In any high-performance cleaning tool, each element plays a significant role in ensuring optimal functionality. Whether you’re dealing with mechanical assemblies or hydraulic systems, a clear understanding of how the various elements work together is essential for maintenance and repair. Properly identifying these elements not only improves efficiency but also extends the longevity of the equipment.

When working with such equipment, it’s important to become familiar with its inner workings, from the smallest valves to the largest connections. By recognizing each component and its purpose, you’ll be better equipped to troubleshoot common issues and perform necessary adjustments or replacements.

This guide offers a comprehensive look at the key elements found in a versatile cleaning device, breaking down the core structure and individual parts for a clearer perspective on how everything functions together. Familiarity with these elements will empower you to keep the system running smoothly and effectively for years to come.

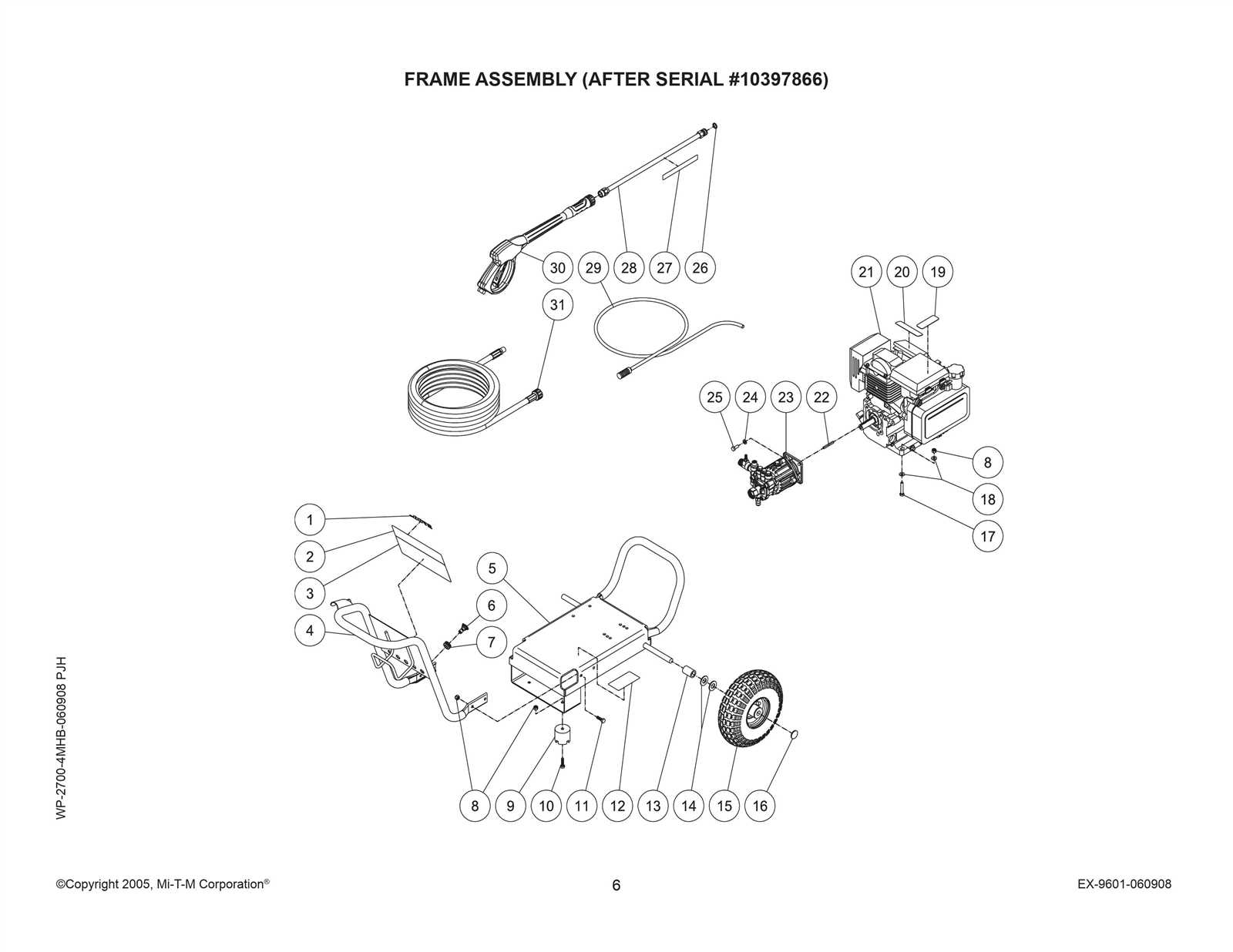

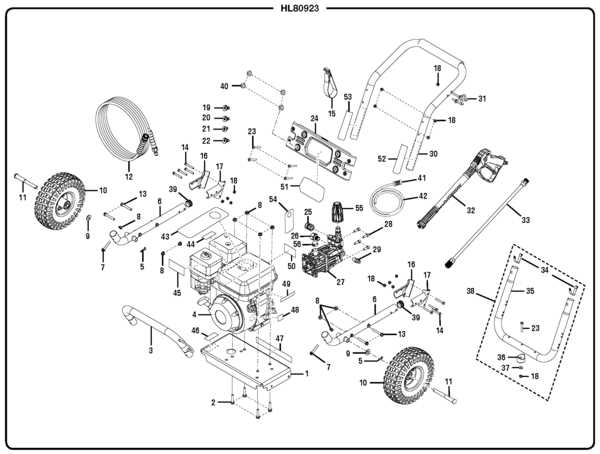

Homdox Pressure Washer Overview

This cleaning tool is designed for efficient outdoor maintenance, making tasks like washing driveways, vehicles, and patios much easier. With its powerful motor and compact design, it provides an excellent solution for removing stubborn dirt and grime. It can be utilized across a variety of surfaces, providing flexibility in its application.

- Powerful motor ensuring efficient performance

- Compact build for easy handling and storage

- Multiple nozzle options for different cleaning tasks

Its versatility makes it a great choice for both residential and commercial use, offering robust cleaning capabilities with minimal effort.

Essential Components of the Homdox System

Every cleaning solution relies on a combination of critical elements that work together to ensure efficiency and reliability. These elements are designed to complement each other, forming a cohesive system that can handle a wide range of tasks, from light maintenance to more demanding jobs. Understanding the core elements is key to maintaining optimal performance.

- Motor Unit: The driving force that powers the entire system, responsible for generating the necessary energy to achieve effective results.

- Water Intake Connector: This part facilitates the flow of liquid into the system, ensuring a steady supply from the source.

- Nozzle Attachments: Various interchangeable tips that allow for adjustments in spray pattern and intensity, depending on the task at hand.

- Hose Assembly: A flexible conduit that delivers the required pressure from the unit to the output point, ensuring consistent delivery across distances.

- Trigger Gun: The control mechanism that allows the user to start and stop the flow

How to Identify the Nozzle Parts

Recognizing the various components of the nozzle system can greatly improve your ability to utilize the equipment efficiently. These small but essential elements play a crucial role in managing the flow and direction of water, and each one has a specific function that contributes to overall performance. Understanding these differences can help you choose the right attachment for different tasks, ensuring you achieve the desired outcome with minimal effort.

The nozzle tip is the part responsible for adjusting the spray pattern. It determines how concentrated or wide the water stream will be. Nozzles often come in a range of colors, each representing a different angle of spray, from focused to broad.

The connecting base, sometimes referred to as the coupling, secures the nozzle tip to the main system. It’s designed to provide a tight seal, preventing leaks while allowing easy swapping of attachments. Ensuring the correct fit is essential for maintaining optimal performance during operation.

The internal mechanism, often overlooked, helps regulate the pressure and consistency of the flow. This hidden element controls the velocity, ensuring even distribution of water through the nozzle, which is vital for both cleaning efficiency and surface protection.

Understanding the Motor and Pump Assembly

The motor and pump system forms the core of any cleaning tool designed for delivering powerful streams of water. These components work in tandem to generate the necessary force to efficiently move water through the device, transforming electrical energy into mechanical movement. The process involves converting rotational motion into high-speed fluid movement, creating the desired flow for various applications.

The motor plays a crucial role by providing the initial energy needed to drive the system. Typically powered by electricity, it spins rapidly, transmitting motion to other mechanical components. The design and strength of this motor determine the overall capability of the equipment.

The pump is the element responsible for building up the force required to propel the fluid. As the motor drives it, the pump compresses and directs the liquid, ensuring consistent and efficient output. The effectiveness of this assembly hinges on precise coordination between the motor and pump, making them indispensable parts of the cleaning apparatus.

Key Hose and Connection Mechanisms

The mechanisms that enable fluid flow within a cleaning device rely on an intricate combination of tubes and connectors. These elements work in harmony to ensure a seamless flow of liquid from the main unit to the nozzle, enabling consistent and efficient performance. Understanding how these components fit together can help with maintenance, troubleshooting, and upgrading.

Main Hose Features

The primary tube is typically flexible yet durable, designed to withstand various levels of force. It often includes reinforced layers to prevent wear and tear, ensuring a long service life. The length and material of the hose play a crucial role in determining how easily it can be maneuvered during operation.

Connection Points

Connection interfaces are essential for securing the tube to different parts of the system. These connectors are usually quick-lock or twist mechanisms, allowing for fast attachment and detachment without the need for additional tools. Reliable connections prevent leaks and ensure steady operation during use.

Component Function Material Main Tube Trigger Gun Breakdown and Functionality

The trigger mechanism is an essential component in high-performance cleaning equipment, playing a crucial role in the overall operation. This device allows users to control the flow of the cleaning solution and manage the pressure, ensuring effective cleaning while maintaining safety. Understanding its structure and how it operates can greatly enhance the user experience and longevity of the equipment.

Components of the Trigger Mechanism

The trigger assembly consists of several key elements, each contributing to its functionality. Below is a table that outlines these components along with their specific roles:

Component Function Trigger Initiates the flow of the cleaning solution when pressed. Valve Controls the release and regulation of fluid pressure. Handle Provides ergonomic support and ease of use. Safety Lock Prevents accidental activation, ensuring user safety. Hose Connector Links the trigger mechanism to the hose and cleaning unit. How the Trigger Functions

When the trigger is engaged, it activates the valve, allowing the flow of the cleaning solution to commence. This mechanism not only ensures efficient use of resources but also allows users to adjust the intensity of the cleaning as needed. The safety lock feature is crucial, preventing any unintended operation, thus safeguarding the user and the equipment.

Filter and Water Inlet Assembly Explained

The component responsible for managing the flow of liquid is crucial for the efficient operation of any cleaning device. Understanding how this assembly functions helps in maintaining optimal performance and ensuring longevity. This section delves into the significance and workings of the filtration and water entry systems, which play a vital role in keeping the system clean and free of debris.

Key Functions of the Assembly

- Filtration: Prevents impurities from entering the mechanism, safeguarding internal components from damage.

- Flow Regulation: Ensures a steady stream of liquid for effective operation.

- System Protection: Acts as a barrier against potential blockages and performance issues.

Components of the Assembly

- Inlet Filter: Traps particles before they enter the main unit.

- Water Intake Valve: Controls the entry of liquid into the system.

- Hoses: Connect various elements of the assembly for seamless operation.

Maintaining this assembly is essential for the overall efficiency of the cleaning device. Regular inspections and timely replacements of worn-out components contribute to smooth functioning and enhance the lifespan of the equipment.

Troubleshooting Common Homdox Washer Issues

Maintaining optimal functionality in cleaning devices can sometimes be challenging. Users often encounter a variety of issues that may hinder performance. Understanding common malfunctions and their solutions can lead to a more efficient and effective experience.

Identifying Common Problems

When faced with operational difficulties, it is crucial to diagnose the underlying cause. Common symptoms may include insufficient cleaning power, unusual noises, or leaks. A systematic approach to troubleshooting can often reveal simple fixes.

Quick Fixes and Solutions

Many issues can be resolved with basic maintenance or adjustments. Here are some frequent challenges and their respective solutions:

Issue Possible Cause Solution Low cleaning efficiency Clogged nozzle or filter Clean or replace the nozzle and filter. Strange noises Worn-out components Inspect for damaged parts and replace as needed. Water leakage Loose connections Tighten all hoses and connectors. Device not starting Power supply issues Check the power source and ensure it is functioning. Maintenance Tips for Long-lasting Performance

Ensuring the longevity of your equipment involves regular care and attention to detail. Simple practices can enhance functionality and extend the lifespan of your device. By following a few straightforward guidelines, you can prevent common issues and maintain optimal performance.

Regular checks and cleaning are essential. Accumulation of dirt and debris can hinder operation, leading to reduced efficiency. It’s advisable to inspect components frequently and clear away any obstructions. Additionally, proper storage conditions help protect the machinery from environmental factors that may cause wear and tear.

Maintenance Task Frequency Description Inspect Hose Weekly Check for cracks or leaks and replace if necessary. Clean Filters Monthly Remove and rinse filters to prevent clogging and maintain flow. Check Oil Levels Before Each Use Ensure adequate oil levels for smooth operation and prevent damage. Inspect Nozzle Every Use Examine for blockages and clean to ensure proper spraying. Following these maintenance practices will help maintain your equipment’s effectiveness and performance. By investing time in care, you can enjoy a longer lifespan and reliable operation.