For those who operate lawn machinery, a comprehensive grasp of its inner workings is crucial for optimal performance. Familiarity with the various elements that contribute to the functionality of your equipment can significantly enhance its longevity and efficiency.

In this section, we will explore the intricate network of components found in specific models of garden machinery. By breaking down these individual parts, users can gain insights into maintenance practices, troubleshooting techniques, and potential upgrades.

Ultimately, an in-depth examination of these mechanical features empowers operators to make informed decisions, ensuring their equipment remains in peak condition throughout its lifespan. Emphasizing the significance of each part not only aids in effective management but also enriches the overall user experience.

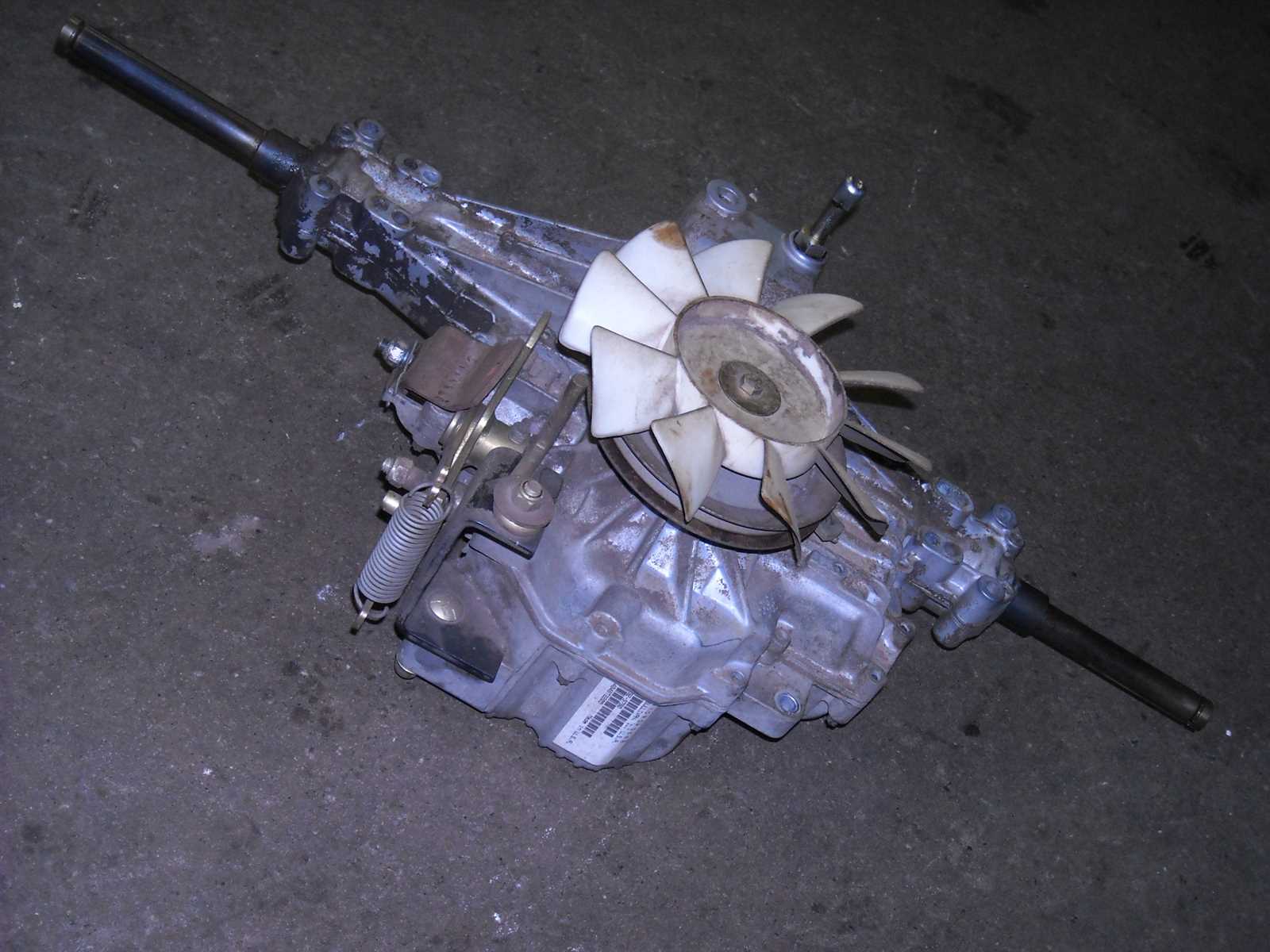

Understanding the Tuff Torq K55

This section explores a particular type of mechanical assembly designed for efficient operation in various applications. Its components work in unison to ensure reliable performance, making it essential for users to comprehend its structure and functionality.

| Component | Description |

|---|---|

| Gear Assembly | Facilitates power transmission between parts. |

| Hydraulic System | Provides smooth operation and control. |

| Drive Belt | Connects the motor to the driven components. |

| Chassis | Houses and supports all internal parts. |

Importance of Replacement Parts

In the realm of machinery and equipment, the significance of substitutive components cannot be overstated. These elements play a crucial role in maintaining optimal performance and extending the lifespan of devices. When original elements wear out or become ineffective, timely replacement ensures continued functionality and prevents further damage.

Enhancing Efficiency

Utilizing new components can greatly enhance the efficiency of a machine. Fresh parts can restore original specifications, leading to improved operation and reduced energy consumption. As a result, users experience better productivity and lower operational costs.

Safety and Reliability

Safety is paramount when dealing with machinery. Worn-out components can lead to malfunctions, which pose risks to operators and equipment alike. By regularly replacing degraded elements, users can significantly reduce the likelihood of accidents, ensuring a safer working environment.

| Benefit | Description |

|---|---|

| Increased Performance | New components restore machine efficiency, leading to better results. |

| Cost-Effectiveness | Investing in replacements can save money in repairs and energy. |

| Improved Safety | Maintaining equipment with new parts reduces the risk of accidents. |

| Extended Lifespan | Regular updates prevent wear and tear, prolonging the machine’s life. |

Common Issues with K55 Components

Various components in lawn and garden equipment can face several challenges that affect their functionality. Understanding these issues can help in maintaining optimal performance and extending the lifespan of the machinery.

- Wear and Tear: Over time, parts may degrade due to regular use.

- Leakage: Seals and gaskets can fail, leading to fluid leaks.

- Clogging: Debris can accumulate, obstructing flow and causing inefficiencies.

- Alignment Problems: Misalignment of components can lead to operational difficulties.

- Electrical Failures: Wiring issues may cause malfunctions in electrical systems.

Addressing these common challenges promptly can ensure smooth operation and prevent further damage.

Where to Find Parts Diagrams

Locating detailed illustrations of components is essential for effective repairs and maintenance. These resources provide valuable information that can assist in identifying and acquiring the necessary elements for machinery.

Online Resources

- Manufacturer Websites: Often, official sites offer comprehensive resources.

- Dedicated Forums: Community-driven platforms can be goldmines for shared diagrams.

- Retailer Sites: Many online sellers include visual guides to assist customers.

Printed Manuals

- Owner’s Manuals: Frequently include helpful visuals and descriptions.

- Service Guides: Often available for purchase, providing in-depth insights.

Step-by-Step Assembly Guide

This section provides a clear and concise approach to assembling the components of your equipment. Following these steps will ensure that each part is correctly positioned and secured, leading to optimal performance.

- Gather Your Tools:

- Screwdriver

- Wrench set

- Torque wrench

- Safety goggles

- Prepare Your Workspace:

- Choose a clean, dry area.

- Ensure good lighting for visibility.

- Have all parts accessible and organized.

- Start with the Base:

- Place the base on a flat surface.

- Check for any protective coverings that need to be removed.

- Attach the Main Components:

- Secure the motor assembly using the provided bolts.

- Ensure all connections are tight but not over-tightened.

- Install Additional Elements:

- Follow the sequence for adding other parts, such as the transmission and linkages.

- Consult your reference materials for specific alignment instructions.

- Check All Connections:

- Review all bolts and screws to confirm they are tightened properly.

- Look for any loose wires or connections.

- Final Inspection:

- Conduct a thorough check of the assembled unit.

- Ensure that all parts are functioning as intended.

By carefully following these steps, you will achieve a successful assembly, setting the stage for reliable operation in the future.

Recommended Maintenance Practices

Regular upkeep of machinery is essential for optimal performance and longevity. By following a structured maintenance routine, operators can prevent potential issues, enhance efficiency, and reduce costly repairs. This section outlines essential practices to ensure your equipment remains in top condition.

Routine Inspections

Conducting frequent inspections is crucial for identifying wear and tear before it becomes a major problem. Consider the following points:

- Check fluid levels regularly to ensure proper operation.

- Examine belts and hoses for signs of cracking or fraying.

- Inspect filters and clean or replace them as needed.

- Look for leaks around hydraulic components.

Cleaning Procedures

Keeping equipment clean is vital for preventing dirt buildup, which can lead to mechanical failures. Implement these cleaning practices:

- Wipe down surfaces to remove dust and debris.

- Use compressed air to clear out hard-to-reach areas.

- Clean undercarriages to prevent corrosion.

- Regularly wash exterior components to maintain visibility and functionality.

By adhering to these maintenance practices, operators can ensure their machinery operates efficiently and effectively over time.

Tools Needed for Repairs

When it comes to maintaining and fixing mechanical equipment, having the right tools is essential for a smooth and efficient process. A well-equipped toolkit not only simplifies repairs but also ensures that tasks are completed safely and effectively. Understanding which instruments are necessary can save both time and frustration during the repair journey.

Essential Hand Tools

Basic hand tools are the backbone of any repair endeavor. These typically include screwdrivers, wrenches, and pliers. Each of these instruments serves a unique function, allowing for precise manipulation of various components. Having a set of socket wrenches can be particularly beneficial for accessing hard-to-reach fasteners.

Power Tools for Efficiency

In addition to hand tools, incorporating power tools can significantly enhance productivity. Drills and impact drivers are invaluable for tackling tougher jobs that require more force. Ensuring that you have a reliable multimeter on hand can also aid in diagnosing electrical issues, making it easier to pinpoint problems that might otherwise go unnoticed.

Customer Reviews on K55 Parts

This section focuses on the feedback and experiences shared by users regarding components designed for a specific model of lawn equipment. The insights provided by customers highlight both the strengths and weaknesses of these products, guiding potential buyers in making informed decisions.

Positive Experiences

Many users have expressed satisfaction with the durability and reliability of the components. Customers often highlight the ease of installation, noting that most parts fit seamlessly and function as expected. This reliability has led to a significant number of repeat purchases among users who value performance in their lawn maintenance tasks.

Areas for Improvement

Despite the overall positive feedback, some reviews point out issues that could be addressed. A few users have mentioned that certain items showed signs of wear sooner than anticipated. Additionally, concerns about customer service response times have been noted, suggesting that improvements could enhance the overall user experience.

| Rating | Comment |

|---|---|

| 5/5 | Excellent quality! Parts fit perfectly and improved my equipment’s performance. |

| 4/5 | Good product, but delivery took longer than expected. |

| 3/5 | Functional but wear out quicker than I hoped. |

| 2/5 | Had issues with installation. Customer service was slow to respond. |

Upgrades for Enhanced Performance

Improving the functionality and efficiency of machinery can significantly elevate overall user experience. Upgrades can involve various components that enhance power, durability, and precision. By focusing on specific areas for enhancement, users can achieve the ultimate performance from their equipment.

Engine Modifications: Enhancing the engine’s capability through performance chips or air filters can lead to increased horsepower and fuel efficiency. These upgrades optimize air intake and exhaust flow, resulting in a smoother operation.

Transmission Enhancements: Upgrading to a high-performance transmission can provide quicker response times and improved gear shifting. This modification ensures better power delivery and smoother transitions during operation.

Suspension Upgrades: A refined suspension system contributes to greater stability and control. Upgrading springs and shock absorbers can minimize vibrations, allowing for a more comfortable and controlled ride.

Wheels and Tires: Investing in high-quality wheels and tires can enhance traction and handling. Better grip improves maneuverability, particularly in challenging terrain, ensuring optimal performance in various conditions.

By strategically selecting upgrades, users can delve into enhancing their machinery, ultimately leading to a more efficient and enjoyable experience.