When it comes to maintaining your outdoor machinery, having a clear understanding of its elements is crucial. Familiarizing yourself with the various components of your lawn care tools can significantly enhance their performance and longevity. This knowledge not only aids in troubleshooting issues but also streamlines the maintenance process, ensuring your equipment operates smoothly.

Visual representations of these components provide an invaluable resource for both new and seasoned users. By exploring these detailed layouts, one can easily identify specific parts and their functions, enabling informed decision-making during repairs and replacements. This understanding leads to greater efficiency and satisfaction with your lawn care practices.

Whether you’re a hobbyist or a professional, comprehending the intricacies of your machinery’s setup will empower you to tackle any challenges that arise. Investing time in learning about these elements will yield dividends in the form of reliable performance and reduced downtime.

This section provides a comprehensive look at the key characteristics and technical details of the lawn care equipment model in question. Understanding these specifications is crucial for effective maintenance, operation, and performance optimization.

Key Features

- Engine Type: Powerful gas engine designed for efficient operation.

- Cutting Width: Wide deck for enhanced cutting performance.

- Transmission: Smooth operation through a reliable gear system.

- Fuel Capacity: Ample tank for extended usage without frequent refueling.

- Weight: Optimized weight for stability and maneuverability.

Dimensions and Capacities

- Overall Length: Specific measurement ensuring compatibility with storage spaces.

- Overall Width: Sufficient to handle larger mowing tasks efficiently.

- Height: Designed for ease of handling and operation.

- Turning Radius: Allows for sharp turns in tight spaces, enhancing agility.

Common Components of the LA100

The model in question consists of various essential elements that work together to ensure optimal performance and functionality. Each component plays a crucial role in maintaining the efficiency and reliability of the machine, contributing to its overall effectiveness in diverse tasks.

Key Features and Functionality

Among the vital elements are the engine, transmission, and deck, each designed to perform specific tasks efficiently. Understanding these features helps users maximize their experience and ensure proper maintenance for longevity.

Maintenance and Care

Regular upkeep of the components is necessary to prevent wear and tear. Users should familiarize themselves with the maintenance routines associated with each part to promote durability and enhance the machine’s performance.

| Component | Function |

|---|---|

| Engine | Powers the unit for various tasks |

| Transmission | Transmits power to the wheels |

| Deck | Facilitates cutting and mowing operations |

| Wheels | Provides mobility and stability |

| Controls | Allows user interaction for operation |

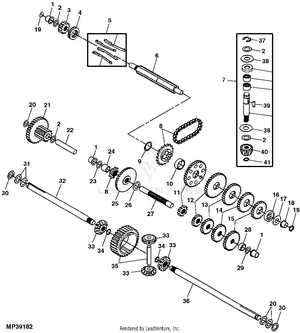

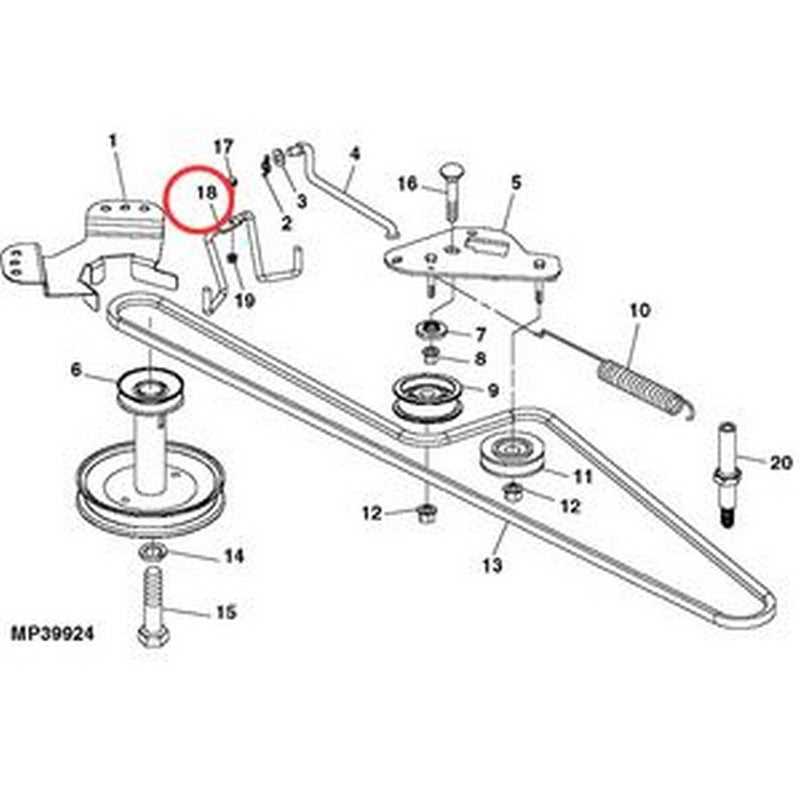

Benefits of Using Parts Diagrams

Utilizing visual representations of components offers numerous advantages for both enthusiasts and professionals. These illustrations serve as a valuable tool for understanding the intricate relationships between various elements within a system, making maintenance and repair tasks significantly easier.

Enhanced Understanding of Assembly

Visual aids facilitate a clearer comprehension of how different components fit together. This clarity allows users to identify the correct sequence of assembly, reducing the likelihood of errors during reassembly.

Improved Maintenance Efficiency

Having a detailed visual reference streamlines the process of locating specific components, enabling quicker and more efficient maintenance. This can lead to reduced downtime and increased productivity, ultimately saving time and resources.

How to Read the Parts Diagram

Understanding the visual representation of components is essential for effective maintenance and repairs. This guide will help you interpret the layout and identify various elements within the illustration, ensuring that you can easily locate the necessary items for your equipment.

Key Elements to Identify

- Labels: Look for annotations that indicate specific components. These often include numbers or letters corresponding to a reference list.

- Groupings: Components are usually organized into sections based on functionality, making it easier to find related parts.

- Connections: Pay attention to lines or arrows that show how different elements interact or connect to each other.

Utilizing the Reference Guide

- Locate the reference key, which provides details about each numbered or lettered component in the illustration.

- Match the labels in the visual representation with those in the reference guide to identify the parts you need.

- Cross-check the identified components with your maintenance or repair requirements to ensure compatibility.

Replacing Parts on the LA100

Maintaining and updating various components of your equipment is essential for ensuring optimal performance and longevity. Whether you are addressing wear and tear or upgrading features, understanding the process of component replacement can enhance the overall efficiency of your machine.

Before initiating the replacement process, it’s crucial to gather all necessary tools and materials. This will streamline the workflow and minimize downtime.

| Component | Common Issues | Replacement Steps |

|---|---|---|

| Blade | Worn edges, uneven cuts | 1. Lift the machine. 2. Remove the old blade. 3. Install the new blade securely. |

| Battery | Short lifespan, slow starts | 1. Disconnect the old battery. 2. Position the new battery. 3. Connect terminals properly. |

| Tires | Flat spots, cracks | 1. Lift the equipment. 2. Remove damaged tires. 3. Mount new tires and secure. |

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring that your equipment operates at its best. By following a few simple guidelines, you can extend the lifespan of your machine while maximizing its efficiency. Proper maintenance not only enhances performance but also reduces the risk of costly repairs in the long run.

Routine Checks

Performing consistent inspections is crucial. Examine the components for any signs of wear or damage. Pay attention to moving parts and connections, ensuring everything is properly lubricated and functioning smoothly. Scheduled maintenance should include checking fluids, filters, and belts.

Cleaning and Storage

Keep your equipment clean to prevent dirt and debris from accumulating. Regularly wash the exterior and clear any obstructions from vents and air filters. Proper storage during off-seasons can prevent rust and other deterioration, further maintaining functionality.

Where to Purchase Replacement Parts

Finding suitable components for your machinery is crucial for maintaining its performance and longevity. Several options are available for sourcing these essential items, ensuring you can keep your equipment running smoothly.

Online Retailers: Numerous online platforms offer a wide selection of components, often at competitive prices. Websites dedicated to outdoor equipment typically provide detailed descriptions and images, making it easier to identify the right items for your needs. Make sure to check customer reviews and ratings to ensure a reliable purchasing experience.

Local Dealers: Visiting local dealerships can be beneficial, as they often have knowledgeable staff who can assist in selecting the correct components. Additionally, purchasing from nearby stores can expedite the process, allowing for quicker repairs without waiting for shipping.

Aftermarket Suppliers: Many companies specialize in aftermarket components, providing alternatives that can sometimes offer better performance or pricing. Researching reputable suppliers is essential, as quality can vary significantly among manufacturers.

Used Parts Market: For those on a budget, exploring used components through classified ads or online marketplaces can be a cost-effective solution. While this option may require more effort to ensure quality, it can yield significant savings.

Frequently Asked Questions about the LA100

This section addresses common inquiries regarding the maintenance and functionality of a specific lawn care model. It aims to provide clear and concise information to assist users in their experience and ensure proper usage.

Common Issues and Solutions

- Starting Problems: If the equipment fails to start, check the battery charge and connections.

- Cutting Performance: Dull blades can affect cutting quality; regular sharpening is essential.

- Fuel Efficiency: Ensure the fuel used is fresh and suitable for optimal performance.

Maintenance Recommendations

- Regularly inspect the oil level and change it as needed.

- Keep the air filter clean to ensure proper airflow.

- Check tire pressure frequently for balanced handling.