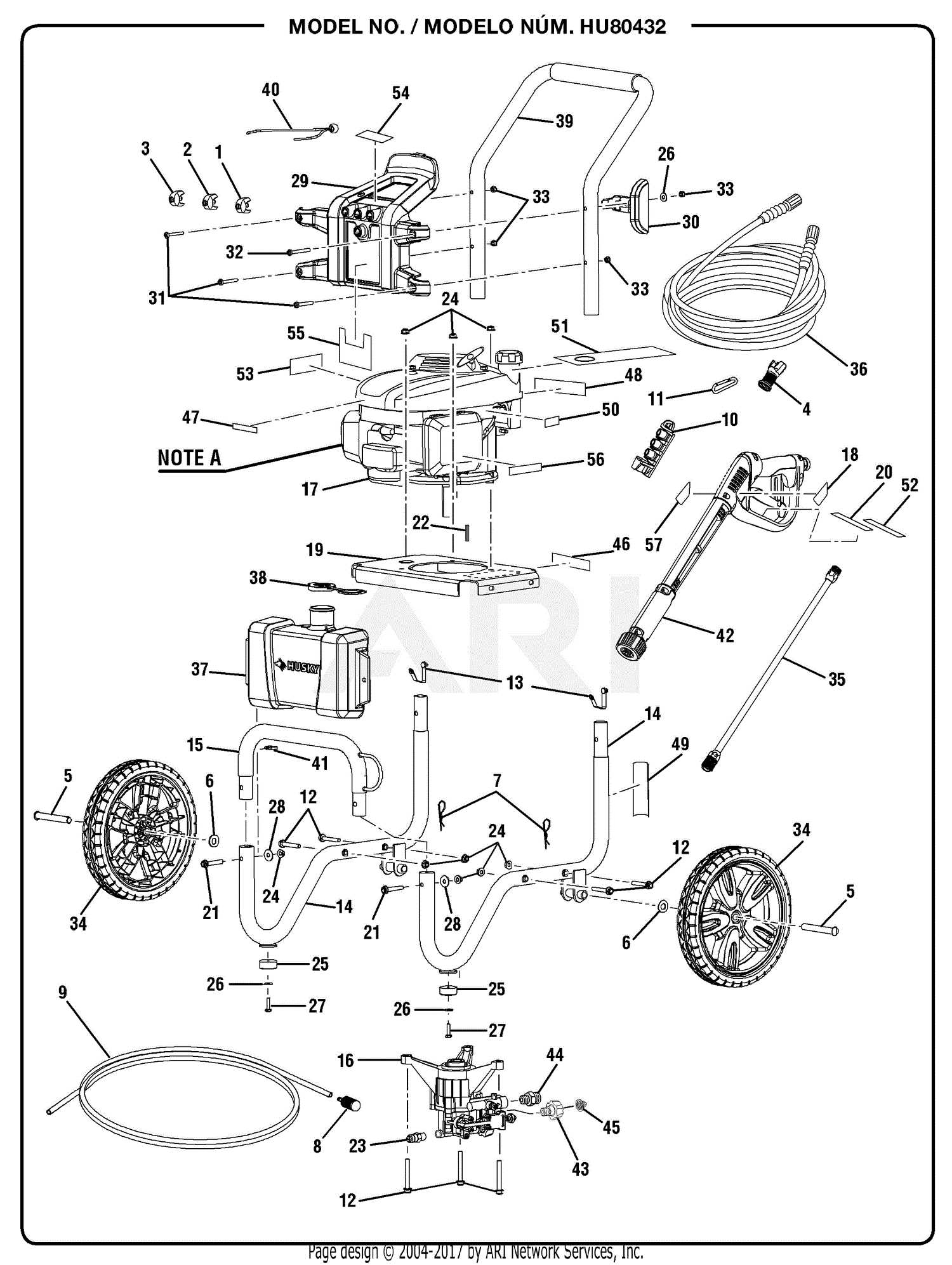

Understanding how the various elements of a high-powered cleaning device come together can significantly improve its efficiency and lifespan. These tools, designed for rigorous outdoor cleaning tasks, consist of several interconnected components, each playing a crucial role in ensuring proper functionality. Knowing how these elements work in harmony allows for easy maintenance and swift repairs when needed.

In this guide, we’ll explore the core elements involved in maintaining your high-performance cleaning equipment. We’ll look at how the different parts interact and what to consider when inspecting them for potential issues. By understanding these fundamentals, you’ll be better equipped to keep your device running smoothly, extending its operational life and avoiding downtime.

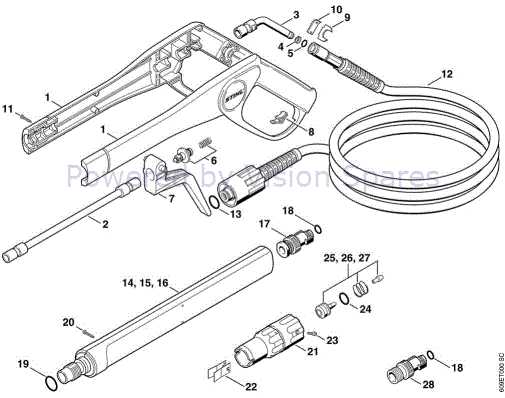

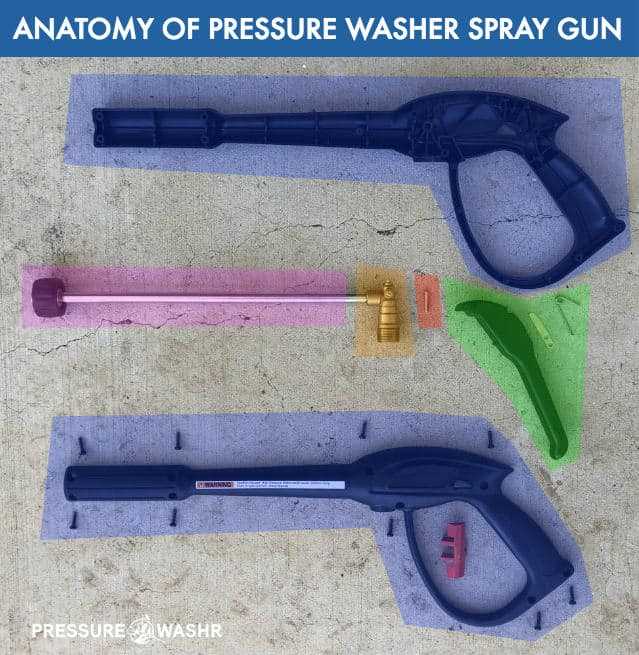

Replacement Pressure Washer Gun Parts Overview

When maintaining and improving equipment for cleaning tasks, it’s crucial to understand the key components that ensure efficient operation. Various elements work together to deliver strong water flow and precision. Over time, wear and tear can affect these essential pieces, making it important to identify the right elements for repair or upgrade.

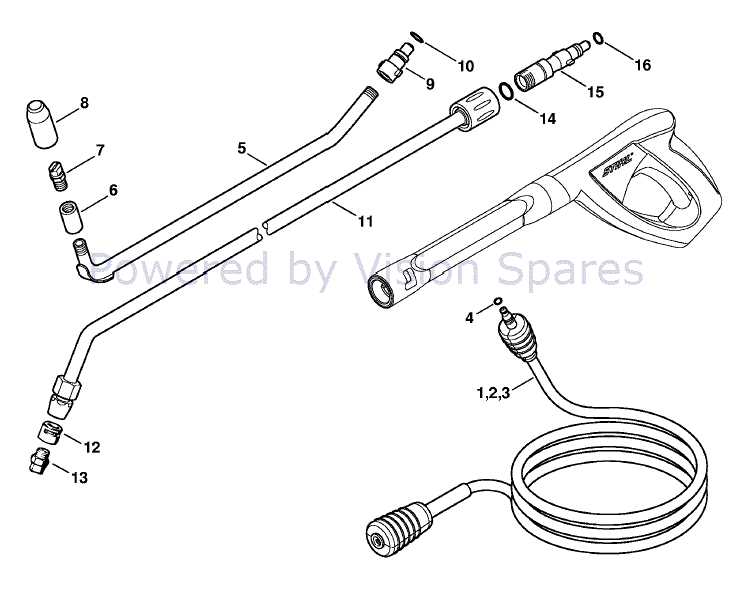

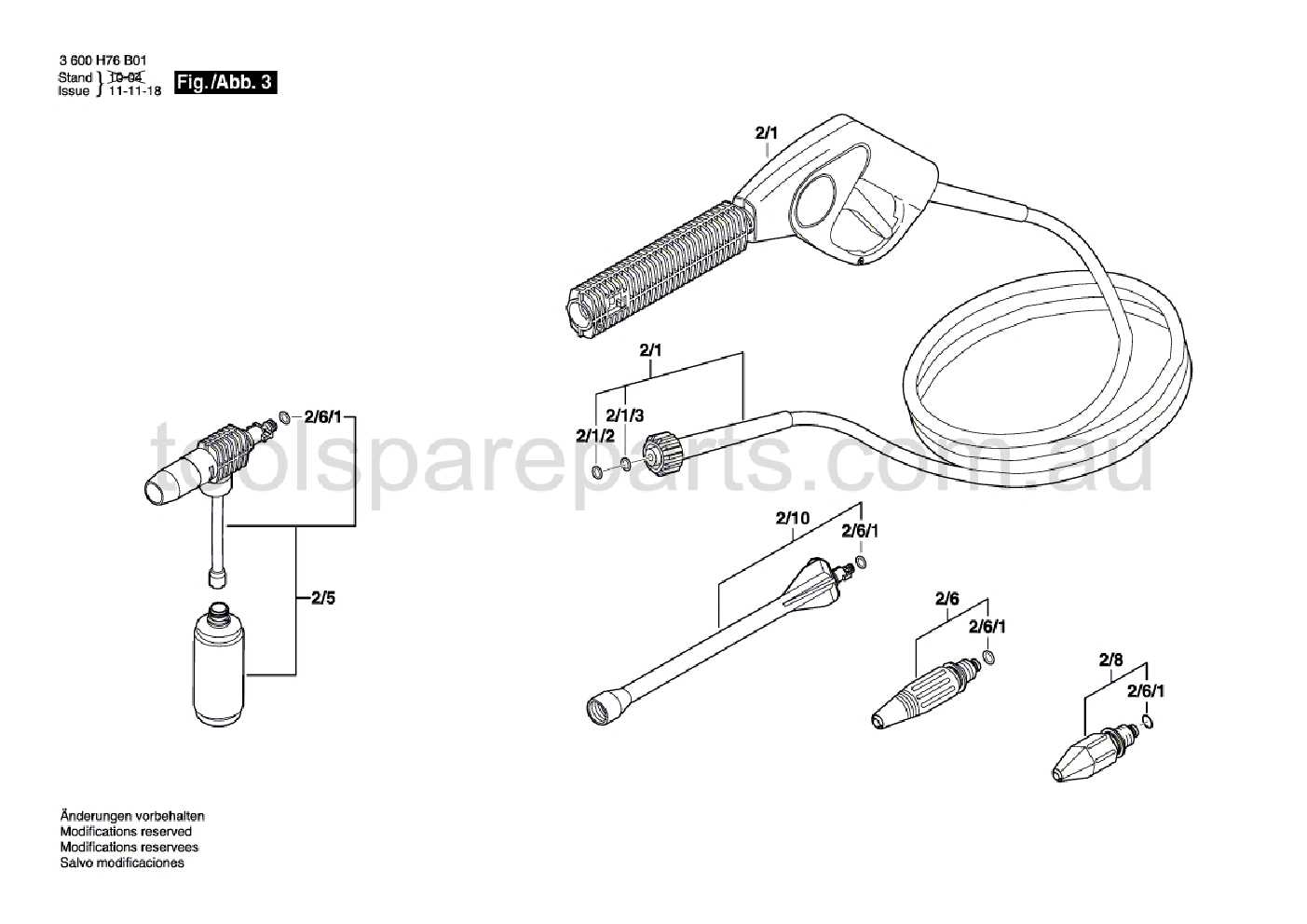

Nozzles play a pivotal role in controlling the flow and pattern of the water stream, allowing for adjustments based on the cleaning surface. Different designs offer variations in pressure and coverage.

The trigger handle is designed to give the user full control over the water output. Ensuring that this component remains functional is essential for both safety and performance.

Seals and connectors form the backbone of the system, preventing leaks and maintaining a steady flow. Regular inspections and replacements of these can extend the life of your cleaning equipment significantly.

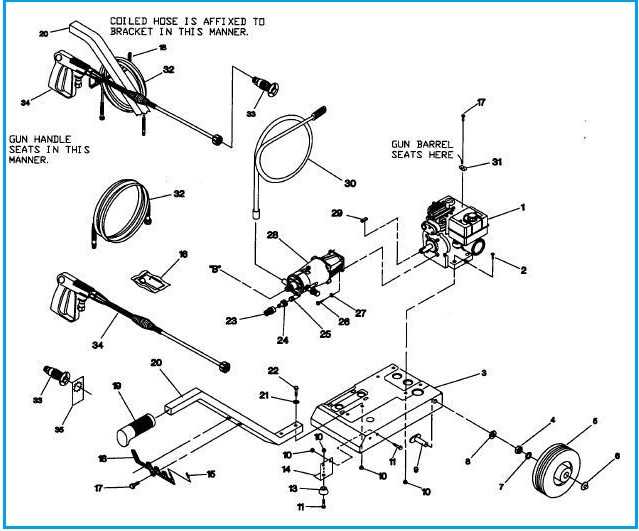

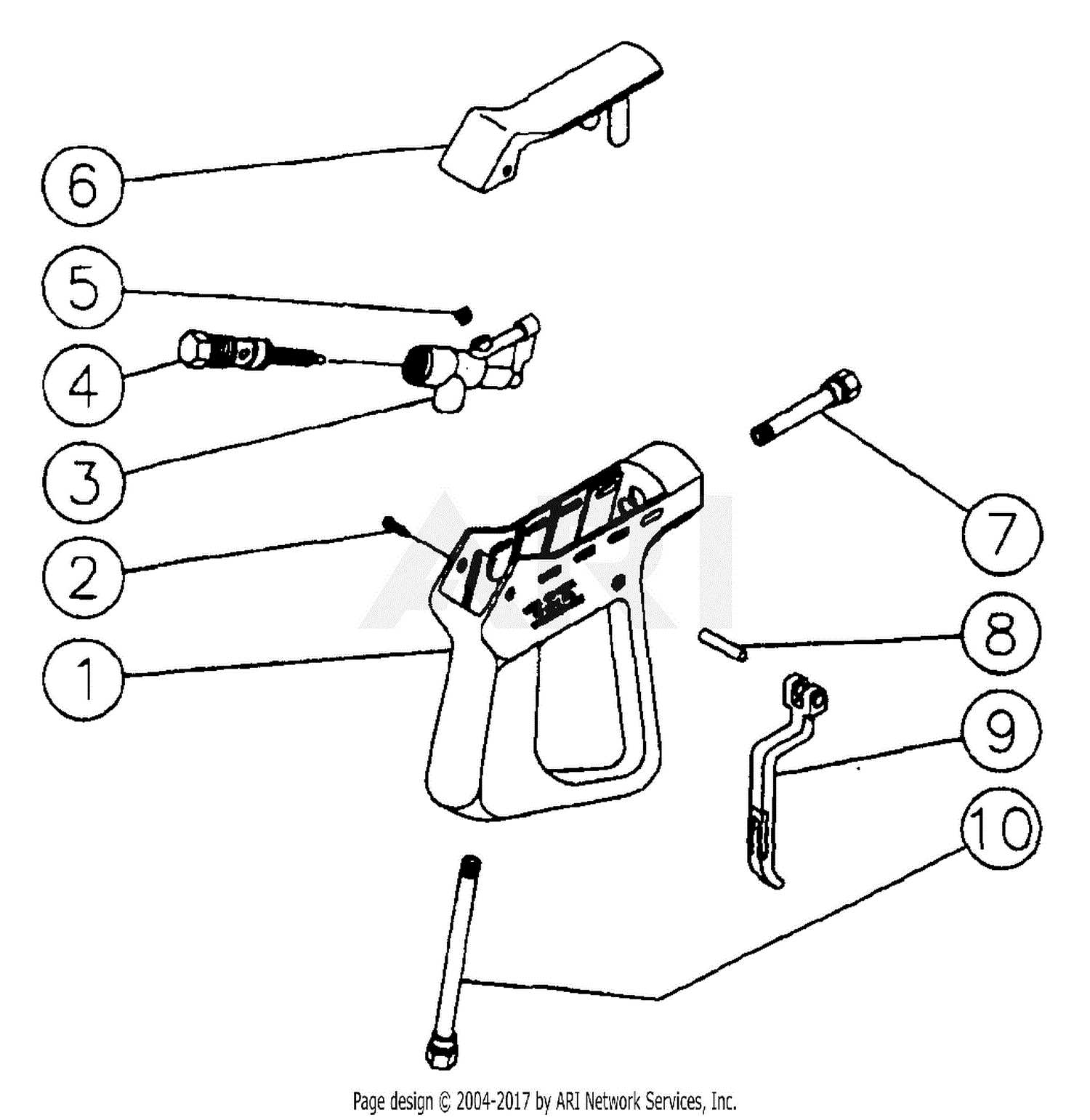

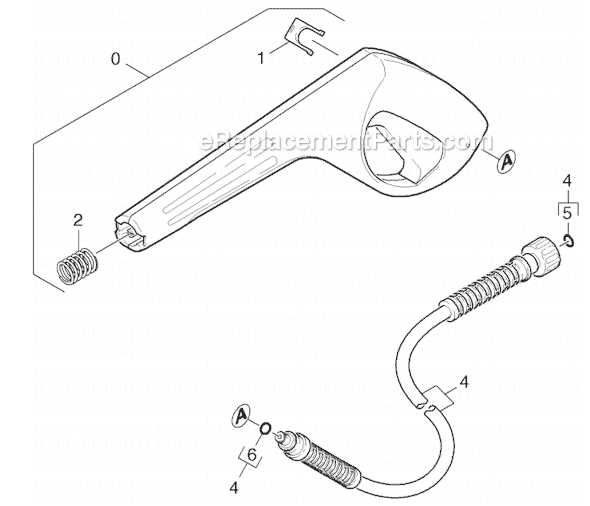

Common Components of a Pressure Washer Gun

The tool used for delivering high-powered water streams consists of several key elements that work together to provide effective cleaning. These components ensure proper functionality, contributing to both performance and ease of use.

Trigger Mechanism

The trigger is a crucial part of the system, allowing users to control the flow of water. When pressed, it opens a valve, releasing the water under high force, while releasing it stops the flow. Its ergonomic design ensures comfortable and safe handling during operation.

Connection Fittings

The fittings serve as the link between the tool and its hose, providing a secure attachment point. These connectors are designed to withstand high water flow and pressure, ensuring a stable connection while minimizing the risk of leaks or disconnections during use.

Identifying Damaged Parts in Your Washer Gun

When your cleaning tool isn’t functioning as expected, it may be due to wear or malfunction in one of its key components. Recognizing which elements are affected is essential to restoring optimal performance. By closely examining various areas of the device, you can detect potential issues that might otherwise go unnoticed.

Start by inspecting the connections and seals for any visible signs of cracks or deterioration. These areas are often the first to show signs of aging, leading to leaks or reduced efficiency. Pay attention to joints and couplings, as even minor wear can impact the tool’s overall operation.

Next, examine the trigger mechanism. If you notice stiffness, unusual resistance, or any difficulty in operation, this could indicate internal damage. The mechanical parts responsible for regulating flow may be affected, and addressing these issues early can prevent further complications.

Finally, observe the tool’s handle and body. Any visible damage, such as cracks or breaks, can compromise the durability and safety of the tool. Regular maintenance checks will help identify such problems before they escalate into larger issues.

Steps for Replacing Pressure Washer Gun Parts

Maintaining your cleaning equipment involves occasionally changing certain components to ensure optimal performance. This guide will walk you through the process of swapping out essential elements, ensuring your tool continues to function efficiently without interruptions.

Step 1: Preparing the Equipment

Before beginning, disconnect the machine from any power source and remove all attachments. This ensures a safe working environment and prevents any accidental activation. It’s also helpful to have a clean workspace where you can organize the elements you’ll be working with.

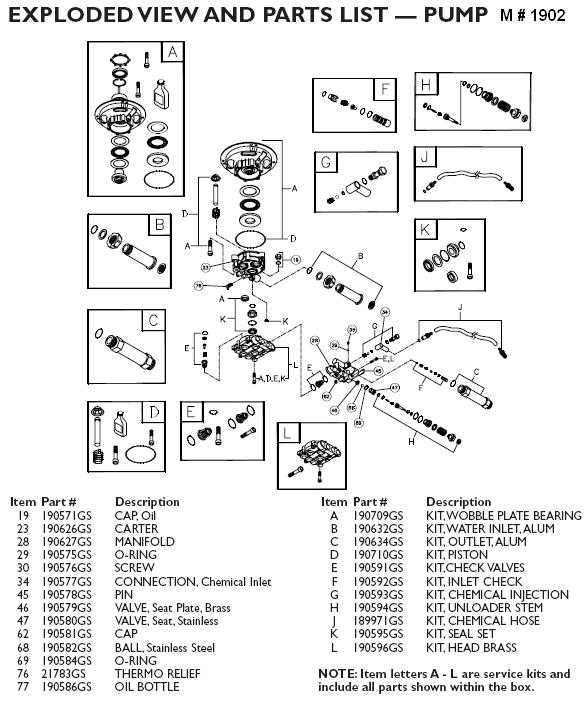

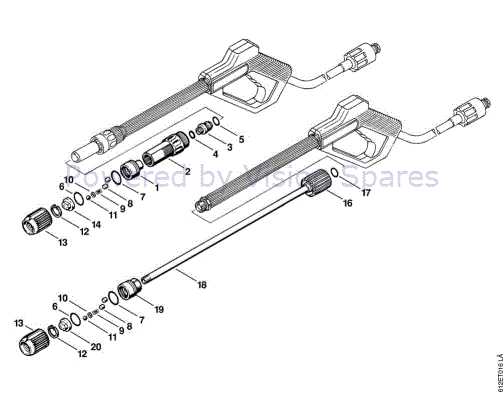

Step 2: Identifying and Removing Worn Components

Carefully inspect the assembly for any signs of wear or damage. Once located, use the appropriate tools to carefully remove the specific item in question. Be sure to note the positioning of each component to assist in the reassembly process. If necessary, consult a visual reference to ensure proper placement during reinstallation.

Tip: Keep small screws and fittings in a secure spot to avoid misplacing them during the process.

Tools Required for Gun Parts Replacement

When undertaking the task of substituting components within a cleaning apparatus, having the right equipment is essential for ensuring a smooth and efficient process. The right tools not only facilitate the disassembly and reassembly of various elements but also enhance safety and effectiveness during the task.

1. Wrenches and Sockets: A set of adjustable wrenches and socket sets will be vital for loosening and tightening screws and fittings. These tools provide the leverage needed to handle stubborn or rusted connections.

2. Screwdrivers: Having both flat-head and Phillips screwdrivers in different sizes is crucial for removing and securing screws that hold various components in place.

3. Pliers: Pliers can be indispensable for gripping, twisting, or cutting wires and small components. They can help in manipulating parts that are difficult to reach.

4. Replacement Components: Ensure you have the new elements on hand that correspond to those being replaced. Having quality replacements ready will minimize downtime and ensure optimal performance.

5. Safety Gear: Always prioritize safety by using protective gloves and goggles. This gear protects against any debris or chemical exposure during the maintenance process.

6. Cleaning Supplies: It may be necessary to have cleaning solutions and cloths available to remove grime and buildup from the equipment before reassembly.

Equipping yourself with these essential tools will streamline the process and help achieve a successful overhaul of the apparatus, ensuring it operates efficiently once more.

Maintenance Tips to Prolong Gun Parts Life

Ensuring the longevity of your equipment’s components requires regular care and attention. By following a few simple practices, you can enhance the durability and efficiency of your tools. Proper maintenance not only minimizes wear and tear but also improves performance, ultimately saving you time and resources.

Here are some essential guidelines to consider:

| Tip | Description |

|---|---|

| Regular Cleaning | After each use, clean the components to remove dirt and debris. This prevents clogging and helps maintain optimal functionality. |

| Inspect for Damage | Periodically check for signs of wear, such as cracks or breaks. Address any issues immediately to avoid further damage. |

| Lubrication | Apply appropriate lubricant to moving parts to reduce friction and ensure smooth operation. This also helps prevent rust formation. |

| Storage Practices | Store your tools in a dry, cool place, protected from direct sunlight. This minimizes exposure to harmful elements that can degrade materials. |

| Use Proper Accessories | Always utilize compatible accessories to avoid unnecessary strain on components. Using the right attachments ensures safe and efficient operation. |

Implementing these practices can significantly extend the lifespan of your equipment, enhancing its performance and reliability. Regular maintenance fosters a proactive approach to care, ultimately leading to a more satisfying experience.

How to Properly Assemble Gun Components

Ensuring that all components are accurately fitted is essential for optimal functionality and safety. Proper assembly techniques not only enhance performance but also extend the lifespan of the equipment. Following the right procedures guarantees a seamless integration of the individual elements, facilitating effective operation.

Start by organizing all components on a clean, flat surface. This will help you easily identify each piece and avoid any confusion during the assembly process. Ensure that you have the necessary tools at hand for efficient work.

Begin with the main body, carefully attaching any necessary connectors or fittings. It is crucial to ensure a snug fit to prevent leaks or malfunctions. Once the main structure is secure, proceed to attach additional elements, making sure each is aligned correctly.

Pay attention to any seals or gaskets during assembly, as these play a vital role in maintaining pressure and preventing leaks. Install them with care, ensuring they are seated properly. Double-check that all components are tightened according to the manufacturer’s specifications to avoid any issues during use.

Finally, test the assembled unit in a safe environment to confirm that everything operates smoothly. Monitoring for any irregularities will help catch potential problems early, ensuring reliable performance when it matters most.

Choosing the Right Parts for Replacement

Selecting the appropriate components for your equipment is crucial to ensure optimal performance and longevity. Understanding the specific requirements of your model and the role of each element will aid in making informed choices. This not only enhances functionality but also contributes to the overall efficiency of your device.

When assessing components, consider the material quality, compatibility with existing fixtures, and the manufacturer’s recommendations. High-quality materials often translate to greater durability and resistance to wear and tear. Furthermore, verifying compatibility prevents future malfunctions and maintains the integrity of your system.

Another important aspect is to evaluate the performance specifications of the items. Each component is designed to fulfill specific functions, and knowing these can help you select options that maximize effectiveness. Pay attention to details such as size, pressure ratings, and flow capacity to ensure that everything fits seamlessly together.

Lastly, don’t hesitate to consult expert resources or customer reviews to gather insights from those who have experience with similar equipment. This collective knowledge can guide you in making choices that lead to a more reliable and efficient operational experience.

Troubleshooting Issues After Part Replacement

After installing new components in your cleaning device, you may encounter unexpected challenges that could affect its performance. Identifying the root causes of these issues is essential to ensure optimal functionality. Below are common problems that might arise following the installation of new elements and suggestions for resolving them.

Common Problems and Solutions

One frequent issue is the presence of leaks, which can result from improper fittings or worn-out seals. Ensure that all connections are tightly secured and that any gaskets or O-rings are in good condition. If leaks persist, double-check the assembly process against the manufacturer’s guidelines to verify that everything has been correctly installed.

Performance Degradation

Another concern is reduced efficiency or output. If the device does not perform as expected, it may indicate a blockage or misalignment. Inspect the intake and discharge areas for obstructions and verify that the newly added components are compatible with the existing system. Regular maintenance and cleaning can help maintain optimal performance and prevent further issues.