Maintaining outdoor machinery requires a clear understanding of its essential elements. Without a grasp of how different mechanisms work together, ensuring efficient operation can become challenging. This guide focuses on exploring the critical mechanical aspects of a well-known lawn tool, breaking down the major sections involved in its function.

We will delve into the primary systems, highlighting their interactions and importance for smooth performance. Whether it’s the power source, the drive system, or cutting mechanisms, every section plays a vital role in ensuring the machine runs effectively and reliably.

Understanding the individual components and their relationships is key to troubleshooting and performing regular maintenance. This breakdown provides a closer look at these mechanical areas, helping you keep your equipment in top condition.

The functionality of any lawn equipment heavily depends on its individual components, which work together to ensure optimal performance. Understanding the key elements involved can help in both maintenance and efficient use. This section will explore the essential mechanisms and their roles in the overall operation.

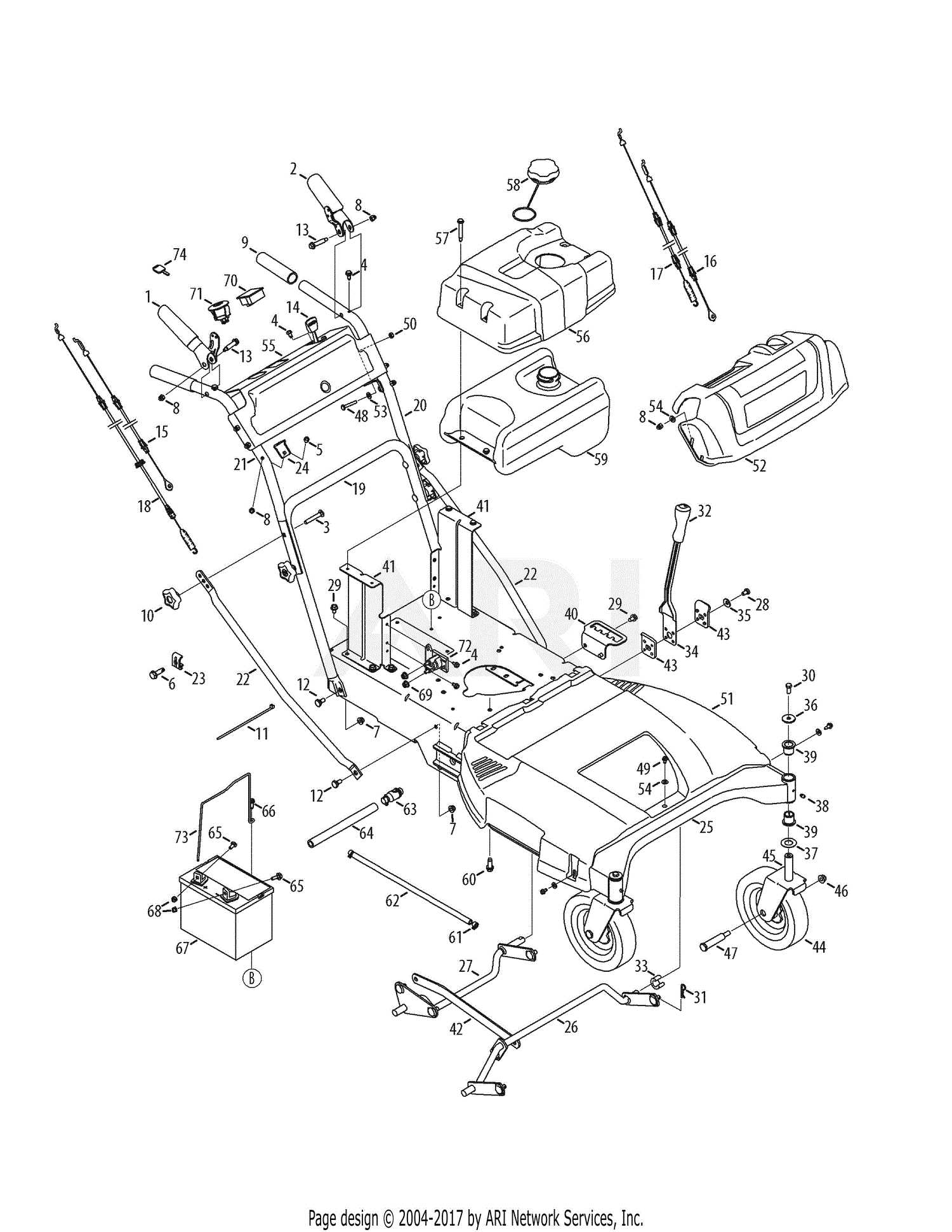

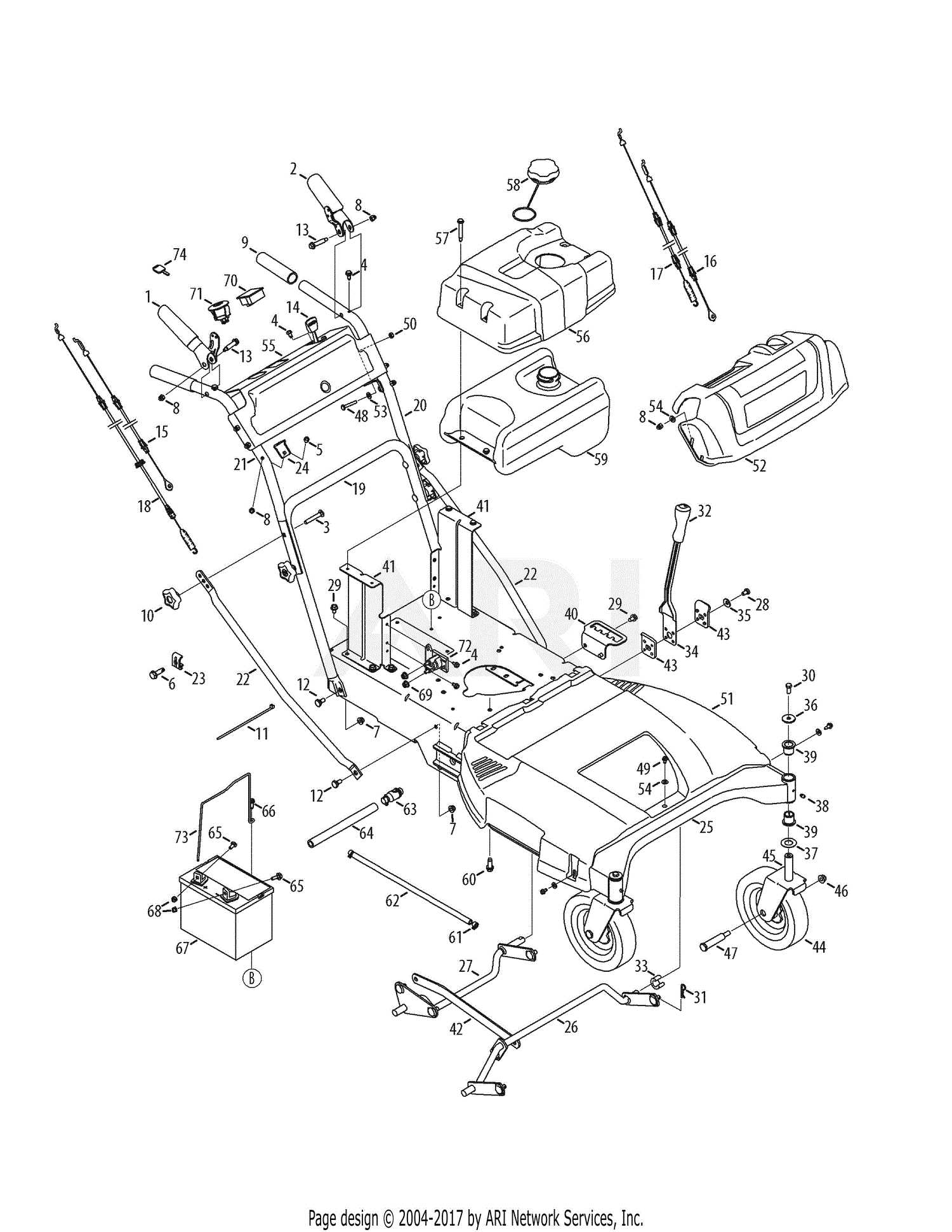

Main Operational Systems

- Drive mechanism ensuring smooth movement

- Blade system for effective cutting

- Handlebars for user control and steering

Supporting Structures and Add-ons

- Wheels and traction enhancers

- Height adjustment system for versatile cutting

- Protective housing and safety guards

Blades and Their Functions in Mowing

Mower blades play a crucial role in achieving a clean and precise cut during lawn care. Each type of blade has specific features that influence how grass is cut and distributed. Choosing the right blade ensures effective trimming and impacts the overall performance of the mowing process.

Types of Blades

There are different blade styles designed for specific mowing needs. Some are crafted for mulching, while others are better suited for bagging or discharging clippings. The shape, thickness, and cutting edges of each blade type are tailored to different outcomes.

Blade Functions

Beyond cutting, blades also assist in directing grass clippings. Mulching blades are designed to finely chop grass, returning nutrients to the soil. On the other hand, bagging blades efficiently channel clippings into a collection system.

| Blade Type |

Primary

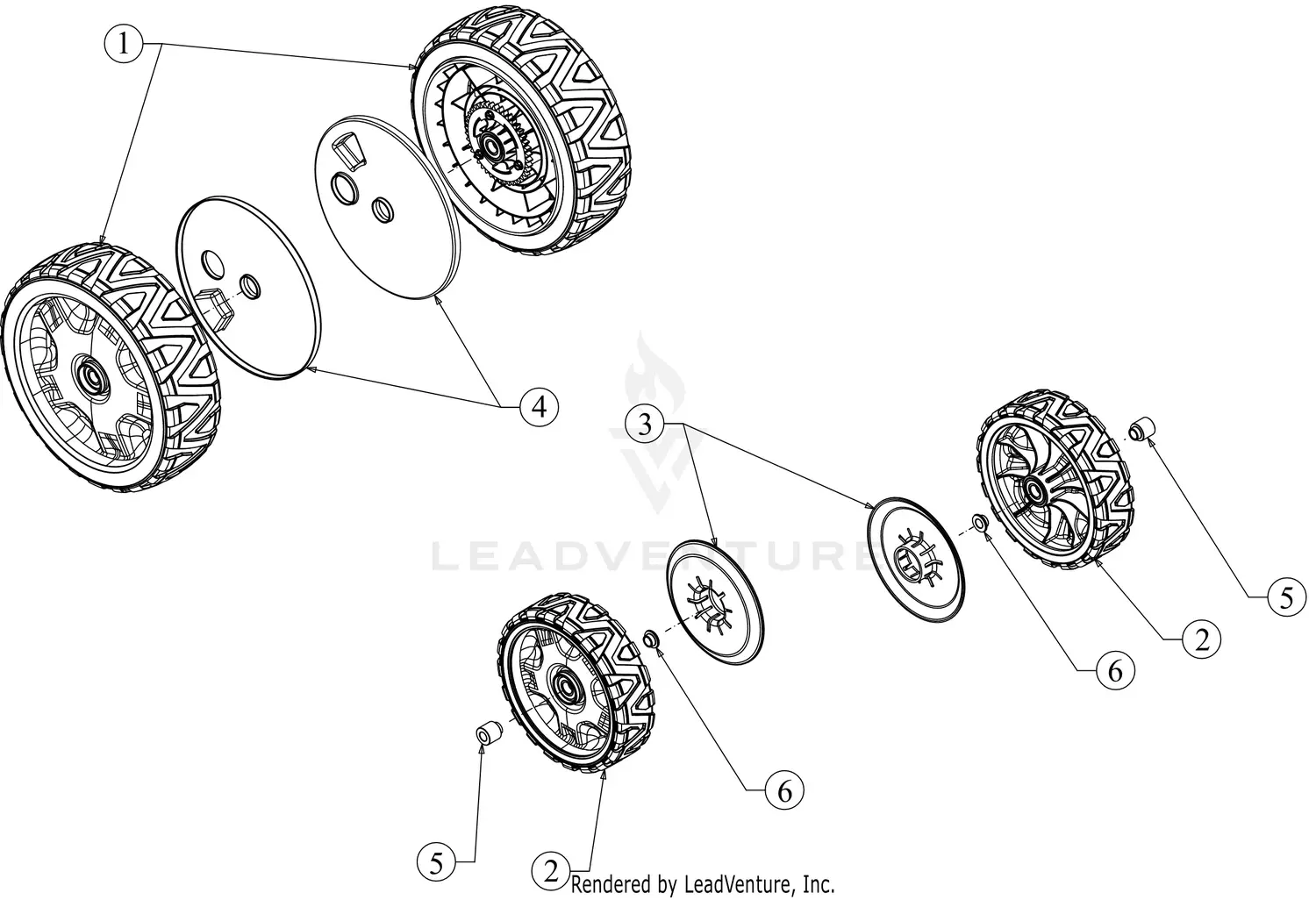

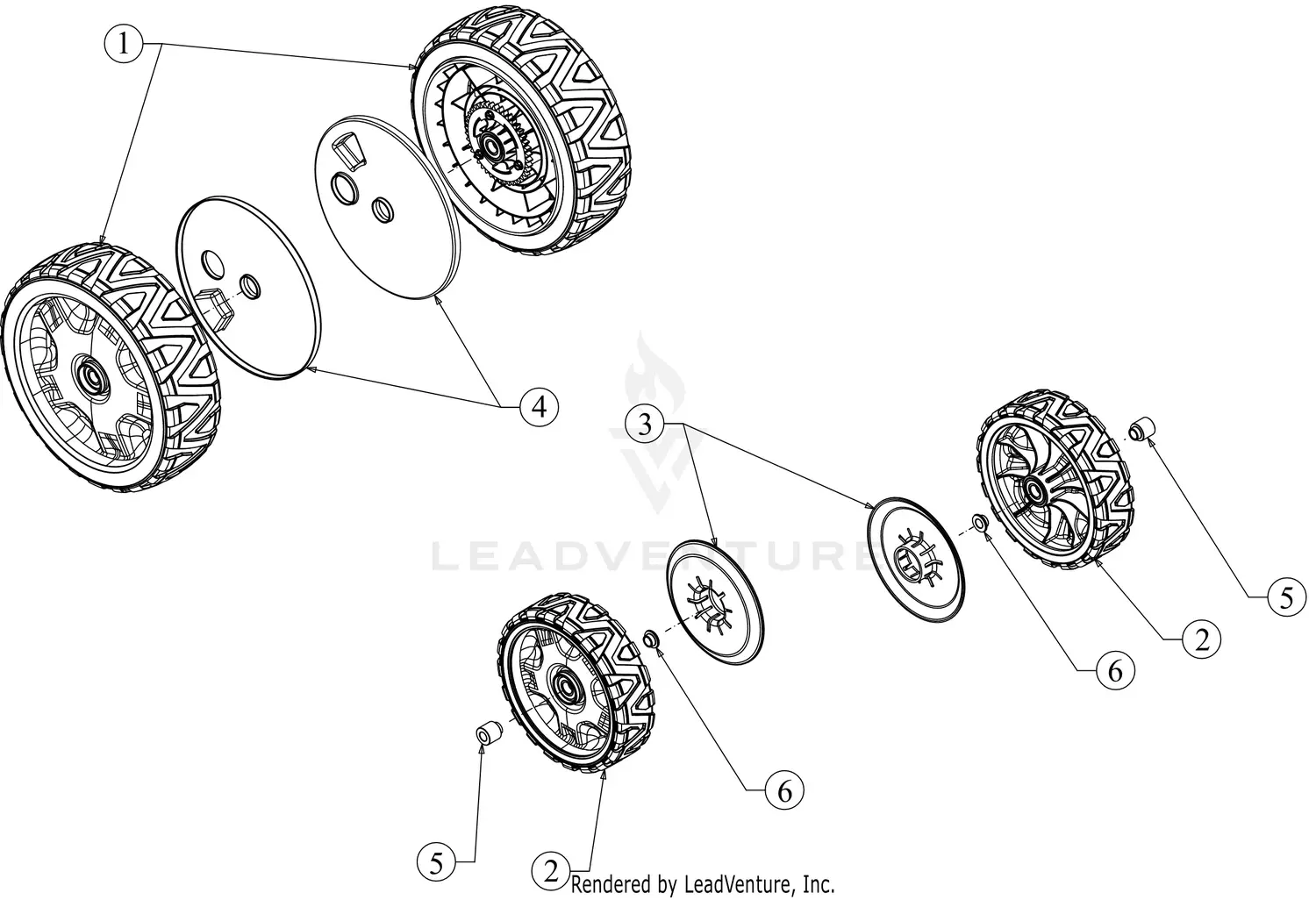

Wheels and Traction Mechanism Overview

The wheels and traction system play a critical role in ensuring smooth movement and control of the equipment on various terrains. This section provides an insight into how these components work together to deliver stability, efficient maneuvering, and consistent performance.

Wheel Structure and Materials

The wheels are designed to provide optimal grip and durability. They are typically constructed from high-quality materials that can withstand different environmental conditions, offering long-term resilience and functionality. The treads ensure enhanced traction, which helps in navigating uneven or slippery surfaces.

Traction System Functionality

The traction mechanism supports the wheels by distributing power efficiently. It ensures a balanced distribution of weight, which prevents skidding and slipping, particularly on slopes. This system works in harmony with the wheels to guarantee smooth and controlled operation, reducing the need for manual effort during use.

- Durable materials for extended life

- Enhanced grip through tread patterns

- Efficient power distribution to prevent slippage

Engine Parts and Maintenance Guide

The efficiency and longevity of any motor greatly depend on regular care and upkeep. Understanding the key components of an engine and following proper maintenance procedures ensures smooth operation and reduces the risk of unexpected issues. This guide provides an overview of essential areas to focus on for optimal performance.

Key Components to Inspect Regularly

- Air filter: Ensure it’s clean to maintain good airflow and avoid overheating.

- Spark plug: Check for wear and replace if necessary to ensure reliable ignition.

- Oil levels: Regularly monitor and replace oil to prevent engine friction and damage.

- Fuel system: Inspect for any blockages or leaks to maintain fuel efficiency.

Maintenance Tips

- Change the oil at recommended intervals to ensure smooth engine performance.

- Clean or replace the air filter to maintain optimal airflow and prevent debris from entering the system.

- Check the spark plug for corrosion and replace it as needed to ensure proper ignition.

- Regularly inspect the fuel system for leaks or blockages to prevent any disruptions in power.

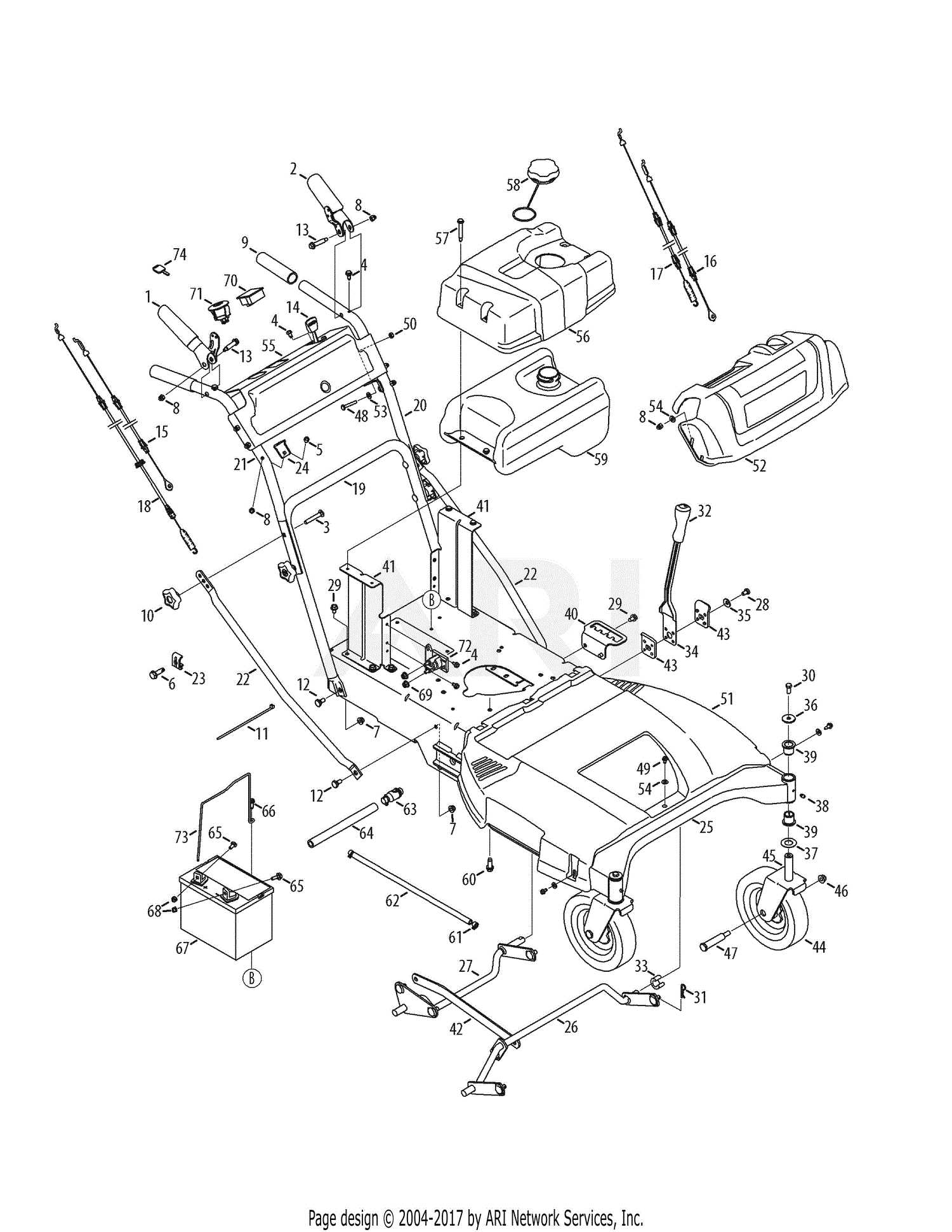

Handle Assembly and Adjustment Tips

Proper handle assembly and alignment are essential for ensuring comfortable operation and reducing fatigue during use. Following simple steps to adjust the handle height and angle will help enhance control and ease of movement, regardless of the user’s preferences.

Steps for Assembly

When assembling the handle, start by aligning the upper and lower sections. Secure the parts using the provided fasteners, ensuring they are tightened properly to prevent any loosening during operation. Pay close attention to the locking mechanisms, as these are crucial for the stability of the handle.

Adjustment Tips

For optimal comfort, adjust the handle to the preferred height by loosening the adjustment knobs and sliding the handle up or down. Make sure to lock the knobs securely once the desired height is achieved. Additionally, ensure the handle’s angle suits your stance to avoid unnecessary strain during extended use.

| Assembly Step |

Instruction |

| Step 1 |

Align the upper and lower handle sections. |

| Step 2 |

Secure with fasteners, ensuring they are tightly locked. |

| Step 3 |

Fuel System Breakdown and Efficiency

The efficiency of any engine significantly relies on its fuel delivery mechanism. Understanding the components involved in this system can lead to better performance and maintenance practices. A well-functioning fuel assembly ensures optimal combustion and can enhance the overall functionality of the machinery.

Key components of the fuel system include:

- Fuel Tank: Stores the fuel and feeds it to the engine.

- Fuel Pump: Delivers fuel from the tank to the engine at the required pressure.

- Fuel Filter: Removes impurities and contaminants from the fuel before it reaches the engine.

- Fuel Lines: Transport the fuel from the tank to the engine and back.

- Injectors or Carburetors: Mix the fuel with air in the correct ratio for combustion.

Efficiency can be influenced by several factors:

- Fuel Quality: Using high-quality fuel reduces deposits and improves combustion.

- Regular Maintenance: Cleaning or replacing filters and inspecting fuel lines can prevent blockages and leaks.

- Optimal Pressure: Ensuring that the fuel pump maintains the right pressure maximizes fuel delivery efficiency.

- System Integrity: Regular checks for leaks or wear can prevent fuel loss and ensure efficient operation.

In conclusion, a thorough understanding of the fuel assembly’s workings and maintaining its components can significantly enhance machinery efficiency and longevity.

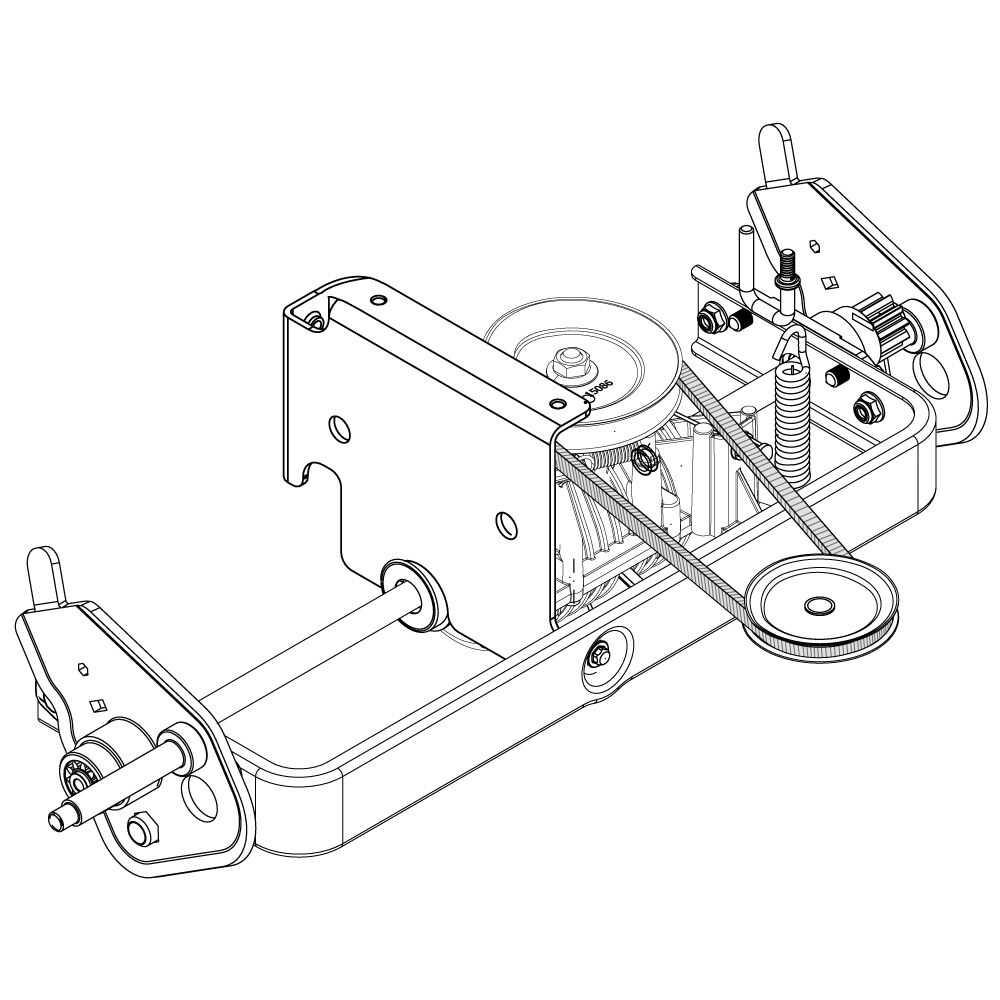

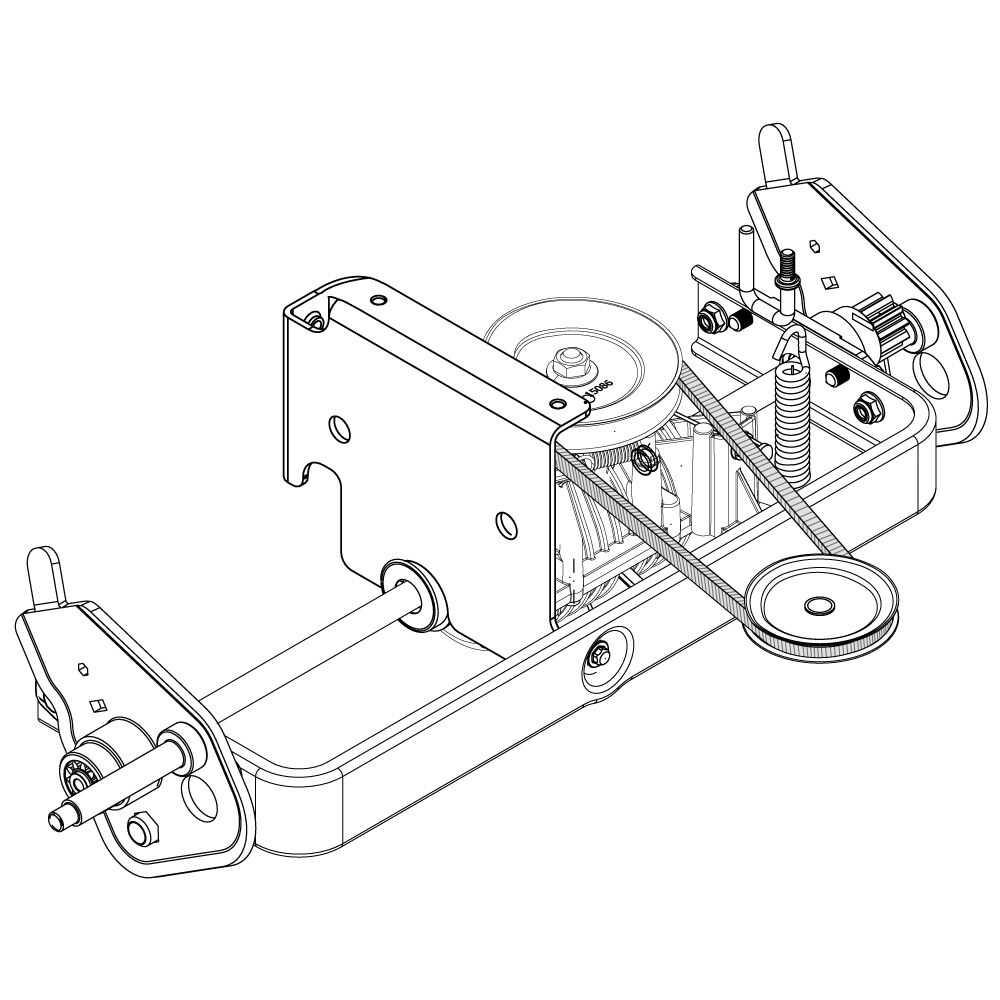

Drive Control System Explained

The drive control mechanism is a crucial component that governs the movement and maneuverability of various equipment. This system ensures that operators can efficiently manage speed and direction, enhancing overall functionality. Understanding its structure and operation is essential for optimal performance and maintenance.

Key elements of the drive control system include:

- Throttle Control: Regulates the engine’s power output, allowing for precise speed adjustments.

- Transmission: Transmits power from the engine to the wheels, enabling smooth transitions between different speeds.

- Steering Mechanism: Facilitates directional changes, providing stability and control during operation.

- Brake System: Ensures safe stopping and control, preventing unwanted movement.

Maintenance of the drive control system is vital for longevity and performance. Regular inspections and timely replacements of worn components can prevent failures and ensure efficient operation. Operators should familiarize themselves with the system’s workings to maximize effectiveness.

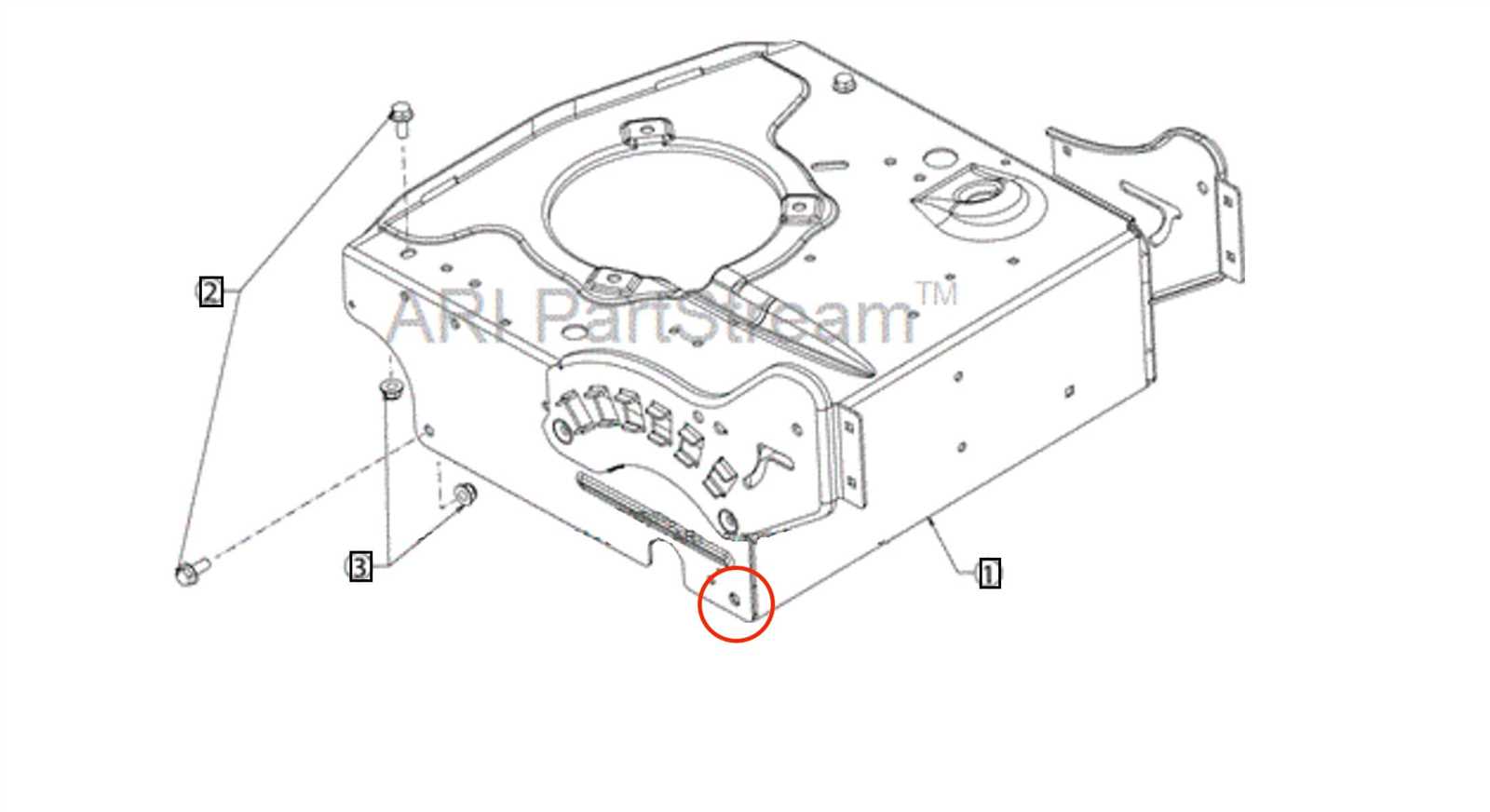

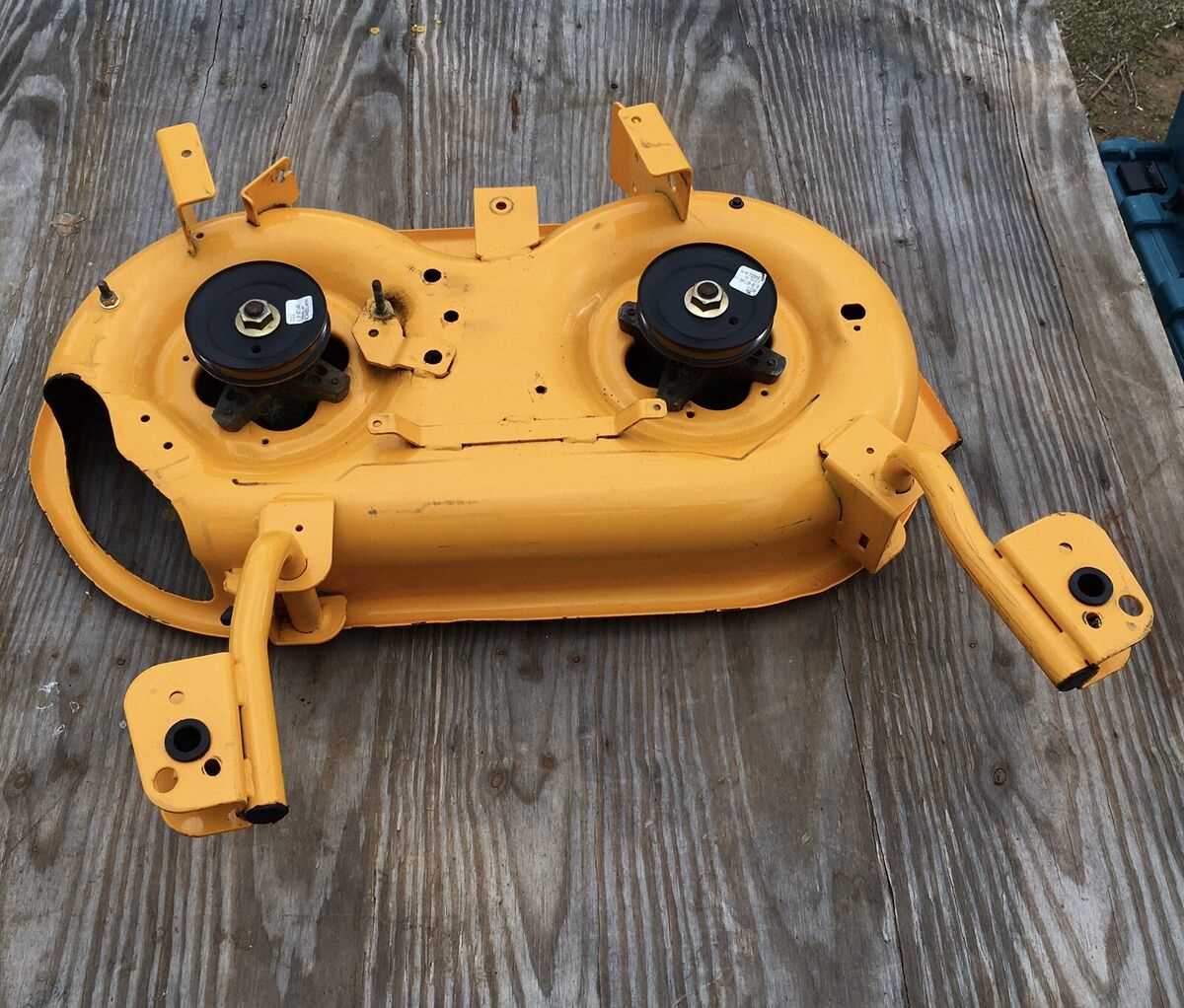

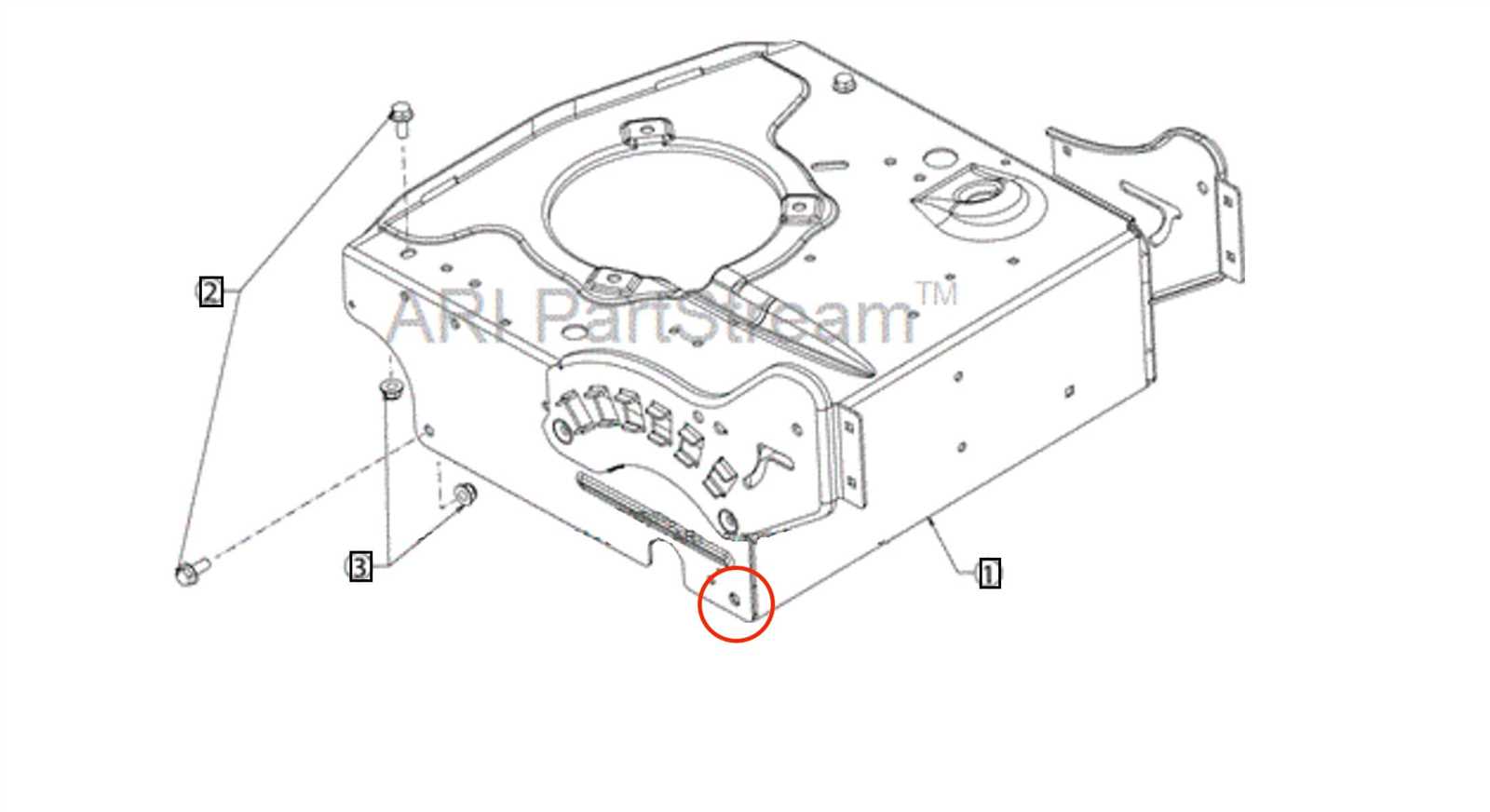

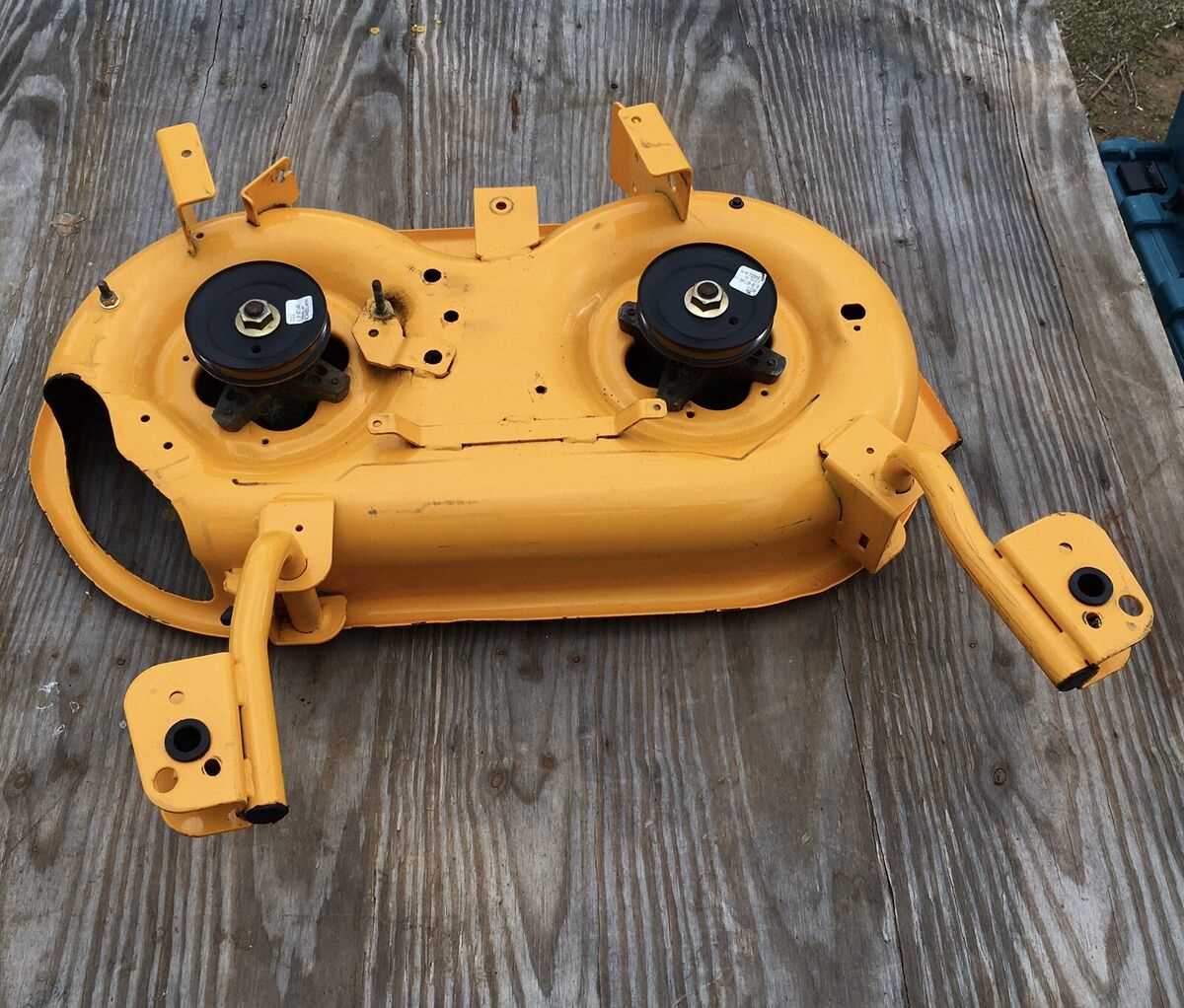

Deck Assembly and Cutting Height Options

This section focuses on the assembly of the mowing deck and the various options available for adjusting the cutting height. Proper assembly ensures optimal performance, while the right cutting height allows for a well-manicured lawn, adapting to different grass types and seasonal conditions.

Components of the Deck Assembly

The deck assembly consists of several crucial parts that work together to create an efficient mowing system. Key components include:

- Blades: Responsible for cutting the grass evenly.

- Spindles: These support and rotate the blades.

- Deck Shell: The main body that houses the blades and spindles.

- Height Adjustment Mechanism: Allows users to modify the cutting height.

- Support Wheels: Ensure stability and reduce scalping.

Adjusting Cutting Height

Adjusting the cutting height is essential for maintaining a healthy lawn. Different grass types thrive at various heights, so consider the following options:

- Low Setting: Ideal for finer grasses, providing a close cut.

- Medium Setting: Suitable for most grass varieties, ensuring balanced growth.

- High Setting: Recommended for taller grasses, promoting deeper roots and drought resistance.

By understanding the deck assembly and height adjustment options, users can achieve optimal mowing results and a beautiful landscape.

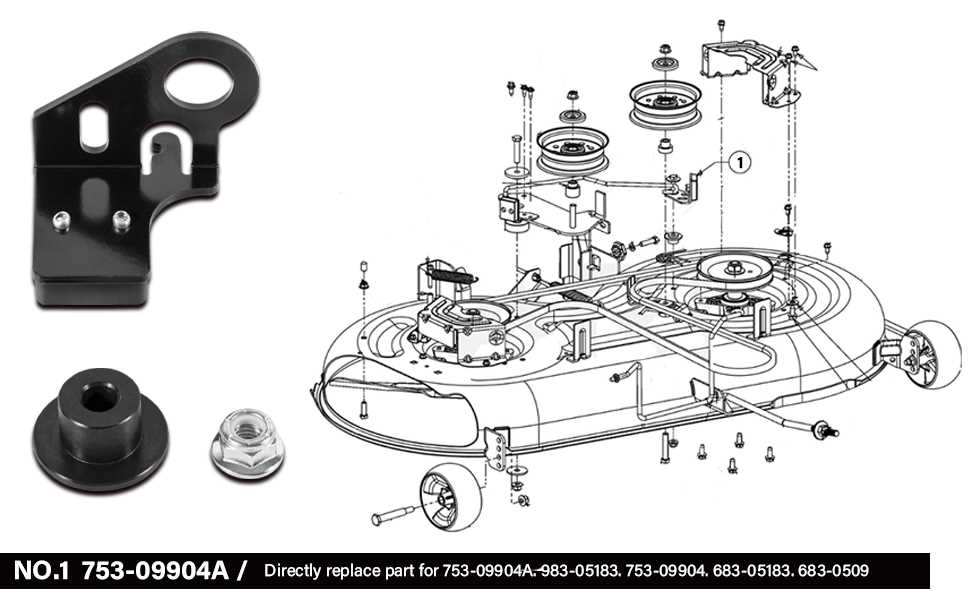

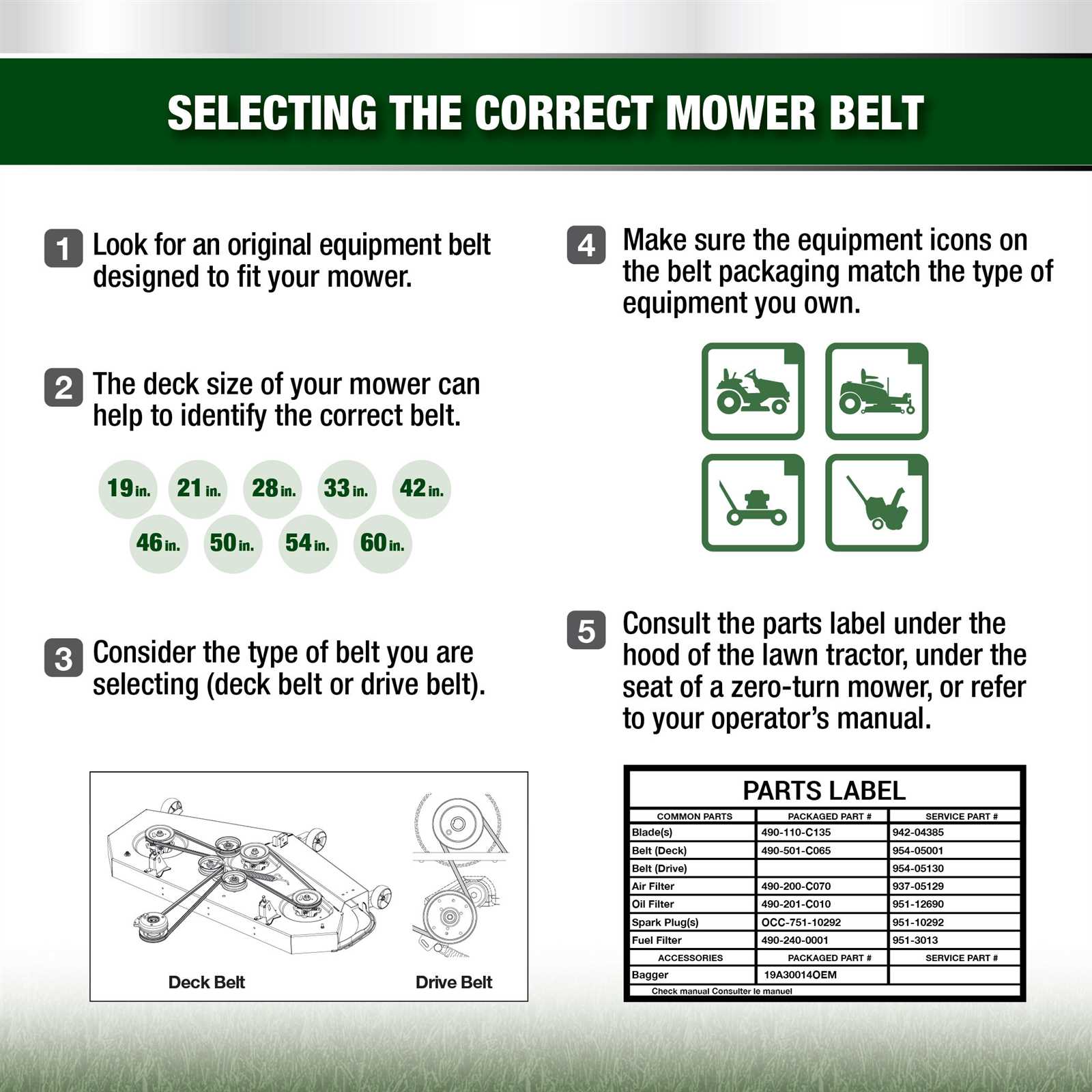

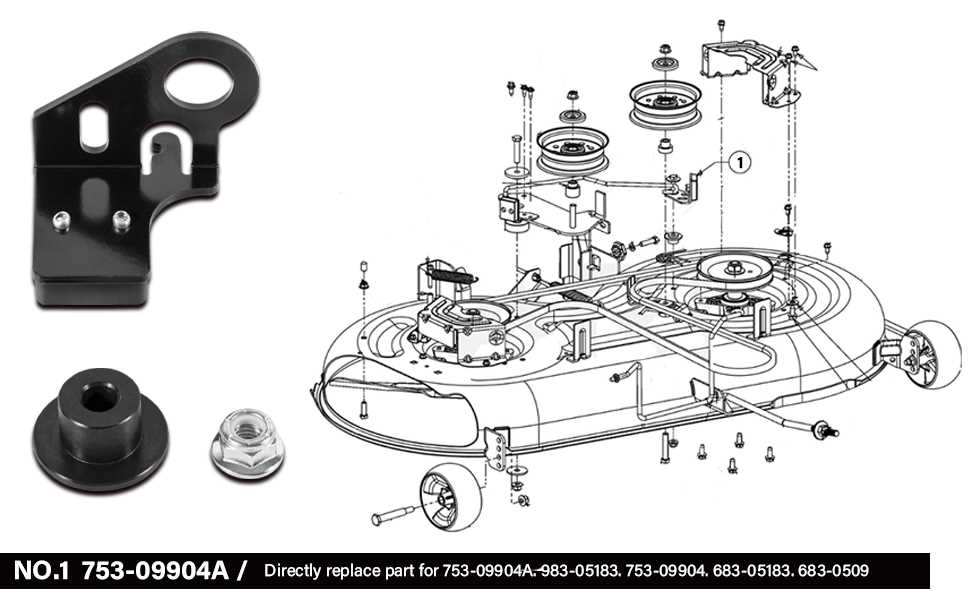

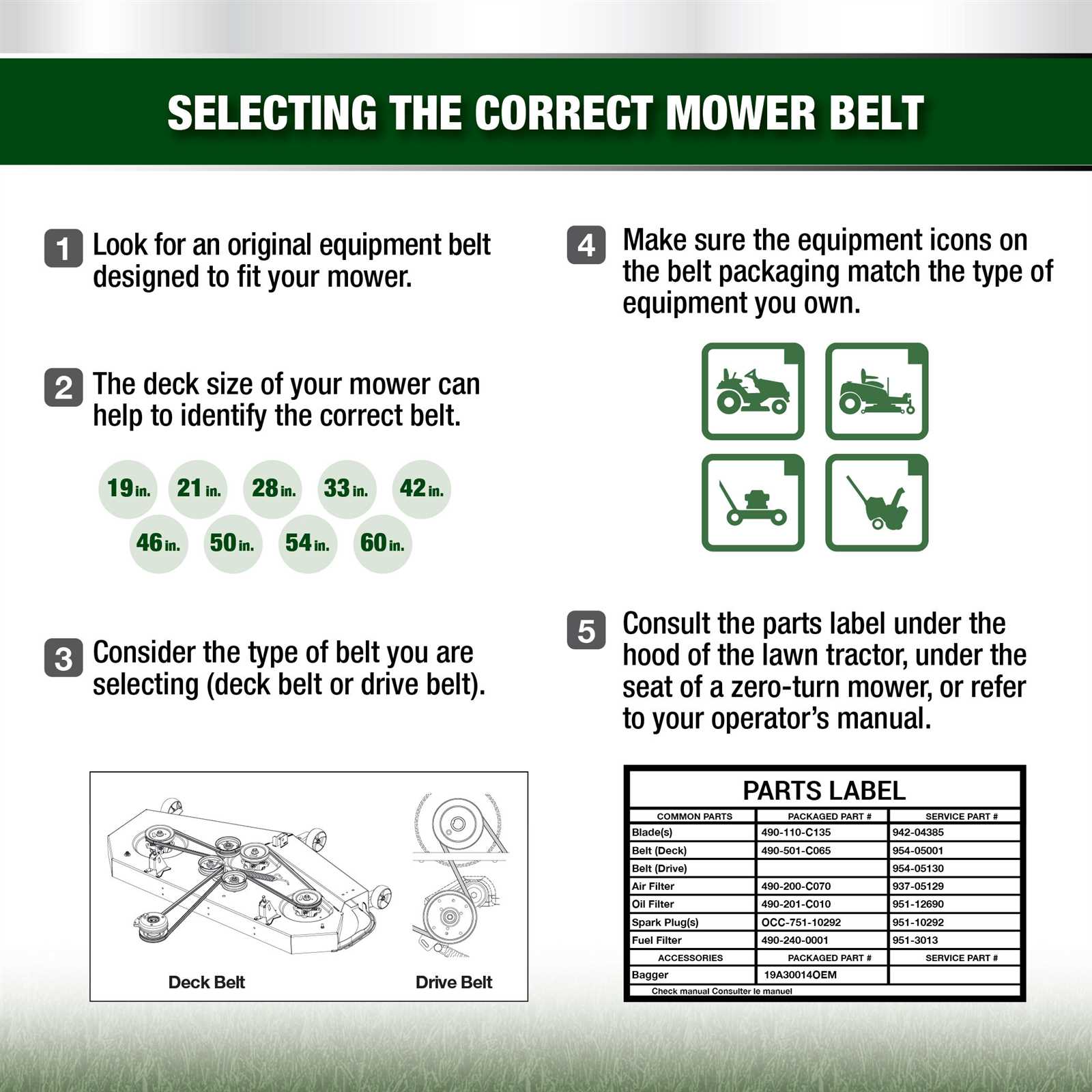

Replacing the Belt: Step-by-Step Instructions

Changing the drive belt is a crucial maintenance task that ensures optimal performance of your equipment. This process can be straightforward with the right approach and tools. Follow these detailed steps to replace the belt effectively.

Tools and Materials Needed

- New drive belt

- Screwdriver set

- Wrench set

- Pliers

- Safety gloves

- Owner’s manual (for reference)

Step-by-Step Replacement Process

- Ensure the equipment is powered off and disconnected from any power source.

- Remove the cover or housing to access the drive belt. This usually involves unscrewing several fasteners.

- Carefully inspect the existing belt for any signs of wear or damage before removing it.

- Release the tension on the old belt by adjusting the tensioner or removing any retaining clips.

- Take out the old belt from the pulleys and discard it appropriately.

- Position the new belt around the pulleys, ensuring it sits properly in the grooves.

- Reapply tension to the belt according to the manufacturer’s specifications, ensuring it is snug but not overly tight.

- Reattach the cover or housing securely, ensuring all screws and fasteners are tightened properly.

- Reconnect the power source and test the equipment to ensure it operates smoothly with the new belt.

|