For enthusiasts of textile creation, having a thorough grasp of the various elements that constitute their equipment is essential. Each segment plays a pivotal role in ensuring seamless operation, contributing to both the functionality and longevity of the apparatus. Whether you are a novice or an experienced user, familiarizing yourself with these components can enhance your overall crafting experience.

The intricacies of the different components can be fascinating, offering insight into how each part interacts to achieve precision in every project. Recognizing the significance of each element allows for better maintenance and troubleshooting, ultimately resulting in a smoother workflow. Moreover, this understanding can inspire confidence in making adjustments or repairs when necessary.

By exploring the layout and arrangement of the individual components, crafters can gain a comprehensive view of how their equipment operates. This knowledge not only fosters a deeper appreciation for the craftsmanship involved but also empowers users to maximize their potential when working on various textile endeavors.

This section aims to provide a comprehensive understanding of a renowned brand known for its exceptional crafting devices. These instruments are designed for precision and reliability, appealing to both hobbyists and professionals alike. Exploring the intricacies of these tools reveals their complexity and the artistry involved in their construction and functionality.

Key Features and Innovations

The renowned brand has consistently integrated cutting-edge technology into its devices, enhancing the user experience. Some of the standout characteristics include advanced stitching options, user-friendly interfaces, and robust construction materials. These features not only improve efficiency but also ensure that users can achieve high-quality results across various fabric types.

Popular Models and Their Characteristics

Among the diverse lineup, several models have gained significant popularity due to their unique functionalities. Each variant offers specific attributes tailored to different sewing techniques and projects, making it essential for users to choose according to their needs and preferences.

| Model Name | Key Features | Ideal For |

|---|---|---|

| Model A | Multiple stitching options, automatic tension adjustment | Beginners and intermediates |

| Model B | Enhanced embroidery capabilities, touch screen interface | Advanced users |

| Model C | Compact design, portable, lightweight | Traveling crafters |

Essential Components of Sewing Machines

Understanding the fundamental elements of textile creation tools is crucial for both beginners and experienced users. Each component plays a vital role in the functionality and performance of these devices, ensuring that fabric manipulation is efficient and precise. Familiarity with these essential features not only enhances the crafting experience but also aids in maintenance and troubleshooting.

Key Elements for Effective Operation

Among the primary elements are the needle, which pierces the fabric, and the feed dogs, responsible for moving the material during operation. Additionally, the bobbin holds the thread necessary for stitching, while the presser foot secures the fabric in place, allowing for accurate sewing. These components work in unison, ensuring smooth and consistent results.

Importance of Maintenance

Regular upkeep of these vital elements can significantly extend the lifespan of the tool. Cleaning lint from the needle area, replacing worn-out needles, and ensuring proper threading are essential practices that contribute to optimal performance. By understanding and caring for these components, users can achieve better results and enhance their crafting skills.

Understanding the Mechanism of Operation

This section delves into the intricate workings of a crafting apparatus, focusing on how various components interact to achieve precise results. The synergy between mechanical parts and user input facilitates the seamless execution of stitching tasks, embodying a harmonious blend of engineering and artistry.

Key Components and Their Functions

At the heart of this apparatus lies a complex assembly of elements, each playing a vital role in its overall functionality. The interplay between the needle, feed dogs, and presser foot is crucial, as these components work together to guide the fabric through the stitching process. Understanding their individual functions enhances the operator’s ability to troubleshoot and optimize performance.

Operation Process Overview

The operation process begins with the user initiating the device, which sets the various parts in motion. As the needle descends and ascends, it pierces the material, creating loops of thread. The feed dogs engage to move the fabric forward, ensuring a consistent and even stitch length. This cycle continues, allowing for intricate patterns and designs to emerge on the fabric surface.

| Component | Function |

|---|---|

| Needle | Pierces the fabric and carries the thread to form stitches. |

| Feed Dogs | Move the material forward to ensure even stitching. |

| Presser Foot | Holds the fabric in place during the stitching process. |

| Bobbin | Houses the lower thread that interlocks with the upper thread. |

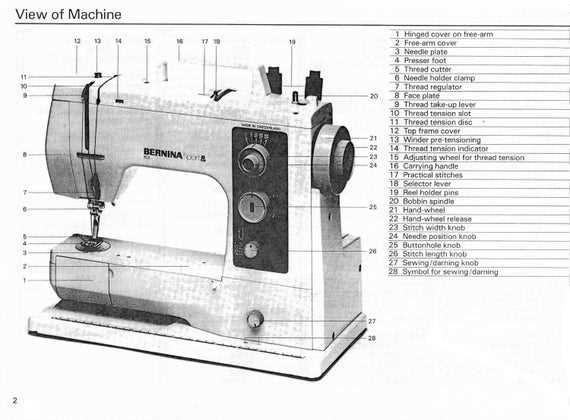

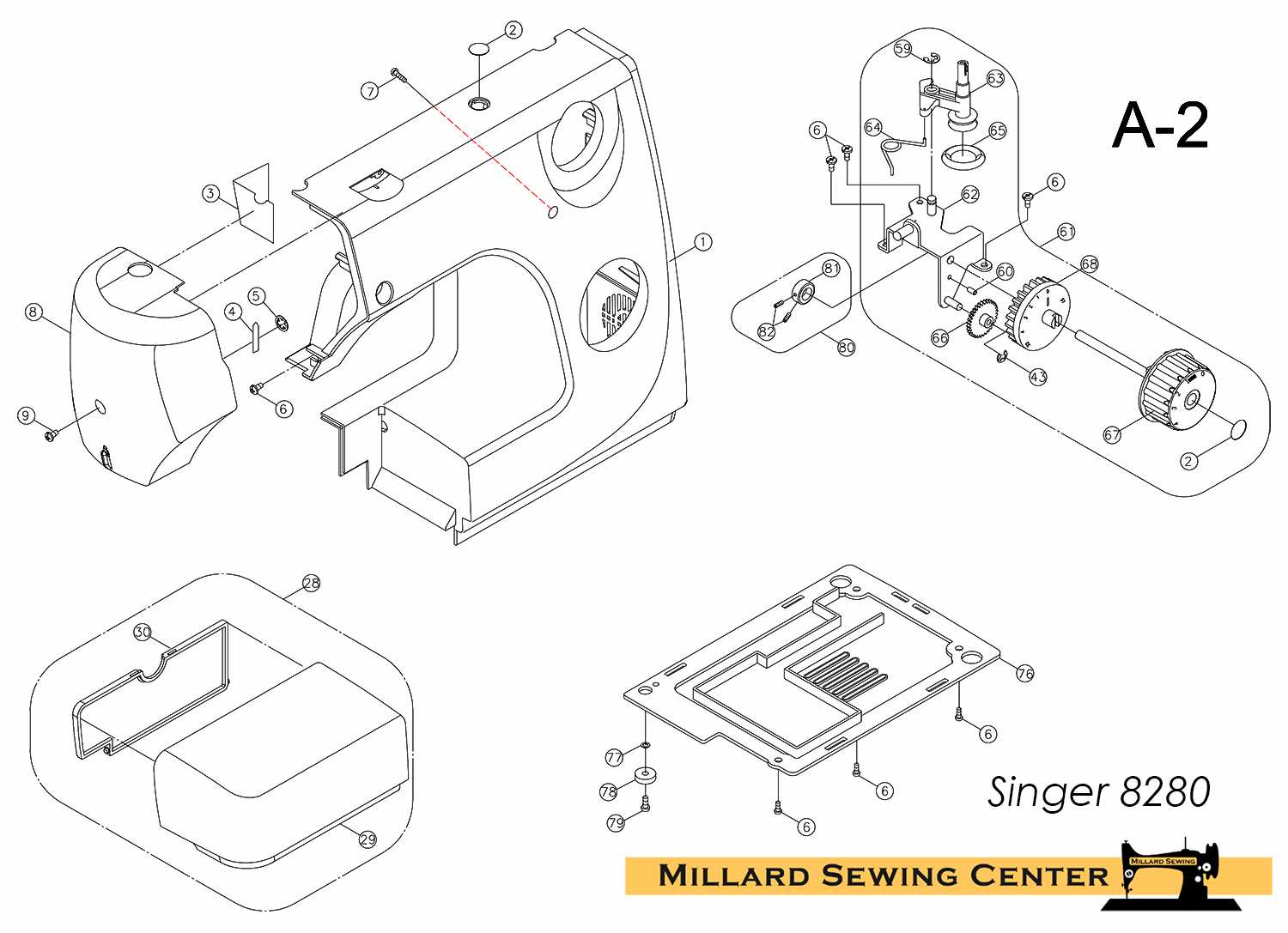

Identifying Key Parts in Diagrams

Understanding the various components depicted in visual representations is essential for effective utilization and maintenance. These illustrations serve as valuable references, highlighting the functional elements and their interconnections. Familiarity with the significant features aids in troubleshooting, repairs, and enhancing overall proficiency.

To successfully navigate these visuals, it is crucial to recognize the most critical components. Here are some fundamental elements to consider:

- Control Elements: These components manage various functions and settings.

- Feed Mechanism: This system ensures the material moves smoothly through the unit.

- Needle Assembly: The part responsible for creating stitches, available in various sizes and types.

- Threading System: This mechanism guides the thread from the spool to the needle.

- Bobbin Area: The section that holds the lower thread, essential for stitch formation.

Recognizing these elements will facilitate better understanding and effective interaction with the equipment. By studying these components, users can enhance their skills and achieve superior results.

Common Issues with Sewing Machine Parts

Understanding the frequent challenges encountered with various components of textile equipment can greatly enhance the user experience. Addressing these issues promptly ensures smoother operation and prolongs the lifespan of the apparatus.

Here are some typical problems that users might face:

- Thread Tension Problems: Improper tension can lead to loose stitches or breakage. Regular adjustments are necessary for optimal performance.

- Needle Issues: A bent or dull needle can cause skipped stitches and fabric damage. It’s advisable to replace needles frequently.

- Bobbin Malfunctions: Incorrectly wound bobbins can result in inconsistent stitching. Ensure that bobbins are properly filled and seated.

- Feed Dog Troubles: If the feed dogs are not engaging correctly, fabric may not move through smoothly. Regular cleaning and maintenance can prevent this issue.

- Motor Problems: Unusual noises or a lack of movement could indicate motor issues. It’s important to consult a technician if these symptoms arise.

By being aware of these common challenges, users can take proactive steps to maintain their equipment, leading to a more enjoyable crafting experience.

Maintenance Tips for Longevity

Proper care and regular upkeep are essential for ensuring the extended life of your crafting equipment. By following a few straightforward guidelines, you can maintain optimal performance and avoid costly repairs or replacements. This section outlines key practices that contribute to the durability and efficiency of your apparatus.

Regular Cleaning

Keeping your device clean is crucial for preventing dust and debris accumulation. Regularly removing lint and residue from the work area can significantly enhance performance. Use a soft brush or cloth to clean the exterior and interior, ensuring that all moving components remain free from obstruction.

Lubrication and Adjustments

Maintaining proper lubrication is vital for smooth operation. Apply appropriate oils to moving parts as recommended in the user manual. Additionally, check for any necessary adjustments that may enhance functionality, such as tension settings and alignment of components.

| Maintenance Task | Frequency |

|---|---|

| Cleaning interior and exterior | After every use |

| Lubricating moving parts | Every 6 months |

| Checking tension settings | Monthly |

| Inspecting electrical components | Annually |

Upgrading and Replacing Components

Enhancing the functionality of your textile apparatus often requires the thoughtful modification or substitution of specific elements. This process can significantly improve performance, extend lifespan, and adapt the device to better meet your creative needs. Whether it’s improving stitching quality or adding new features, understanding how to effectively upgrade or replace these components is essential for any enthusiast.

Identifying Components for Upgrade

Before proceeding with enhancements, it’s crucial to assess which elements could benefit from an upgrade. Common areas include the feed mechanism, needle system, and electronic controls. By researching compatible options and understanding the advantages they offer, you can make informed decisions that enhance your overall experience.

Steps for Replacement

Replacing an element typically involves a few straightforward steps. First, ensure you have the necessary tools and new components at hand. Carefully consult the user manual for guidance on disassembly and reassembly. When removing the old part, take note of its placement and orientation, as this will aid in correctly installing the new component. Finally, after installation, perform a test run to confirm that everything functions smoothly.

Resources for Parts and Repair Manuals

Accessing reliable resources for components and repair documentation is essential for maintaining and restoring your equipment. A variety of platforms and sources can provide valuable insights, ensuring that users have the necessary tools to perform efficient repairs or upgrades.

One of the most effective ways to find specific components is through online marketplaces that specialize in replacement items. These websites often feature extensive catalogs, making it easy to locate the exact items needed for various models. Additionally, manufacturer websites may offer downloadable manuals that provide detailed information about assembly, disassembly, and troubleshooting procedures.

Forums and online communities dedicated to enthusiasts can also be invaluable. Members frequently share their experiences, recommendations, and links to helpful resources, creating a collaborative environment for problem-solving. Social media groups focused on similar topics can further enhance access to useful documentation and guides.

Local repair shops or specialty stores often maintain physical copies of manuals and may have knowledgeable staff who can assist in identifying components or provide advice on repairs. Networking with professionals in the field can lead to discovering alternative sources for obtaining necessary materials.