The ability to control direction and movement is essential for any lawn vehicle, ensuring smooth navigation across varied terrains. This guide explores the intricate network of elements responsible for translating user input into fluid movement. Each piece of the mechanism plays a vital role in the system, working together to provide precision and ease of control during operation.

Focusing on the central components that manage navigation, this overview highlights the important features that contribute to optimal performance. These parts ensure that the operator can adjust direction effortlessly, even on uneven surfaces or challenging landscapes. Whether you’re maintaining a residential lawn or working on larger areas, having a solid understanding of these systems is essential for keeping the vehicle in top condition.

In the following sections, we will delve into the key mechanical structures, their functions, and the significance of each element in maintaining smooth and reliable movement. Proper care and understanding of these eleme

Overview of the Steering System Components

The mechanism responsible for controlling the direction of the vehicle consists of multiple key elements working together to ensure precise handling and smooth maneuvering. Each of these elements plays a critical role in transmitting the driver’s input into physical movement, allowing the vehicle to turn and navigate various terrains with ease.

Among the primary elements, one can identify those responsible for transferring force, those that provide stability, and those that help maintain alignment. These interconnected components must function seamlessly to ensure reliability and safety during operation. The design of the system is engineered to offer both durability and responsiveness, adapting to various driving conditions while minimizing wear and tear.

Critical connections within this setup include links between the input device and the control mechanism, designed to amplify the driver’s actions. Furthermore, the system is designed with safety in mind, incorporating features to prevent mechanical failure and ensure long-term performance under varying loads and stresses.

Main Parts of Craftsman YT4000 Steering

The mechanical system responsible for maneuvering the vehicle is made up of several essential elements that work together to ensure smooth and precise directional control. Understanding these components can help identify issues and maintain optimal performance over time.

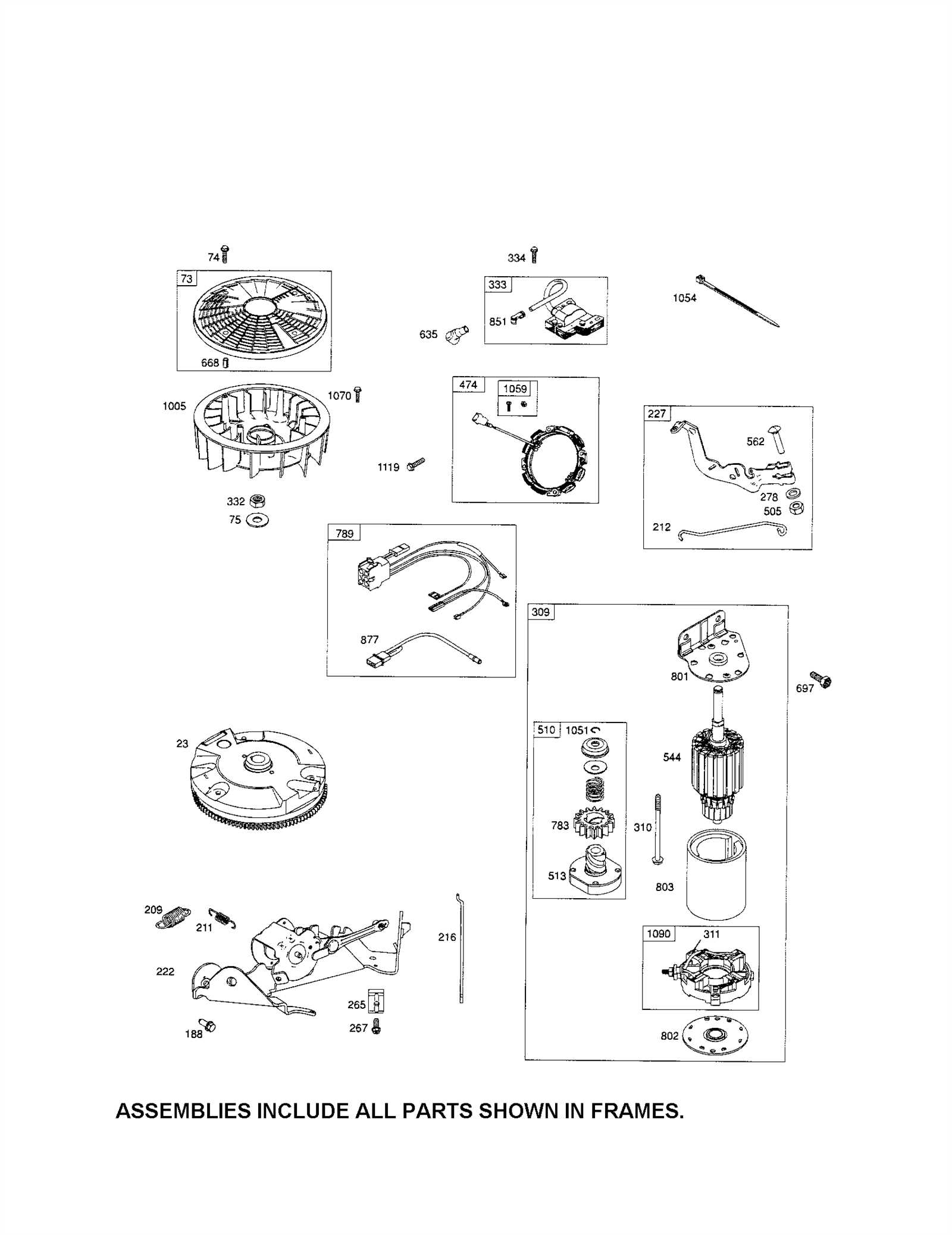

Key Mechanisms Involved

At the core of this system are components that translate rotational movement into lateral motion, allowing the operator to guide the machine effectively. A crucial element is the linkage, which connects the rotating mechanism to the wheels, ensuring they turn in unison with the operator’s input. Additionally, the control shaft plays an important role by transferring energy from the operator’s control unit to the rest of the system, facilitating accurate adjustments.

Support and Stability Components

Another significant aspect of the system is the presence of stabilizers and mounts that hold everything in place, ensuring that directional changes are smooth and consistent. These parts are designed to minimize vibrations and maintain stability, especially during turns. Regular inspection of these

How the Steering Mechanism Works

The control mechanism of a vehicle relies on a complex system that allows for precise direction changes while maintaining stability and safety. This system ensures the smooth operation of guiding the wheels to respond to the operator’s input, allowing for effortless turns and adjustments during movement.

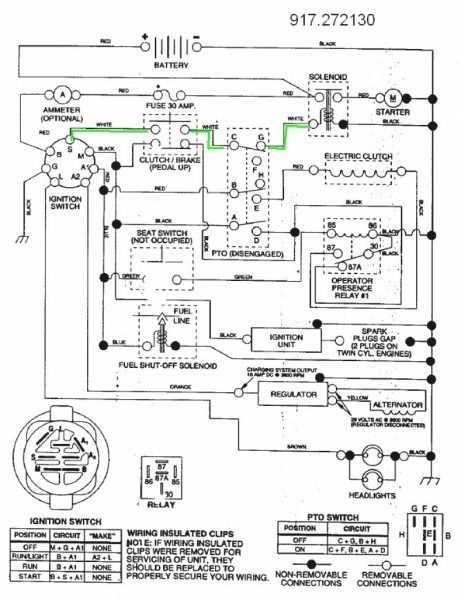

The mechanism typically consists of several essential components working together:

- Control input linkage: This part translates the operator’s commands into physical movement, sending signals from the control lever to the wheels.

- Turning joints: These joints allow for rotational motion, ensuring that directional changes are fluid and seamless. They are designed to minimize friction and provide durability over time.

- Guidance rods: These rods transmit force from the central control system to the wheel assemblies, maintaining alignment and balance.

- Pivot points: Pivoting elements enable the structure to change direction without compromising stability, distributing the weight and ensur

Identifying Common Issues in Steering

One of the most crucial components in ensuring smooth maneuverability and control is the system responsible for direction changes. Over time, certain problems can arise that impact its functionality, affecting overall ease of operation. Recognizing these issues early can prevent further complications and ensure consistent performance.

Below is a list of typical challenges and potential causes:

Problem Possible Cause Difficulty in turning Wear and tear on linkages or misalignment Vibration while changing direction Loose or damaged components Uneven movement Obstructions or resistance in the mechanism Steering Wheel and Shaft Assembly Details

The assembly responsible for connecting the operator’s control interface with the mechanism that directs movement is a crucial component in ensuring smooth and responsive handling. This section will explore the essential elements involved in transferring the input from the operator to the mechanical system that guides direction. By understanding these components, one can grasp how effective control is maintained during operation.

Main Components

- Control Interface: The main interface that the operator uses to direct movement is ergonomically designed to provide comfort and ease of use during prolonged operation.

- Rotational Column: A rigid, central column connects the interface to the mechanism below, transmitting rotational motion efficiently and precisely.

- Support Bearings: These crucial elements reduce friction and allow smooth, effortless rotation of the control interface.

Mechanical Integration

At the base of

Connecting Rods and Their Function

Connecting rods play a crucial role in the functionality of various machinery and vehicles. They serve as vital components that link the moving parts, translating motion and force from one section to another. This connection allows for efficient energy transfer, ensuring smooth operation and performance within the overall system.

Structure and Design

The design of connecting rods varies depending on the application, but they generally consist of a sturdy body that withstands significant stress. The ends of these rods are typically fitted with bearings or other attachments that allow for seamless movement. The material composition is also essential, as it needs to provide both strength and flexibility to accommodate different operational demands.

Importance in Machinery

In machinery, connecting rods are indispensable for maintaining balance and stability during operation. They help in minimizing vibrations, contributing to the longevity of the equipment. Additionally, their ability to absorb shocks and impacts plays a vital role in protecting other components from excessive wear and tear, ultimately enhancing overall performance.

Troubleshooting Steering Gearbox Problems

Addressing issues with the directional control mechanism of your machinery can be essential for maintaining optimal performance and safety. Identifying symptoms early can save time and resources during repairs. This section provides guidance on diagnosing and resolving common challenges associated with the control system.

Here are some prevalent problems you might encounter:

- Excessive play in the mechanism: This can result in poor control responsiveness.

- Unusual noises: Grinding, clicking, or clunking sounds can indicate internal wear or damage.

- Difficulty in turning: This may suggest issues with lubrication or blockages within the assembly.

- Leakage: Fluid escaping from the unit can lead to reduced functionality and should be addressed promptly.

To effectively troubleshoot these issues, follow these steps:

- Inspect the assembly: Look for any visible signs of damage or wear.

- Check for fluid leaks: Ensure all seals and connections are secure and free from cracks.

- Test the responsiveness: Gently manipulate the control and observe if it returns to the neutral position.

- Listen for abnormal sounds: If noises persist, consider disassembling the unit for a closer examination.

- Lubricate moving parts: Apply the appropriate lubricant to ensure smooth operation.

By systematically assessing these factors, you can identify and resolve issues, ensuring the directional control system functions effectively. Regular maintenance can also prevent these problems from recurring in the future.

Maintenance Tips for Craftsman YT4000 Steering

Proper upkeep of your equipment’s maneuvering system is crucial for ensuring optimal performance and longevity. Regular maintenance can prevent unnecessary wear and tear, enhancing the overall functionality and safety of the machinery.

Inspect Regularly: Frequently examine the maneuvering mechanism for signs of wear, such as frayed cables or loose components. Catching issues early can prevent more significant problems down the line.

Lubrication: Keep moving parts well-lubricated to reduce friction and prevent corrosion. Use a suitable lubricant and apply it as per the manufacturer’s recommendations.

Check Alignment: Ensure that the assembly is properly aligned. Misalignment can lead to uneven wear and affect handling. Adjust as necessary to maintain correct positioning.

Clean Thoroughly: Remove debris and dirt that may accumulate around the maneuvering components. A clean environment promotes smooth operation and prevents damage.

Replace Worn Components: If you notice any parts that are significantly worn or damaged, replace them promptly. Using degraded components can lead to further complications and affect performance.

Consult the Manual: Always refer to the maintenance manual for specific guidelines tailored to your model. Following the manufacturer’s instructions will help ensure you are taking the right steps for upkeep.