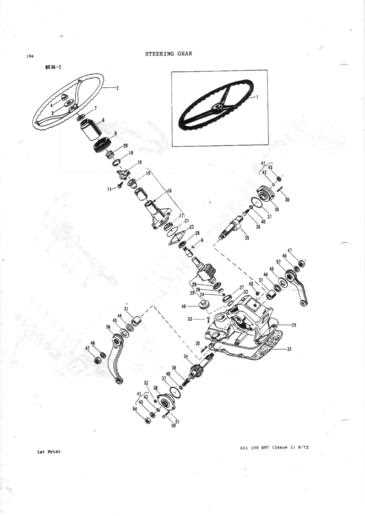

Every machine designed for movement relies on a network of essential mechanisms that guide its overall direction and control. These elements ensure that the operator can smoothly adjust and maintain the vehicle’s path during operation. The efficiency of this system is vital for maintaining balance, precision, and overall maneuverability.

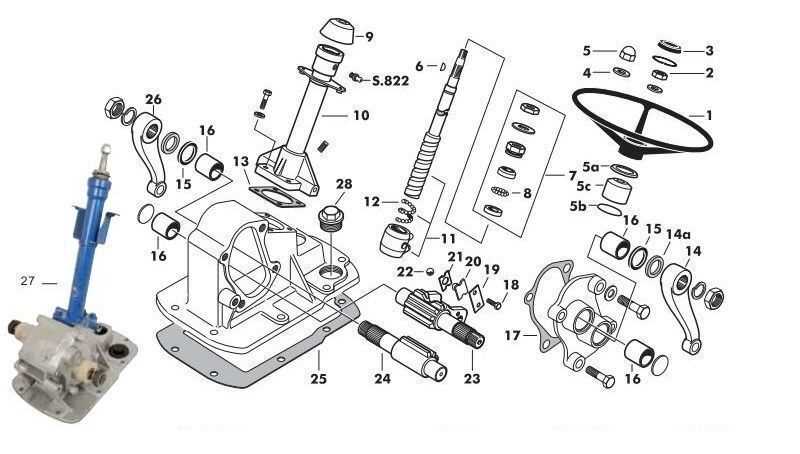

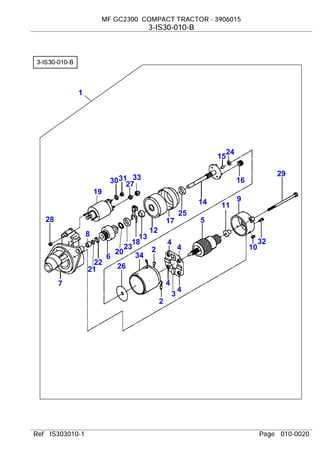

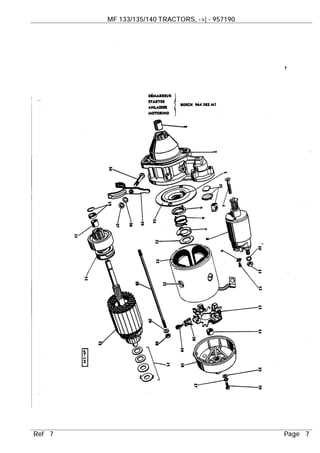

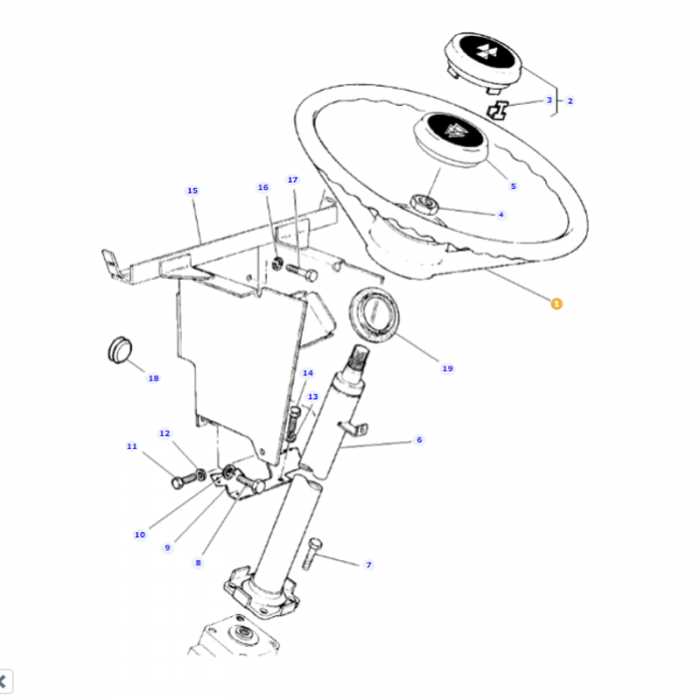

The main components involved in this process consist of a series of interconnected elements working together. These parts must be in proper alignment and functionality to allow seamless transitions and adjustments. Regular maintenance and understanding the structure of this system can enhance the performance of the entire machine.

Exploring the arrangement of these control elements provides a deeper insight into how machines function when navigating different terrains. Recognizing potential wear or misalignment in these areas helps prevent major issues and ensures continued operational reliability.

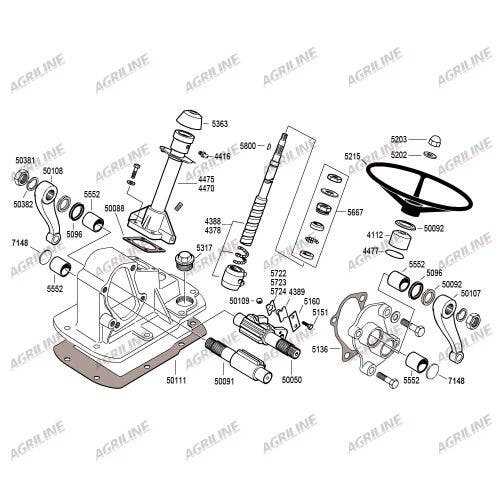

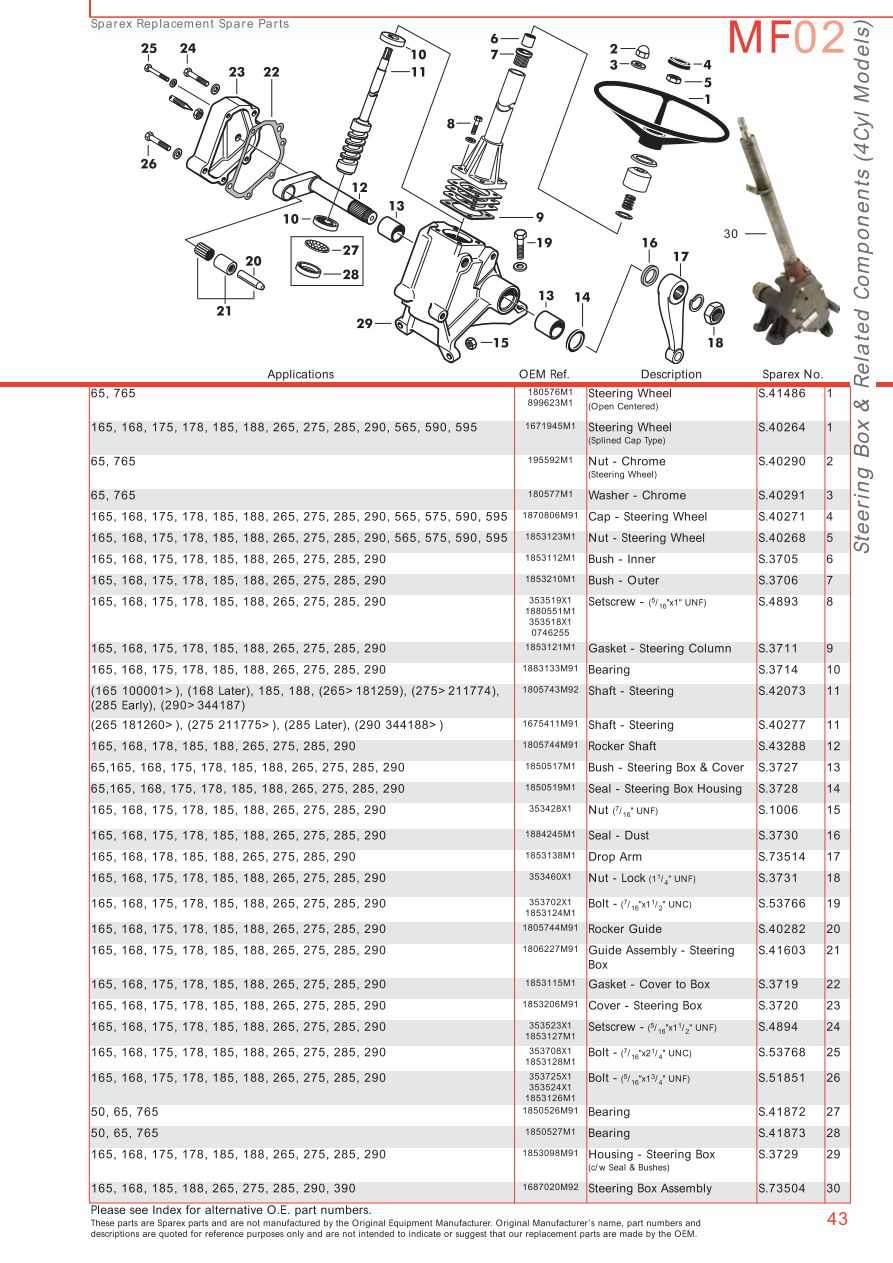

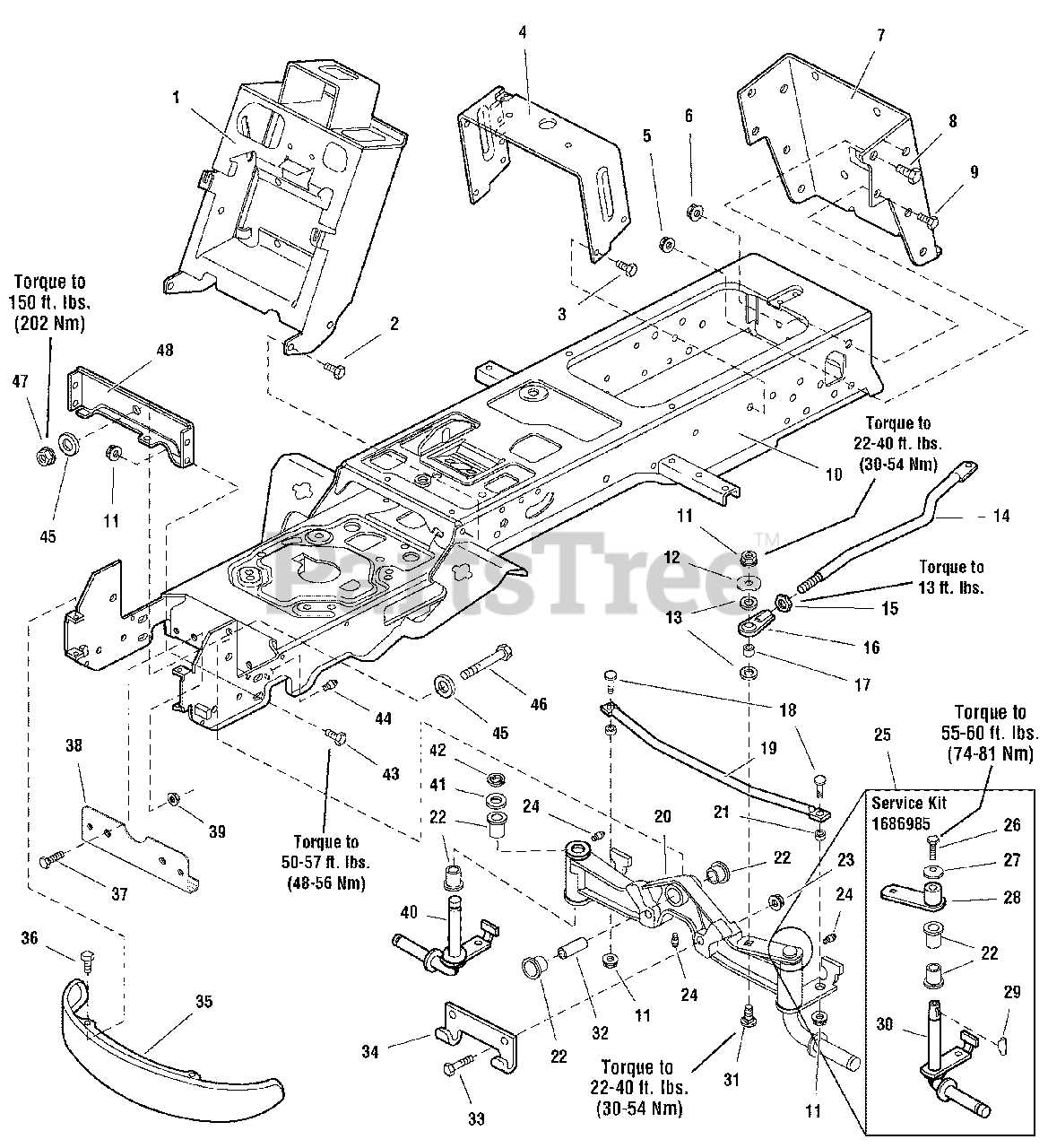

Understanding Massey Ferguson Steering Components

The guiding mechanism of agricultural machinery plays a critical role in ensuring smooth operation and maneuverability, especially when handling challenging terrains or heavy loads. This system consists of interconnected elements that work together to provide precise control and reliable direction changes. Each element in this structure contributes to the overall handling and responsiveness of the machine.

- Main axis: The central shaft is responsible for transmitting input from the operator’s control to the wheels, allowing for accurate turning and movement.

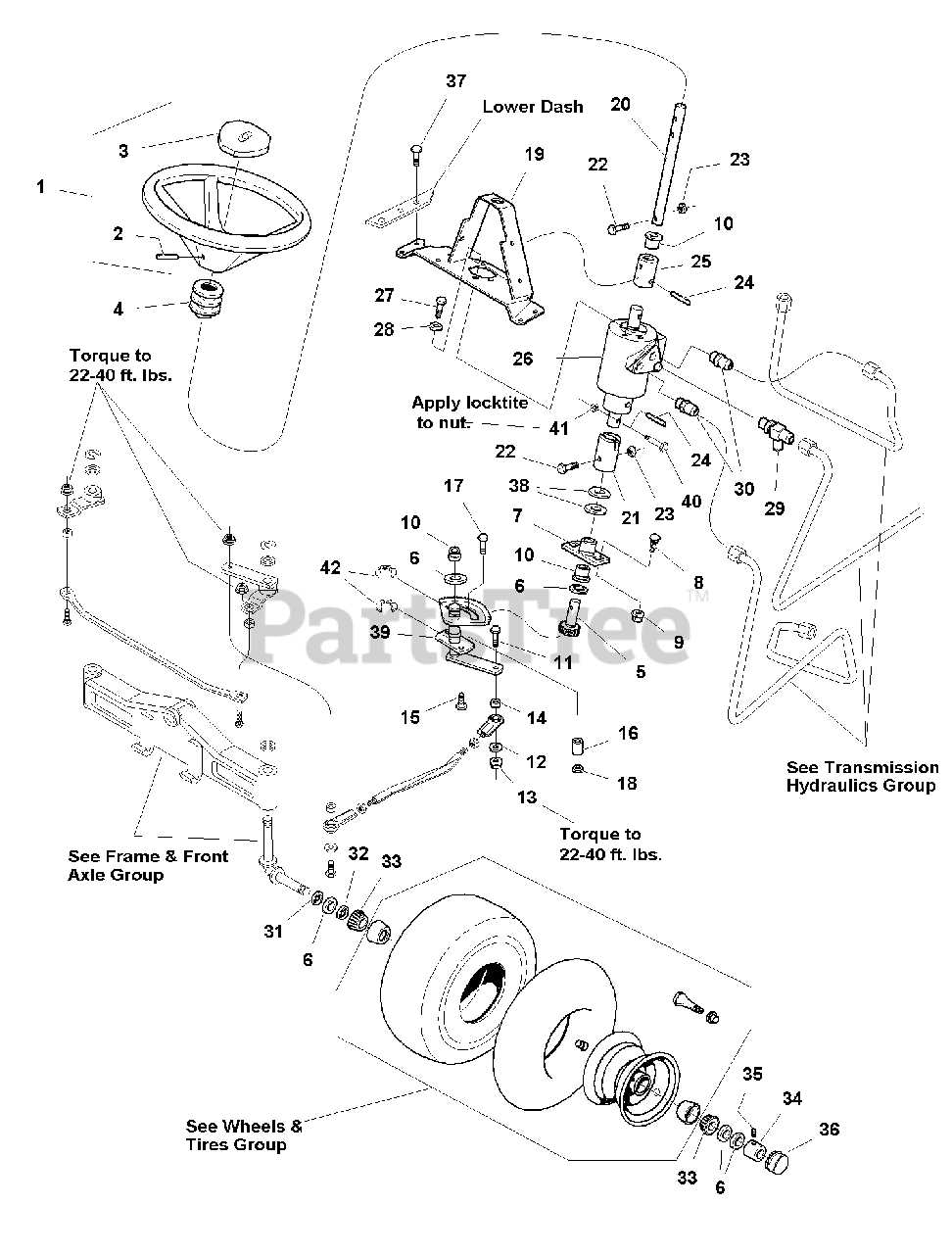

- Linkage arms: These connectors translate the motion from the control system to the wheels, ensuring coordinated movement and stability.

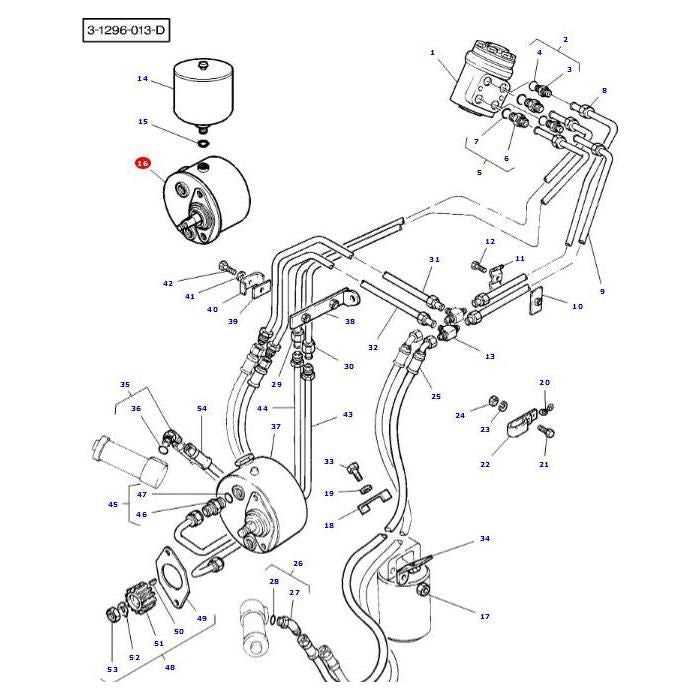

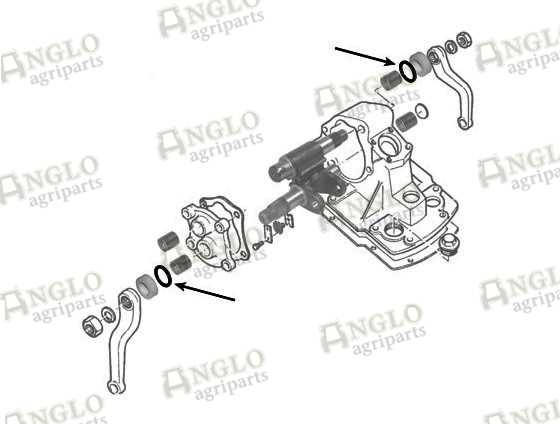

- Hydraulic support: Often integrated into the control system, hydraulics provide additional force, making it easier to control and adjust the direction, even under heavy loads.

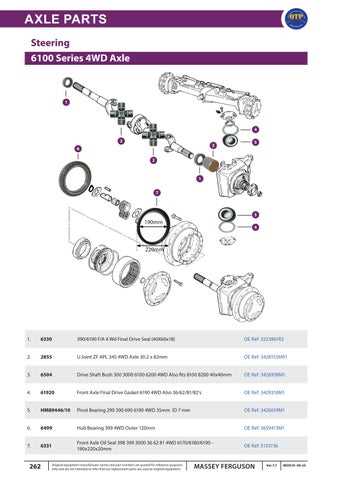

- Wheel hubs: These components attach directly to the machine’s wheels, allowing for efficient direction changes and steady performance during operations.

Proper understanding and maintenance of these elements are essential for maximizing the lifespan and effectiveness of agricultural equipment, ensuring seamless operation across different types of terrains

Key Elements of the Steering System

The system responsible for directing the movement of a vehicle consists of various components that work together to ensure precise control. Each element has a unique function, contributing to the overall responsiveness and stability. This section will explore the core elements that allow a vehicle to change its course efficiently.

Control Column: The interface that allows the driver to manipulate direction. It transfers the driver’s input to the underlying mechanisms, initiating the process of turning.

Linkage Assembly: This part connects the control input to the mechanical framework, ensuring the power is smoothly transmitted to the rest of the system. It serves as a bridge between the driver’s action and the vehicle’s response.

Axle Components: These crucial components support the front wheels and facilitate their motion. They maintain alignment and ensure consistent rotation, providing balance and maneuverability.

Directional Stabilizers: These ensure that the vehicle maintains its path with minimal correction. They prevent excessive play and enhance the predictability of the movement

Common Issues with Steering Mechanisms

Steering systems in vehicles can face several challenges over time, especially when subjected to heavy usage and rough conditions. These problems can manifest in different ways, often affecting the overall handling and control of the machine. Identifying the root cause is key to ensuring smooth operation and long-term reliability.

Wear and Tear in Mechanical Components

One of the most common problems is the gradual degradation of mechanical parts due to regular usage. Moving parts such as joints, linkages, and other connectors may loosen or wear out, leading to imprecise movements. This can result in difficulty maintaining direction or unusual play in the controls.

Hydraulic System Failures

In systems that rely on hydraulics, leaks or pressure loss are frequent concerns. When fluid escapes or pressure decreases, it can cause delays or a lack of responsiveness, making it harder to maneuver. Regular checks and timely maintenance of seals and lines can prevent these issues.

| Issue | Possible Cause | Solution | |||||

|---|---|---|---|---|---|---|---|

| Unusual Noises | Squeaking or knocking sounds when turning can indicate that some of the mechanical elements have become loose or damaged. |

| Difficulty Turning | If you experience resistance or stiffness when adjusting the vehicle’s direction, this could be a sign of wear in key components. |

| Vibration or Shaking | Excessive vibration during operation, particularly when maneuvering, often points to imbalanced or degraded elements that need inspection. |

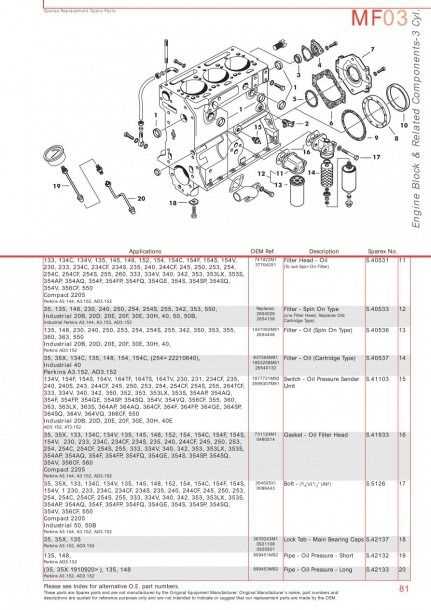

| Inconsistent Response | Choosing Quality Steering Parts for Your Tractor

When it comes to maintaining the functionality of your agricultural machinery, selecting high-quality components is crucial. Ensuring that every element involved in navigation and control is reliable will not only enhance performance but also prolong the lifespan of your equipment. One key aspect to consider is the material used in manufacturing. Opt for durable substances that can withstand the rigors of daily use, as well as varying environmental conditions. This will help prevent premature wear and tear, leading to fewer replacements and repairs over time. Compatibility with your specific model is equally important. Always verify that the components you choose are designed to fit seamlessly with your equipment, ensuring optimal operation and safety. Consulting with manufacturers or experts can provide valuable insights into the best options available. Additionally, investing in trusted brands can make a significant difference. Reputable manufacturers often offer warranties and support, which can save you from unexpected costs in the future. Prioritize those with a proven track record in the industry. Finally, consider customer reviews and testimonials. Real-world experiences can offer a glimpse into the performance and reliability of the components you’re considering. Gathering information from fellow users can guide you toward making informed decisions that benefit your machinery in the long run. |