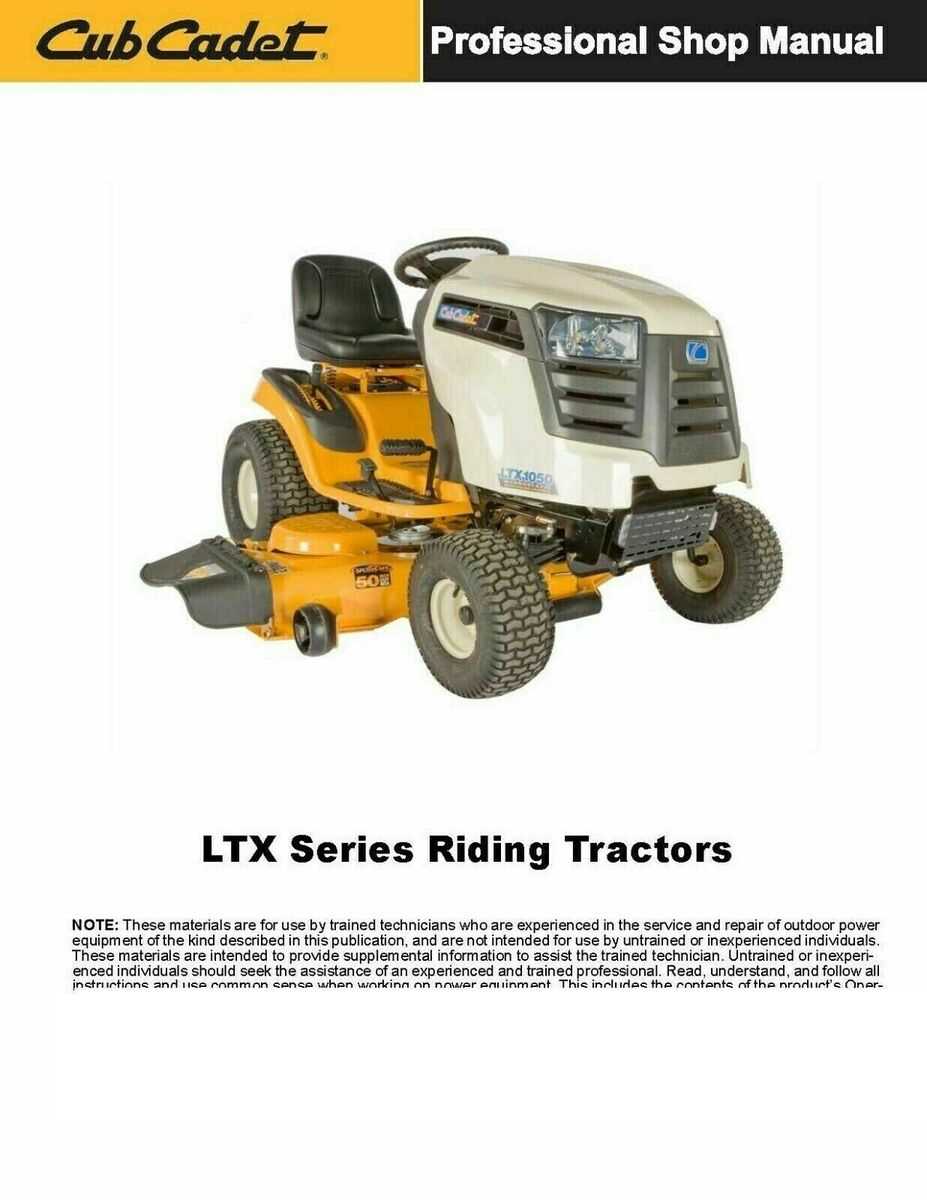

When it comes to maintaining your lawn tractor, having a comprehensive understanding of its various components is essential for ensuring optimal performance and longevity. By familiarizing yourself with the layout and function of each element, you can easily identify any issues that may arise and make informed decisions regarding repairs and replacements.

In this section, we will explore the intricate structure of a popular riding mower model, highlighting the essential features that contribute to its functionality. Each segment plays a vital role in the overall operation, from the engine assembly to the cutting system, and knowing their arrangement can greatly enhance your maintenance efforts.

Whether you are a seasoned mechanic or a novice user, having access to a detailed illustration of the mower’s configuration can serve as a valuable reference. This knowledge not only empowers you to tackle maintenance tasks more effectively but also helps in making educated choices when sourcing replacement components.

This section aims to provide a comprehensive understanding of a specific model of lawn maintenance machinery, detailing its components and how they contribute to optimal performance. By exploring the various sections, readers will gain insights into the intricate workings of the machine and the importance of each part.

1. Introduction to the Machine

Gain a basic understanding of this versatile lawn care equipment, designed for efficiency and ease of use. Its construction and features are tailored to meet the needs of both homeowners and professionals.

2. Importance of Component Knowledge

Understanding the various components is crucial for effective maintenance and repair. Familiarity with each part enhances the ability to troubleshoot and ensure longevity.

3. Key Functional Areas

- Power System

- Cutting Mechanism

- Transmission Components

- Steering and Control

4. Maintenance Recommendations

Regular maintenance is vital for optimal performance. Here are some recommended practices:

- Routine inspections of moving parts.

- Timely lubrication of necessary components.

- Cleaning filters and checking oil levels.

5. Troubleshooting Common Issues

Many common issues can arise during operation. Here are some typical problems and their solutions:

- Engine won’t start: Check the battery and fuel supply.

- Uneven cutting: Inspect the blades for wear.

- Transmission slipping: Check for fluid levels and leaks.

6. Replacement Parts Overview

In cases where components wear out or fail, knowing where to find replacements is essential. Consideration should be given to compatibility and quality.

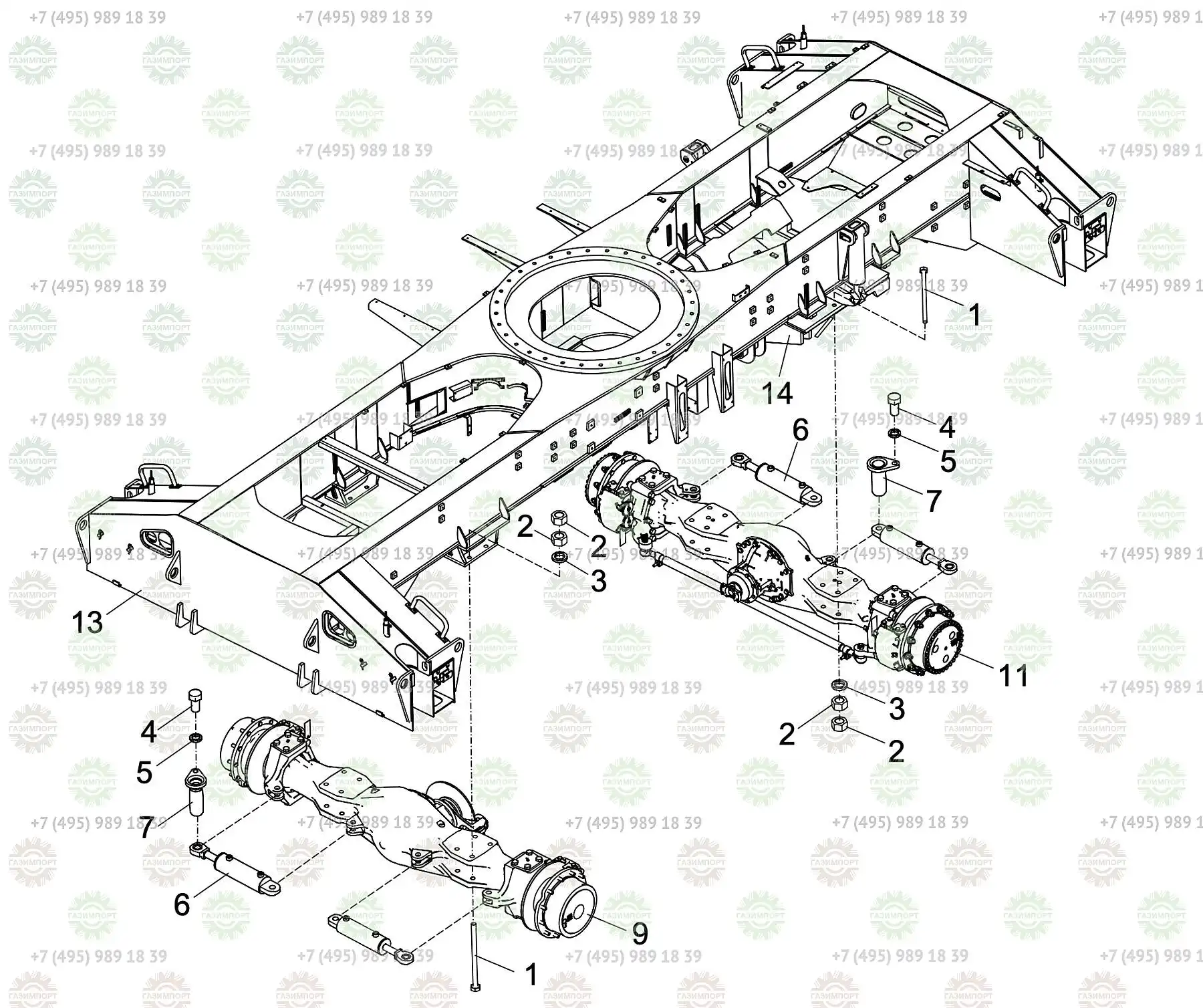

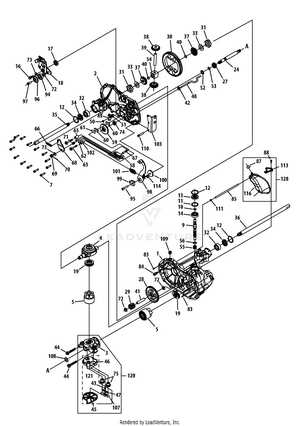

7. Diagrammatic Representation

A visual representation aids in identifying each component. Understanding how the parts fit together can greatly enhance repair and assembly tasks.

8. Conclusion

Having a detailed understanding of the various components allows for better upkeep and enhances the efficiency of the equipment. Regular attention to each area discussed will ensure the machine remains in peak condition.

Importance of Parts Diagrams

Understanding the layout and components of a machine is essential for effective maintenance and repair. Visual representations help users identify each element’s function, ensuring that they can make informed decisions during servicing. Such illustrations are crucial for both professionals and enthusiasts who want to keep their equipment in optimal condition.

Enhancing Repair Efficiency

Visual guides streamline the repair process, enabling users to quickly locate and assess individual elements. This efficiency reduces the time spent troubleshooting and allows for faster resolutions, minimizing downtime. Clear visual references contribute to a more organized approach to maintenance tasks.

Facilitating Accurate Ordering

When replacements or upgrades are needed, visual references allow users to accurately identify what is required. This accuracy is vital in preventing costly mistakes associated with ordering incorrect components. Ensuring compatibility and fitting becomes much easier with comprehensive visuals.

| Benefit | Description |

|---|---|

| Improved Understanding | Clear visuals enhance comprehension of each component’s role. |

| Time Savings | Streamlined identification leads to quicker repairs. |

| Cost Efficiency | Accurate identification helps avoid ordering errors. |

Identifying Key Components

Understanding the essential elements of a machinery system is crucial for effective maintenance and troubleshooting. By recognizing the primary components, users can enhance the operational efficiency and longevity of their equipment. This section focuses on the significant parts that play a pivotal role in the functioning of the machine.

Main Assembly

The main assembly serves as the backbone of the equipment, housing various interconnected systems. It provides structural integrity and facilitates the operation of numerous mechanical functions. Proper identification of this assembly is fundamental for users aiming to perform repairs or upgrades effectively.

Powertrain System

The powertrain system is responsible for transmitting power from the engine to the wheels, ensuring smooth mobility. Key elements within this system include the transmission and drive shafts, which play vital roles in movement and control. Recognizing these components allows for better maintenance practices and can prevent potential failures.

How to Read the Diagram

Understanding technical illustrations is crucial for effective maintenance and repair. These visual aids provide valuable insights into the assembly and function of various components within machinery. By learning to interpret these representations, users can enhance their troubleshooting skills and ensure proper handling of each element.

Key Elements to Focus On

- Labels and Numbers: Each section is usually marked with identifiers that correspond to specific components. Pay attention to these as they help in locating parts.

- Connections: Observe how different parts interact with one another. Lines often indicate connections, which can clarify how various elements work together.

- Legends: Many illustrations include a legend or key, explaining symbols and colors used. Familiarizing yourself with this information can simplify interpretation.

Steps to Effective Interpretation

- Start by identifying the overall structure and organization of the illustration.

- Focus on the labeled sections to understand the function of each part.

- Cross-reference with the user manual or other resources for additional context.

- Take notes on the connections and interactions that appear complex or unclear.

Common Replacement Parts

When maintaining outdoor equipment, understanding the components that often require substitution is crucial for optimal performance. Regular usage can lead to wear and tear on various elements, necessitating timely replacements to ensure the machinery operates smoothly and efficiently.

Key items frequently needing attention include the cutting blade, which is essential for achieving a clean cut; the air filter, vital for maintaining engine performance; and the battery, crucial for reliable starting. Additionally, the drive belt is important for power transmission, while spark plugs play a significant role in engine efficiency.

Other notable components that may require replacement include wheel bearings, ensuring smooth mobility, and fuel filters, which help maintain the quality of the fuel being used. Addressing these common issues not only prolongs the lifespan of the machinery but also enhances its overall functionality.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and optimal performance of your outdoor equipment. By adhering to a consistent maintenance schedule, you can significantly extend the lifespan of your machinery, minimize the risk of unexpected breakdowns, and enhance overall efficiency.

Start by regularly inspecting the engine and replacing the oil as needed. This will keep the internal components lubricated and functioning smoothly. Additionally, make it a habit to clean or replace air filters periodically to ensure proper airflow and prevent engine strain.

Check the blades frequently for sharpness and signs of wear. Dull blades can damage the grass and stress the motor. Maintaining sharp blades not only improves cutting performance but also contributes to a healthier lawn.

Inspect belts and cables for fraying or signs of damage. Replacing worn components promptly can prevent further issues and costly repairs. Furthermore, ensure that all nuts and bolts are tightened to avoid vibrations that may lead to structural damage over time.

Finally, store your equipment in a dry and sheltered area during off-seasons. This will protect it from the elements and reduce the likelihood of rust and corrosion. Following these simple yet effective maintenance tips will ensure your outdoor machinery remains reliable for years to come.

Where to Find OEM Parts

Finding original equipment manufacturer components is crucial for maintaining the performance and longevity of your machinery. These authentic replacements ensure compatibility and reliability, making them a preferred choice for many users. Here are some effective ways to locate these essential items.

Authorized Dealers

One of the most reliable sources for obtaining original components is through authorized dealers. These outlets typically offer:

- Genuine products directly from the manufacturer

- Expert advice from knowledgeable staff

- Access to warranties and customer support

Online Retailers

Another convenient option is to explore various online retailers that specialize in equipment components. Many of these platforms provide:

- A wide selection of genuine items

- Competitive pricing and special offers

- User reviews for informed decision-making

When searching online, be sure to verify the seller’s reputation to ensure you are receiving authentic merchandise. This approach not only saves time but can also lead to significant cost savings.

DIY Repair vs. Professional Help

When it comes to fixing mechanical equipment, individuals often face the decision of whether to tackle repairs themselves or to seek assistance from skilled technicians. Each option has its own set of advantages and challenges that can influence the outcome of the repair process.

Self-repair can be a rewarding experience, allowing individuals to develop their technical skills while saving on labor costs. Many enthusiasts enjoy the satisfaction that comes from troubleshooting and resolving issues on their own. Additionally, DIY repairs often provide a deeper understanding of how the machinery functions, which can be beneficial for future maintenance.

On the other hand, seeking professional assistance ensures that repairs are handled by experienced individuals who possess the necessary expertise and tools. Professionals can often diagnose problems more quickly and accurately, minimizing downtime. Their familiarity with various types of equipment can lead to more effective and long-lasting solutions, which may ultimately prove cost-effective despite higher initial expenses.

Ultimately, the choice between self-repair and hiring a professional depends on factors such as the complexity of the issue, available tools, and the individual’s confidence in their mechanical abilities. Weighing these elements carefully can lead to a more informed decision that meets both immediate needs and long-term goals.

Community Resources and Support

Accessing the right resources and support can significantly enhance the experience of maintaining and operating your outdoor equipment. Engaging with local communities and online platforms provides invaluable insights, troubleshooting tips, and assistance in acquiring necessary components for repairs. This section highlights various avenues where users can seek help and share knowledge related to their equipment.

Online Forums and Discussion Groups

Participating in online forums is an excellent way to connect with fellow enthusiasts. Here, users can:

- Ask questions and share experiences related to equipment maintenance.

- Access troubleshooting guides and helpful tips shared by experienced users.

- Exchange ideas on upgrades and modifications to enhance performance.

Local Community Workshops

Many communities offer workshops that focus on equipment care and repair. These sessions often include:

- Hands-on demonstrations of maintenance techniques.

- Expert advice from seasoned professionals in the field.

- Networking opportunities with other equipment owners.