In the realm of farming equipment, comprehending the intricate assembly of each machine is essential for effective maintenance and repair. These powerful machines, vital for modern agriculture, consist of various elements that work together harmoniously. Grasping how each component functions not only enhances operational efficiency but also prolongs the lifespan of the machinery.

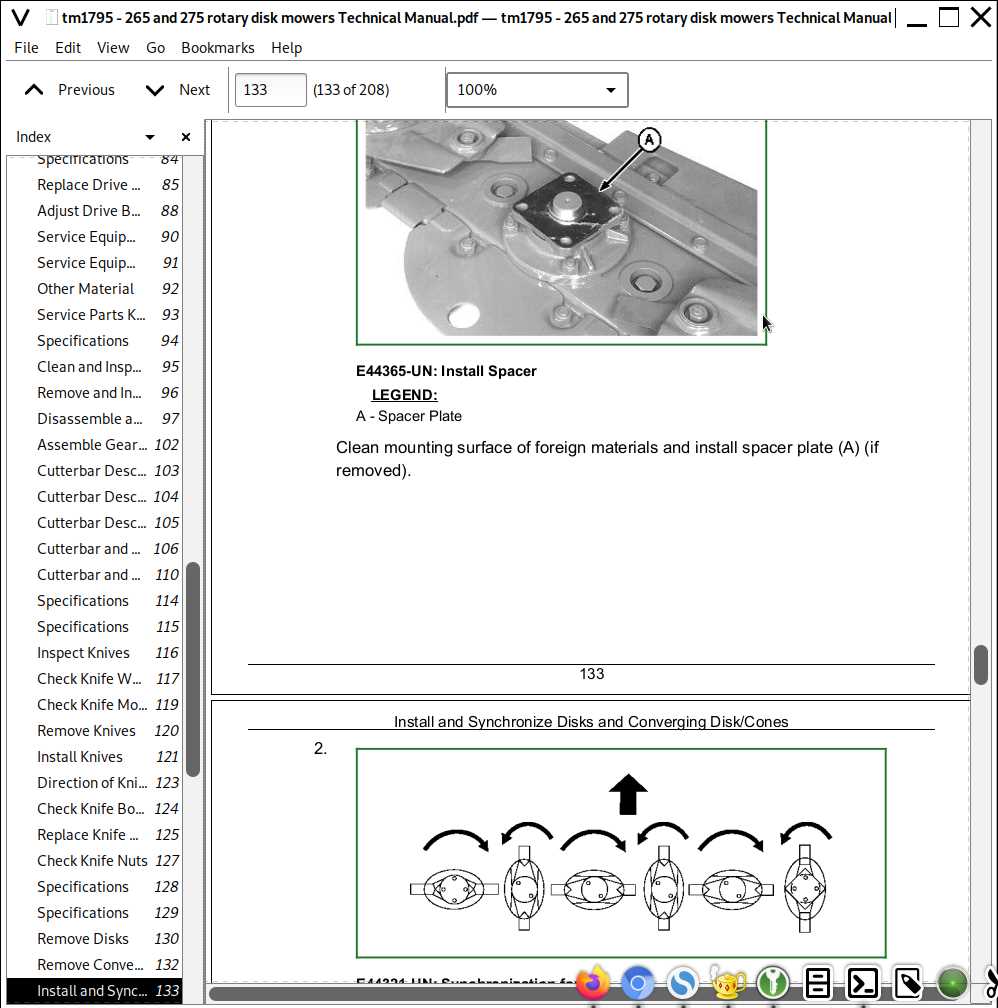

Visual aids play a crucial role in this understanding, offering a clear representation of how individual elements are interconnected. By examining these illustrations, operators can easily identify where issues may arise and address them promptly. Moreover, having a detailed view fosters a deeper appreciation for the engineering that drives these robust tools.

As we delve into the specifics of the various segments within these machines, we aim to provide an ultimate guide that empowers users with the knowledge needed for optimal performance. This exploration will cover everything from the most common wear parts to the less frequently addressed components, ensuring a comprehensive understanding of your agricultural asset.

Understanding the Anatomy of John Deere 265 Components

In this section, we delve into the intricate details that comprise the fundamental elements of the John Deere 265 equipment. Here, we explore the essential structures and functional units that collectively form the operational framework of this machinery.

The Core Framework

At the heart of this machinery lies a framework designed to endure rigorous tasks and maintain stability under diverse operating conditions. This foundational structure supports and integrates various components critical to its overall performance.

Key Operational Units

Comprising a series of interconnected units, each playing a distinct role in its functionality, these components synergistically enable the equipment to achieve optimal efficiency and reliability. They encompass mechanisms that facilitate movement, control, and precision in its operation.

Importance of Accurate Parts Diagrams

Having precise illustrations of components is crucial for effective maintenance and repair. These visuals not only simplify the identification of each piece but also enhance the overall efficiency of service tasks. When individuals can easily reference these images, they minimize the risk of errors during replacements or repairs.

Benefits of Detailed Illustrations

- Improved understanding of assembly and disassembly.

- Reduced downtime by facilitating quicker repairs.

- Enhanced accuracy in ordering the correct components.

Impact on Long-term Maintenance

- Consistency in performance due to proper replacements.

- Cost savings through informed purchasing decisions.

- Prolonged lifespan of equipment through timely maintenance.

Key Components of John Deere 265

Understanding the essential elements of this agricultural machine is crucial for effective maintenance and operation. Each component plays a vital role in ensuring optimal performance and longevity. From the engine to the transmission, each part contributes to the overall efficiency and reliability of the equipment.

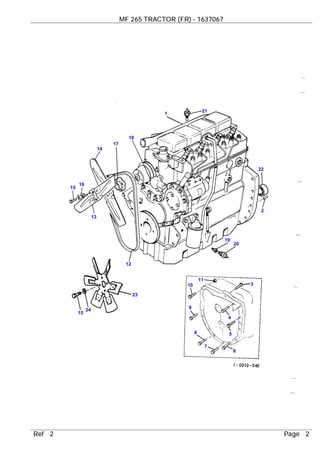

Engine and Powertrain

The heart of the machinery lies in its engine, which powers all operations. Coupled with a robust powertrain, it enables smooth movement and efficient task execution. Regular checks on these components are essential to prevent downtime and enhance productivity.

Hydraulic System

An effective hydraulic system is critical for various functions, including lifting and steering. This system allows for precise control and responsiveness, making it a key feature for operators. Maintaining hydraulic fluid levels and checking for leaks are important practices to ensure uninterrupted functionality.

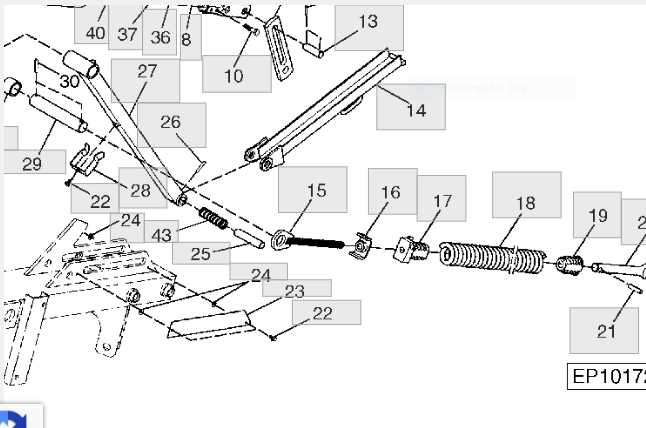

How to Read Parts Diagrams

Understanding visual schematics is essential for anyone working with machinery. These illustrations serve as guides, showcasing the various components and their relationships within a system. By grasping how to interpret these visuals, you can effectively identify parts and their functions, leading to more efficient maintenance and repairs.

Key Elements to Consider

- Labels and Annotations: Pay attention to any markings that indicate part numbers or descriptions.

- Connection Points: Look for lines or arrows that illustrate how components are linked.

- Symbols: Familiarize yourself with common icons that represent specific functions or types of parts.

Steps to Follow

- Begin by identifying the overall layout and the main assembly depicted.

- Locate each labeled item and cross-reference it with any accompanying lists.

- Trace the connections to understand how components interact with one another.

- Refer to your equipment manual for any additional information or clarifications needed.

By following these guidelines, you will enhance your ability to decipher complex schematics and streamline your repair processes effectively.

Common Issues with John Deere 265

Every machinery model may encounter specific challenges that can affect its performance and longevity. Understanding these common problems is essential for efficient maintenance and operation. Below are several issues that operators frequently face, along with potential solutions to ensure smooth functioning.

Engine Performance Problems

One of the primary concerns involves the engine, which may exhibit symptoms such as rough idling or difficulty starting. These issues can stem from fuel system blockages, air filter obstructions, or electrical faults. Regularly checking and replacing filters, as well as ensuring proper fuel flow, can mitigate many of these concerns.

Transmission Difficulties

Transmission-related troubles can lead to operational inefficiencies. Common signs include slipping gears or delayed response during shifting. These symptoms often result from low fluid levels or worn components. Maintaining the correct fluid levels and performing routine inspections can help address and prevent transmission issues.

Finding OEM vs Aftermarket Parts

When maintaining machinery, one of the crucial decisions is choosing between original components and alternatives. Each option offers distinct advantages and considerations that can significantly impact performance, reliability, and cost. Understanding these differences is essential for making informed choices that align with your needs and budget.

Original equipment manufacturer options are designed specifically for certain machines, ensuring compatibility and quality. These components often come with warranties and are tested to meet strict standards, providing peace of mind to users. However, they can be more expensive, which may not suit everyone’s financial plan.

On the other hand, alternative solutions can offer cost savings and greater availability. Many third-party manufacturers produce compatible parts that perform well, though they may vary in quality. It is vital to research and select reputable sources to ensure that these components meet necessary specifications and will not compromise the machinery’s functionality.

Ultimately, the choice between original and alternative components will depend on individual circumstances, including budget constraints, the importance of brand assurance, and the specific requirements of the equipment. Careful consideration will help you make the best decision for maintaining the longevity and performance of your machinery.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended life of your machinery. Regular maintenance not only enhances performance but also minimizes the risk of unexpected failures. Adopting a consistent care routine can significantly extend the lifespan of your equipment, providing you with reliable service for years to come.

1. Regular Inspections: Conduct frequent checks on all critical components to identify wear and tear early. Look for signs of damage or loose fittings, and address any issues promptly to avoid more significant problems.

2. Cleanliness is Key: Keeping your equipment clean prevents the buildup of dirt and debris, which can hinder performance. Regularly wash and inspect parts to maintain optimal functionality.

3. Lubrication: Ensure that all moving parts are adequately lubricated. This reduces friction and wear, promoting smoother operation. Follow manufacturer guidelines on the types and frequencies of lubricants to use.

4. Fluid Levels: Regularly check and replace fluids as necessary. Maintaining appropriate oil, coolant, and hydraulic fluid levels is vital for preventing overheating and ensuring efficient operation.

5. Follow Manufacturer Guidelines: Adhere to the recommended maintenance schedule provided by the manufacturer. This includes regular servicing and part replacements, which are crucial for longevity.

6. Store Properly: When not in use, store your equipment in a dry, sheltered environment to protect it from the elements. This helps prevent rust and other environmental damage.

By implementing these maintenance strategies, you can enhance the durability and reliability of your machinery, ensuring it serves you well for an extended period.

Where to Purchase Replacement Parts

Finding high-quality components for your machinery is essential for maintaining optimal performance and longevity. There are several reliable sources where you can acquire these essential items, ensuring that your equipment runs smoothly and efficiently.

Authorized Dealers: One of the best options is to purchase from official representatives of the brand. These dealers typically offer genuine components that meet the original equipment specifications, providing peace of mind regarding quality and compatibility.

Online Retailers: The internet offers a vast array of options, with numerous e-commerce platforms specializing in machinery supplies. These websites often feature user reviews and competitive pricing, allowing you to compare different offerings easily.

Local Repair Shops: Many local mechanics and repair shops stock a selection of necessary items. They can also provide expert advice on the best options for your specific needs, and in some cases, can even help with installation.

Salvage Yards: For those looking for budget-friendly alternatives, salvage yards can be a treasure trove of usable components. While availability may vary, it’s possible to find parts that are still in good condition at a fraction of the original price.

Regardless of where you choose to buy, ensuring that the components you select are compatible with your machinery is crucial for maintaining its performance and efficiency.

Resources for Further Information

Exploring comprehensive materials can significantly enhance your understanding of machinery components and their functionalities. Accessing various sources will provide you with detailed insights, ensuring that you are well-informed about maintenance and repair processes.

Online Communities

Engaging with online forums and communities dedicated to equipment enthusiasts can be invaluable. Platforms such as Reddit and specialized websites allow users to share experiences, troubleshooting tips, and recommendations for reliable resources. These communities often discuss modifications, upgrades, and common issues, fostering a collaborative environment.

Official Manufacturer Resources

Visiting the official website of the equipment manufacturer can yield essential documentation, including user manuals and maintenance guides. These resources typically offer in-depth information regarding specifications and recommended practices, ensuring that you have access to the most accurate data. Additionally, many manufacturers provide video tutorials and webinars to further assist users in understanding their products.