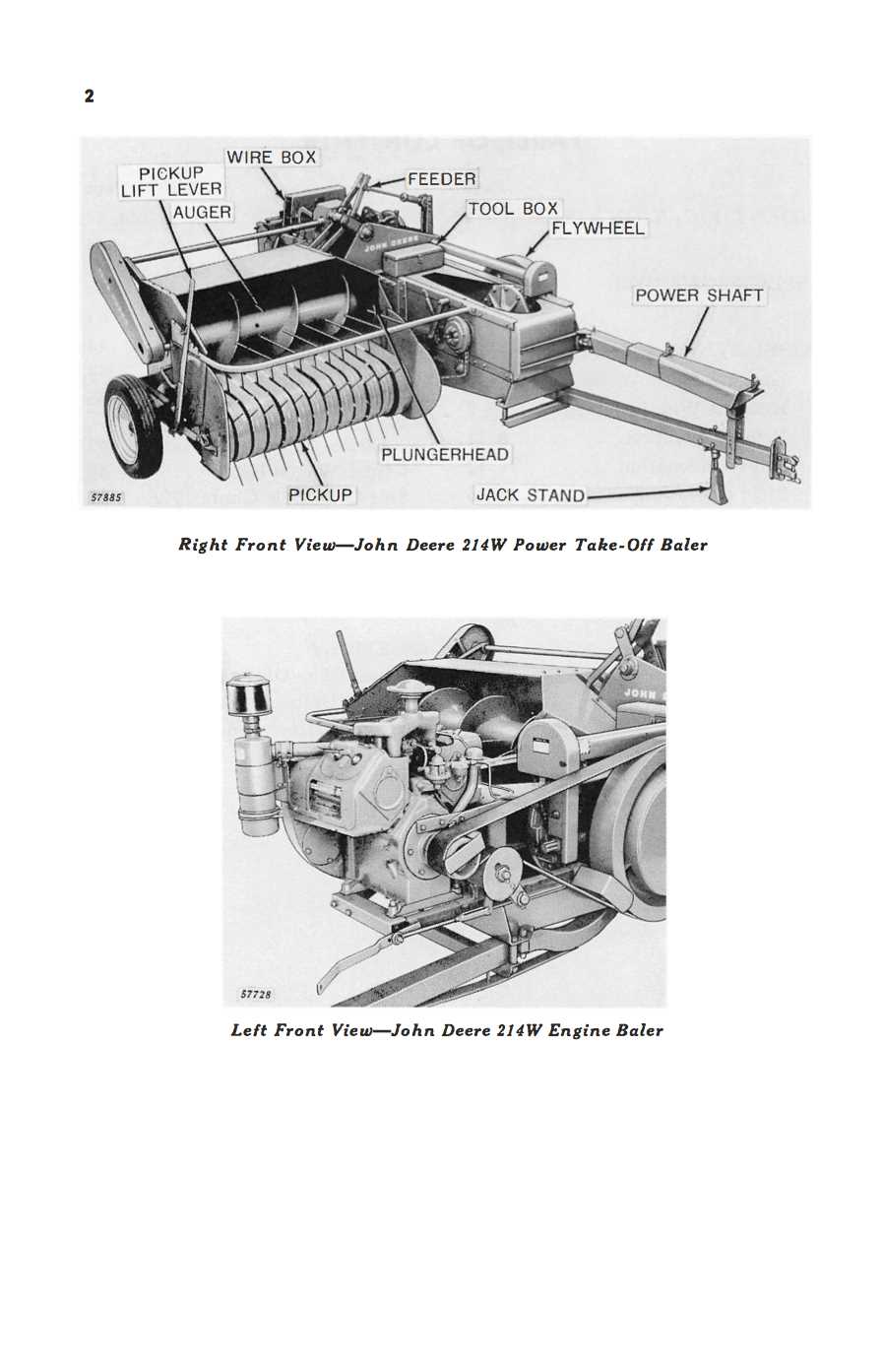

Essential Components of the John Deere 214

Understanding the main elements of this model is key to maintaining its longevity and performance. Each component works together to ensure smooth operation and reliable service, offering users a machine capable of handling various tasks efficiently. Below, we will explore the vital sections and systems that make this equipment durable and effective in different settings.

Engine Assembly: The heart of the machine, the motor system powers all operations, ensuring a consistent and powerful output. Proper care of this area is crucial for optimal performance and extended service life.

Transmission and Drive Mechanism: This section is responsible for delivering power to the wheels, allowing for precise movement and control. The drive system is designed to offer smooth transitions, making it easier to operate in a variety of terrains.

Cutting and Handling Systems

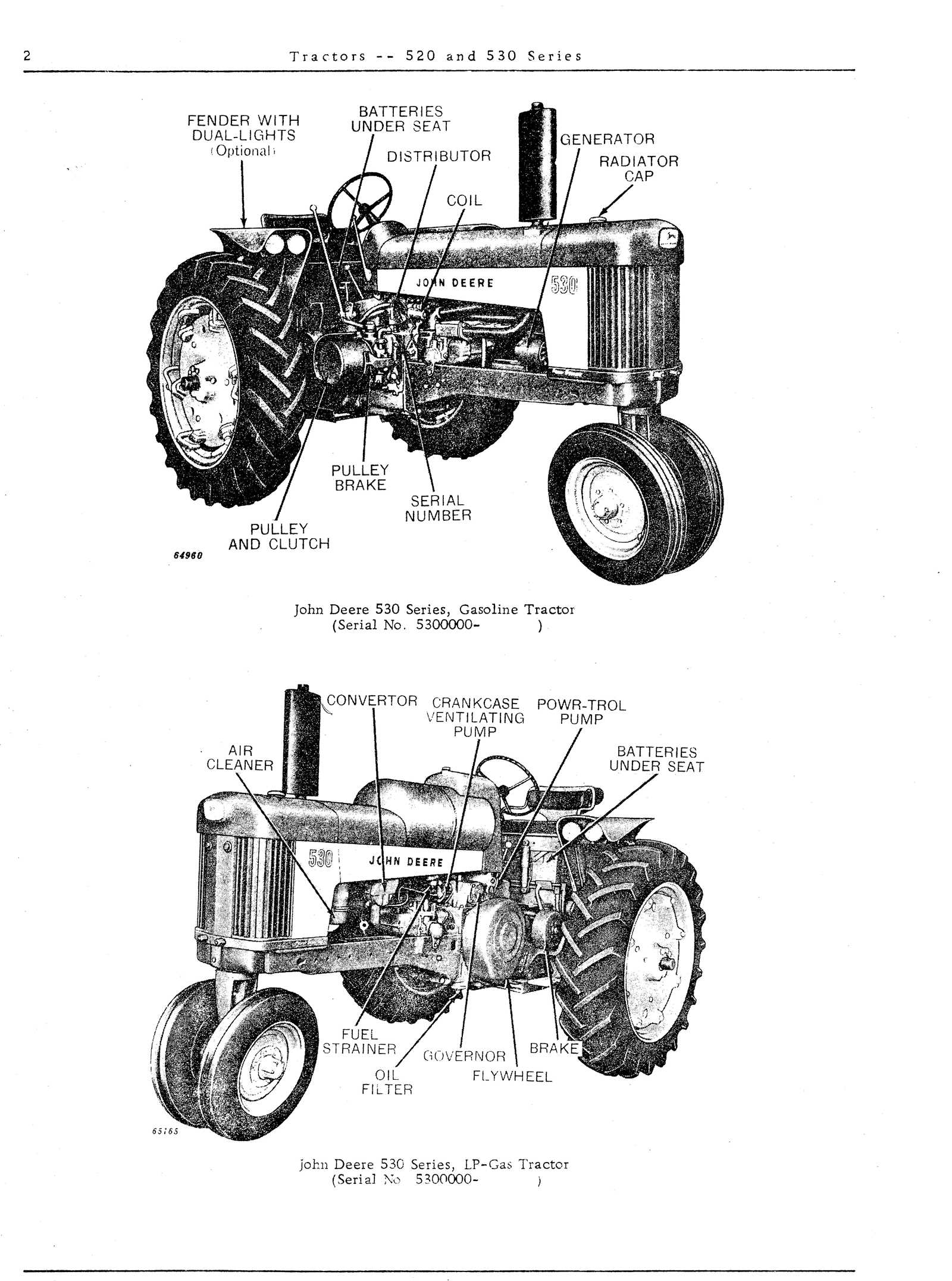

Engine Assembly and Key Elements

The internal configuration of this machine’s engine is a sophisticated integration of critical components, each playing a vital role in ensuring smooth and efficient operation. The overall structure is designed to optimize performance while maintaining durability, with each element carefully crafted to fit within the system’s mechanical layout.

Main Structural Components

At the core of the engine lies a robust framework consisting of multiple essential elements, including the cylinder block, pistons, and crankshaft. These elements work in unison to convert fuel into mechanical energy, driving the system forward with precision. Each component is engineered to withstand significant stress while maintaining efficiency under various conditions.

Supporting Mechanisms

Beyond the primary structure, several supporting systems are integrated to enhance functionality. These include the fuel delivery system, cooling mechanisms, and exhaust handling, all of which are crucial for maintaining optimal temperatures and preventing overheating. The harmonious interaction of these parts ensures reliable performance across a wide range of applications.

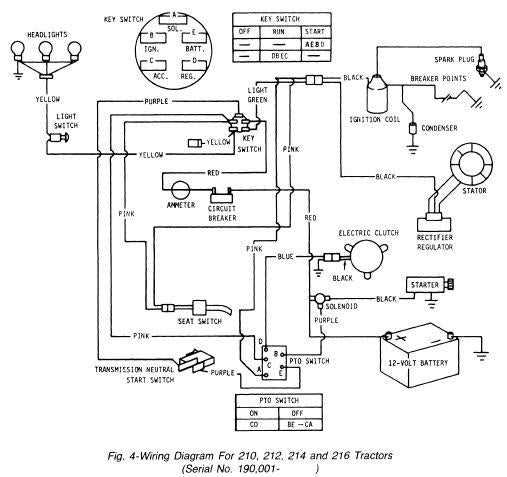

Understanding the Electrical System Layout

The layout of the electrical framework is essential for ensuring proper operation and maintenance of machinery. By familiarizing yourself with the structure, you can diagnose issues more effectively and prevent unnecessary downtime. This section covers the arrangement of key components and how they interact with the overall mechanism.

Main Components and Their Roles

The electrical system consists of several integral elements that work together to power and control various functions. The primary units include the energy source, conductors, and controlling elements. These components are connected in a way that optimizes efficiency and safety, ensuring consistent performance even under heavy workloads.

Wiring and Connection Points

The wiring serves as the backbone of the system, linking each part together. Connection points play a crucial role in

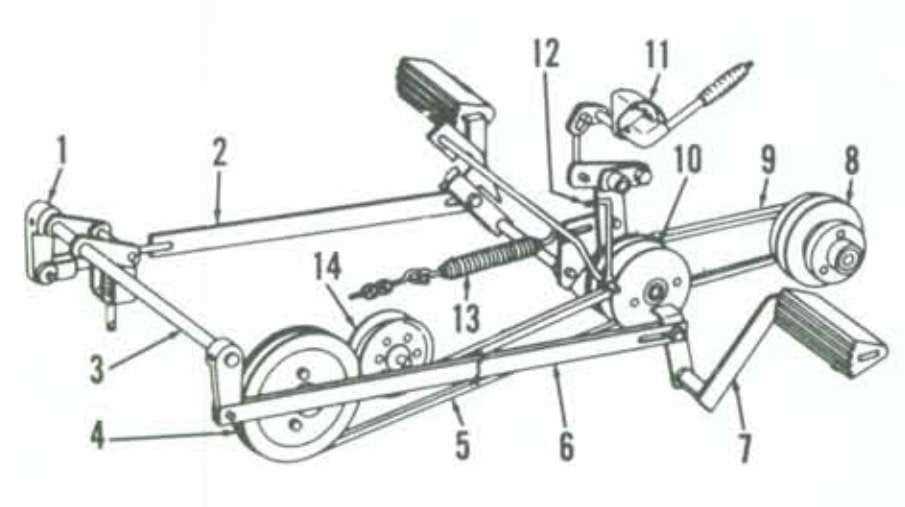

Transmission and Drive Belt Configuration

The mechanical system responsible for movement and power transfer in various equipment relies on a well-coordinated setup of interconnected components. One of the key elements in this process is the arrangement of the transmission system and the belt that connects essential parts, ensuring smooth and efficient motion.

Drive Belt Alignment: Proper alignment is critical for the longevity and functionality of the equipment. The belt must be correctly positioned along the pulleys and tensioned appropriately to prevent slippage or wear. This ensures that power is transmitted effectively between different sections of the machine.

Transmission Layout: The configuration of gears and related mechanisms plays a central role in controlling speed and torque

Steering Mechanism and Adjustments

The steering system plays a crucial role in ensuring precise control and maneuverability of the vehicle. A well-maintained system provides smooth handling, allowing the operator to effectively guide the machine. However, over time, various components may require realignment or tightening to maintain optimal functionality.

Key components involved in the steering system include the linkage, gear assemblies, and shafts. Regular inspection of these elements is essential to detect any wear or misalignment that could affect overall control.

To adjust the system, fine-tuning the linkage and ensuring proper alignment of the shafts is critical. Small corrections can significantly enhance steering accuracy and responsiveness, ensuring the vehicle operates as intended.

Fuel System Structure and Parts

The internal combustion engine relies on an intricate mechanism to deliver the necessary liquid for powering its operation. Understanding how this mechanism functions is key to maintaining the flow of energy and ensuring efficient performance. The arrangement of the components involved allows for a seamless process from storage to combustion, which optimizes engine efficiency and minimizes potential breakdowns.

This system consists of various elements that work together to transport the essential liquid from the reservoir through a series of conduits and regulators. Key elements include filters, pumps, and injectors, each playing a crucial role in controlling the flow, pressure, and purity of the substance as it enters the combustion chambers. Proper maintenance and understanding of these elements is essential for maximizing operational longevity and avoiding unnecessary downtime.

Detailed Overview of the Cutting Deck

The cutting deck plays a critical role in ensuring precise and efficient grass trimming, making it a vital component of any lawn maintenance equipment. This section will explore its structural design, how it interacts with the overall system, and what makes it crucial for achieving uniform results. Understanding the key features of this component helps ensure smoother operation and longer-lasting performance in various terrain conditions.

Constructed with durability in mind, this section is designed to handle different environments while maintaining sharpness and efficiency. Equipped with several blades, it provides a balanced and even cut across wide areas, which reduces the need for repeated passes. Additionally, the mechanism is engineered for easy height adjustment, allowing users to customize the cut based on specific grass types and lawn conditions.

For optimal results, regular maintenance of this system is

Rear Axle and Wheel Connections

The rear axle and wheel assembly plays a crucial role in the overall stability and movement of the machine. Understanding how these components fit together ensures efficient performance and maintenance. This section will outline the key elements involved in the rear assembly, focusing on how each part interacts within the system.

Key Components Overview

- Axle shaft: The primary element transferring torque to the wheels.

- Bearings: Ensures smooth rotation and supports the axle under load.

- Mounting brackets: Secures the axle in place, providing a firm attachment to the frame.

Wheel Mounting Structure

- Wheel hubs: Designed to connect the wheels to the axle, allowing rotation

Maintenance Tips for Key Parts

Proper upkeep of essential components is crucial for ensuring optimal performance and longevity of machinery. Regular maintenance not only helps in avoiding unexpected breakdowns but also enhances efficiency, resulting in better productivity. Below are some practical suggestions to keep these critical elements in top condition.

Component Maintenance Tip Engine Check oil levels regularly and replace the oil as recommended to ensure smooth operation. Filters Inspect and clean air and fuel filters frequently to prevent clogs and maintain optimal airflow. Belts Examine belts for signs of wear or cracks and replace them if necessary to avoid failure. Tires Monitor tire pressure and tread depth, rotating tires as needed to ensure even wear and traction. Batteries Keep battery terminals clean and check the charge regularly to prevent starting issues.