Maintaining a well-kept lawn requires not only dedication but also a solid understanding of the machinery involved. One of the essential elements of these machines is the undercarriage structure, which plays a crucial role in ensuring efficiency and performance. A thorough examination of this assembly can lead to better upkeep and functionality, enhancing the overall experience of lawn care.

For enthusiasts and professionals alike, familiarizing oneself with the intricate details of the assembly can greatly simplify maintenance tasks. Knowledge of the individual components allows for easier identification of wear and tear, facilitating timely replacements and repairs. By grasping the layout and function of each element, users can ensure their machinery operates at its peak, ultimately leading to a healthier lawn.

Additionally, understanding how each piece fits together can aid in troubleshooting common issues. Whether it involves minor adjustments or significant replacements, having a comprehensive view of the assembly will empower users to make informed decisions. This knowledge not only prolongs the life of the machinery but also enhances the efficiency of the mowing process, ensuring that users achieve their desired results effortlessly.

Overview of the Lawn Mower Model

This section provides a comprehensive look at a popular model in the realm of outdoor power equipment, specifically designed for maintaining residential landscapes. Its engineering reflects a commitment to durability and performance, making it a favored choice among homeowners.

Key features of this model include:

- Robust construction for long-lasting use

- Efficient cutting mechanism that enhances grass management

- Easy-to-use controls that simplify operation

- Comfortable seating for extended periods of use

- Versatile design that accommodates various attachments

The machine is built to tackle a variety of mowing tasks, ensuring that users can achieve optimal results with minimal effort. Its reliability in various weather conditions further contributes to its reputation as a top choice for yard maintenance.

In summary, this model stands out for its combination of power, efficiency, and user-friendly features, making it an ideal option for anyone looking to maintain their lawn with ease.

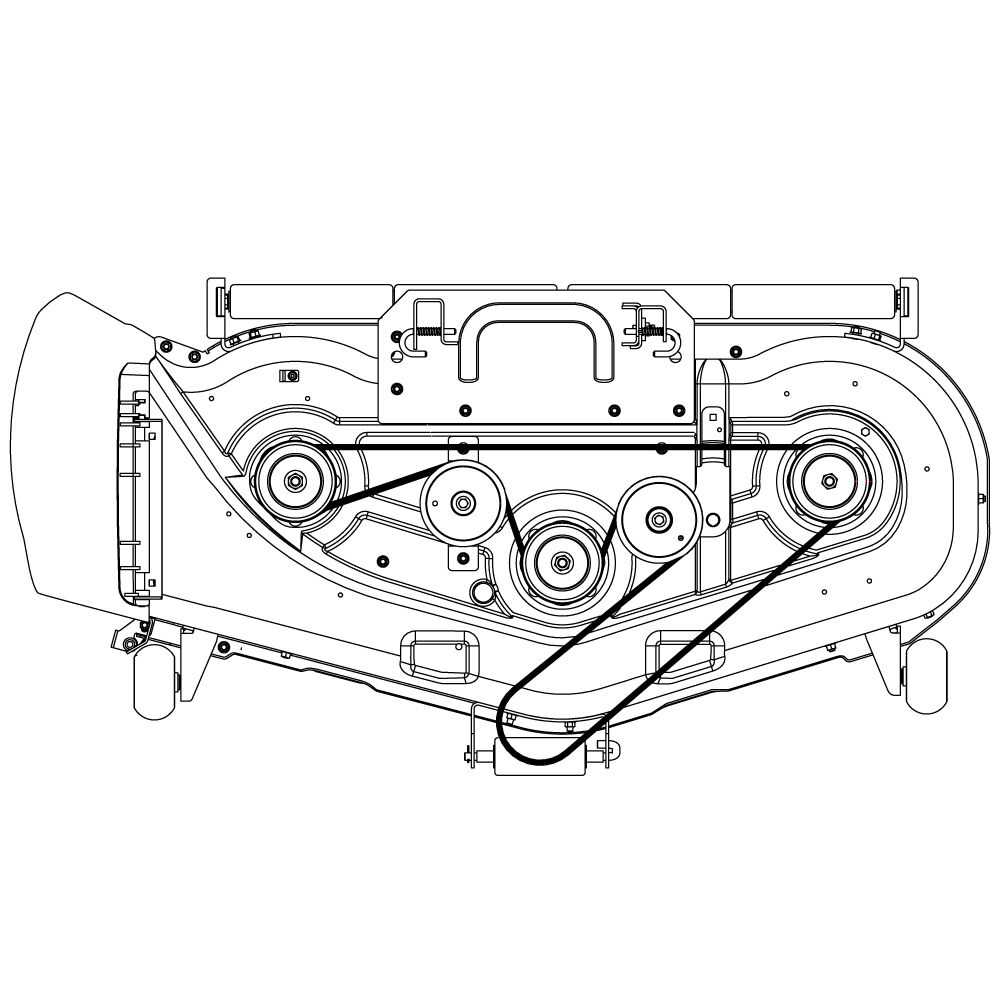

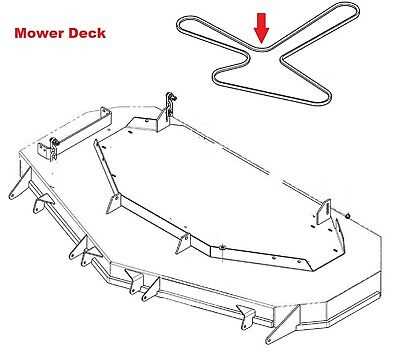

Understanding the Mower Deck Functionality

The mechanism responsible for cutting grass is an essential component of any lawn maintenance machine. Its design and operation play a crucial role in achieving a well-manicured lawn. A deeper comprehension of this apparatus can enhance performance and prolong its lifespan.

This cutting assembly typically includes several key elements:

- Blades: These sharp implements rotate at high speeds to effectively trim grass.

- Housing: The enclosure that protects the blades and directs the cuttings.

- Spindles: These support the blades and allow for their rotation.

- Adjustable Height Mechanism: This feature enables users to change the cutting height according to their preferences.

- Drive System: This component transfers power from the engine to the cutting blades.

Understanding how these elements interact can significantly impact mowing efficiency and grass health. Regular maintenance and inspection of these components ensure optimal performance and can prevent costly repairs.

To maintain the efficiency of this cutting mechanism, consider the following practices:

- Regularly sharpen the blades to ensure a clean cut.

- Inspect and clean the housing to prevent buildup of grass clippings.

- Check the spindles for wear and ensure they are properly lubricated.

- Adjust the height settings to accommodate different grass types and seasonal changes.

- Monitor the drive system for any signs of wear or malfunction.

By focusing on these aspects, users can maximize the effectiveness of their lawn care equipment and achieve a lush, healthy lawn.

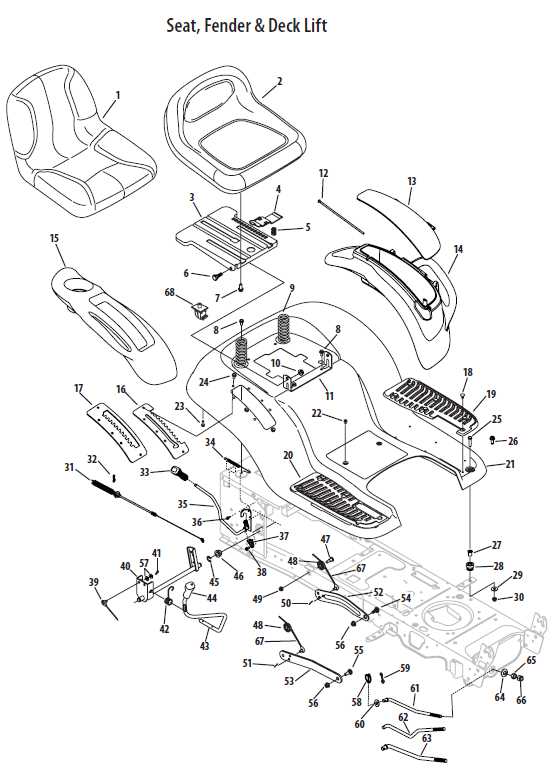

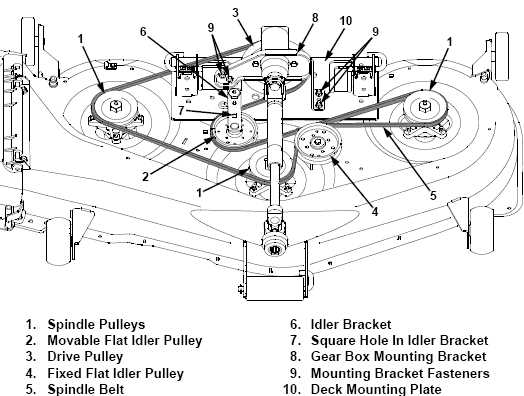

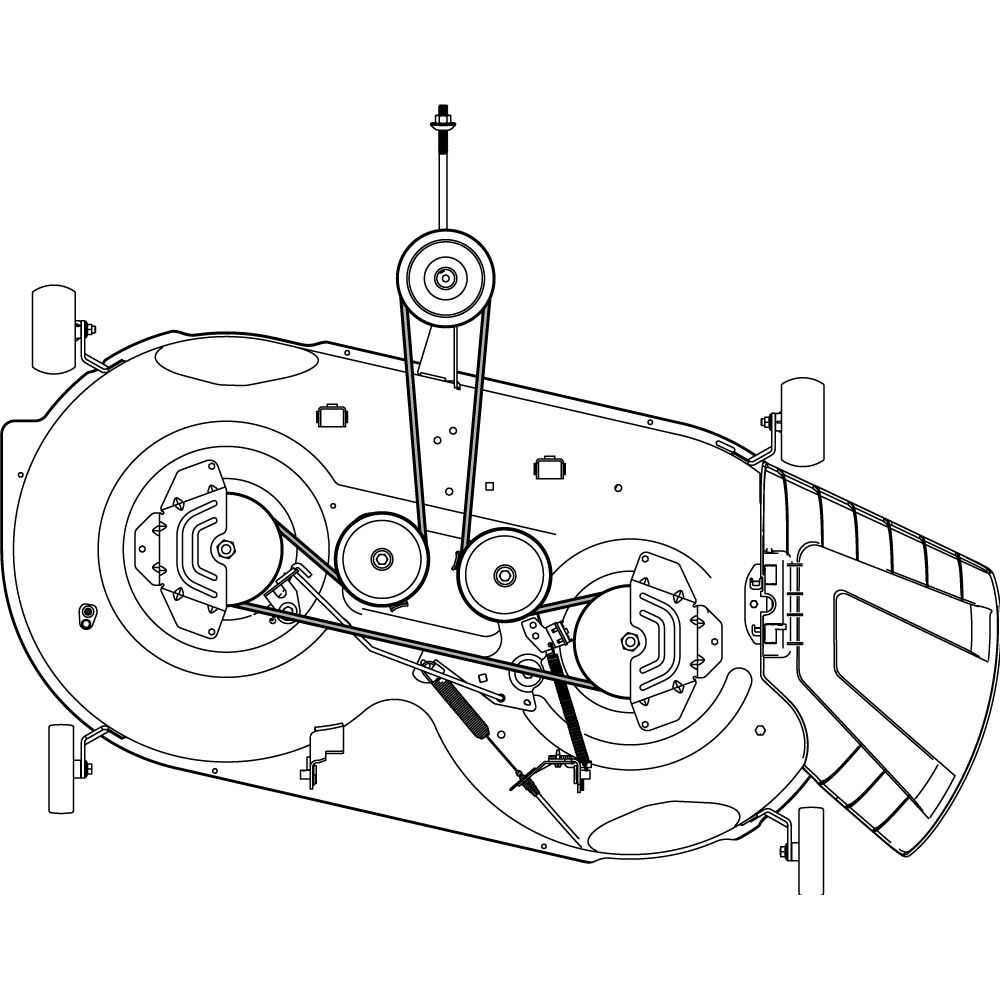

Identifying Key Deck Components

Understanding the primary elements of your lawn care equipment is essential for effective maintenance and optimal performance. Each component plays a crucial role in ensuring that the machinery operates smoothly, contributing to the overall efficiency of the cutting process. Familiarity with these parts will aid in troubleshooting and repairs, making it easier to keep your equipment in peak condition.

Essential Elements of the Cutting System

At the heart of the operation are the blades, which are responsible for achieving a clean and even cut. Regular inspection is vital, as dull or damaged blades can lead to uneven results. Adjacent to the blades are the spindles, which support the rotation and are often a source of wear. Ensuring they are well-lubricated and free from debris is crucial for longevity.

Supporting Structures and Adjustments

The chassis provides the necessary stability, while various belts facilitate power transfer from the engine. Tension adjustments on these belts are necessary to maintain proper function. Additionally, understanding the role of the lift system allows users to adjust the height of the cut effectively, enhancing the versatility of the equipment for different types of grass and terrain.

Maintenance Tips for Mower Deck

Proper upkeep of your mowing apparatus is essential for ensuring optimal performance and longevity. Regular attention not only enhances cutting efficiency but also prevents costly repairs. Here are some effective practices to keep in mind.

Regular Cleaning

After each use, it’s important to remove grass clippings, dirt, and debris from the cutting unit. This helps maintain sharpness of the blades and prevents rust. A clean surface also allows for better airflow and improved cutting performance.

Blade Maintenance

Inspecting and sharpening the blades regularly is crucial. Dull blades can tear grass rather than cut it cleanly, leading to a frayed appearance. Aim to sharpen the blades every 20-25 hours of operation, or replace them if they are excessively worn.

| Task | Frequency |

|---|---|

| Clean cutting unit | After each use |

| Inspect blades | Every 10 hours |

| Sharpen blades | Every 20-25 hours |

| Check belts and cables | Seasonally |

| Lubricate moving parts | Monthly |

By following these guidelines, you can ensure your mowing equipment remains in peak condition, leading to a healthier lawn and a more enjoyable mowing experience.

Replacing Worn Deck Parts

Maintaining optimal performance of your mowing equipment is essential for achieving a well-manicured lawn. Over time, various components can wear out due to exposure to elements and regular use. Identifying and replacing these components promptly will not only enhance functionality but also prolong the lifespan of your machinery.

Identifying Worn Components

Before undertaking any replacements, it’s crucial to assess the condition of individual elements. Look for signs of damage such as cracks, bends, or excessive rust. Additionally, listen for unusual sounds during operation, as they may indicate that certain parts are no longer functioning effectively. Regular inspections will help you stay ahead of potential issues.

Steps for Replacement

Once you’ve identified the components needing replacement, gather the necessary tools and new items. Begin by ensuring the machine is powered off and securely positioned. Remove the old elements carefully, taking note of their arrangement for easier installation of the new ones. After placing the new components, double-check all connections and ensure everything is secure. Finally, test the equipment to confirm that it operates smoothly.

Proactive maintenance is key to enjoying a well-maintained lawn care experience. By regularly replacing worn items, you ensure not only better performance but also a safer operating environment.

Common Issues with Deck Assembly

When working on the assembly of lawn care machinery, several challenges can arise that may affect performance and efficiency. Understanding these issues can help in troubleshooting and ensuring a smooth operation.

- Misalignment: One of the most frequent problems is the misalignment of components. This can lead to uneven cutting and increased wear on the blades.

- Loose Connections: Fasteners that are not tightened properly can cause parts to vibrate or come loose during operation, resulting in potential damage.

- Worn Bearings: Bearings that have not been maintained may wear out quickly, leading to increased friction and potential failure of moving parts.

- Corrosion: Exposure to moisture can lead to rust and corrosion on metal components, compromising their integrity and functionality.

Addressing these issues promptly can significantly enhance the longevity and performance of your equipment. Regular maintenance and inspection are key to preventing these common assembly-related problems.

Deck Adjustment Techniques Explained

Maintaining optimal performance of your mowing equipment involves understanding the nuances of height modifications and alignment. Proper adjustments not only enhance cutting efficiency but also promote even wear and prolong the lifespan of the machinery.

1. Height Settings: Adjusting the cutting height is crucial for achieving a well-manicured lawn. This can be accomplished by modifying the positioning of the cutting units, allowing for precise control over the grass length.

2. Leveling Mechanisms: Ensuring that the blades are level is vital for an even cut. This involves checking the height on both sides of the equipment and making necessary tweaks to maintain symmetry.

3. Tension Adjustments: The tension of the drive belts can affect the efficiency of the blades. Regular checks and adjustments help ensure optimal performance and reduce the risk of slippage.

4. Alignment Checks: Misalignment can lead to uneven cutting. Regularly inspecting the position of the blades and making necessary adjustments ensures a consistent cut across the entire width.

Incorporating these techniques into your maintenance routine will not only improve the quality of your lawn but also enhance the overall performance of your machinery.

Importance of Regular Inspections

Regular evaluations of your machinery are crucial for maintaining optimal performance and extending the lifespan of the equipment. Consistent checks help identify potential issues before they escalate, ensuring that your investment remains in top condition. By prioritizing inspections, users can prevent unexpected breakdowns and costly repairs, contributing to a more efficient operation overall.

Enhancing Safety

One of the primary benefits of routine assessments is the enhancement of safety. Machinery that is not regularly inspected can pose serious risks to operators and bystanders. Detecting wear and tear or malfunctioning components early on can prevent accidents and ensure a safer working environment.

Improving Efficiency

Frequent inspections not only safeguard against hazards but also improve overall efficiency. Well-maintained equipment runs more smoothly and consumes less energy, which can lead to significant cost savings. Addressing minor issues during inspections prevents them from becoming major problems that could disrupt productivity.

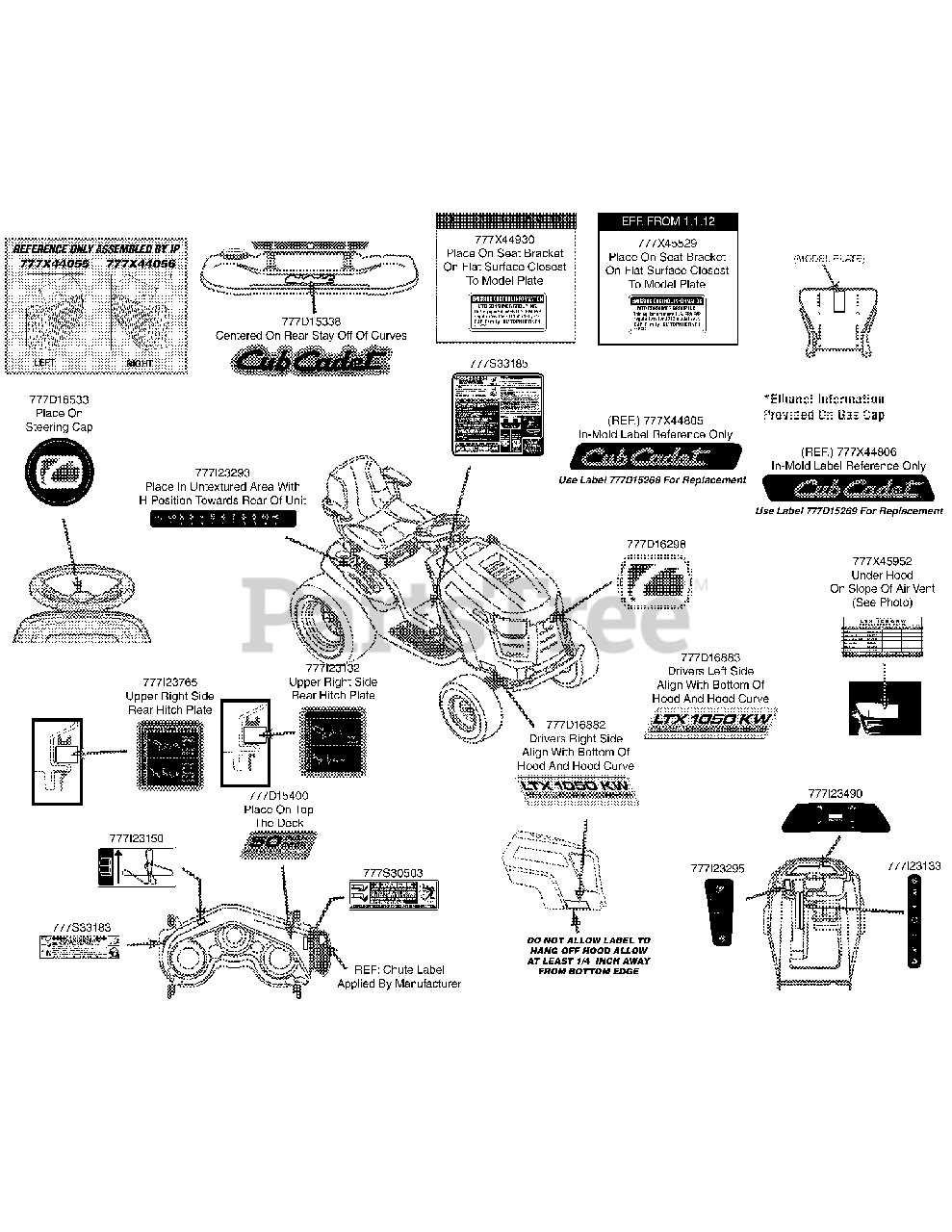

Resources for Parts and Repairs

When it comes to maintaining and restoring your outdoor machinery, having access to the right resources is essential. Whether you’re looking for components, tools, or repair guides, various avenues can help ensure your equipment runs smoothly. Understanding where to find these materials can save time and enhance the overall experience of upkeep.

Online Retailers offer a vast selection of components for various models. Websites dedicated to outdoor equipment often provide detailed catalogs, making it easier to locate specific items. Additionally, many platforms feature customer reviews, which can guide purchasing decisions and highlight the most reliable options.

Manufacturer Websites frequently host valuable resources, including manuals and exploded views of machinery. These documents are invaluable for understanding assembly and disassembly, as well as identifying necessary components. Utilizing these official resources can provide assurance regarding compatibility and quality.

Community Forums can be an excellent place to seek advice and share experiences with fellow enthusiasts. These platforms allow users to discuss common issues, share repair tips, and even recommend reliable suppliers for hard-to-find items. Engaging with a community can provide insights that are not readily available elsewhere.

Local Dealers and Repair Shops often maintain a stock of essential components and can offer expert advice on repairs. Establishing a relationship with a trusted local dealer can facilitate quick access to items and professional services, ensuring your machinery remains in top condition.

By exploring these resources, you can effectively maintain your equipment and tackle repairs with confidence, ensuring longevity and optimal performance.