The effective operation of marine vehicles relies on a variety of mechanisms that facilitate navigation and control. These systems are designed to enhance performance and provide a seamless experience for users. A comprehensive exploration of these mechanisms reveals the intricate relationships between their individual elements, which work together to ensure reliable functionality.

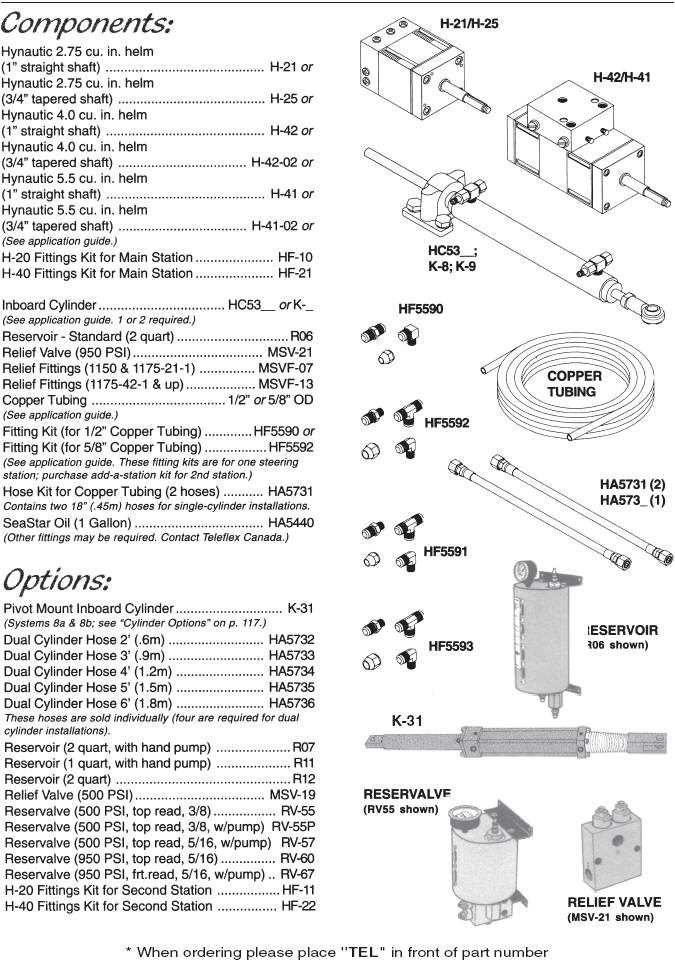

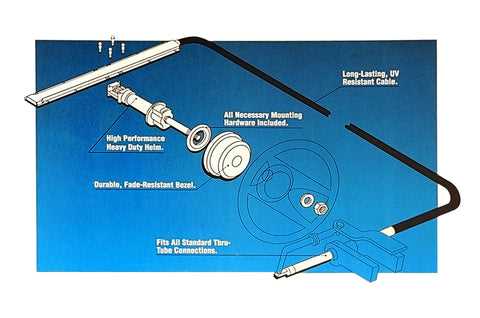

Within this context, it is essential to familiarize oneself with the various components involved in these control mechanisms. Each element plays a crucial role in the overall system, influencing aspects such as maneuverability and responsiveness. By gaining insight into the layout and arrangement of these components, users can better appreciate how they contribute to the effective functioning of the vehicle.

Furthermore, understanding the configuration of these mechanisms can aid in maintenance and troubleshooting. Recognizing the specific roles of each component allows for more efficient identification of potential issues, ultimately leading to enhanced performance and longevity. This exploration serves as a valuable resource for anyone looking to deepen their knowledge of marine control systems.

Overview of Steering System Components

The functionality of a navigational system relies on several critical elements that work together seamlessly to provide optimal maneuverability. Understanding these components is essential for ensuring efficiency and reliability in operation. Each element plays a unique role, contributing to the overall performance and responsiveness of the mechanism.

Control Mechanisms serve as the primary interface for the user, allowing for the initiation of movement. They are designed to provide feedback and facilitate precise adjustments. Another vital component is the linkage system, which transmits the user’s commands to the mechanisms that dictate direction. This connection is crucial for maintaining control and ensuring that movements are accurately conveyed.

Additionally, support structures play an integral role in maintaining stability and alignment throughout the operation. These components are engineered to withstand various forces, ensuring durability and longevity. Lastly, hydraulic or mechanical systems are often employed to enhance the overall functionality, providing necessary assistance in achieving smooth and effortless navigation.

Key Functions of the Steering Assembly

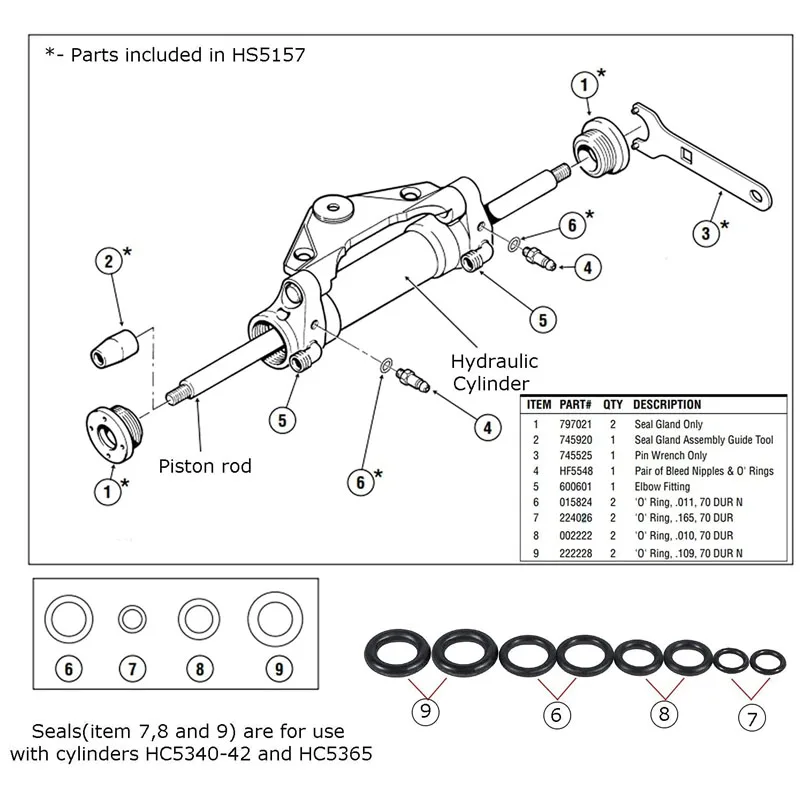

The assembly responsible for directional control in vehicles plays a crucial role in ensuring smooth navigation and stability. This system facilitates the interaction between the driver and the vehicle, allowing for precise maneuvers while enhancing overall safety during operation. Understanding its key functions is essential for proper maintenance and effective troubleshooting.

Directional Control

One of the primary roles of this assembly is to provide accurate directional control. It enables the operator to guide the vehicle along the desired path, responding promptly to inputs. The effectiveness of this function is critical for maintaining balance and alignment, especially during high-speed travel or sharp turns.

- Facilitates quick adjustments to maintain a straight trajectory.

- Supports smooth turning by reducing resistance during cornering.

- Ensures stable handling under various driving conditions.

Feedback Mechanism

This assembly also incorporates a feedback mechanism that enhances the driving experience. By providing tactile sensations, it informs the operator about the vehicle’s current state, contributing to improved situational awareness.

- Delivers sensations that indicate road conditions and vehicle behavior.

- Promotes a responsive feel that fosters confidence in handling.

- Helps the driver anticipate necessary adjustments based on feedback.

Types of Steering Mechanisms in Marine Vessels

In marine vessels, the control of direction is essential for navigation and safety. Various systems are utilized to achieve this control, each with its own advantages and operational characteristics. Understanding these mechanisms helps in selecting the appropriate system for different types of watercraft and their intended use.

Manual Control Systems

Manual control systems are often preferred for smaller vessels where simplicity and direct feedback are crucial. These systems rely on the operator’s physical input to maneuver the craft. Key features include:

- Direct connection between the helm and the rudder

- Enhanced feel and responsiveness

- Low maintenance requirements

Hydraulic and Electronic Systems

For larger vessels, hydraulic and electronic systems provide advanced control capabilities. These systems utilize fluid pressure or electrical signals to operate steering components, offering precision and ease of use. Notable aspects include:

- Reduced effort needed for maneuvering

- Improved accuracy in directional changes

- Integration with autopilot and navigation systems

By understanding the various control mechanisms available, vessel operators can make informed decisions to ensure optimal performance and safety on the water.

Common Materials Used in Steering Components

The selection of materials utilized in the assembly of guiding mechanisms plays a crucial role in their performance and durability. Various substances are employed to ensure optimal functionality, enhance strength, and reduce wear over time. Understanding these materials can provide insights into the effectiveness and reliability of the entire system.

Metals

Metals are often the primary choice due to their exceptional strength and resistance to deformation. Components crafted from aluminum are favored for their lightweight properties, while steel offers robustness and durability, making it suitable for high-stress applications.

Plastics and Composites

Plastics and composite materials have gained popularity in recent years, especially for non-load-bearing elements. These materials provide excellent resistance to corrosion and wear, while also reducing overall weight. Polymer composites are frequently used in applications where flexibility and impact resistance are essential.

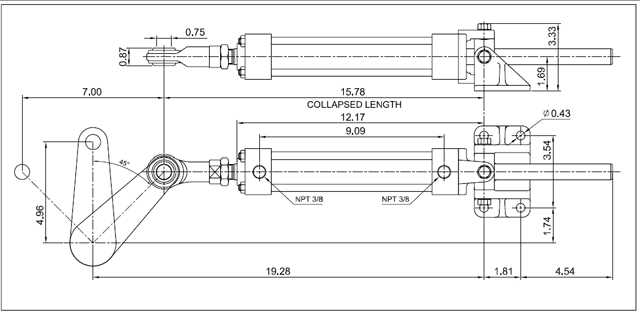

Installation Guidelines for Steering Systems

Proper installation of control mechanisms is crucial for ensuring safe and efficient operation. Following the right procedures and guidelines can significantly enhance performance and longevity. Below are key considerations to keep in mind during the installation process.

Preparation Steps

- Review the manufacturer’s instructions thoroughly to understand the requirements.

- Gather all necessary tools and components before starting the installation.

- Ensure the workspace is clean and free of any obstructions to facilitate smooth installation.

Installation Process

- Begin by securing the main assembly in the designated location, ensuring proper alignment with the vessel’s structure.

- Attach any necessary linkages or connectors, making sure they fit snugly without excessive force.

- Test the range of motion by manually moving the assembly to confirm there are no blockages.

- Finally, double-check all connections and tighten them securely before conducting a functional test.

Maintenance Tips for Long-Lasting Steering Performance

Ensuring the longevity of your navigation system requires regular care and attention. By following a few essential practices, you can maintain optimal functionality and enhance the overall experience while operating your vessel.

Regular Inspections: Conduct frequent checks to identify any signs of wear or damage. This proactive approach allows for early detection of issues, preventing potential failures during use.

Lubrication: Keep moving components well-lubricated to minimize friction and wear. Using appropriate lubricants not only enhances performance but also extends the lifespan of various elements.

Cleaning: Regularly clean the system to remove dirt and debris that may interfere with operation. A clean environment reduces the risk of corrosion and ensures smooth functionality.

Storage Practices: When not in use, ensure the equipment is stored in a dry and safe place. Proper storage protects against environmental factors that could lead to deterioration.

Follow Manufacturer Recommendations: Adhere to the guidelines provided by the manufacturer for maintenance and care. These recommendations are tailored to optimize performance and durability, ensuring that all components function effectively.

Identifying Wear and Tear in Steering Components

Recognizing signs of degradation in maneuvering systems is crucial for ensuring safe and effective vehicle operation. Various elements within these systems are subject to stress and wear over time, leading to potential performance issues. Early detection of these problems can prevent costly repairs and enhance the longevity of the components.

When assessing the condition of maneuvering elements, several indicators can signal wear. These may include unusual noises during operation, difficulty in maneuverability, and visible damage to the components. Regular inspections can help in identifying these issues before they escalate.

| Indicator | Description |

|---|---|

| Unusual Noises | Strange sounds, such as grinding or squeaking, may indicate that components are not functioning smoothly. |

| Difficulty in Control | Challenges in turning or maintaining direction can suggest that parts are worn or improperly aligned. |

| Visible Damage | Cracks, bends, or excessive rust on any component can be signs of serious wear that requires immediate attention. |

| Fluid Leaks | Leaks from the system can signify deterioration of seals or hoses, impacting performance and safety. |

Conducting routine checks and being attentive to these signs can significantly improve the performance and safety of the maneuvering system. Addressing wear and tear promptly ensures the overall integrity and functionality of the vehicle.

Best Practices for Replacing Steering Parts

When it comes to enhancing the control mechanism of your vehicle, understanding the essentials of part replacement is crucial. Ensuring that every component functions optimally can significantly impact the overall performance and safety of the system. Adopting effective techniques during the replacement process can lead to improved handling and longevity of the equipment.

1. Prepare Adequately: Before initiating any replacements, gather all necessary tools and equipment. Familiarize yourself with the specific components involved to streamline the process. This preparation helps in minimizing errors and ensuring a smooth workflow.

2. Follow Manufacturer Guidelines: Always refer to the manufacturer’s recommendations regarding specifications and procedures. Adhering to these guidelines not only ensures compatibility but also maintains the integrity of the assembly, reducing the risk of future complications.

3. Inspect Surrounding Components: During the replacement, take the time to examine adjacent elements for wear and tear. Addressing these issues proactively can prevent further damage and enhance the reliability of the overall system.

4. Secure Proper Alignment: Alignment is critical for optimal function. Ensure that all components are correctly positioned and tightened to prevent misalignment that can lead to operational difficulties.

5. Test Thoroughly: After completing the replacement, conduct comprehensive tests to verify that everything operates as intended. This step is essential for identifying any potential issues before they escalate into significant problems.

Safety Considerations for Steering Systems

Ensuring safety in navigation mechanisms is crucial for both operators and passengers. Various factors can influence the effectiveness of these systems, and understanding them helps prevent potential accidents. Proper maintenance and awareness of key elements are vital for a secure experience.

Regular Maintenance and Inspections

Routine checks are essential to identify any wear or damage. Keeping components in good condition enhances reliability and reduces the risk of failures. Consider the following maintenance tips:

- Inspect all connections for signs of corrosion or looseness.

- Check fluid levels and replace fluids as necessary.

- Test the functionality of the control mechanisms regularly.

- Ensure that all components are properly lubricated.

Awareness of Environmental Factors

Environmental conditions can significantly impact performance. Operators should consider the following:

- Monitor weather conditions before operating, as strong winds can affect maneuverability.

- Be aware of water currents and obstacles that may interfere with navigation.

- Adjust operating techniques based on visibility and environmental challenges.