The functionality of lawn maintenance machinery hinges on the intricate systems that govern their movement. A thorough comprehension of these mechanisms not only enhances operational efficiency but also ensures a longer lifespan for the equipment. This section delves into the essential components that contribute to the control and maneuverability of such machines.

By exploring the configuration of various elements, operators can better appreciate how their equipment responds to input and navigates through diverse terrains. Clear visualization of these systems aids in troubleshooting and maintenance, allowing for timely interventions and repairs.

For enthusiasts and professionals alike, having access to detailed representations of the control system can significantly improve hands-on skills. Understanding the interplay of each component fosters a deeper connection with the machinery, promoting a more effective and satisfying user experience.

Understanding the LT155 Steering System

The mechanism responsible for directional control in garden machinery is a vital component that ensures smooth navigation across various terrains. A comprehensive grasp of this system can enhance maintenance efforts and improve overall performance. In this section, we will delve into the key elements that contribute to its efficient operation, as well as some common issues and solutions.

Key Components

Several essential elements work together to facilitate the movement of the vehicle. Understanding these components can help users identify potential problems and maintain their equipment effectively. The primary components include:

- Control mechanism: This allows the operator to influence the direction of movement.

- Connecting linkages: These transfer motion from the control mechanism to the wheels.

- Support framework: Provides stability and alignment for the various components.

- Friction elements: Assist in maintaining control and preventing slippage.

Common Issues and Maintenance Tips

Regular upkeep can prevent many issues associated with the directional control system. Here are some frequent problems and recommended solutions:

- Wear and tear: Inspect all moving parts for signs of wear. Replace any components that show significant damage.

- Alignment problems: Ensure all linkages are properly aligned. Misalignment can lead to uneven handling.

- Fluid leaks: Check for any leaks in hydraulic components. Address leaks promptly to maintain system efficiency.

- Lubrication: Regularly apply suitable lubricants to moving parts to reduce friction and wear.

By understanding the fundamental aspects of this control mechanism and adhering to proper maintenance practices, operators can ensure optimal performance and longevity of their garden equipment.

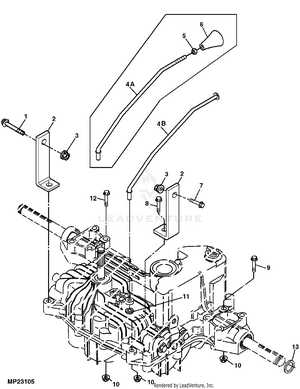

Key Components of the Steering Assembly

The effectiveness of maneuverability in any machinery is largely influenced by the construction and functionality of its control mechanism. A well-designed assembly ensures that operators can navigate effortlessly, providing both precision and responsiveness. Understanding the critical elements that make up this system is essential for maintenance and repairs, ensuring optimal performance and safety.

Essential Elements

This assembly typically consists of several vital components, each playing a specific role in facilitating smooth directional changes. The following table summarizes these key elements along with their primary functions:

| Component | Function |

|---|---|

| Wheel | Allows for turning and direction control. |

| Column | Supports the steering mechanism and connects the wheel to the control system. |

| Linkage | Transfers movement from the wheel to the front axle. |

| Pivot | Enables rotational movement for turning. |

| Bearings | Facilitate smooth movement and reduce friction. |

Maintenance Considerations

Regular inspection and maintenance of these components are crucial to ensure longevity and functionality. Operators should pay close attention to signs of wear and tear, as well as proper lubrication, to avoid operational failures and enhance the overall performance of the machinery.

Common Issues with Steering Parts

Understanding the typical challenges associated with directional control mechanisms is crucial for maintaining optimal performance. Various factors can contribute to these complications, affecting the overall functionality and safety of the machinery.

Wear and Tear: Over time, components may experience degradation due to regular usage. This can lead to a noticeable decrease in responsiveness, making navigation more difficult.

Misalignment: Improper alignment of essential components can result in uneven handling and unintended movements. Regular checks can help identify these discrepancies before they escalate into more significant problems.

Fluid Leaks: Hydraulic systems, often used in such mechanisms, may develop leaks, leading to a drop in pressure. This situation can severely impair the efficiency of control and response time.

Loose Connections: Fasteners and joints may become loose over time, causing vibrations and instability. Ensuring that all connections are secure is vital for smooth operation.

Foreign Objects: Debris or obstructions can interfere with the proper functioning of control elements. Regular cleaning and inspection are necessary to prevent such issues from arising.

Inadequate Lubrication: Proper lubrication is essential for reducing friction and wear. Lack of maintenance can lead to accelerated deterioration of moving components, negatively impacting their longevity and performance.

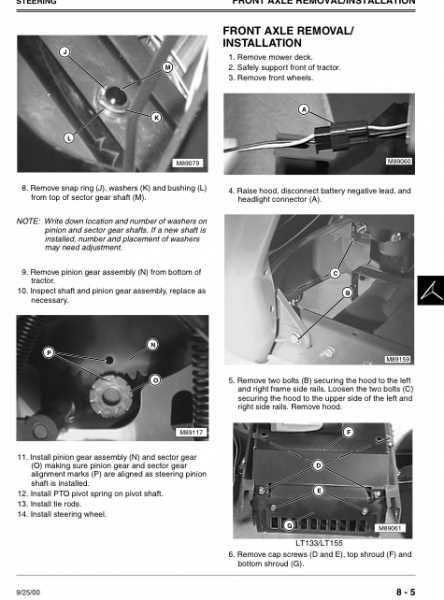

How to Read the Parts Diagram

Understanding an assembly blueprint is essential for anyone looking to maintain or repair machinery. These visual representations provide detailed information about the components involved, their arrangement, and how they interact with each other. Learning to interpret this information can streamline the repair process and ensure that all necessary elements are addressed.

Identifying Components

Begin by familiarizing yourself with the various symbols and labels present in the illustration. Each piece is typically numbered or marked in a way that corresponds to a list of items. Take note of these identifiers, as they are crucial for locating specific elements during the reassembly or replacement phases. Understanding the shape and placement of each item will also help in recognizing similar parts within your equipment.

Understanding Relationships

Next, focus on how the components connect with one another. The layout often reveals the order of assembly and the interactions between different sections. Pay attention to any indications of orientation or alignment, as this can significantly affect performance. Recognizing how components fit together will provide insight into the overall function of the machinery and assist in troubleshooting any issues that arise.

Replacing Steering Components: A Guide

Maintaining the precision and functionality of your machinery is essential for optimal performance. Over time, certain elements that control direction may wear out or become damaged, necessitating replacement. This guide outlines the steps to effectively replace these critical components, ensuring your equipment operates smoothly and efficiently.

Before beginning the replacement process, it is vital to gather the necessary tools and replacement components. Here’s a brief list of what you might need:

- Wrenches and sockets

- Screwdrivers

- Replacement components

- Lubricants

- Safety gear

Once you have everything prepared, follow these steps to successfully complete the replacement:

- Safety First: Ensure that the machinery is turned off and securely parked on a flat surface. Use wheel chocks to prevent any movement.

- Access the Components: Remove any covers or shields obstructing access to the elements in question. This may involve unscrewing bolts or unclipping fasteners.

- Inspect the Current Setup: Take a moment to examine the existing components. Note any wear or damage that may indicate other areas needing attention.

- Remove the Old Components: Carefully detach the worn or broken pieces. Keep track of any screws or bolts, as they will be needed for reassembly.

- Install New Components: Position the replacement items in their designated spots. Make sure they are secured tightly and aligned correctly.

- Reassemble the Machinery: Replace any covers or shields that were removed. Ensure all fasteners are tightened to the manufacturer’s specifications.

- Test the Functionality: Once everything is back in place, start the equipment and check for proper operation. Make any necessary adjustments.

By following these steps, you can ensure that the directional control mechanisms of your machinery are functioning effectively, enhancing overall performance and reliability.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring that your equipment operates smoothly and efficiently. By following a consistent maintenance routine, you can enhance longevity, prevent breakdowns, and improve overall functionality.

- Inspect Regularly: Check all components frequently for wear and tear. Early detection of issues can save time and costs in the long run.

- Lubricate Moving Parts: Keep all moving elements well-lubricated to reduce friction and prevent premature wear.

- Clean Thoroughly: Remove dirt and debris from critical areas to maintain optimal performance. Regular cleaning helps prevent damage and maintains efficiency.

- Check Fluid Levels: Ensure that all necessary fluids are at appropriate levels. Low fluids can lead to overheating and reduced performance.

- Replace Worn Components: Timely replacement of any worn-out pieces is crucial. Using high-quality replacements will ensure the best performance.

By adhering to these guidelines, you can maximize the functionality and lifespan of your equipment, leading to a more productive and hassle-free experience.

Tools Needed for Steering Repairs

To ensure effective maintenance and repair of the directional system, having the right tools is essential. These instruments not only facilitate the process but also enhance precision and safety during the task.

- Socket Set: A variety of sizes is crucial for loosening and tightening various components.

- Wrenches: Adjustable wrenches and torque wrenches are important for achieving the correct fit and tension.

- Replacement Components: Ensure you have quality replacements for any worn or damaged parts.

- Grease Gun: Lubrication is key for smooth operation, so a grease gun is necessary.

- Safety Gear: Gloves and goggles protect you while working on the mechanism.

Having these tools at your disposal will ultimately streamline the repair process, making it efficient and effective.

Where to Buy Replacement Parts

Finding suitable components for your machinery can be a straightforward process if you know where to look. Numerous sources offer reliable and quality options to ensure your equipment runs smoothly. Whether you prefer online shopping or local vendors, you have various avenues to explore.

Here are some recommended places to consider:

- Online Retailers: Websites such as Amazon, eBay, and specialized machinery sites often have a wide selection of components available for purchase. You can compare prices and read customer reviews to make informed decisions.

- Local Dealerships: Authorized dealers provide original equipment, ensuring compatibility and quality. Visiting a local outlet can also give you access to expert advice.

- Aftermarket Suppliers: Numerous companies specialize in manufacturing compatible components. These can often be more affordable while still maintaining good quality.

- Salvage Yards: If you’re looking for cost-effective solutions, salvage yards may have used components in good condition. This option can be budget-friendly and environmentally conscious.

- Online Forums and Communities: Engaging with fellow enthusiasts or professionals online can lead to recommendations for reputable suppliers or even direct sales between users.

Before making a purchase, ensure to check compatibility and warranty options. Doing thorough research can save you time and money while providing the best solution for your equipment needs.

Expert Advice on Steering Adjustments

Achieving optimal maneuverability is crucial for enhancing the performance of your machine. Fine-tuning the directional control not only improves handling but also extends the lifespan of the equipment. Understanding how to make precise modifications can significantly impact your overall experience.

Begin by assessing the alignment and play in the control mechanism. Regular checks can help identify any discrepancies that may require correction. Utilizing the appropriate tools and following manufacturer recommendations ensures that adjustments are made effectively and safely.

When making alterations, it’s essential to document the original settings for future reference. This allows for a more straightforward reversion if needed. Gradually implement changes and test the responsiveness after each adjustment to gauge improvements.

Lastly, consider consulting with professionals who specialize in machine adjustments. Their insights can provide valuable guidance, enabling you to achieve the ultimate precision and efficiency in handling.