In the realm of lawn maintenance, efficient operation relies heavily on the interaction of various elements within the cutting mechanism. This intricate assembly is designed to optimize grass handling and enhance the overall mowing experience. Knowledge of how each component functions and fits together is essential for ensuring optimal performance and longevity of the equipment.

Exploring the intricate workings of these elements allows users to better comprehend their roles in maintaining a pristine lawn. Each section plays a crucial role in achieving effective cutting and collection, ensuring that grass is not only trimmed but also managed in a manner that promotes healthy growth. Understanding this complex system is vital for both routine maintenance and troubleshooting potential issues that may arise during operation.

By familiarizing oneself with the various segments and their configurations, operators can make informed decisions about upkeep and repairs. A comprehensive grasp of how these elements collaborate can lead to more efficient practices and ultimately a more beautiful landscape. Investing time in this knowledge not only enhances the user experience but also prolongs the life of the equipment.

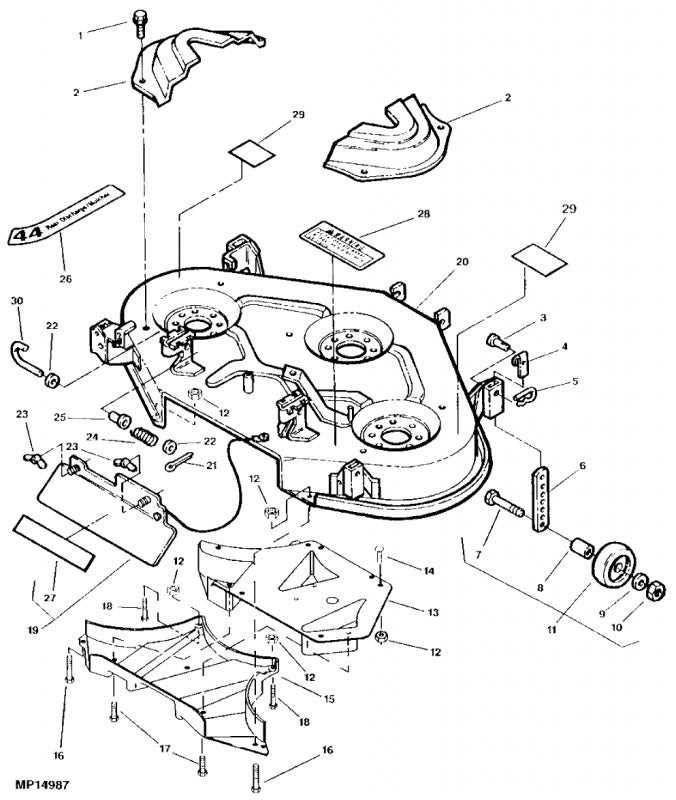

Piranha 44 Mulching Deck Overview

The innovative cutting platform is designed to enhance the efficiency of lawn maintenance by effectively processing grass clippings. This system not only provides a clean and precise cut but also promotes healthy growth by returning nutrients to the soil. Understanding its structure and functionality is essential for users seeking optimal performance and longevity.

Key Features

One of the standout attributes of this model is its exceptional cutting ability, which ensures uniform results across various grass types. Additionally, the robust construction offers durability, allowing for consistent use in different conditions. The intuitive design also facilitates easy maintenance, ensuring users can keep the equipment in peak condition with minimal effort.

Benefits of Efficient Cutting Systems

Employing advanced cutting mechanisms leads to superior results in lawn care. Not only does it save time during mowing, but it also reduces the need for additional lawn treatments. By recycling clippings, the system supports environmental sustainability while enhancing the overall aesthetics of outdoor spaces.

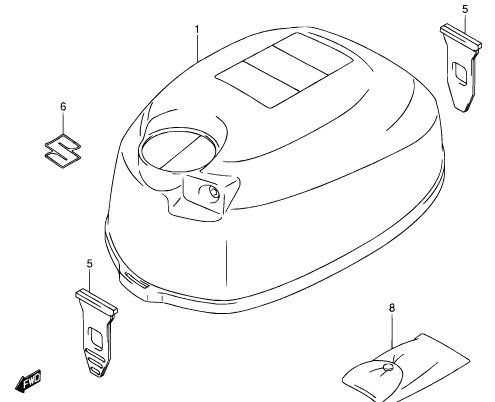

Key Components of Mulching Deck

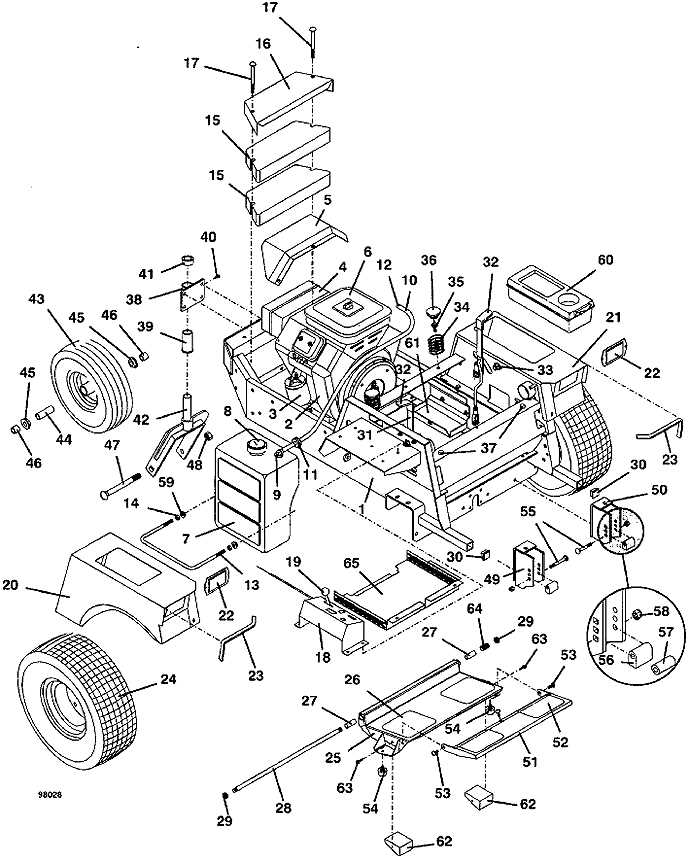

Understanding the essential elements of a cutting assembly is crucial for optimal performance and maintenance. Each component plays a significant role in ensuring effective grass management, enhancing the overall functionality of the machinery. This section will delve into the main features that contribute to the efficiency and longevity of the assembly.

1. Blades: These are the primary instruments responsible for cutting the grass. Their sharpness and design directly impact the quality of the cut and the ability to finely chop the clippings for better decomposition.

2. Housing: The outer shell encasing the cutting elements. Its design aids in the airflow, helping to distribute the clippings evenly while also providing protection to the internal components.

3. Chassis: This structural framework supports the entire assembly. A robust chassis ensures stability and minimizes vibrations during operation, contributing to a smoother mowing experience.

4. Discharge Ports: These openings facilitate the exit of clippings. Proper placement and size are crucial for efficient material dispersion, preventing clogging and ensuring optimal cutting performance.

5. Drive Mechanism: This component is responsible for transferring power from the engine to the cutting elements. A reliable drive system ensures consistent performance and can significantly affect the efficiency of the operation.

By understanding these critical elements, operators can better appreciate their roles and perform necessary maintenance, ensuring a longer lifespan and improved functionality of the equipment.

Understanding Deck Assembly Process

The assembly of a cutting unit is a crucial step in ensuring efficient and effective lawn maintenance. This process involves a series of components working together harmoniously to deliver optimal performance. Understanding how these elements fit together can greatly enhance the functionality and longevity of the equipment.

Components Involved in the Assembly

Each assembly consists of various elements, including the frame, blades, and drive mechanisms. The frame provides structural support, while the blades are responsible for the actual cutting action. Proper alignment and secure attachment of these components are essential to achieving a balanced and efficient operation.

Assembly Techniques and Best Practices

Utilizing the right techniques during assembly can significantly affect performance. It is important to follow manufacturer guidelines and use appropriate tools to ensure all components are tightened to the specified torque. Regular inspections after assembly can help identify any wear or misalignment that may occur during operation.

Maintenance Tips for Optimal Performance

Ensuring the highest level of efficiency and longevity for your equipment requires regular upkeep and attention to detail. Consistent maintenance practices not only enhance the functionality but also prevent potential issues that can disrupt operations. By adhering to a few simple guidelines, you can achieve peak performance and extend the lifespan of your machinery.

Regular Cleaning

Cleaning is essential for maintaining efficiency. Remove any debris, dirt, or buildup that may accumulate over time. This practice helps to prevent blockages and ensures that all components operate smoothly. Pay particular attention to areas where materials can gather, as they can hinder performance.

Inspection and Lubrication

Conducting routine inspections is vital to identify wear and tear. Examine belts, blades, and other moving parts for signs of damage. Additionally, proper lubrication of mechanical components is crucial to reduce friction and wear, contributing to smoother operation and preventing costly repairs.

Common Issues and Solutions

Maintaining lawn care equipment can lead to various challenges that may hinder performance and efficiency. Understanding the typical problems that arise during usage and their potential solutions is crucial for ensuring optimal operation and longevity of the machinery.

1. Uneven Cutting

One frequent concern is achieving an uneven cut, which can result in a patchy lawn. This issue may arise from improper height adjustments or worn-out blades. To resolve this, regularly check the cutting height and adjust it according to the manufacturer’s recommendations. Additionally, inspect the blades for damage or dullness, replacing them if necessary.

2. Clogging

Clogging can impede the flow of grass clippings, leading to inefficient operation. This often occurs when the grass is too tall or wet. To mitigate this issue, mow only when the grass is dry and avoid cutting excessively long grass. Regular cleaning of the equipment after each use can also prevent buildup and maintain optimal performance.

Parts Replacement Guide

This section provides essential information on how to effectively replace components of your lawn care equipment. Understanding the process of swapping out worn or damaged elements is crucial for maintaining optimal performance and extending the lifespan of your machinery. Regular maintenance not only enhances functionality but also ensures safety during operation.

Identifying Components for Replacement

Before commencing any replacement task, it is vital to correctly identify the specific elements that require attention. Regular inspections can help detect wear and tear early, allowing for timely replacements. Make a list of the identified components, and consult your user manual for recommendations on suitable replacements.

Step-by-Step Replacement Process

Once you have gathered the necessary tools and replacement items, follow these steps for efficient execution:

- Safety First: Ensure the machine is powered down and disconnected from any power sources.

- Remove the Old Component: Carefully detach the worn item, taking note of how it was installed.

- Install the New Item: Align and secure the new element in place, ensuring it fits properly.

- Test the Equipment: Reconnect any power sources and conduct a thorough test to ensure functionality.

By adhering to this guide, you can maintain your lawn care equipment in peak condition, ensuring reliability and performance for years to come.

Importance of Proper Deck Alignment

Maintaining accurate positioning of cutting equipment is crucial for optimal performance and longevity. When the components are correctly aligned, it ensures even cutting and enhances the overall efficiency of the machinery.

Improper alignment can lead to various issues, such as uneven wear, increased fuel consumption, and compromised cutting quality. Furthermore, misalignment may cause additional strain on the engine and other mechanical parts, leading to premature failures and costly repairs.

Regular inspections and adjustments are necessary to achieve the best results. By taking the time to ensure everything is properly positioned, operators can maximize the effectiveness of their equipment while minimizing downtime and maintenance costs. Ultimately, investing in alignment is an investment in the performance and reliability of your machinery.

Comparative Analysis of Mulching Decks

This section provides an overview of various types of cutting assemblies designed for efficient grass management. The focus will be on evaluating different features, advantages, and drawbacks of these systems, enabling users to make informed decisions based on their specific requirements.

When considering different cutting mechanisms, several factors come into play. These include design efficiency, ease of maintenance, compatibility with various mowing equipment, and the quality of the finish produced. Below is a comparison table highlighting key attributes of different assemblies.

| Feature | Type A | Type B | Type C |

|---|---|---|---|

| Cutting Width | 30 inches | 36 inches | 48 inches |

| Material | Steel | Aluminum | Composite |

| Weight | 150 lbs | 120 lbs | 100 lbs |

| Durability | High | Medium | Low |

| Maintenance Level | Moderate | High | Low |

| Performance in Thick Grass | Excellent | Good | Average |

Understanding these distinctions can greatly enhance the mowing experience, allowing for optimal performance and desired results in lawn care. Choosing the right assembly can lead to more efficient grass management and a healthier lawn.

Resources for Further Information

For those seeking to deepen their understanding of specific components and mechanisms related to lawn care equipment, various resources are available. These materials can provide valuable insights, maintenance tips, and operational guidance. Below are some recommended references that can aid in further exploration of the subject matter.

| Resource Type | Description | Link |

|---|---|---|

| Manufacturer Manuals | Comprehensive guides that detail the operation and maintenance of equipment. | View Manuals |

| Online Forums | A community of enthusiasts sharing experiences and solutions regarding various models. | Join Forums |

| Video Tutorials | Step-by-step visual guides demonstrating assembly, repair, and usage techniques. | Watch Tutorials |

| Parts Suppliers | Websites offering a wide selection of components necessary for repairs and upgrades. | Find Parts |

| Technical Support | Professional assistance for troubleshooting and maintenance inquiries. | Contact Support |