The intricacies of heavy machinery can often seem daunting, yet a closer look reveals the fascinating interplay of various elements that enable these powerful machines to perform efficiently. Each component plays a crucial role, and knowing how they fit together is essential for any operator or enthusiast.

In this section, we will delve into the specific assembly of a well-known piece of equipment, providing a comprehensive overview of its critical features. Understanding these components not only enhances operational knowledge but also aids in effective maintenance and troubleshooting.

Whether you’re a seasoned professional or a newcomer to the field, grasping the layout and functionality of each segment will empower you to achieve optimal performance. Join us as we explore the ultimate configuration of this iconic machinery.

Understanding John Deere 70 Loader

This section explores the essential components and functionalities of a specific piece of heavy machinery, highlighting its significance in various applications. A deeper comprehension of its structure can enhance maintenance and operational efficiency.

The machinery features robust construction, designed to handle demanding tasks. Its versatility makes it suitable for both agricultural and construction projects, emphasizing the importance of familiarity with its inner workings.

By examining its components, operators can optimize performance and ensure longevity, ultimately leading to improved productivity in diverse settings.

Key Components of the Loader

Understanding the essential elements of a heavy-duty machine is crucial for effective operation and maintenance. Each part plays a vital role in ensuring optimal performance and efficiency.

Essential Elements

- Hydraulic System

- Frame Structure

- Bucket Assembly

- Transmission Unit

- Engine

Functional Overview

- Hydraulic System: Powers various movements and provides lifting strength.

- Frame Structure: Supports the overall integrity and stability during operation.

- Bucket Assembly: Interacts with the ground, allowing material handling.

- Transmission Unit: Transfers power from the engine to the wheels.

- Engine: Serves as the powerhouse, driving the machine’s functions.

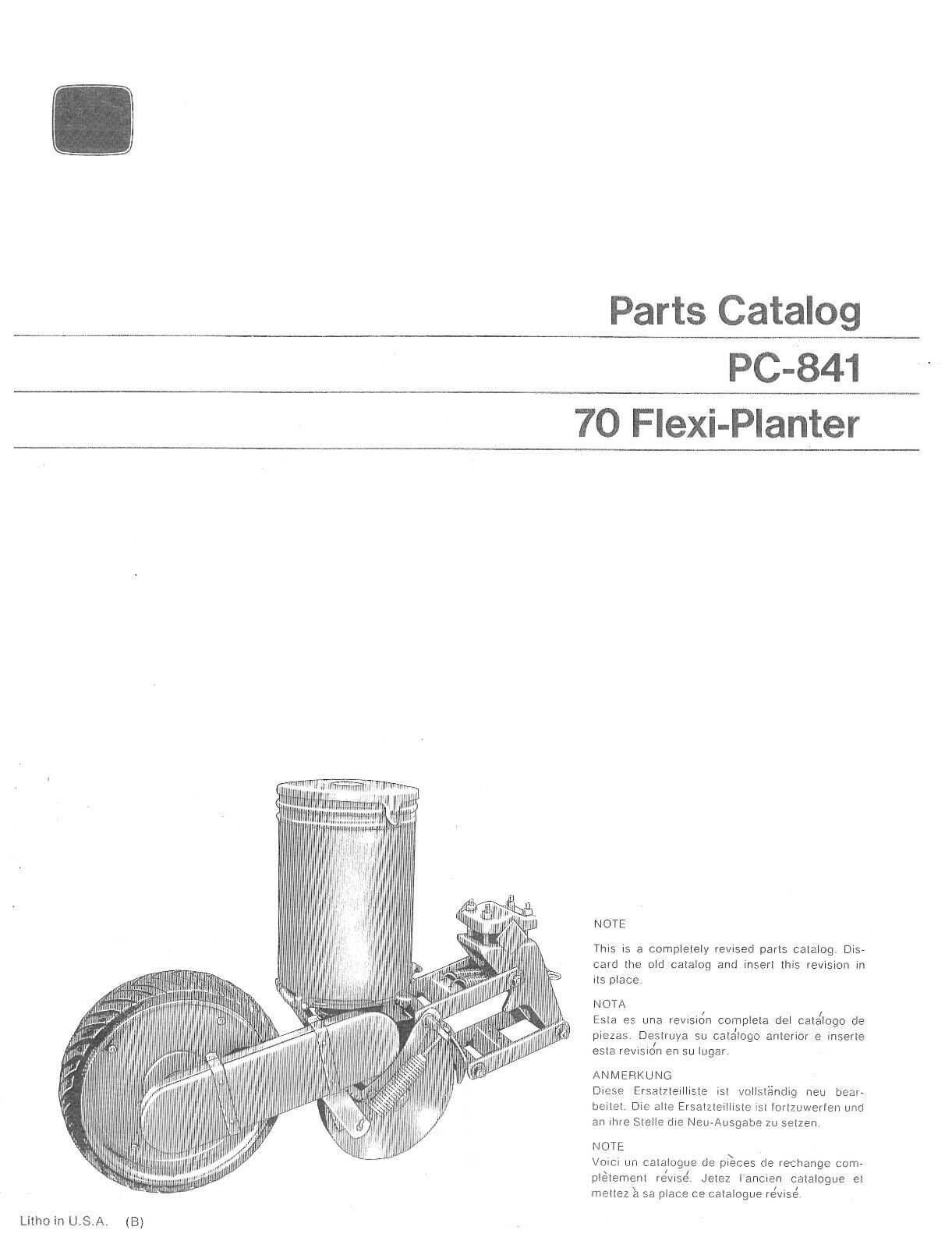

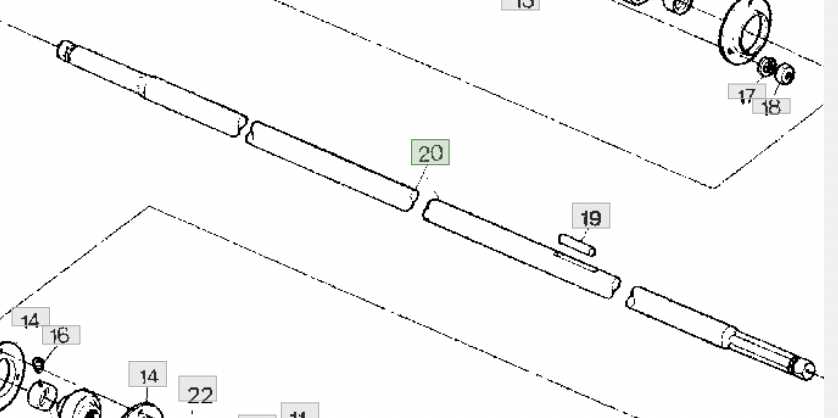

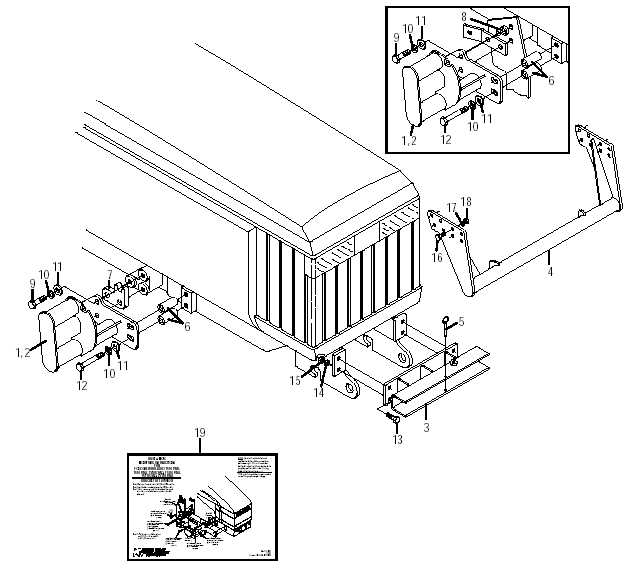

Importance of Parts Diagrams

Understanding the components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools, enabling users to identify individual elements and their relationships within the assembly. This clarity can significantly reduce downtime and enhance overall efficiency.

Enhancing Repair Efficiency

When issues arise, having a clear illustration of the assembly allows technicians to quickly locate and address faults. This streamlined approach minimizes confusion, ensuring that repairs are executed with precision and speed.

Facilitating Proper Maintenance

Regular upkeep is vital for longevity. Diagrams provide insights into necessary servicing routines, making it easier to follow guidelines and maintain optimal functionality. They emphasize the importance of each component’s role in the system.

Common Issues with 70 Loader Parts

When operating heavy machinery, certain challenges frequently arise due to wear and tear, improper maintenance, or manufacturing flaws. Identifying these concerns early can prevent significant downtime and costly repairs. Here are some prevalent issues that users may encounter.

Wear and Tear

- Hydraulic leaks can lead to performance drops.

- Excessive friction may cause component failure.

- Cracks in the structure may compromise integrity.

Maintenance Oversights

- Neglecting lubrication can result in seized components.

- Ignoring warning signals often leads to larger issues.

- Failure to replace worn-out components can increase repair costs.

Finding Replacement Parts Effectively

Locating suitable components for machinery can be a straightforward process with the right approach. Understanding where to search and how to evaluate options is essential for ensuring optimal performance.

- Utilize online marketplaces that specialize in heavy equipment.

- Consult manufacturer websites for authentic components.

- Explore forums and community groups for recommendations and advice.

- Visit local dealers for immediate availability and support.

Additionally, it’s important to:

- Keep a record of your machine’s specifications.

- Compare prices and reviews to find the best deals.

- Consider the warranty and return policies before making a purchase.

By following these strategies, one can effectively delve into the search for replacements and ensure reliable operation for years to come.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires regular care and attention. By implementing effective maintenance strategies, you can enhance performance and prolong its lifespan. Consistent upkeep not only minimizes the risk of breakdowns but also optimizes functionality, allowing for smoother operations.

Regular Inspections

Conducting frequent evaluations is essential. Look for signs of wear and tear, such as leaks or unusual noises. Addressing minor issues promptly can prevent them from escalating into significant problems.

Proper Lubrication

Using appropriate lubricants can significantly reduce friction and wear. Ensure all moving parts are adequately greased, as this will help maintain efficiency and reduce the likelihood of premature failure. Regularly check levels and replenish as needed.

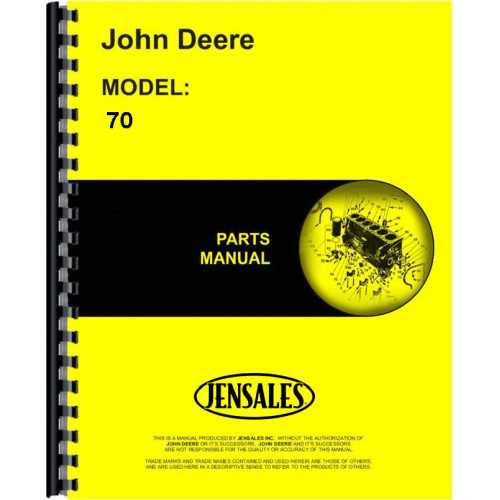

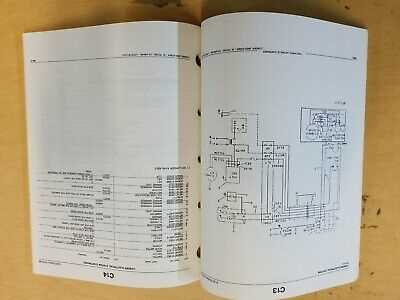

Resources for Diagram Access

Accessing detailed schematics and illustrations for machinery components is essential for effective maintenance and repair. Numerous resources are available online and offline to help users find the necessary information quickly and efficiently.

Online Platforms

Numerous websites specialize in providing comprehensive resources for machinery enthusiasts and professionals. Websites like OEM parts suppliers often have searchable databases that allow users to locate specific illustrations based on model numbers. Additionally, forums and community sites can offer shared experiences and insights regarding component assembly and troubleshooting.

Manuals and Guides

Physical and digital manuals serve as invaluable references. Users can often find official service manuals that contain detailed images and assembly instructions. Local libraries or specialized bookstores may also stock technical literature that covers a wide range of machinery models and their components.

Comparative Analysis with Other Models

This section explores the distinctions and similarities among various machinery options within the same category, focusing on functionality, efficiency, and component availability.

When examining different models, several factors come into play:

- Performance: How each model handles various tasks under different conditions.

- Durability: The longevity of materials used and overall build quality.

- Maintenance: Ease of access to components and frequency of required upkeep.

- Cost-effectiveness: Initial investment versus long-term operational costs.

Understanding these elements provides valuable insights for users aiming to select the most suitable machinery for their needs.

Customer Reviews and Experiences

This section highlights the feedback and insights shared by users who have interacted with machinery components. Their testimonials offer valuable perspectives on performance, reliability, and overall satisfaction.

Many users have taken the time to share their experiences, which can be categorized into several key themes:

- Performance: Users often discuss how well the equipment operates under various conditions, noting its efficiency and capability in handling tasks.

- Durability: Feedback frequently highlights the longevity of components, with many expressing satisfaction regarding the robustness of the machinery.

- Maintenance: Reviews often include insights on ease of maintenance, with some users appreciating the straightforward nature of repairs and upkeep.

- Customer Support: Experiences with service and support teams are a common topic, where many emphasize the helpfulness and responsiveness of representatives.

Overall, the shared experiences create a comprehensive understanding of what to expect from the equipment, guiding potential buyers in their decision-making process.