In the intricate world of automotive engineering, the control mechanism plays a vital role in ensuring optimal maneuverability and driver comfort. This assembly not only facilitates the handling of the vehicle but also houses various crucial elements that contribute to its functionality. A comprehensive grasp of these components is essential for both enthusiasts and professionals in the field.

To appreciate the sophistication of this system, one must delve into the specific elements that work in harmony to enable precise navigation. Each component has a distinct purpose, and understanding how they interconnect provides valuable insights into the overall design and operation. This knowledge is not only beneficial for maintenance and repair but also enhances the driving experience.

In the following sections, we will explore the individual elements that comprise this essential assembly, highlighting their roles and interactions. By gaining clarity on these aspects, readers will develop a deeper understanding of the engineering marvel that supports vehicle control.

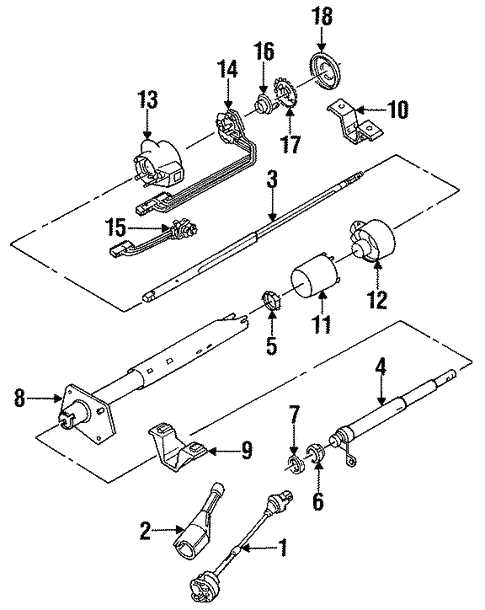

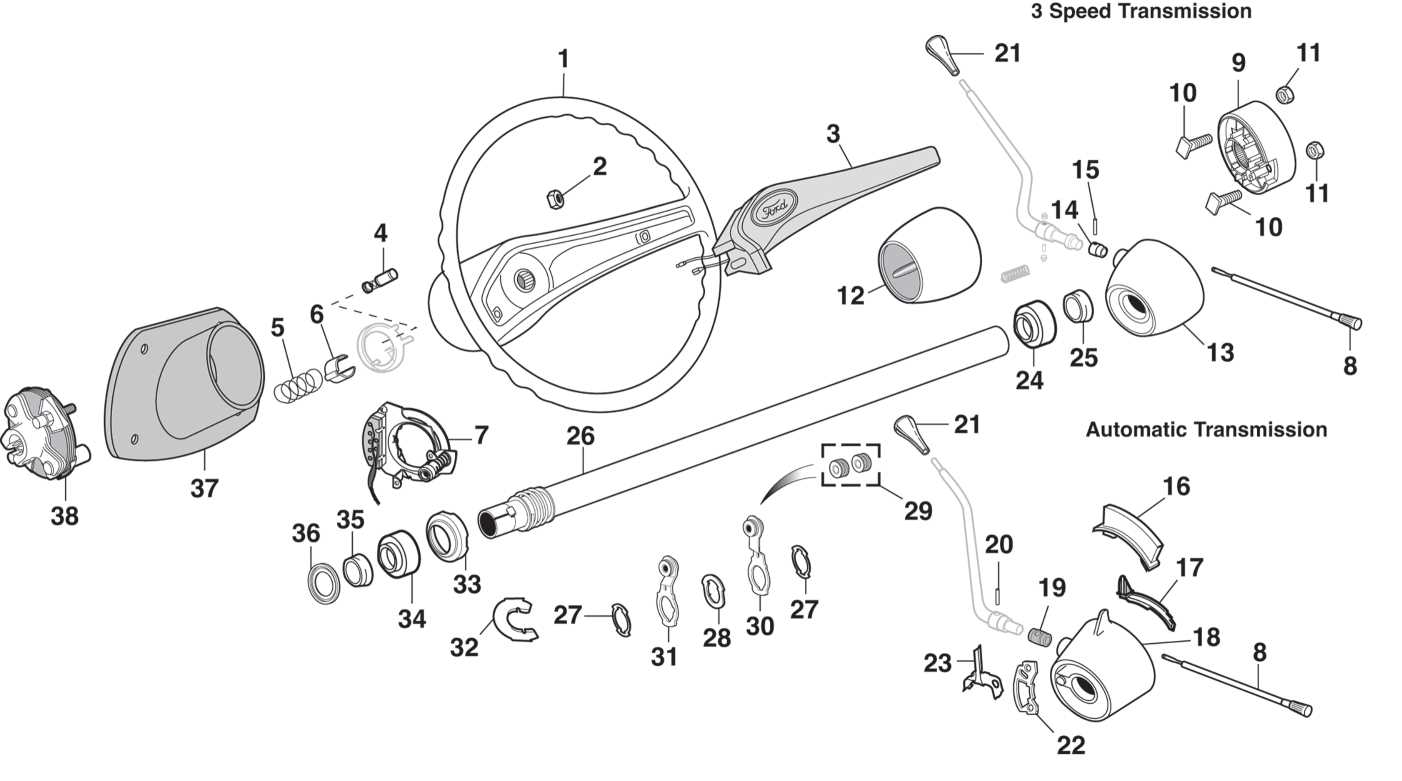

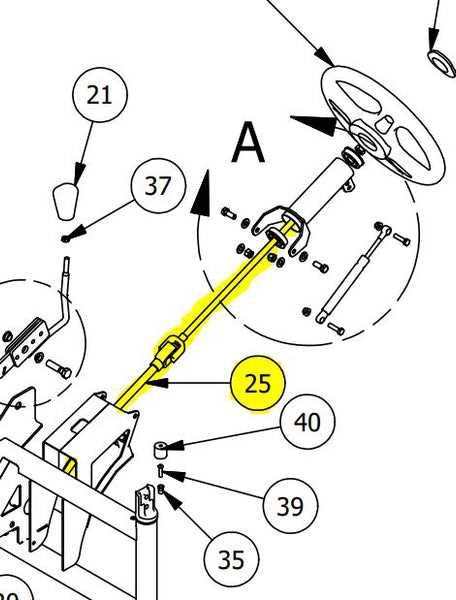

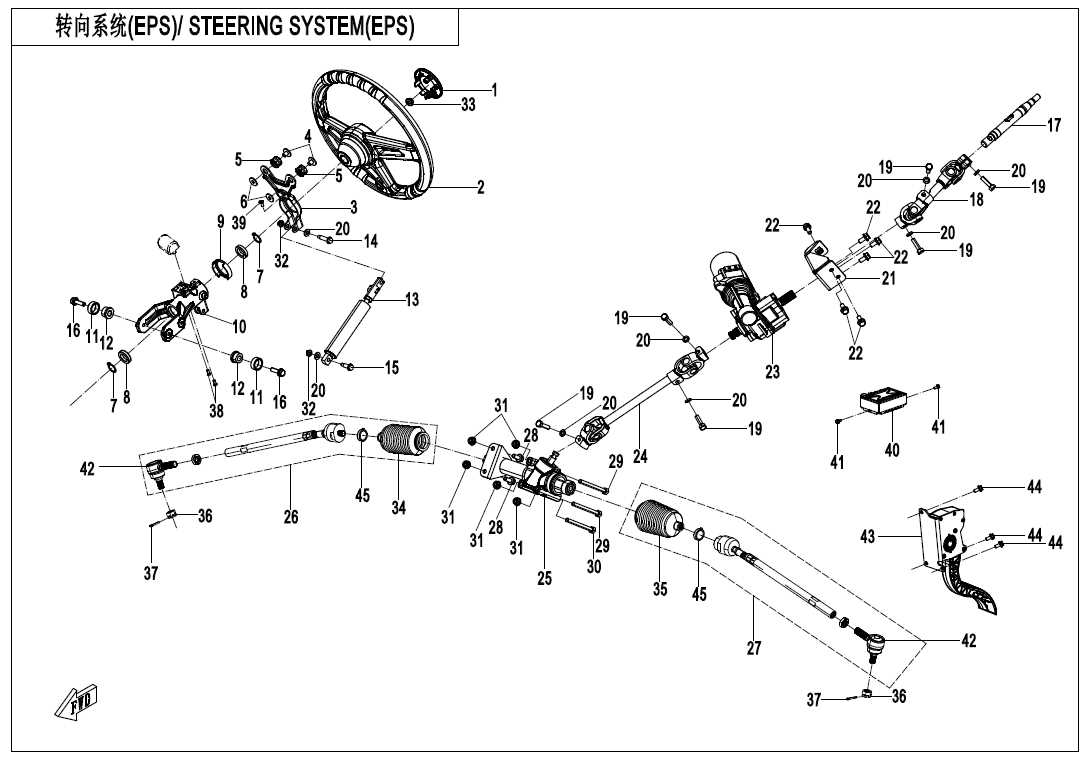

Understanding the Steering Column Assembly

The assembly responsible for directional control in a vehicle plays a crucial role in ensuring safe and efficient navigation. Comprising various components, this mechanism allows drivers to maneuver effectively while integrating essential functions such as ignition control and gear shifting.

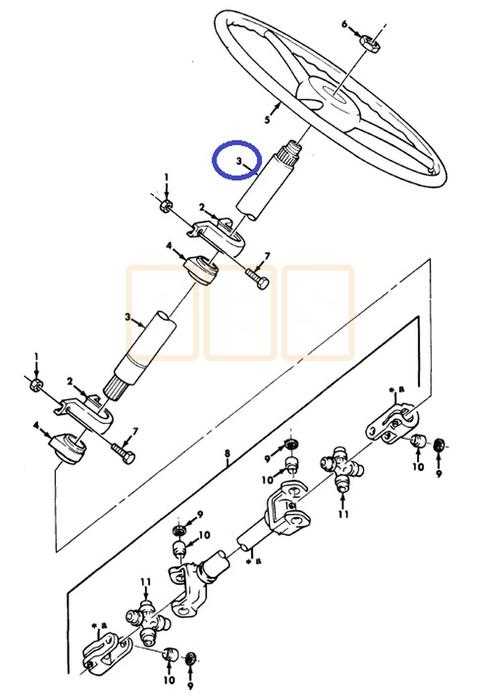

At the core of this assembly lies a shaft that connects the driver’s inputs to the wheels. This shaft is supported by bearings, enabling smooth movement and stability. Adjacent to it, a housing encases critical elements, providing protection and enhancing the overall functionality of the system.

In addition to the mechanical components, electronic elements have become increasingly important, offering features like cruise control and advanced driver-assistance systems. These innovations improve the driving experience by adding convenience and safety, highlighting the evolution of this integral assembly.

Regular maintenance and understanding of the various elements involved can help in identifying issues early, ensuring longevity and performance. By familiarizing oneself with these components, drivers can gain a deeper appreciation for the intricate design that facilitates their daily journeys.

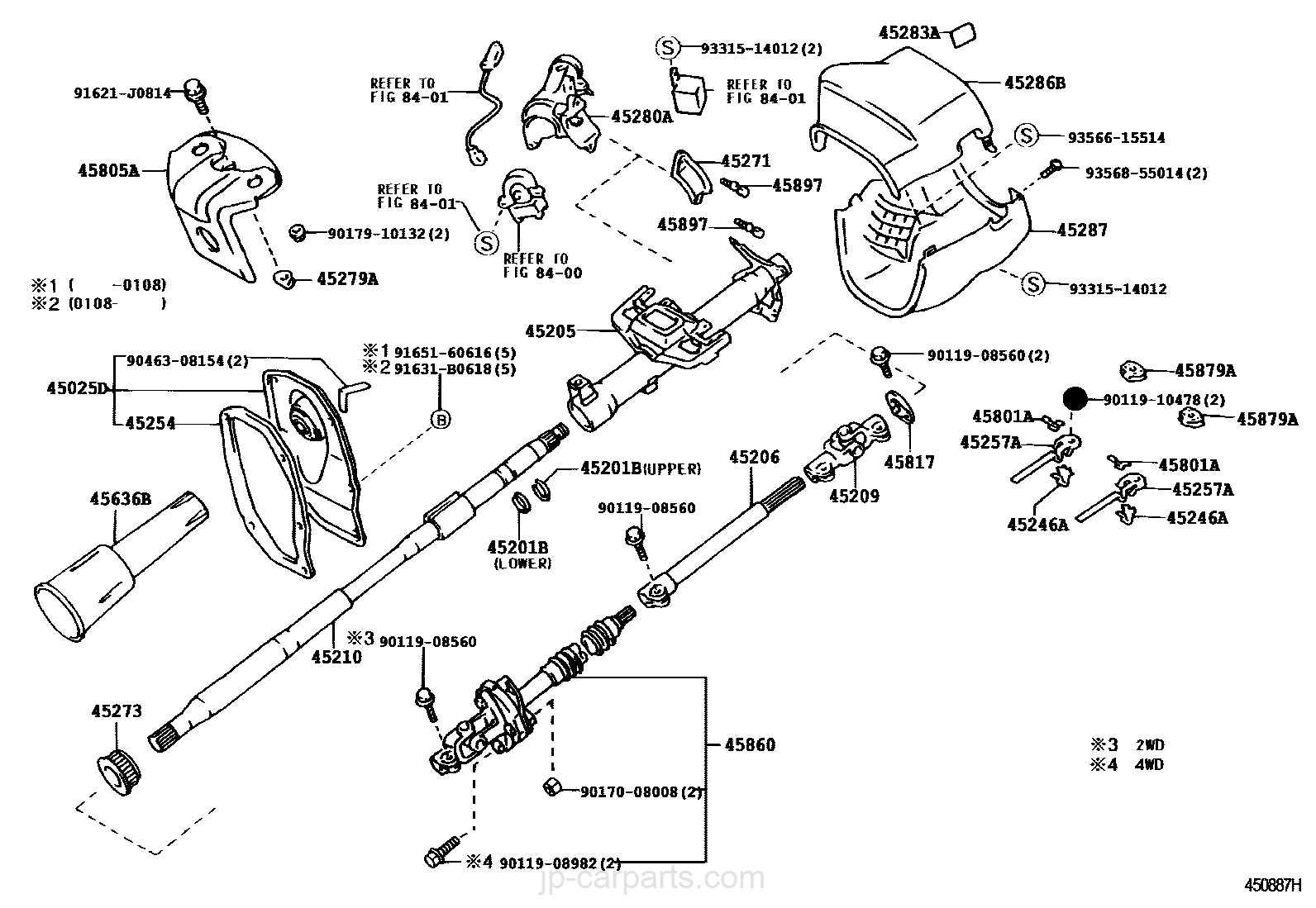

Key Components of the Steering Column

The mechanism that facilitates directional control in vehicles comprises several essential elements that work together seamlessly. Each component plays a vital role in ensuring safety, comfort, and maneuverability for the driver. Understanding these fundamental elements can enhance one’s appreciation for the intricacies of automotive design.

Primary Elements

At the core of this system are components like the shaft, which transmits motion from the driver’s input to the wheels. This element is typically robust to withstand significant force and ensure durability. Coupled with the shaft is the universal joint, which allows for flexibility in movement and accommodates changes in direction.

Safety Features

Another crucial aspect is the ignition switch, integrated into the assembly to enhance security. This mechanism not only starts the vehicle but also includes features that prevent accidental activation. Additionally, the inclusion of a crash management system ensures that, in the event of an impact, the assembly absorbs energy, reducing the risk of injury to occupants.

Functionality of Each Steering Part

This section delves into the various components that contribute to the directional control of a vehicle. Understanding the specific roles of each element is essential for grasping how they work in unison to ensure smooth navigation and safety on the road.

Control Mechanisms

The control mechanisms are vital for enabling the driver to influence the vehicle’s direction. These elements provide the necessary feedback and responsiveness, allowing for precise adjustments while driving. For instance, the primary lever facilitates the initial input from the driver, transmitting their intentions to the underlying systems.

Safety Features

Safety features integrated within this system enhance driver confidence and vehicle stability. Components such as locking mechanisms and collapsible structures are designed to protect occupants in the event of a collision. Their functionality ensures that even during unexpected situations, the integrity of the driving experience is maintained, minimizing risks for all road users.

Common Issues with Steering Columns

In any vehicle, certain mechanical components can present challenges over time, affecting performance and safety. Understanding these issues is crucial for maintenance and effective resolution, ensuring a smoother driving experience.

Frequent Problems Encountered

Common difficulties include irregular noise, misalignment, and difficulty in maneuvering. These symptoms may indicate underlying wear or damage that requires attention.

Impact on Vehicle Performance

Unaddressed issues can lead to compromised control and safety hazards. Timely inspections and repairs can mitigate risks associated with these components.

| Issue | Description | Possible Solutions |

|---|---|---|

| Noisy operation | Unusual sounds during use may signal wear. | Lubrication or part replacement. |

| Difficulty turning | Resistance when attempting to steer. | Inspection for obstructions or damage. |

| Alignment problems | Vehicle does not track straight. | Realignment or adjustment needed. |

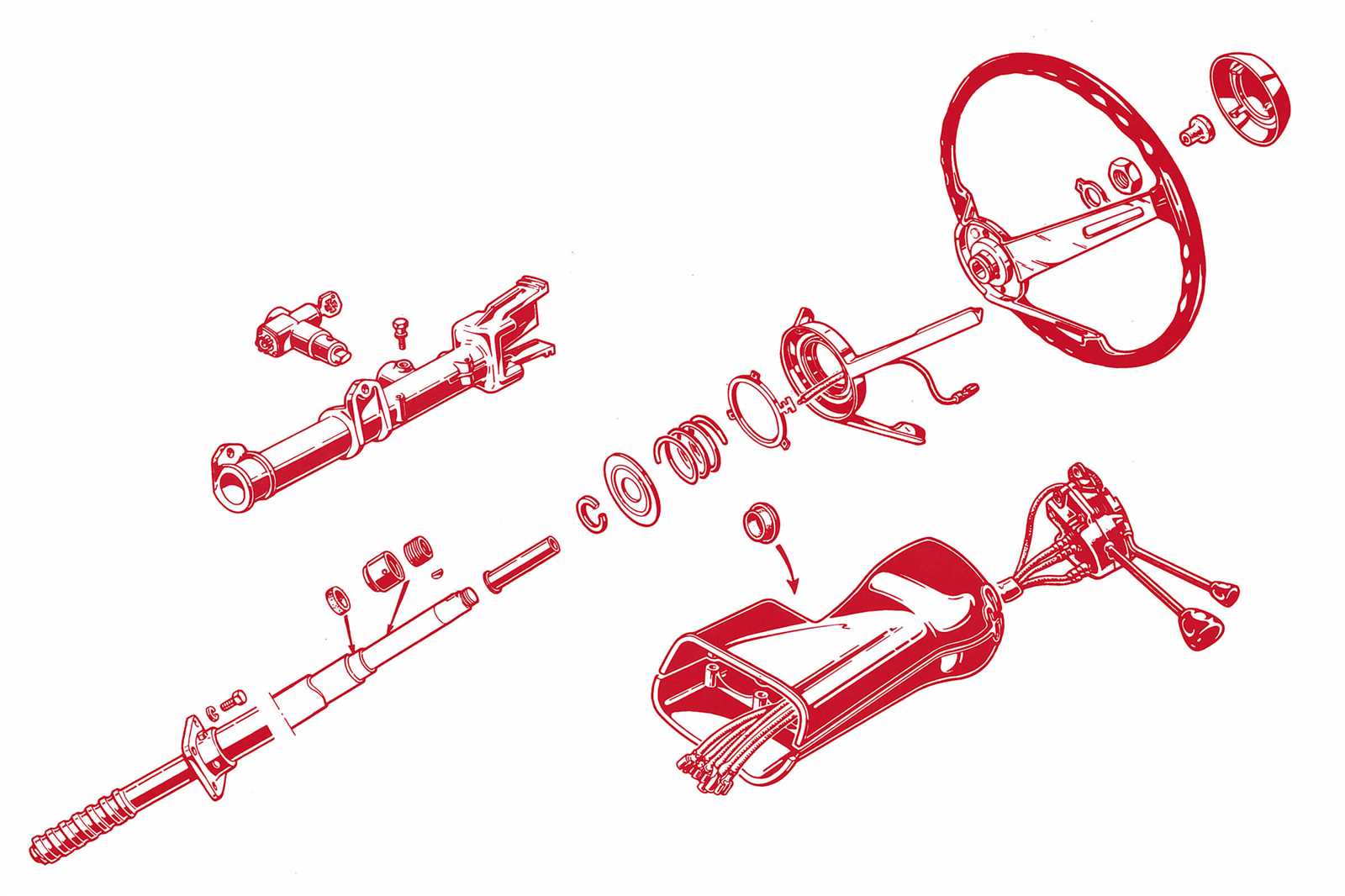

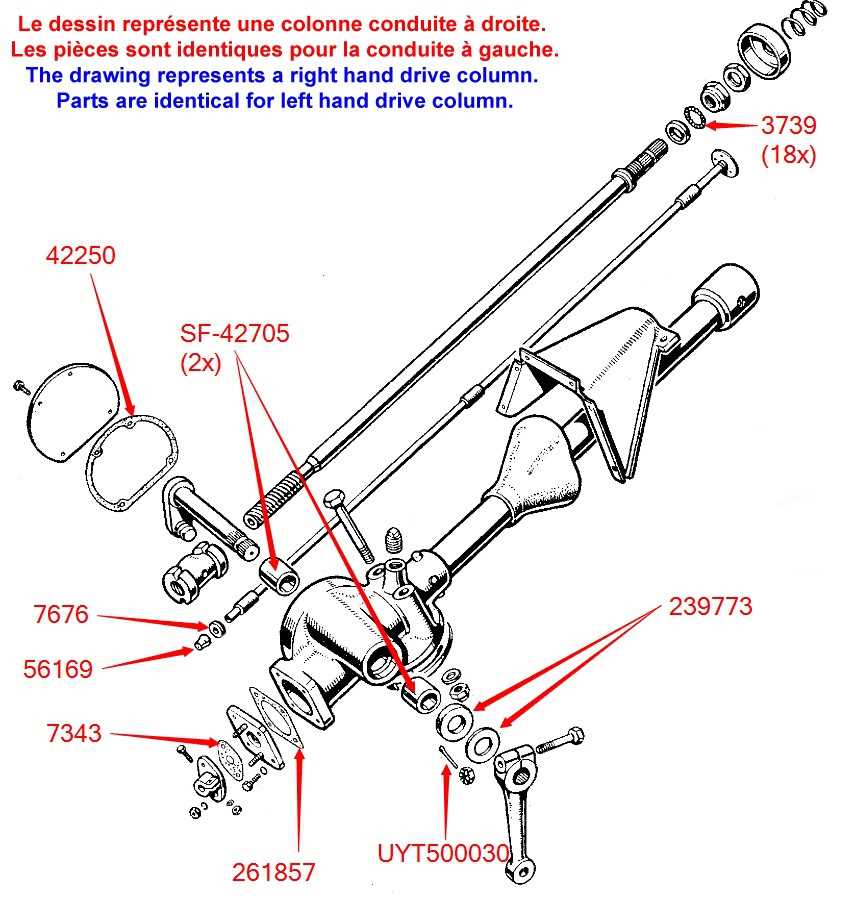

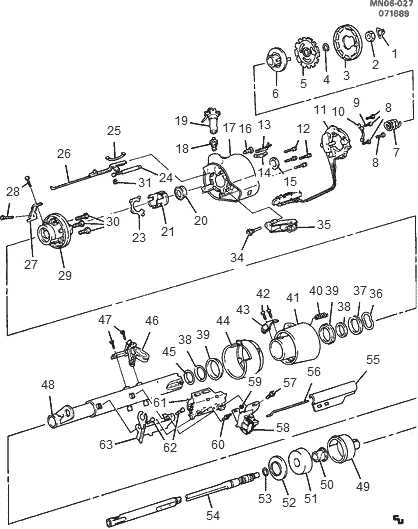

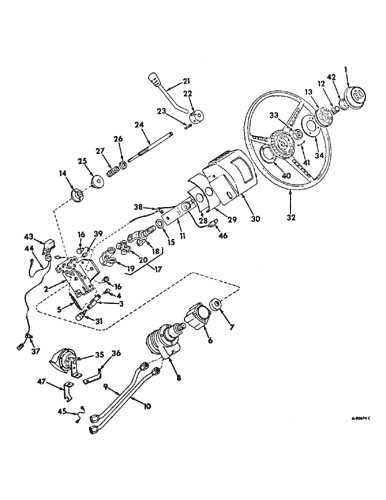

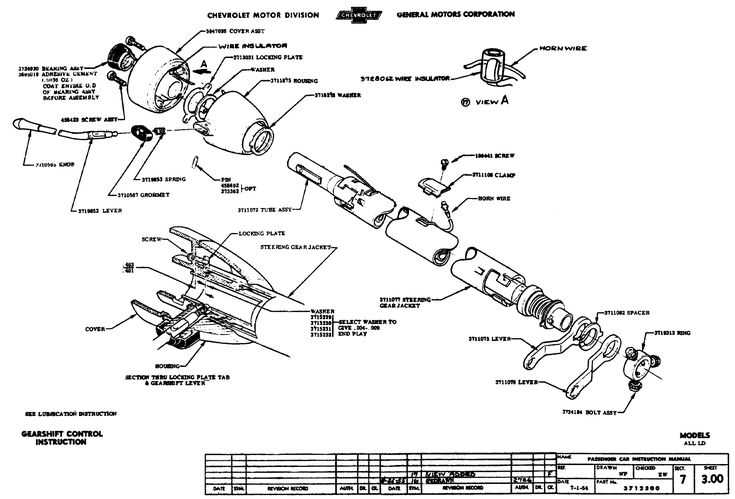

How to Read a Parts Diagram

Understanding a schematic representation of components is crucial for effective maintenance and repair. Such visual guides provide a comprehensive overview, enabling users to identify each element and its relationship to others. Familiarity with these illustrations enhances one’s ability to troubleshoot and replace parts accurately.

To effectively interpret these visual aids, consider the following steps:

- Familiarize with Symbols:

Different symbols represent various components. Take time to learn the common icons used in the illustration.

- Identify Labels:

Most schematics include labels that provide additional information about each element. Pay attention to these annotations for clarity.

- Understand Connections:

Examine how components are connected. Lines or arrows indicate relationships, showing how elements interact with each other.

- Consult a Legend:

If available, refer to the legend or key. This will explain any color coding or symbols that may not be immediately clear.

By following these steps, you can enhance your proficiency in interpreting these visual guides, leading to more effective repairs and better understanding of the overall assembly.

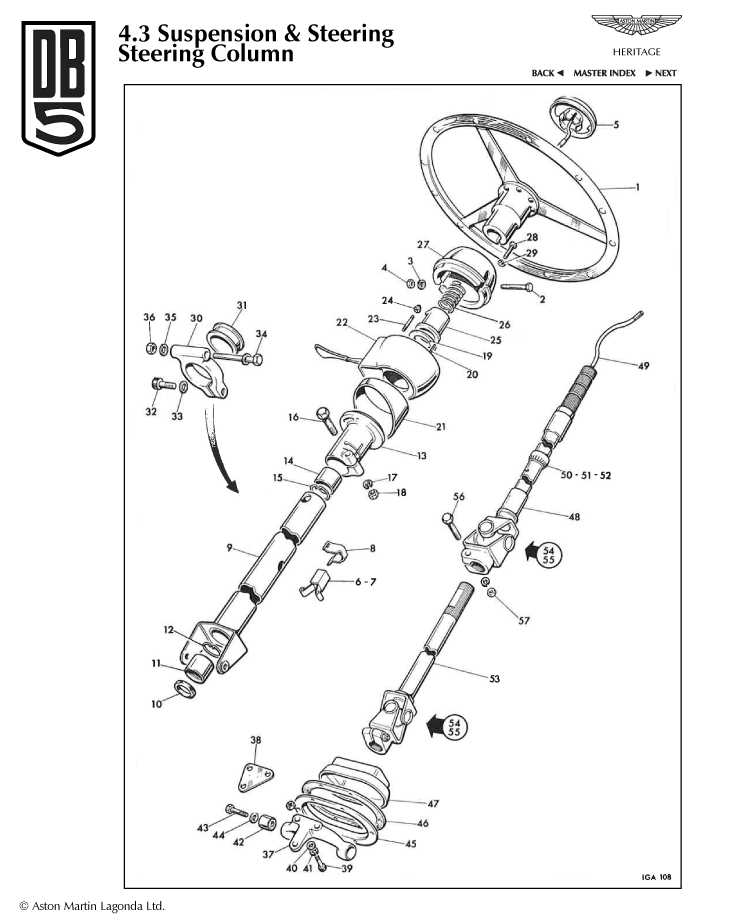

Importance of Accurate Diagrams

Precision in visual representations is crucial for effective understanding and communication within technical fields. Accurate illustrations serve as essential tools for professionals and enthusiasts alike, ensuring that everyone involved has a clear view of the components and their interactions. This clarity helps prevent misunderstandings that can lead to costly errors during assembly or maintenance tasks.

Benefits of Detailed Visual Guides

- Enhanced Understanding: Clear representations break down complex systems into manageable sections, facilitating comprehension.

- Efficient Troubleshooting: When issues arise, reliable visuals help technicians identify problems quickly and accurately.

- Streamlined Assembly: Well-drafted guides reduce assembly time and minimize the likelihood of mistakes.

- Standardization: Consistent illustrations across documentation ensure uniformity in processes and training.

Consequences of Inaccurate Representations

- Misinterpretation of Functions: Flawed visuals can lead to incorrect assumptions about how components operate.

- Increased Risk of Damage: Misguided assembly may result in component damage or failure.

- Wasted Resources: Time and materials can be squandered due to confusion stemming from unclear visuals.

- Safety Hazards: Inaccurate instructions may pose risks, compromising user safety during operation.

Maintenance Tips for Steering Columns

Proper care and attention are essential for ensuring the longevity and functionality of your vehicle’s control mechanisms. Regular maintenance not only enhances performance but also ensures safety while driving. Following a few straightforward practices can prevent wear and tear, leading to a smoother driving experience.

Regular Inspections

- Check for any unusual noises during operation.

- Inspect for signs of wear or damage on components.

- Ensure that all connections are secure and functioning properly.

Lubrication and Cleaning

- Apply lubricant to moving parts to reduce friction.

- Clean any accumulated dirt and debris to prevent interference.

- Use appropriate cleaning agents to avoid damage to materials.

Choosing Quality Replacement Parts

When it comes to maintaining vehicle functionality, selecting high-grade components is crucial. Quality replacements ensure longevity, enhance performance, and ultimately provide safety while driving. Understanding the importance of sourcing reliable alternatives can make a significant difference in your overall experience.

Factors to Consider

- Material Quality: Opt for components made from durable materials to withstand wear and tear.

- Brand Reputation: Research brands known for reliability and customer satisfaction.

- Warranty: Look for products that offer a warranty, indicating confidence in their durability.

Where to Find Reliable Options

- Authorized dealerships that provide OEM alternatives.

- Reputable auto parts retailers with a solid track record.

- Online marketplaces that feature customer reviews and ratings.