Keeping your equipment in top condition ensures long-lasting performance and efficiency. Proper care and timely upgrades can greatly improve the lifespan and effectiveness of your machine. Regular attention to key components helps maintain its reliability, allowing you to tackle any outdoor task with ease.

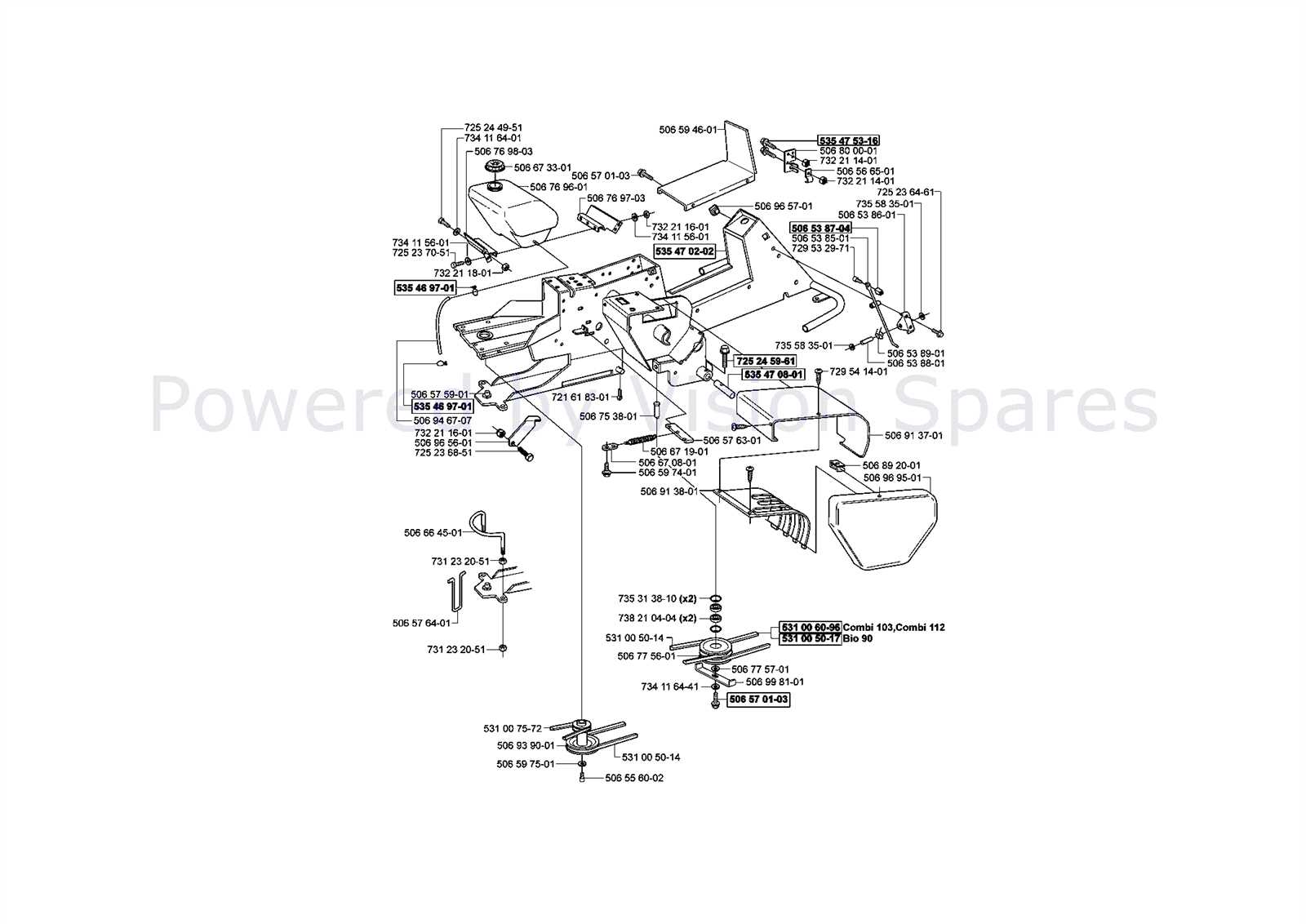

To maintain smooth operation, it’s essential to familiarize yourself with the core elements of your blower. Knowing how each component works can assist you in identifying potential issues early on, preventing bigger problems down the line. A good grasp of the internal setup allows for easier upkeep and occasional adjustments when needed.

In this section, we will explore the various elements that keep your machine running smoothly. You’ll learn how to easily recognize these components, ensuring your equipment remains in peak condition for every task you face.

Overview of the BG 50 Blower

The BG 50 model is a lightweight, easy-to-handle tool designed for clearing outdoor spaces efficiently. Known for its user-friendly operation, it offers excellent power-to-weight balance, making it suitable for homeowners and casual users who need to maintain driveways, sidewalks, and gardens. With this blower, managing leaves and debris becomes a quick and simple task.

Performance and Power

Equipped with a high-output engine, this blower delivers impressive airspeed, allowing for the fast removal of dirt, leaves, and small debris. The engine is engineered for reliability, ensuring long-lasting performance even under regular use. Its streamlined design reduces fatigue during extended periods of operation.

Key Features

This model features an ergonomic handle, providing comfort and control during use. The controls are conveniently placed for easy access, enabling smooth operation. With its compact frame, it’s easy to store and transport, adding to its appeal for users looking for a practical and efficient tool.

Common Parts for Maintenance and Repair

Regular upkeep and occasional fixes are essential to ensure the longevity and optimal performance of any tool. Over time, various components may wear out or require attention due to frequent use. Replacing these elements can prevent more significant issues and extend the life of your equipment.

Here’s a list of commonly addressed components during routine care and repairs:

- Filters: Keeping air and fuel systems clean is crucial for smooth operation.

- Spark plugs: Regularly checking and swapping them out ensures proper ignition and efficiency.

- Fuel lines: These can become brittle or clogged, requiring periodic replacement.

- Carburetor components: Adjusting or replacing small elements here can resolve performance issues.

- Starter assembly: Replacing springs or pulleys helps maintain smooth startup functionality.

Finding the Right Replacement Components

Maintaining your equipment in top condition requires careful attention to detail, especially when individual elements need to be substituted. It’s essential to choose suitable components that ensure optimal performance and extend the lifespan of your tools. By understanding your device’s specific requirements, you can avoid unnecessary complications and ensure smooth operation.

Begin by assessing which elements are showing signs of wear or damage. Make sure to review technical documentation to identify the specifications you need. It’s important to use compatible alternatives that match the original configuration, ensuring both safety and efficiency.

To ensure the best fit, always rely on verified sources when purchasing replacements. By doing so, you avoid potential issues with quality or durability, keeping your equipment running smoothly for longer periods of time.

Key Elements to Check for Wear

Proper maintenance of outdoor equipment ensures its longevity and smooth performance. Regular inspections help identify potential issues early, preventing more significant problems from arising. It’s essential to monitor various components for signs of degradation to maintain efficiency and avoid downtime.

- Engine components: Look for any visible signs of oil leaks or buildup of debris. Check if the housing remains intact without cracks.

- Air filter: Regularly assess the filter to ensure it’s free from excessive dirt or wear. A clogged filter can hinder performance.

- Fuel system: Examine fuel lines and connections for any cracks or leaks. Replace any tubing that shows signs of brittleness.

- Inspect for correct branding logos and names.

- Check for serial numbers or identification codes on both the item and its packaging.

- Compare the packaging design with trusted reference images to ens

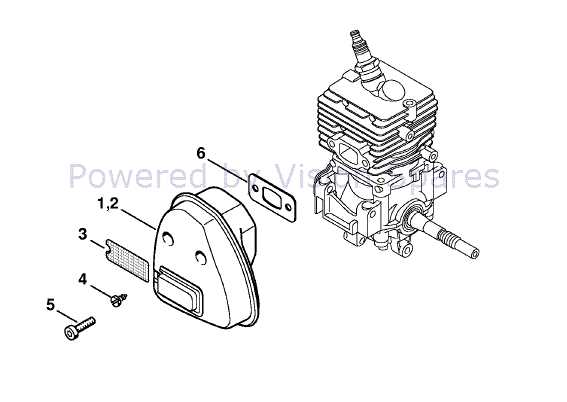

Steps for Replacing the Air Filter

Maintaining the airflow in your equipment is essential for optimal performance. An air filter that is clogged or dirty can hinder the efficiency of the machine. This guide outlines the process to effectively change the air filter, ensuring that your equipment continues to operate smoothly.

- Gather Necessary Tools:

- New air filter

- Screwdriver (if required)

- Clean cloth

- Turn Off the Equipment:

Ensure that the machine is turned off and disconnected from any power source to prevent accidents during maintenance.

- Locate the Air Filter:

Find the compartment housing the air filter. This is usually accessible on the side of the machine.

- Remove the Cover:

If the filter is covered, use the screwdriver to remove the screws and take off the cover.

- Take Out the Old Filter:

Carefully remove the old air filter from its housing. Be cautious to avoid any debris falling into the intake area.

- Clean the Compartment:

Use a clean cloth to wipe down the area where the filter sits. This helps remove any dust or dirt that may have accumulated.

- Install the New Filter:

Place the new air filter into the compartment, ensuring it fits securely and seals properly.

- Replace the Cover:

Reattach the cover and secure it with screws if necessary. Make sure it is tightly fastened to prevent any contaminants from entering.

- Test the Equipment:

Finally, turn on the machine to check for proper operation. Ensure that it runs smoothly and without any unusual noises.

Troubleshooting Ignition Coil Issues

Diagnosing problems related to the ignition coil can significantly enhance engine performance and reliability. This critical component is responsible for generating the electrical spark needed to ignite the fuel-air mixture in the combustion chamber. If you encounter starting difficulties or erratic engine behavior, it may be time to investigate the condition of this essential element.

Identifying Symptoms: Common signs of ignition coil malfunctions include hard starting, engine misfires, or stalling. You might also notice a decrease in power or poor acceleration, indicating that the ignition system is not functioning optimally. Observing these symptoms is crucial for determining whether the ignition coil is the root cause.

Visual Inspection: Begin troubleshooting by conducting a thorough visual examination of the ignition coil and its connections. Look for any signs of damage, such as cracks, corrosion, or loose wires. Ensure that all connections are secure, as poor contact can lead to ignition failures.

Testing the Coil: To assess the functionality of the ignition coil, use a multimeter to measure resistance. Follow the manufacturer’s specifications for the acceptable resistance values. If the readings fall outside the recommended range, this indicates a faulty coil that needs replacement.

Checking Spark Output: An effective way to verify the ignition coil’s performance is to check the spark output. Remove a spark plug and connect it to the ignition coil. Crank the engine and observe the spark. A weak or absent spark indicates that the coil may be defective and should be replaced.

Consulting the Manual: If you are uncertain about any step in the troubleshooting process, referring to the service manual can provide additional guidance. This resource typically includes specific testing procedures and specifications that can aid in accurately diagnosing ignition coil issues.

Conclusion: Addressing ignition coil problems promptly can prevent further engine damage and improve overall performance. By following these troubleshooting steps, you can efficiently identify and resolve any issues related to this vital component.

Where to Buy Affordable Spare Parts

Finding economical components for your tools can greatly enhance your experience and prolong the lifespan of your equipment. Numerous options are available to help you source these essentials without breaking the bank.

Online Retailers offer a wide selection of affordable components. Websites specializing in tool accessories often feature competitive prices and regular discounts. Comparing prices across various platforms can yield significant savings.

Local Hardware Stores can also be a great resource. Many shops carry a range of essential components and may offer loyalty programs or discounts for regular customers. Building a relationship with your local dealer can lead to personalized advice and potential deals.

Second-Hand Marketplaces provide opportunities to find gently used items at reduced prices. Websites and apps dedicated to local sales can be particularly useful for finding what you need without spending a fortune.

Manufacturer Outlets sometimes sell overstock or refurbished items at a lower cost. These outlets can provide quality components while keeping your budget in check.

By exploring these avenues, you can ensure your equipment remains functional without overspending. Always consider reviews and recommendations to make informed choices.

- Gather Necessary Tools:

How to Identify Genuine Stihl Parts

Ensuring you use authentic components is crucial for the performance and longevity of your equipment. Knowing how to distinguish original products from counterfeit or substandard alternatives can prevent potential malfunctions and costly repairs. Below are some key ways to identify authentic pieces and ensure optimal operation.

Look for Manufacturer’s Markings

Genuine components typically feature distinct markings that certify their authenticity. These symbols, numbers, or logos are often engraved or printed on the surface, reflecting quality control measures. Make sure these markings are clear and correctly placed.

Packaging and Documentation

Authentic products usually come in high-quality packaging that includes proper labeling and documentation. Check for a secure seal, clear instructions, and any warranty or certification information that accompanies the product.