In the realm of aquatic navigation, precision and reliability are paramount. Mastery of control mechanisms enables vessels to maneuver effortlessly through various conditions, ensuring both safety and efficiency. This section will explore the intricacies of such systems, shedding light on their components and functions.

Detailed insights into the various elements that comprise these mechanisms can significantly enhance one’s knowledge. By examining their configuration, one can better appreciate how each piece contributes to the overall functionality, ultimately improving the performance of the marine craft.

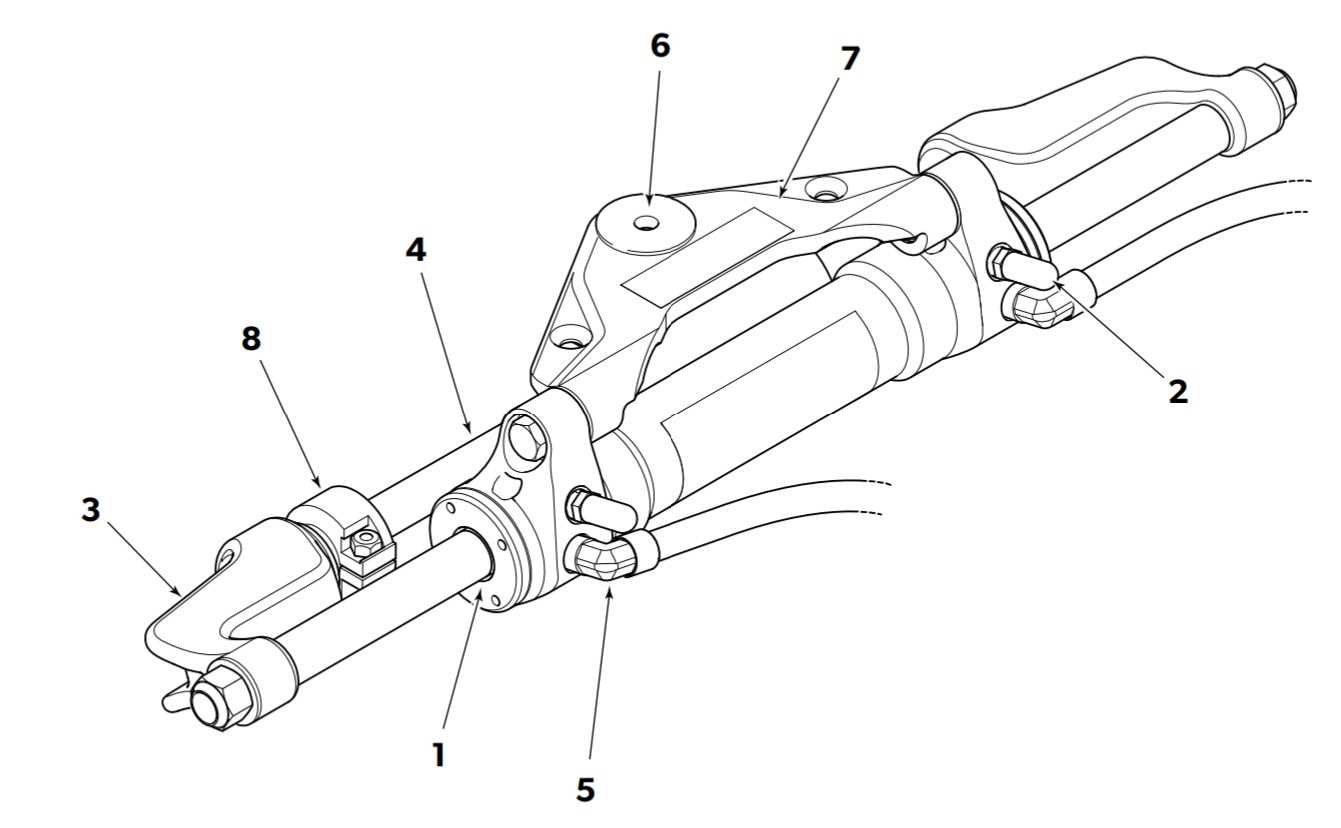

Furthermore, visual representations of these systems can aid in understanding the relationships between components. By delving into these diagrams, enthusiasts and professionals alike can grasp the ultimate workings of these essential technologies, paving the way for informed decisions and effective troubleshooting.

Understanding Seastar Hydraulic Steering

This section aims to delve into the mechanisms that facilitate smooth navigation and control in aquatic vessels. The system utilizes fluid dynamics to provide effortless maneuverability, enhancing the overall experience on the water. By exploring its components and functions, we can appreciate how these elements work in harmony to ensure stability and responsiveness.

At the core of this system lies a series of interconnected elements designed to transmit force effectively. When the operator engages with the control interface, fluid is directed through tubes, creating pressure that influences the directional movement of the vessel. This process not only reduces physical strain on the user but also allows for precise adjustments even in challenging conditions.

Understanding the various components involved is essential for maintaining and troubleshooting the system. Each element, from the reservoirs to the cylinders, plays a pivotal role in ensuring optimal performance. Regular inspection and proper care can significantly extend the lifespan of these mechanisms, preventing costly repairs and enhancing safety on the water.

In summary, grasping the functionality and significance of this control system empowers users to maximize their aquatic adventures. Whether for leisure or sport, a well-functioning system is key to enjoying seamless navigation and achieving the desired agility on the water.

Components of Hydraulic Steering Systems

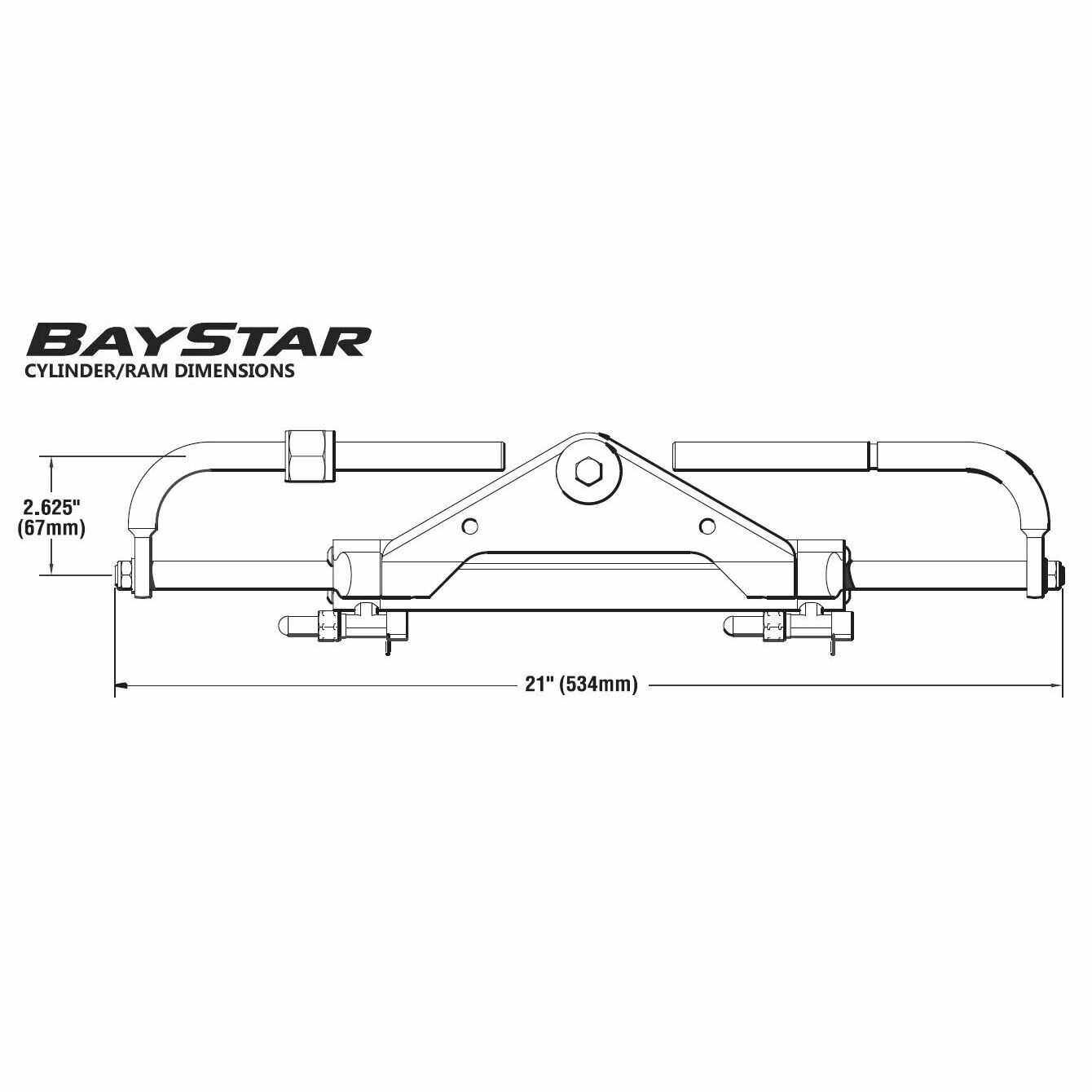

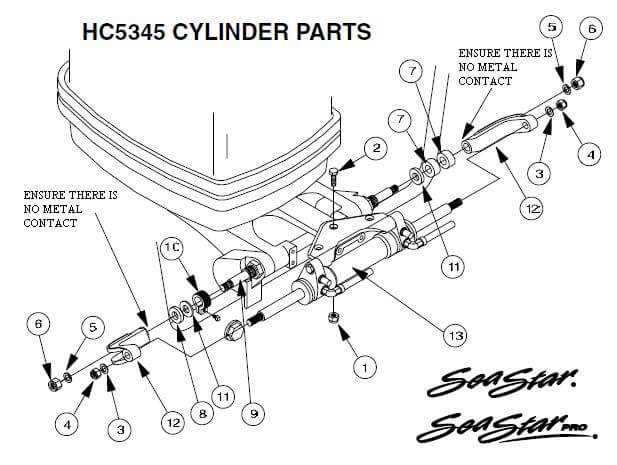

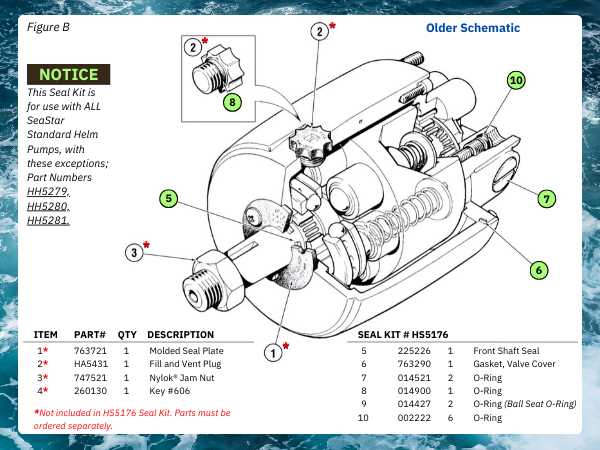

This section explores the essential elements that contribute to the functionality of a fluid-based directional control mechanism. Understanding these components is vital for proper maintenance and effective operation, ensuring a smooth and responsive experience while navigating various terrains.

Main Elements

- Pump: The heart of the system, responsible for generating the necessary pressure to facilitate movement.

- Actuator: Converts fluid pressure into mechanical force, enabling the directional changes.

- Reservoir: Stores the fluid and maintains a supply for the entire mechanism.

- Hoses and Fittings: Connect various components, allowing for the smooth transfer of fluid.

- Valves: Control the flow and direction of the fluid, ensuring precise operation.

Supporting Components

- Seals: Prevent leakage and maintain system integrity.

- Filters: Remove contaminants from the fluid to protect sensitive parts.

- Indicators: Provide visual feedback regarding system pressure and fluid levels.

Each of these components plays a critical role in ensuring the system operates efficiently and reliably, making it essential to understand their functions and interrelations.

Importance of Proper Maintenance

- Enhances Performance: Regular checks and servicing can optimize functionality.

- Increases Lifespan: Consistent maintenance helps in prolonging the life of components.

- Reduces Costs: Preventative measures can save money on future repairs and replacements.

- Ensures Safety: Well-maintained systems are less likely to malfunction, enhancing user safety.

Establishing a maintenance routine not only preserves efficiency but also prevents unforeseen issues, ultimately leading to a smoother operational experience.

Common Issues with Steering Parts

In any marine control system, certain challenges frequently arise that can affect performance and reliability. Understanding these potential problems is crucial for maintaining safe and efficient navigation. Users often encounter issues that can stem from wear and tear, improper installation, or environmental factors, each contributing to a less than optimal experience.

1. Leakage Problems

Fluid leaks are one of the most prevalent concerns, often caused by degraded seals or damaged connections. These leaks can lead to reduced functionality and may pose safety risks if not addressed promptly. Regular inspections can help detect and mitigate this issue before it escalates.

2. Difficulty in Maneuvering

Another common challenge is inconsistent responsiveness, which can stem from air bubbles in the system or obstructions in the mechanism. This lack of fluidity can hinder control and create frustration for users. Ensuring proper maintenance and purging of air can help restore smooth operation.

Installation Guide for Seastar Parts

This section provides a comprehensive overview for the assembly and setup of various components involved in marine navigation systems. Following the outlined steps will ensure optimal performance and safety during use. Proper installation is crucial for the longevity and reliability of your equipment.

Preparation Steps

Before beginning the installation, gather all necessary tools and components. Make sure to review the user manual for specific instructions related to your model. Here are the steps to prepare:

- Check the inventory of all required components.

- Gather essential tools such as wrenches, screwdrivers, and pliers.

- Ensure a clean working environment to avoid losing small parts.

Installation Process

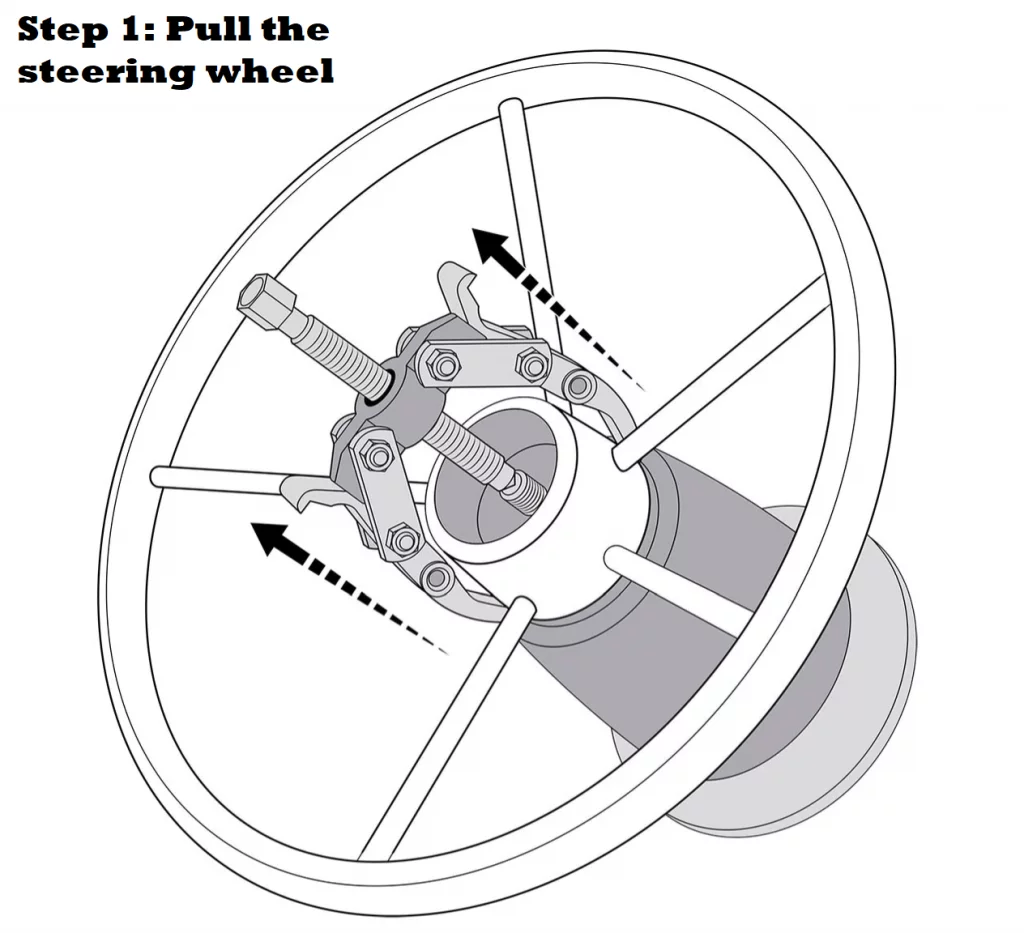

Follow these steps to successfully install your navigation system components:

- Begin by securing the main unit to the designated area, ensuring it is level and stable.

- Connect the necessary hydraulic lines, making sure they are free of kinks and tightly fitted.

- Attach any electronic connections, following the color-coded wiring guidelines.

- Test the system by cycling through the controls to verify responsiveness.

- Finally, secure all components with bolts and fasteners to prevent movement during operation.

Regular maintenance checks will help keep your equipment in top condition and enhance its lifespan.

Diagram Interpretation for DIY Repairs

Understanding visual representations of mechanical systems is crucial for anyone looking to perform maintenance or repairs on their equipment. These illustrations serve as valuable guides, enabling enthusiasts to identify components, troubleshoot issues, and execute repairs with confidence. By breaking down complex information into simpler visual formats, users can navigate the intricacies of their machinery more effectively.

Key Components to Identify

When examining a schematic, it’s essential to recognize the various elements depicted within. Each symbol and line serves a specific purpose, providing insight into how the system operates. Familiarizing yourself with these components can significantly enhance your repair capabilities.

| Symbol | Description |

|---|---|

| Circle | Represents a connection point or junction. |

| Arrow | Indicates the direction of fluid flow or movement. |

| Square | Denotes a component such as a valve or pump. |

| Dotted Line | Shows a temporary or optional connection. |

Steps for Effective Interpretation

To effectively utilize a schematic for repairs, follow these steps:

- Study the overall layout to grasp how components interact.

- Identify each symbol and consult the accompanying legend if available.

- Trace the pathways to understand fluid dynamics and control mechanisms.

- Make notes on any components that appear damaged or misaligned.

With practice, interpreting these visuals will become second nature, making your repair projects smoother and more successful.

Choosing the Right Replacement Parts

When it comes to maintaining optimal performance in marine systems, selecting the appropriate components is crucial. The right replacements not only ensure functionality but also enhance safety and durability. Understanding the specifications and compatibility of various items can make a significant difference in overall efficiency.

Quality Matters: Prioritizing high-quality alternatives is essential. Investing in reputable brands and verified products guarantees reliability and longevity, reducing the frequency of future replacements.

Compatibility is Key: Before making a decision, it’s important to verify that the new components align with existing configurations. Mismatched elements can lead to malfunctions, so always consult product manuals or expert advice.

Consider Application: Different setups may require specific features. Assessing the intended use of the system will guide you toward the most suitable options, whether for recreational boating or professional applications.

Seek Expert Guidance: Consulting with professionals or experienced users can provide valuable insights. Their expertise can help you navigate through choices and identify the best solutions for your needs.

In summary, careful consideration of quality, compatibility, application, and expert advice will lead to informed decisions when selecting replacements, ultimately ensuring smooth operation and peace of mind.

Benefits of Upgrading Steering Systems

Enhancing your control mechanism can significantly improve your overall experience on the water. With advancements in technology, modern systems offer numerous advantages that can transform handling, safety, and performance. Investing in an upgraded configuration is not merely a luxury; it can be essential for ensuring efficiency and reliability in navigation.

Improved Precision and Responsiveness

One of the most notable advantages of modern configurations is the enhanced precision they provide. Contemporary systems are designed to deliver more accurate and responsive maneuverability, allowing for effortless adjustments during operation. This means you can navigate tighter turns and react more swiftly to changing conditions, ultimately leading to a safer and more enjoyable experience.

Increased Durability and Reduced Maintenance

Modern solutions often incorporate advanced materials and engineering techniques that enhance durability. This translates into a lower likelihood of wear and tear, leading to reduced maintenance requirements over time. With fewer breakdowns and repairs, users can spend more time enjoying their activities rather than worrying about mechanical issues. This efficiency not only saves money but also enhances peace of mind.

Frequently Asked Questions on Steering

This section addresses common inquiries related to the control mechanisms that guide vessels and vehicles. Understanding these queries can enhance your knowledge and help in the maintenance and operation of these systems.

What is the main function of a control mechanism?

The primary purpose is to enable smooth navigation and provide the operator with precise control over direction and movement.

How often should I check my control system?

Regular inspections are recommended, ideally before each use or at least once a season, to ensure optimal performance and safety.

What are the signs of a malfunctioning control system?

Common indicators include unusual noises, difficulty in maneuvering, or leaks in the hydraulic components. Addressing these issues promptly is crucial.

Can I repair these systems myself?

While minor adjustments can often be handled independently, it’s advisable to consult a professional for significant repairs or when you’re unsure of the issue.

What should I do if I notice a fluid leak?

If you observe any fluid leakage, it’s essential to stop using the system immediately and seek professional assistance to prevent further damage.