Proper upkeep of agricultural machinery is a critical aspect of ensuring optimal field performance. Understanding how various components function and how they interconnect is key to maintaining the overall efficiency of equipment. Regular checks and timely replacements can significantly reduce downtime and prolong the lifespan of the machines.

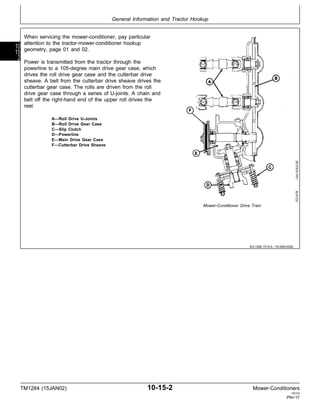

Mechanisms involved in harvesting often require a detailed understanding of their internal structures. By analyzing technical illustrations, operators can quickly identify areas that need attention, making repair and maintenance tasks more efficient.

For effective field operations, it is vital to be familiar with the configuration of each mechanism involved. This knowledge allows for prompt identification of potential issues and ensures that necessary adjustments are made, contributing to a smoother agricultural process.

John Deere 1209 Haybine Overview

The equipment in question is a widely used tool for handling hay crops, recognized for its reliability and performance in various field conditions. This machine is particularly valued for its efficient cutting and conditioning of forage, which helps reduce drying time and improves the overall quality of the hay. It is an ideal solution for farmers seeking to maximize productivity during the harvesting season.

Main Components and Their Functions

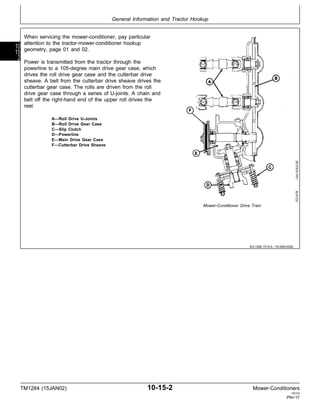

The core mechanisms of this agricultural machine are designed to work together efficiently, ensuring smooth operation and effective performance in the field. Understanding each element and its role is crucial for maintaining and repairing the equipment.

Cutter Bar: This essential part is responsible for trimming the crop close to the ground. It operates swiftly, ensuring clean cuts and minimizing damage to the plants.

Reel: The reel helps in gathering the cut crop and moving it towards the feeding system, ensuring a consistent flow of material for further processing.

Conditioner Rollers: These rollers play a significant role in crushing the stems of the harvested material, aiding in faster drying. They are crucial for efficient crop conditioning.

Frame and Wheels: The structure and wheels

Key Differences from Similar Models

When comparing this equipment with other models, it’s essential to consider various design and functionality aspects that set it apart. The unique features in its construction, along with the performance capabilities, make it stand out among similar options available on the market.

Design and Build Quality

The overall structure has been optimized for durability and efficiency, providing enhanced maneuverability compared to competing versions. Additionally, the frame and mechanical components are tailored for more efficient handling of rough terrain, which contributes to prolonged usage with minimal wear.

Performance and Efficiency

In terms of operational efficiency, this model outperforms others in its class due to its improved cutting mechanism and the ability to process larger volumes in less time. The advanced blade system allows for smoother operation, reducing energy consumption while maintaining high productivity.

| Feature |

Common Parts and Their Locations

Understanding the different components and where they are situated helps in maintaining the machine and ensuring smooth operation. This section provides an overview of the essential elements and their placement within the system, allowing for easier identification during maintenance or repair tasks.

| Component |

Location |

| Cutter Bar |

Located at the front, responsible for cutting crops at the base. |

| Roller Assembly |

Positioned directly behind the cutter bar, used to crimp and condition the crops for faster drying. |

| Drive Mechanism |

Found near the center, this transfers power to the cutting and conditioning units. |

| Hydraulic Cylinder |

Typically located on the side, controlling the height and angle adjustments. |

How to Maintain and Replace Parts

Proper upkeep and timely replacement of components are essential for ensuring optimal functionality and longevity of your agricultural equipment. Regular attention to maintenance routines can prevent unexpected breakdowns and enhance performance during operation.

Start by consulting the user manual for specific guidelines on the maintenance schedule and replacement intervals of various elements. Routine inspections should include checking for wear and tear, lubricating moving parts, and ensuring all systems are functioning correctly.

When it becomes necessary to substitute a component, always choose high-quality replacements that meet the manufacturer’s specifications. Follow the outlined procedures for disassembly and reassembly to ensure that everything is fitted correctly and safely. Keeping a record of all maintenance activities and replacements can also help track the condition and history of the equipment.

Troubleshooting Issues with Specific Components

Identifying and resolving challenges with individual parts of agricultural machinery can significantly enhance performance and longevity. This section focuses on common problems encountered with various elements and offers guidance for effective solutions.

When troubleshooting, it’s essential to follow a systematic approach. Below are some typical components and potential issues associated with them:

-

Drive Belts:

- Check for wear or fraying, which may lead to slippage.

- Inspect alignment to ensure proper tension and positioning.

-

Cutting Blades:

- Monitor for dullness; regular sharpening is crucial for efficient cutting.

- Examine for damage or chips that can impact functionality.

-

Gearbox:

- Listen for unusual noises indicating internal issues or insufficient lubrication.

- Check for leaks to ensure proper sealing and functionality.

-

Hydraulic System:

- Inspect hoses for leaks or cracks that may affect pressure.

- Ensure fluid levels are adequate and clean to maintain performance.

By addressing these specific components and their common challenges, operators can maintain optimal functionality and prevent further complications.

Tips for Finding Original Parts

Locating authentic components for agricultural machinery can greatly enhance performance and longevity. This section provides insights into effective strategies for sourcing reliable items, ensuring that your equipment operates at its best.

Research Authorized Dealers

Start by identifying authorized distributors or retailers specializing in agricultural equipment. These suppliers often have direct access to genuine items and can offer valuable advice on compatibility and installation.

Utilize Online Resources

Take advantage of online platforms dedicated to agricultural machinery. Websites and forums often feature listings of original components, as well as user reviews and recommendations that can guide your purchasing decisions. Additionally, manufacturers’ websites may provide resources to help you verify authenticity.

Keep Receipts and Documentation for all purchases to ensure that you can trace the source of your items. This can be helpful for warranty claims or future service needs.

Installation Guidelines for New Parts

Proper installation of new components is crucial for optimal performance and longevity of the machinery. Following a systematic approach ensures that each element is securely fitted and functions correctly within the system.

Before starting the installation process, gather the necessary tools and materials. This preparation will streamline the task and minimize potential disruptions.

- Safety First: Always wear appropriate safety gear to protect yourself during the installation process.

- Refer to the Manual: Consult the manufacturer’s guidelines to understand the specific requirements and steps for installation.

- Organize Components: Lay out all new elements in an orderly fashion to easily access them during installation.

During the installation, follow these steps:

- Remove the existing components that need replacement, ensuring that all fasteners are kept in a safe place.

- Clean the installation area to remove debris and old lubricant, ensuring a proper fit for the new items.

- Install the new components carefully, paying attention to alignment and positioning.

- Secure all fasteners according to the specified torque settings to prevent loosening during operation.

- Conduct a thorough inspection to verify that everything is in place and functioning correctly.

Finally, after the installation is complete, run a brief test to ensure the machinery operates smoothly with the new elements. Address any irregularities immediately to maintain efficiency.

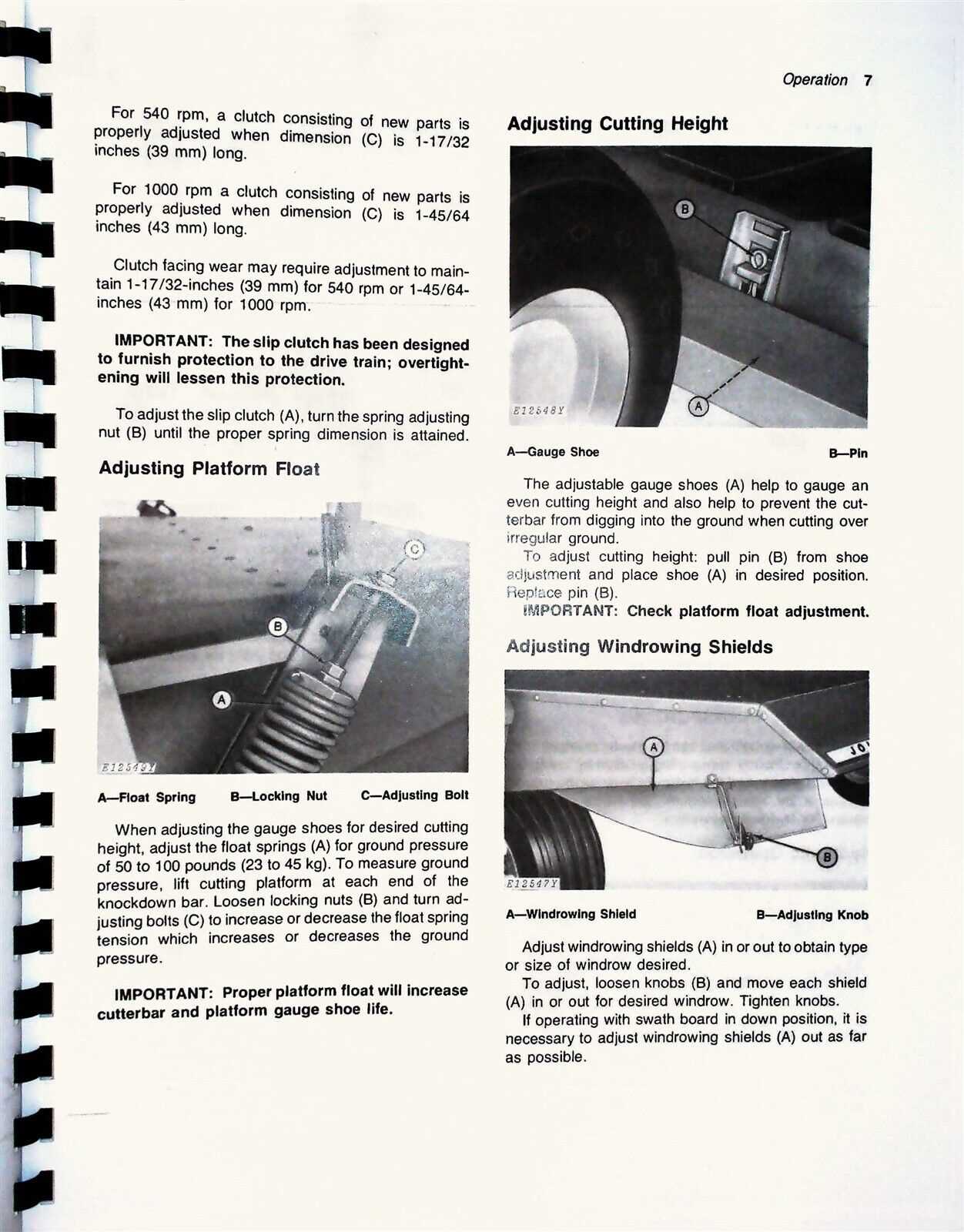

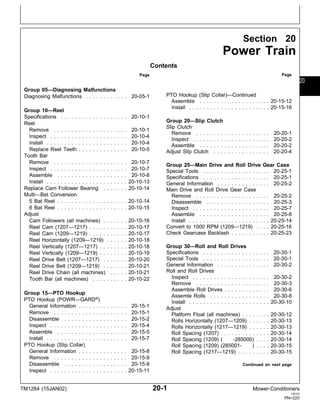

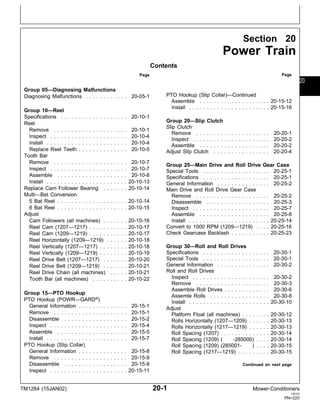

Understanding the Parts Diagram

Comprehending the visual representation of components is essential for effective maintenance and repair. This illustration serves as a valuable reference for identifying various elements, ensuring proper assembly and functionality of the equipment. By familiarizing oneself with this guide, operators can enhance their knowledge and streamline their workflow.

Key Components and Their Functions

Each element in the illustration has a specific role, contributing to the overall operation of the machinery. Understanding these roles can lead to better troubleshooting and efficient performance.

- Drive Mechanism: Responsible for transmitting power and enabling movement.

- Cutter Bar: Engages in the cutting process, ensuring clean and efficient harvesting.

- Frame: Provides structural integrity and support for all components.

- Wheels: Facilitate mobility across various terrains.

How to Use the Illustration

Utilizing the visual representation effectively involves a systematic approach:

- Identify the components you need to inspect or replace.

- Cross-reference with the maintenance manual for specifications.

- Follow the assembly sequence provided in the guide for proper reinstallation.