When it comes to maintaining a lush and vibrant yard, having a thorough understanding of the essential equipment is crucial. This section aims to explore the intricate elements that contribute to optimal performance in grass management machinery. By familiarizing oneself with these components, users can enhance their operational efficiency and prolong the lifespan of their tools.

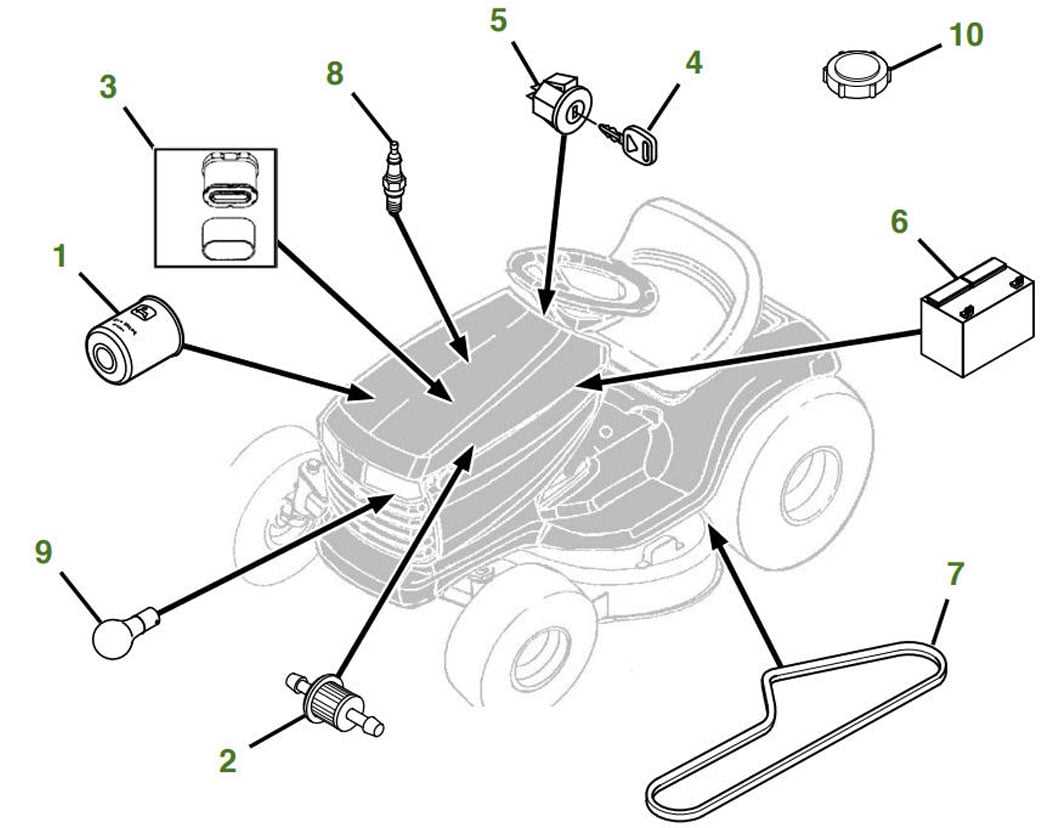

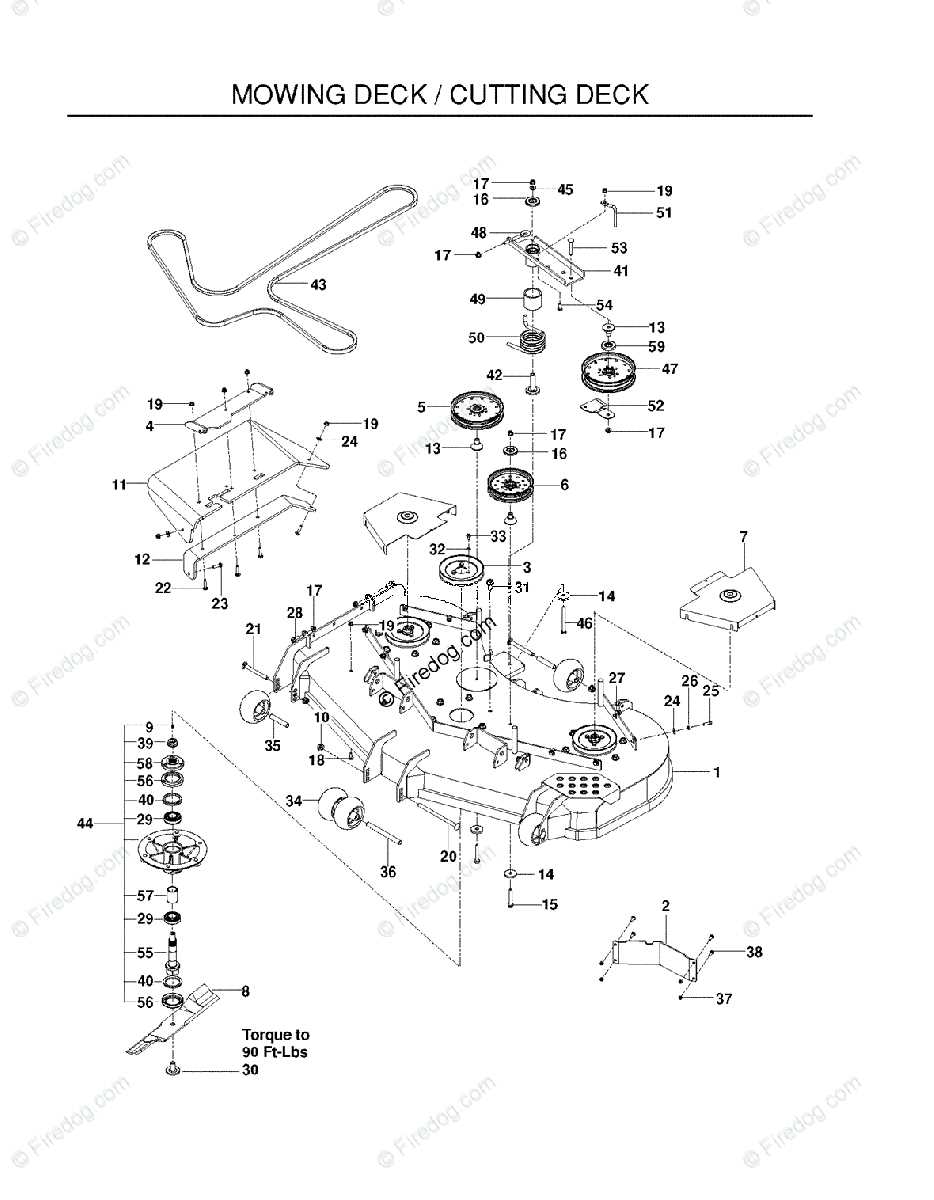

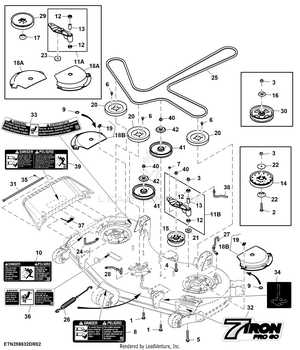

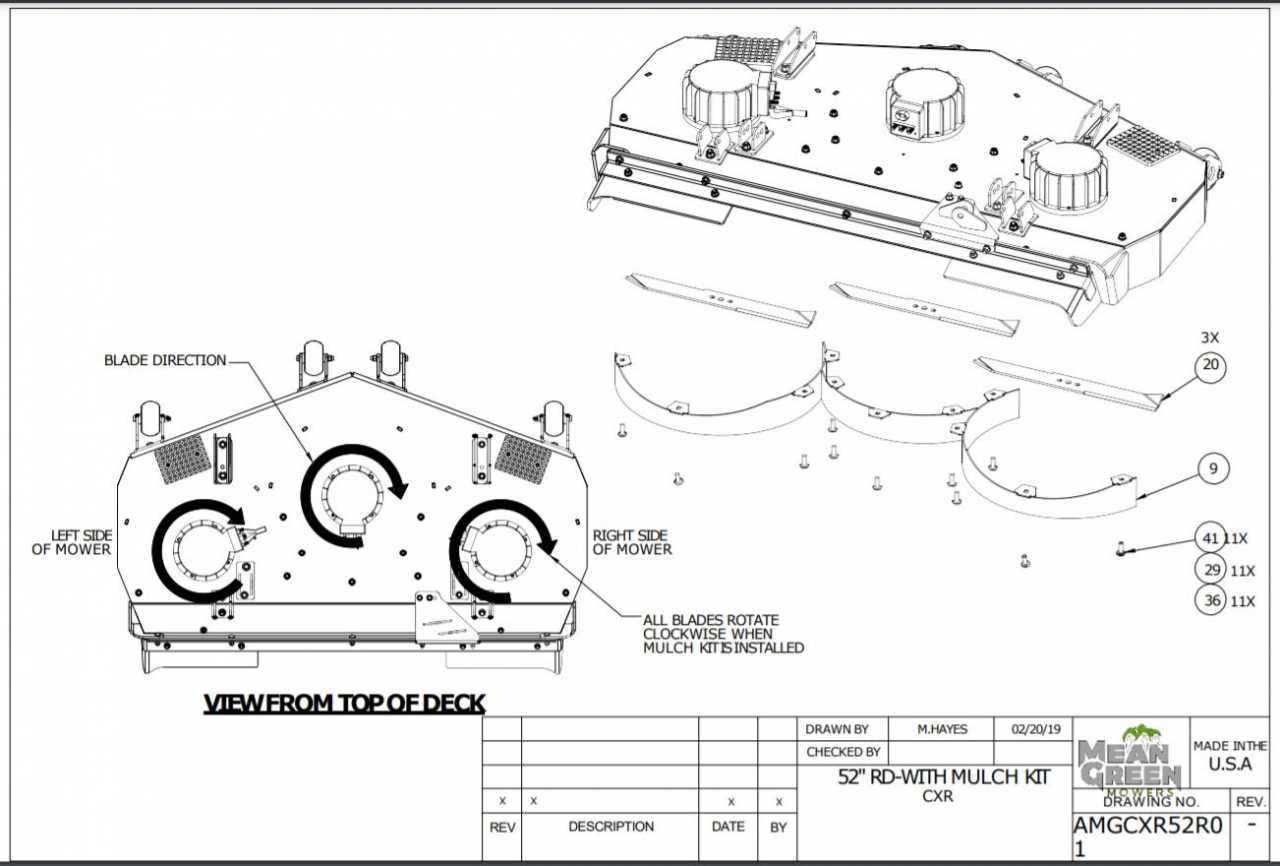

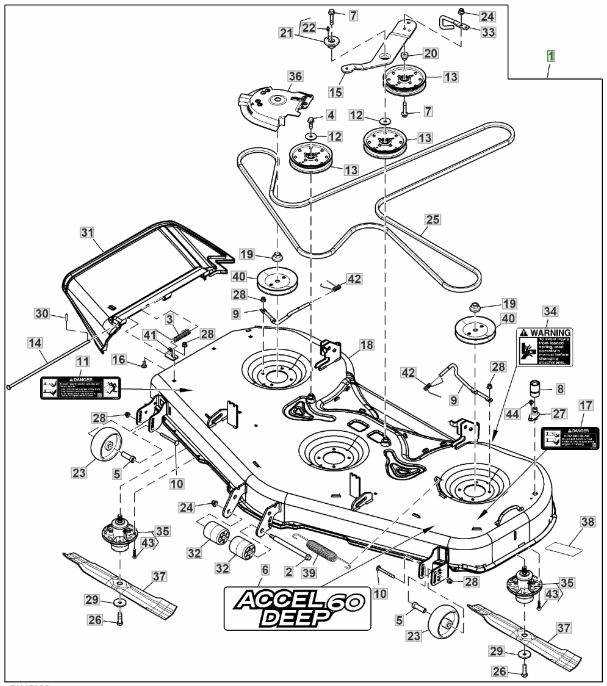

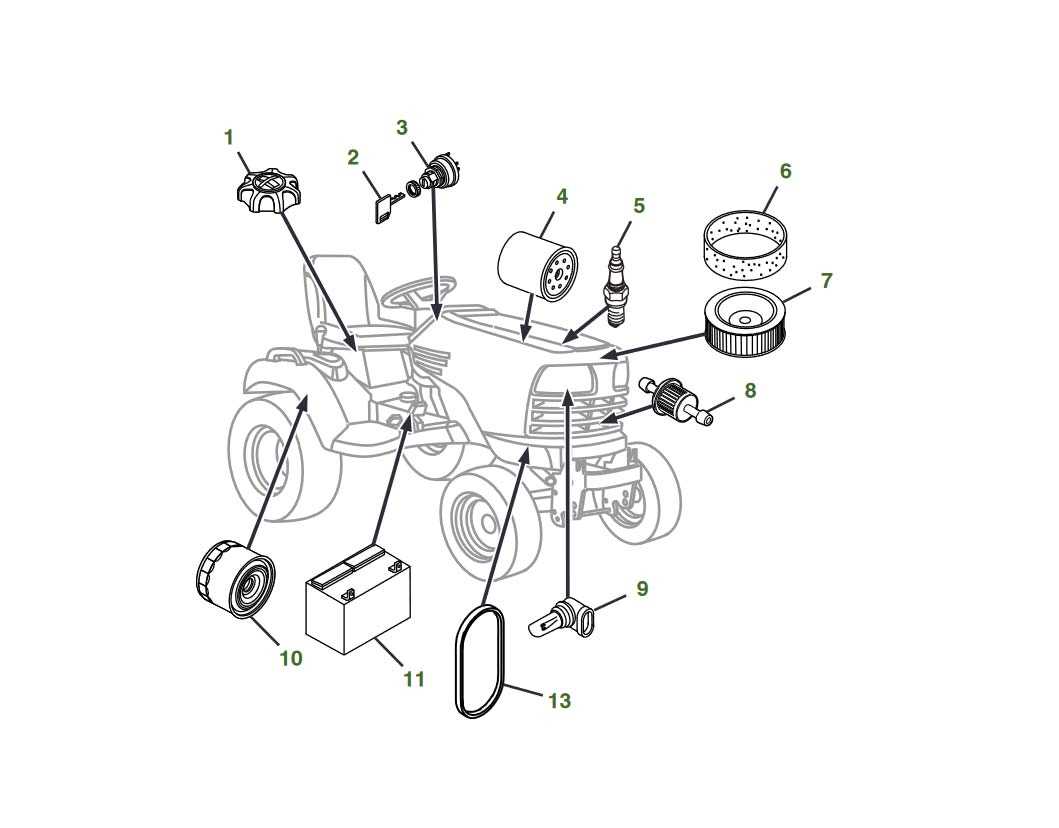

Visual representations serve as valuable resources for both novices and seasoned operators. They provide clarity on the relationships between different elements and facilitate easier troubleshooting and repairs. In this exploration, we will delve into the specifics of various attachments, ensuring you have the ultimate guidance for your maintenance needs.

Equipping yourself with knowledge about these crucial segments not only aids in effective handling but also empowers you to make informed decisions regarding upgrades and replacements. Join us as we dissect the key features that make up this vital machinery, paving the way for a healthier landscape.

John Deere 60 Mower Deck Parts: Understanding the Basics

Understanding the components of a specific machine is crucial for effective maintenance and operation. Each element plays a significant role in ensuring optimal performance and longevity. Familiarity with these elements can greatly assist users in troubleshooting and performing necessary repairs.

The essential elements of this equipment include various functional components that contribute to its overall efficiency. Knowing the names and functions of these parts enables users to better manage maintenance tasks and identify potential issues before they become significant problems.

| Component Name | Function |

|---|---|

| Blade | Cuts grass and maintains desired height. |

| Spindle | Supports and rotates the blade. |

| Belt | Transmits power from the engine to the spindle. |

| Housing | Encloses the cutting mechanism for safety and protection. |

| Idler Pulley | Adjusts tension on the belt to ensure proper operation. |

By grasping the basic functions of these components, operators can enhance their understanding and maintenance practices, leading to improved efficiency and reliability.

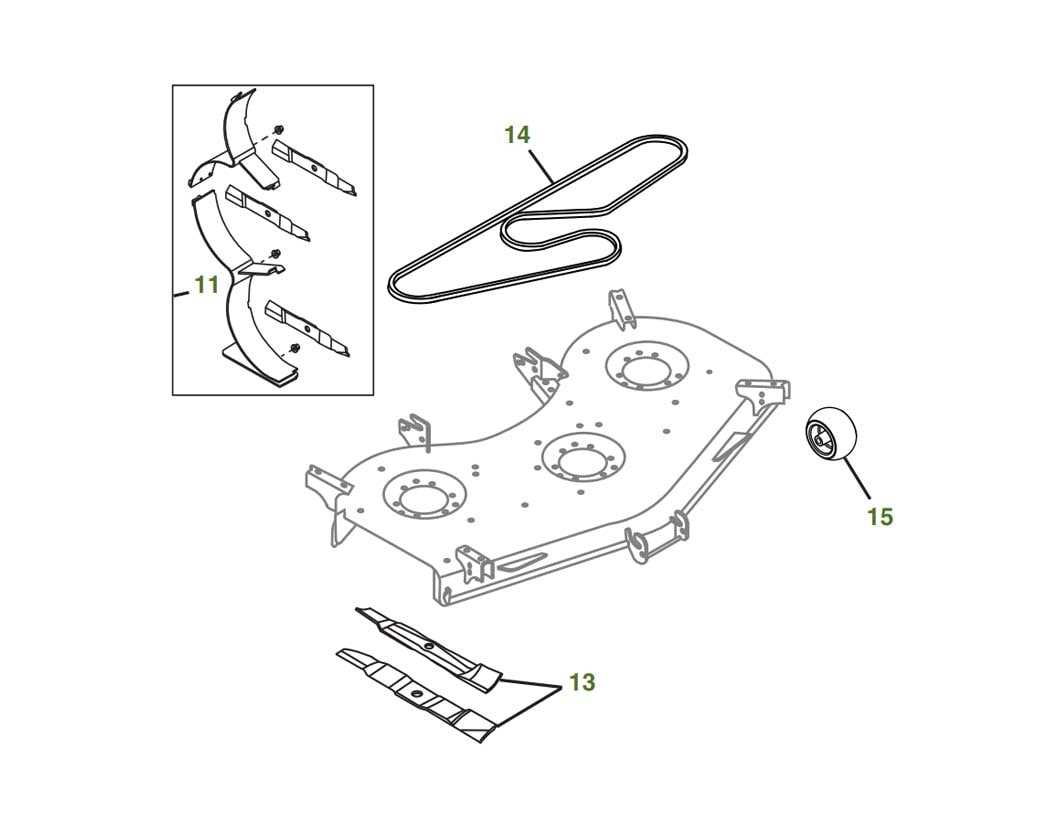

Exploring the Components of the John Deere 60 Mower Deck

Understanding the intricate elements of a cutting apparatus can significantly enhance its functionality and longevity. This exploration delves into the various components that contribute to the overall performance of the machine, ensuring efficient operation and maintenance.

Key Elements and Their Functions

Each segment of the cutting system plays a crucial role in delivering optimal results. Blades are engineered for precision, ensuring a clean cut, while the housing provides necessary protection and support. Additionally, drive mechanisms facilitate smooth operation, allowing for seamless maneuverability across various terrains.

Maintenance and Care Considerations

Regular inspection and timely replacement of worn components are vital for maintaining performance. Lubrication of moving parts reduces friction, thereby prolonging the life of the equipment. Understanding these aspects not only aids in efficient usage but also fosters a deeper appreciation for the engineering behind the cutting tool.

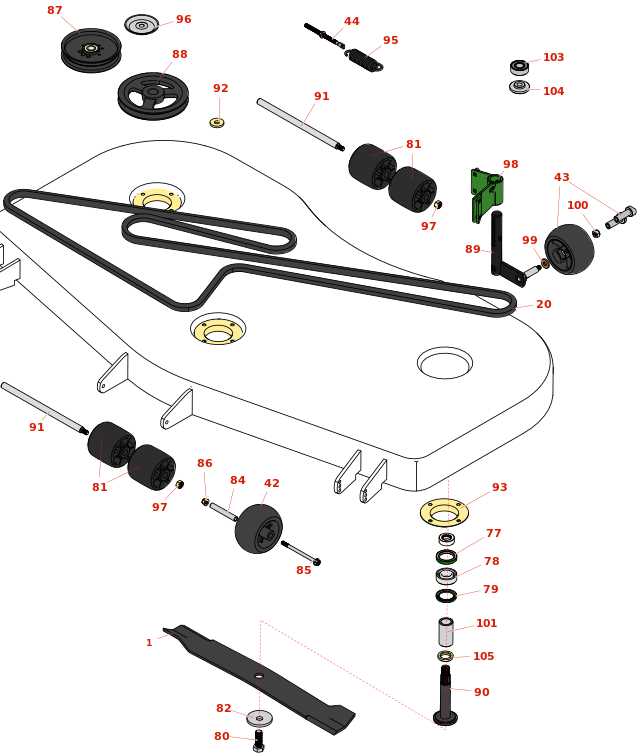

Identifying Key Parts in the John Deere 60 Mower Deck Diagram

Understanding the essential components of a cutting assembly is crucial for maintenance and repair. Recognizing each element allows for efficient troubleshooting and ensures optimal performance. Familiarity with these components enhances the user experience and prolongs the life of the equipment.

Main Components Overview

At the core of any cutting unit are several key elements that work in harmony. The cutter blades are pivotal, providing the primary function of cutting grass. Additionally, the spindle assembly is vital for supporting and rotating the blades effectively. Furthermore, the housing encapsulates these parts, providing protection and stability during operation.

Understanding Connections and Adjustments

Each component is interconnected, necessitating a proper understanding of how adjustments impact overall functionality. The drive belt connects the engine to the spindle, transferring power efficiently. Regular inspection of the adjustment mechanisms ensures that the height and angle of the cut remain precise, catering to varying lawn conditions.

An In-Depth Look at Essential Components

Understanding the vital elements of lawn care machinery can significantly enhance its performance and longevity. Each component plays a crucial role in ensuring optimal functionality, contributing to the overall efficiency of the equipment. By exploring these key features, users can better appreciate how they work together to achieve desirable outcomes.

Key Functional Elements

Among the most critical elements are the cutting blades, which are designed to deliver precision and uniformity. Their sharpness and durability affect not only the quality of the cut but also the energy efficiency of the entire system. Regular maintenance of these components is essential to ensure they operate at peak efficiency.

Supportive Mechanisms

Another important aspect includes the supporting structures that enhance stability and control during operation. These mechanisms ensure that the machine can navigate various terrains without compromising performance. Understanding their function can lead to better management practices and improved results in lawn maintenance.

How to Use a John Deere 60 Mower Deck Parts Diagram Effectively

Understanding the components of your cutting equipment is crucial for maintaining its performance and longevity. Utilizing a visual representation of these components can streamline the repair process, making it easier to identify and source the necessary elements for maintenance. This guide will help you navigate the visual reference effectively, ensuring you get the most out of your equipment.

Identifying Key Components

Start by familiarizing yourself with the various sections depicted in the visual guide. Each segment typically highlights specific parts and their functions. Pay attention to labels and numbers that correspond to each item, as this will help you quickly locate what you need when troubleshooting or performing repairs.

Sourcing Replacement Items

Once you have a clear understanding of the components, use the information to find replacements. Refer to the provided references for part numbers, which can be invaluable when searching for specific items online or at a local supplier. Knowing the exact names and numbers will facilitate a smoother purchasing process and ensure compatibility with your equipment.

Tips and Tricks for Efficient Navigation

In exploring the intricate layout illustration, mastering effective strategies can significantly enhance your user experience. Understanding key features and utilizing smart techniques will empower you to swiftly locate essential components without unnecessary complexity.

Utilize Visual Cues

Visual cues such as line thickness, color differentiations, and shading variations are invaluable aids. They highlight distinct parts and connections, guiding your focus to critical areas swiftly and accurately. By leveraging these visual markers, you can streamline your navigation through the intricate design effortlessly.

Employ Systematic Approach

Employing a systematic approach ensures thorough coverage of the diagram. Begin with identifying major sections, then progressively zoom in on finer details. This methodical strategy helps maintain clarity and prevents overlooking crucial elements amidst the complexity of the illustration.

Common Maintenance Tasks for John Deere 60 Mower Deck Parts

Regular upkeep is essential for ensuring the longevity and efficiency of your equipment. Implementing consistent maintenance tasks can prevent issues and enhance performance over time.

- Check and replace blades regularly to ensure a clean cut.

- Inspect belts for wear and tension; replace if necessary.

- Clean the underside to prevent grass build-up and corrosion.

- Lubricate moving components to reduce friction and wear.

- Examine wheel bearings and replace any that are damaged.

By adhering to these practices, you can enhance the functionality and durability of your equipment, ultimately leading to better results in your lawn care endeavors.

Ensuring Longevity and Performance

Maintaining optimal functionality and durability of outdoor machinery is crucial for achieving the best results in lawn care and landscaping. Proper upkeep not only enhances efficiency but also extends the lifespan of the equipment. Understanding the essential components and their roles can significantly impact overall performance.

Regular Inspections: Frequent checks for wear and tear can help identify potential issues before they escalate. Look for signs of damage or deterioration in crucial elements, ensuring everything operates smoothly.

Proper Lubrication: Keeping moving parts well-lubricated minimizes friction and prevents overheating. Use high-quality oils and greases specifically designed for the equipment to achieve the best results.

Timely Replacements: Components that show signs of significant wear should be replaced promptly. Using original or high-quality replacement parts ensures compatibility and reliability, which are vital for maintaining performance.

Cleanliness: Regular cleaning of the machinery is essential to prevent buildup that can affect functionality. Debris and grass clippings can obstruct moving parts, leading to inefficiencies and potential damage.

By following these guidelines, users can ensure their equipment remains in peak condition, ultimately resulting in enhanced performance and longevity.

Replacing Parts: Step-by-Step Guide for the John Deere 60 Mower Deck

Maintaining the functionality of your equipment is crucial for optimal performance. This section provides a comprehensive guide to assist you in the replacement process, ensuring your machinery operates smoothly and efficiently.

Before starting the replacement, gather the necessary tools and components. Here’s a list to help you prepare:

- Wrenches and sockets

- Screwdrivers (flathead and Phillips)

- Replacement components

- Safety gloves and goggles

- Grease or lubricant

Follow these steps to successfully replace the required components:

- Safety First: Disconnect the power source to avoid any accidental starts.

- Access the Area: Remove any coverings or shields that obstruct access to the components you intend to replace.

- Inspect and Identify: Examine the parts for wear and damage to ensure you replace only what is necessary.

- Remove Old Components: Use the appropriate tools to detach the damaged items carefully.

- Install New Components: Position the new items accurately and secure them tightly.

- Reassemble: Replace any coverings or shields removed earlier.

- Final Check: Inspect your work to confirm everything is in place and secure before reconnecting the power.

By following these steps, you can effectively ensure your equipment remains in excellent condition, enhancing its longevity and performance.

Practical Advice on DIY Replacement

Embarking on a do-it-yourself replacement project can be rewarding and cost-effective. With the right preparation and knowledge, you can tackle repairs and maintenance with confidence, ensuring your equipment runs smoothly and efficiently.

Preparation Steps

- Gather Tools: Ensure you have all necessary tools on hand, such as wrenches, sockets, and screwdrivers.

- Read the Manual: Familiarize yourself with the specifications and instructions provided by the manufacturer.

- Safety First: Always wear protective gear to avoid injuries during the replacement process.

Replacement Process

- Identify the Issue: Determine which components need replacement by inspecting for wear or damage.

- Remove Old Components: Carefully detach the faulty elements, taking note of how they are assembled.

- Install New Components: Position the new parts correctly and secure them as per the manual’s guidelines.

- Test Functionality: After installation, run a test to ensure everything operates as intended.

By following these practical tips, you can successfully carry out replacements and maintain your equipment in optimal condition. Regular upkeep not only extends the life of your machinery but also enhances its performance.