When maintaining or upgrading certain devices, it’s crucial to familiarize yourself with the intricate elements that make up the system. Every part serves a unique role, contributing to the overall performance and reliability. Proper knowledge of these elements can lead to more efficient repairs, reducing downtime and ensuring optimal operation.

In this section, we’ll explore the essential mechanisms that drive these systems. By identifying each component and understanding its role, you will gain a deeper appreciation of how everything works in harmony. Knowing how to navigate and recognize these crucial details can make troubleshooting easier and more effective.

Through a comprehensive overview of key features, this guide aims to offer valuable insights into the inner workings of various mechanical setups. This information will be especially useful when dealing with issues or replacements, ensuring that you can handle maintenance with confidence and precision.

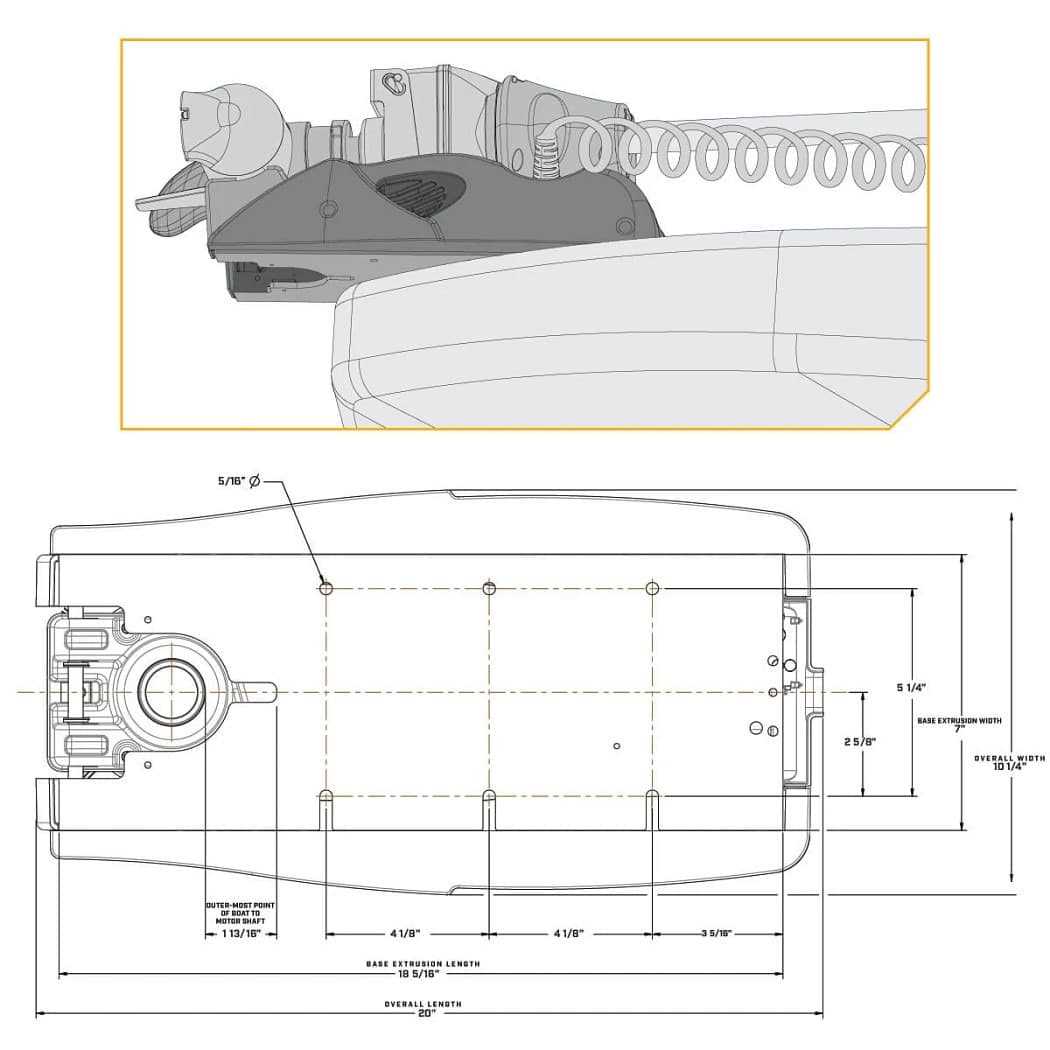

Understanding the Minn Kota Motor

The electric propulsion unit used in small watercraft is designed to offer smooth and efficient navigation, often serving as an essential component for anglers and boating enthusiasts. With its precise construction and attention to durability, this motor ensures reliable performance even in challenging aquatic environments. Understanding its core functions and key mechanisms can help you make the most out of your time on the water.

Core Components of the Propulsion System

At the heart of the motor lies a robust drive mechanism that converts electrical power into motion. This process is supported by high-quality internal elements, each contributing to the motor’s ability to deliver steady thrust. Additionally, the unit is equipped with advanced control features to enhance maneuverability and speed regulation.

Key Features and Benefits

Some of the standout characteristics include adjustable speed settings and energy-efficient design, which allow for extended use on the water without draining power quickly. These motors are also designed with minimal noise output, ensuring a quiet and unobtrusive ride, ideal for those who seek a peaceful and smooth experience on lakes or rivers.

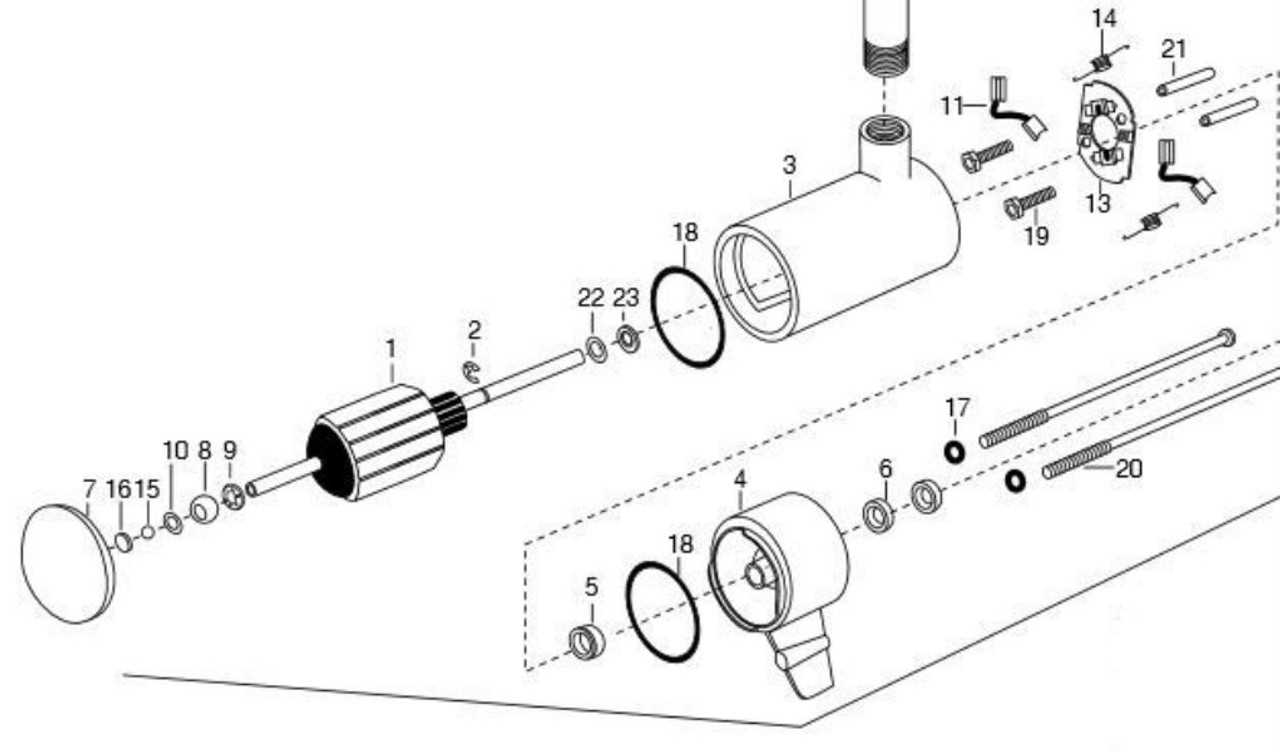

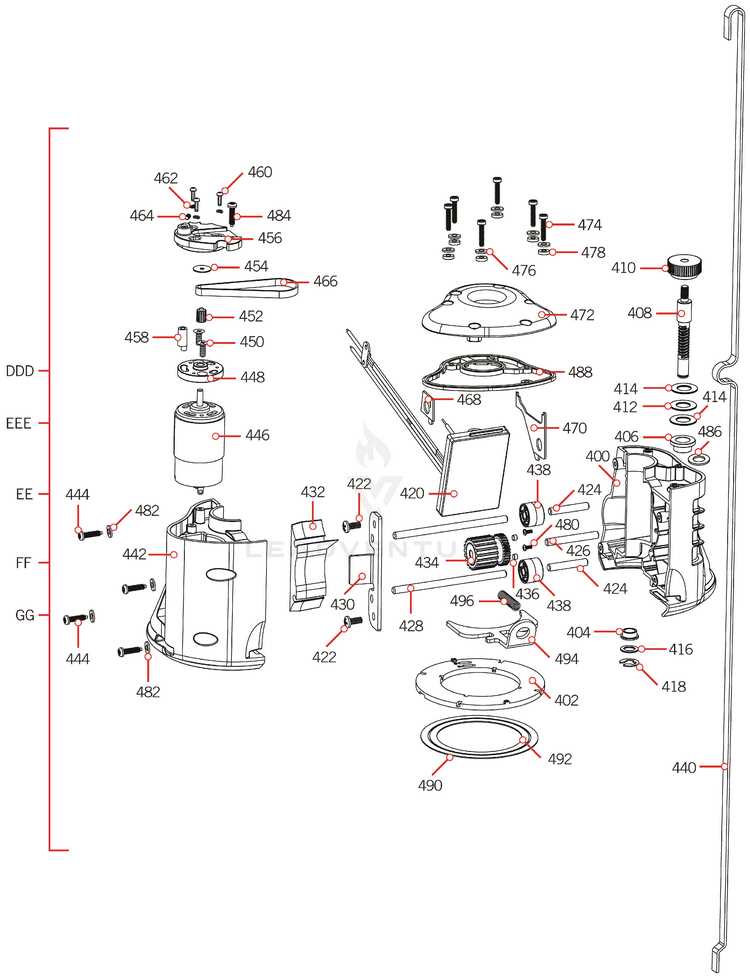

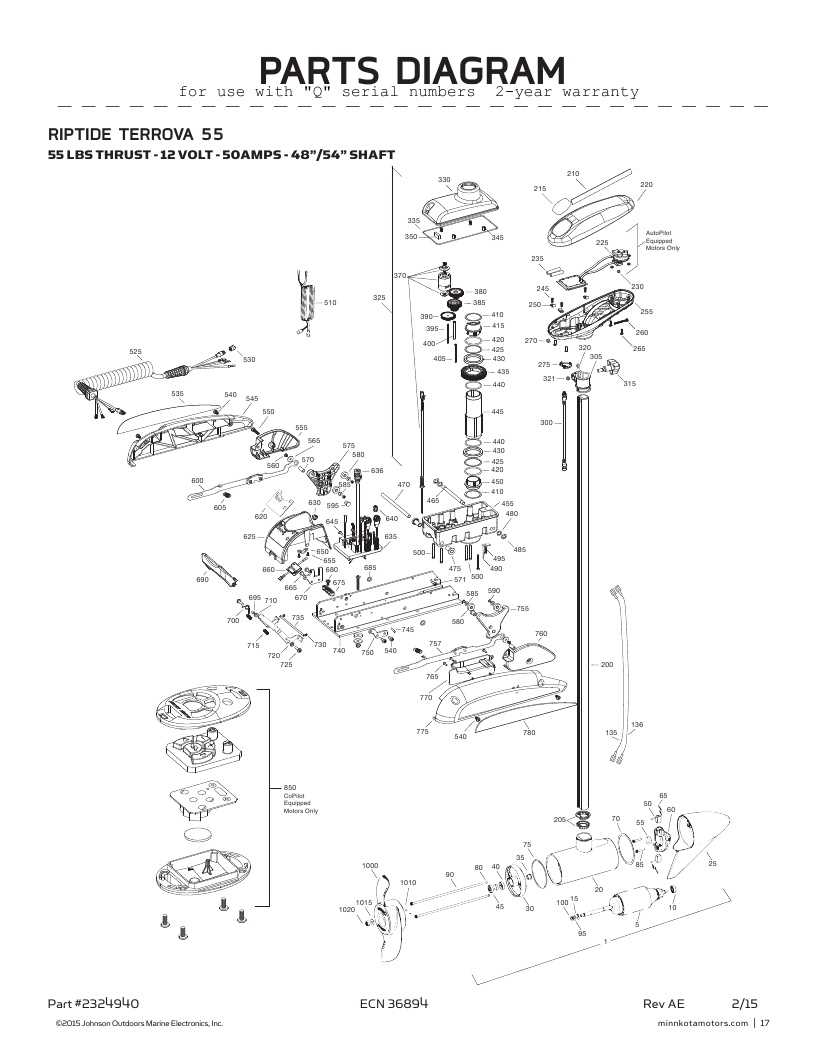

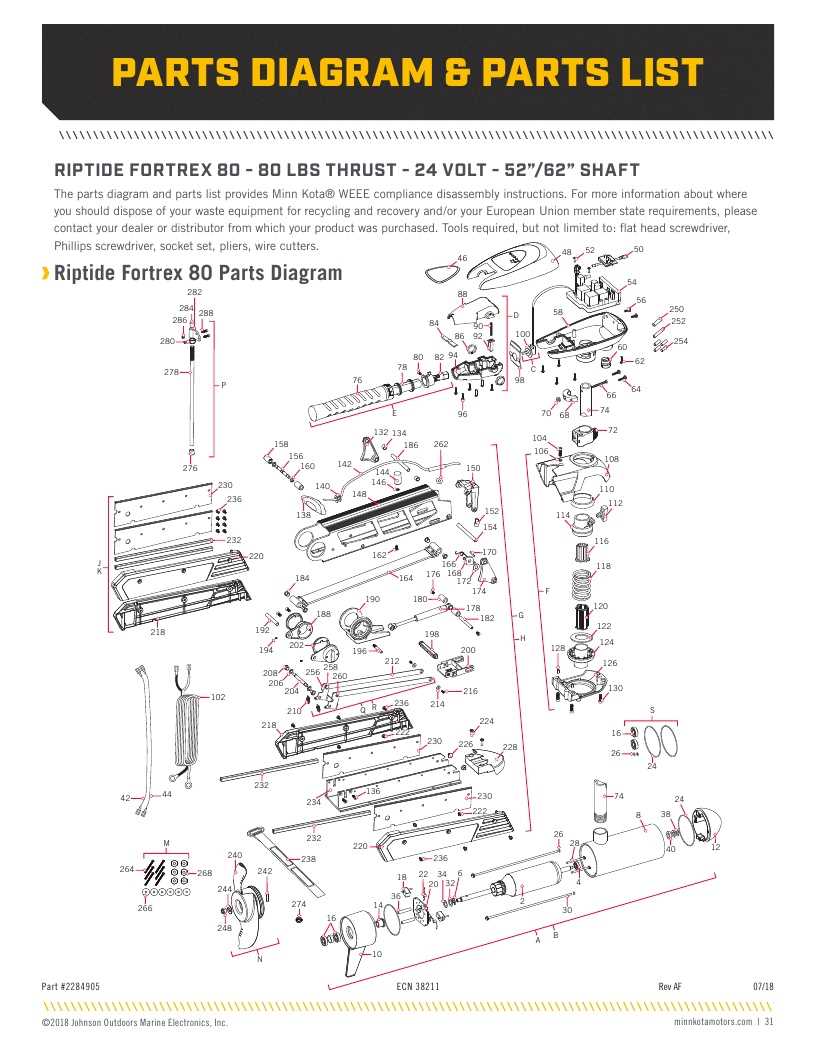

Key Components Breakdown

In this section, we will explore the essential elements that contribute to the functionality and performance of this mechanical system. Understanding the individual components is crucial for proper maintenance and effective troubleshooting. By analyzing each part, you can ensure smooth operation and extend the lifespan of the device.

- Motor Assembly: The core of the system, responsible for driving the movement and providing power.

- Control Unit: Manages the various functions and allows for user adjustments, ensuring precision and ease of use.

- Propeller: Converts power into motion, pushing the device through the water efficiently.

- Battery Connections: Ensure stable power delivery to the motor, a critical factor for consistent performance.

- Steering Mechanism: Allows for directional control, offering smooth and responsive movement.

Each of these components plays a vital role in the overall system, making it important to regularly check and maintain them to prevent potential issues.

How to Identify Replacement Parts

When dealing with repairs or maintenance, knowing how to recognize and locate the necessary components is crucial. Whether you are addressing mechanical issues or updating specific elements, identifying the right replacement piece ensures functionality and longevity.

First, it is important to carefully inspect the equipment for any visible wear or damage. This can help you pinpoint the area that requires attention, allowing you to narrow down the range of components needed.

Next, refer to the original specifications or user manual. These documents typically provide a detailed breakdown of the item’s structure, helping you confirm the exact model and type of part required for a proper fit.

Lastly, verify the size, shape, and material of the replacement. This step guarantees that the chosen item matches the original specifications and will perform correctly once installed.

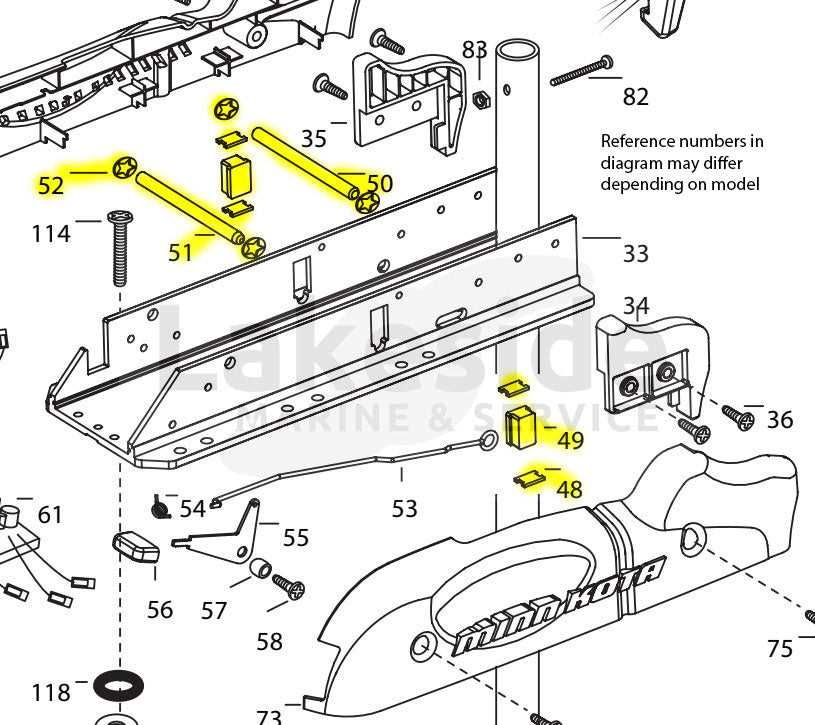

Detailed Assembly Process Explained

The process of reassembling mechanical components requires careful attention to each step, ensuring that all elements fit together smoothly and function as intended. By following a structured approach, you can efficiently bring together all necessary pieces, resulting in a reliable and durable system. This section will guide you through the essential steps, providing clarity on how different elements interact during the reassembly.

Key Components Overview

Before beginning, it’s important to identify the critical elements involved in the setup. Ensuring that each component is accounted for and in proper working condition will help avoid complications later in the process. Below is an overview of some of the most significant parts involved in this assembly:

| Component | Function |

|---|---|

| Motor Housing | Encases the motor, protecting it from external factors while ensuring stable operation. |

| Propeller | Generates the necessary thrust for movement. |

| Mounting Bracket | Secures the assembly to the surface, providing stability and alignment. |

Step-by-Step Reassembly

Once the key components are identified, the reassembly can proceed. Start by securing the main frame and ensure that all mounting points align correctly. Afterward, attach the propeller and verify that it spins freely without obstruction. Finally, complete the process by connecting any necessary wiring

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires consistent care and attention to detail. Regular maintenance can greatly extend the lifespan of various components, preventing breakdowns and costly repairs.

- Clean regularly: Remove debris, dirt, and grime after each use. This simple step helps prevent corrosion and wear.

- Lubricate moving parts: Apply appropriate lubricants to all moving mechanisms to reduce friction and ensure smooth operation.

- Inspect for damage: Routinely check all elements for signs of wear, cracks, or other issues that could affect performance. Early detection can prevent bigger problems.

- Store properly: Keep the equipment in a dry, cool environment when not in use. This minimizes exposure to harsh conditions that could accelerate deterioration.

- Follow manufacturer guidelines: Adhere to the maintenance schedule and recommendations provided by the maker for optimal performance.

Common Issues and Troubleshooting

Understanding frequent challenges and effective solutions is essential for maintaining optimal performance in watercraft propulsion systems. By addressing common problems, users can enhance reliability and extend the lifespan of their equipment.

Battery and Power Issues

One of the most prevalent problems arises from power supply complications. If the device fails to start, check the battery connections, ensuring they are clean and tightly secured. A depleted battery may also be the culprit; consider recharging or replacing it as needed. Additionally, inspect the wiring for any signs of wear or damage that could disrupt power flow.

Mechanical Failures

Mechanical issues can significantly impact functionality. Listen for unusual noises during operation, which may indicate a malfunctioning motor or propeller. Regularly examine the propeller for debris or damage that could hinder performance. If the unit overheats, it may signal an internal fault, requiring professional inspection.

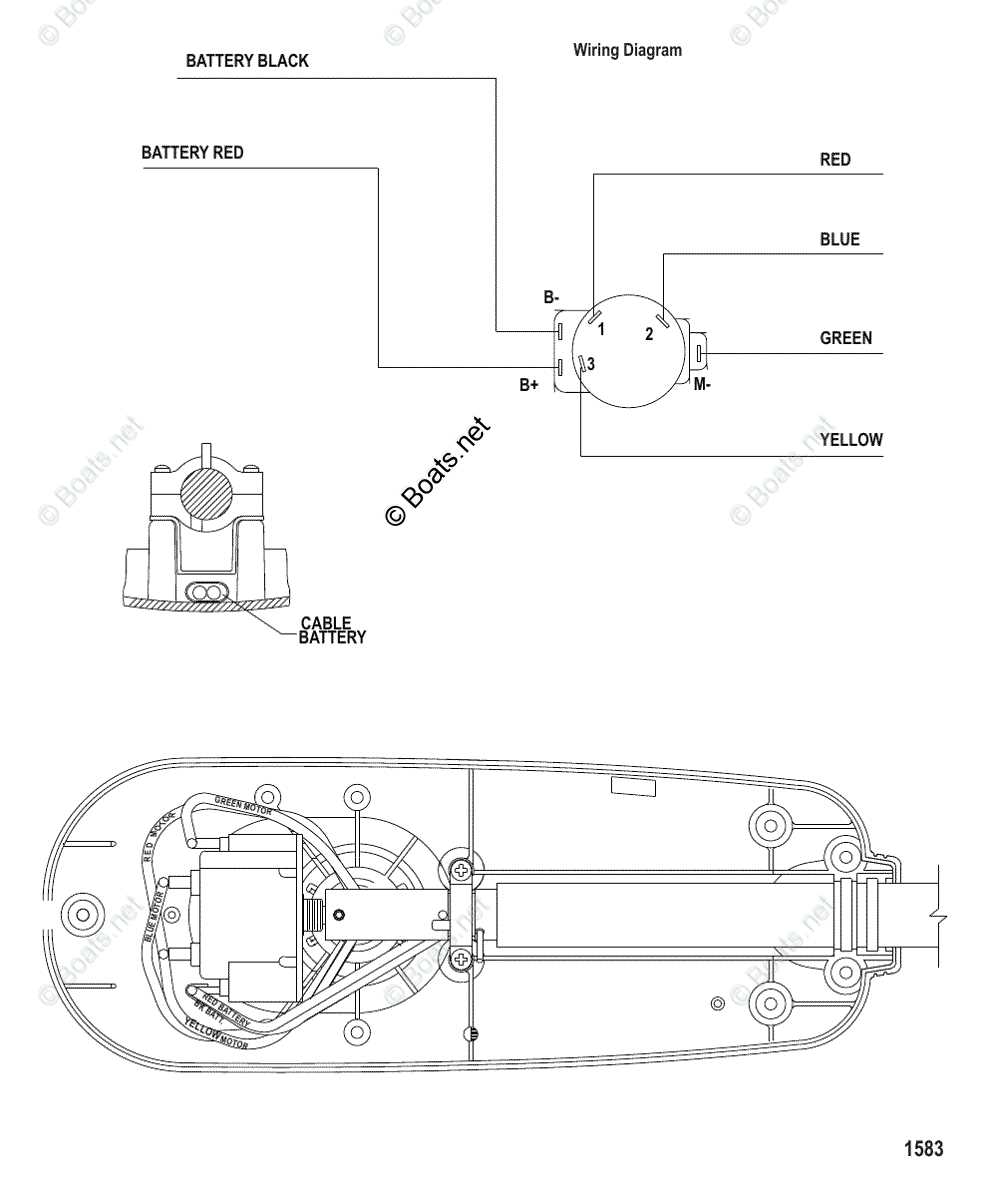

Wiring and Electrical Diagrams

The proper understanding of wiring and electrical schematics is crucial for ensuring optimal functionality and safety in any electronic device. These representations provide a visual guide that simplifies the assembly and troubleshooting processes. By studying these illustrations, one can gain insights into the flow of electricity, the relationship between components, and potential points of failure.

Understanding Connections

Connections between various elements are vital for achieving seamless operation. Each wire and terminal has a specific role, contributing to the overall performance of the system. Familiarizing oneself with these connections allows for effective maintenance and repair, minimizing the risk of malfunctions.

Safety Considerations

When dealing with electrical systems, safety must always be a priority. Properly labeled diagrams help users identify hazardous areas and avoid accidents during installation or repairs. Ensuring that all components are correctly wired not only enhances functionality but also protects against electrical failures that could lead to serious injuries.

How to Upgrade Your Motor

Enhancing your propulsion system can significantly improve performance and efficiency. This process often involves selecting the right components and understanding the necessary modifications to achieve optimal results. By carefully considering your specific needs, you can make informed decisions that elevate your experience on the water.

Evaluate Current Performance

Before making any upgrades, it’s essential to assess the existing functionality of your unit. Consider the following factors:

- Power output and efficiency

- Weight and size of the current unit

- Battery life and compatibility

- Speed and maneuverability

Selecting Upgrades

Once you have evaluated the performance, you can explore various enhancement options. Here are some popular choices:

- Propeller: Upgrading to a high-performance propeller can improve thrust and speed.

- Battery: Investing in a more powerful or lightweight battery can increase runtime.

- Control System: Advanced controls can provide better responsiveness and features.

- Mounting Hardware: Ensure that your motor is securely and effectively mounted for optimal performance.

By following these steps, you can successfully elevate your motor’s capabilities, ensuring a more enjoyable and efficient experience on the water.

Essential Tools for Installation

When undertaking the installation of various components for marine propulsion systems, having the right tools is crucial. These instruments not only facilitate a smoother installation process but also ensure that all parts are securely fitted and function as intended. Below is a list of essential tools that will aid in achieving optimal results.

Basic Hand Tools

Every installation kit should include a variety of hand tools. Wrenches and screwdrivers in different sizes are fundamental for tightening and loosening fasteners. Additionally, a reliable pair of pliers will help manipulate wires and other materials effectively. A utility knife is also recommended for cutting through packaging or trimming components to fit properly.

Specialized Equipment

In addition to basic hand tools, specialized equipment can significantly enhance the installation experience. A torque wrench is vital for applying the correct amount of force to bolts, preventing damage from over-tightening. An electrical multimeter is indispensable for testing connections and ensuring that the electrical system operates correctly. Finally, a heat gun can be useful for shrink-wrapping connections and securing various components against water damage.