In the world of maritime machinery, the functionality and longevity of watercraft heavily rely on the intricate assembly of various mechanical elements. A clear representation of these components is essential for maintenance and repair, allowing boat owners and technicians to identify and address issues effectively. Knowledge of each element’s role can enhance performance and ensure safe navigation.

Having a visual reference of the essential parts not only aids in troubleshooting but also provides insight into the assembly and disassembly processes. By studying the arrangement and interconnection of these components, one can gain a deeper understanding of how they work together to create a seamless experience on the water. This knowledge empowers users to make informed decisions when it comes to repairs and upgrades.

Furthermore, familiarizing oneself with the specific attributes of each component fosters a greater appreciation for marine engineering. With the right resources and guidance, enthusiasts can ensure their vessels remain in optimal condition, enhancing their overall maritime adventures. Proper maintenance ultimately leads to improved efficiency and durability, allowing for more enjoyable time spent on the waves.

Understanding the Volvo Penta 275 Outdrive

The marine propulsion system is a crucial component in ensuring smooth navigation and optimal performance on the water. This section delves into the various elements that make up this specific model, highlighting its importance for both recreational and professional use. Understanding how these systems operate can significantly enhance the user experience and maintenance practices.

Key Components and Their Functions

At the heart of this propulsion mechanism lies a combination of mechanical and hydraulic elements that work in unison. The transmission system is designed to convert engine power into thrust, facilitating efficient movement through the water. Additionally, the steering apparatus plays a vital role in maneuverability, allowing the vessel to change direction with precision.

Maintenance and Troubleshooting

Regular upkeep is essential for ensuring the longevity and reliability of the propulsion system. Users should be familiar with the common indicators of wear and tear, such as unusual noises or performance issues. Performing routine inspections and addressing minor concerns promptly can prevent significant complications in the future.

In conclusion, a comprehensive understanding of this marine propulsion system not only aids in effective usage but also empowers users to undertake necessary maintenance, ensuring a safe and enjoyable experience on the water.

Key Components of the Marine Propulsion System

In understanding the essential elements that comprise a marine propulsion system, it is crucial to delve into the intricate components that work in harmony to propel vessels through water. These components, carefully engineered and integrated, ensure optimal performance and reliability in maritime operations.

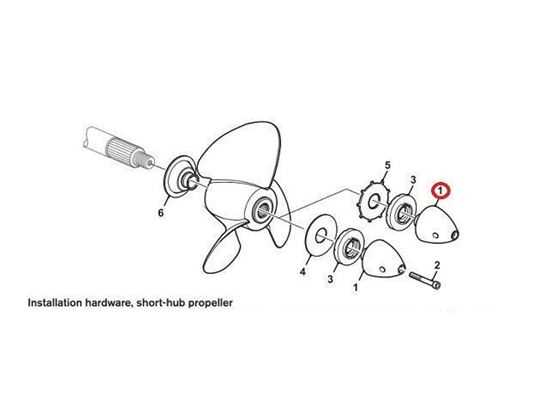

1. Propeller Assembly

The propeller assembly stands as the pivotal component responsible for converting engine power into thrust. It consists of blades strategically designed to generate propulsion by pushing water in a controlled manner, thereby propelling the vessel forward.

2. Gear Mechanism

Integral to the propulsion system, the gear mechanism facilitates the transfer of power from the engine to the propeller shaft. This transmission system ensures efficient power delivery, enabling the vessel to achieve desired speeds and maneuverability.

| Component | Description |

|---|---|

| Propeller | Bladed assembly converting engine power into thrust. |

| Gearbox | Mechanism for transferring power to the propeller shaft. |

Each element within the propulsion system plays a critical role in ensuring the efficiency and functionality of marine vessels. Understanding these components enhances appreciation for the complexity and engineering prowess required to navigate and operate effectively on water.

Maintenance Tips for Volvo Penta Parts

Proper upkeep of marine components is essential for ensuring optimal performance and longevity. Regular maintenance not only helps in identifying potential issues early but also enhances the overall efficiency of your vessel. This guide offers valuable advice on caring for your crucial maritime equipment.

To maintain the functionality of your marine gear, consider the following recommendations:

| Task | Frequency | Tips |

|---|---|---|

| Inspect fluid levels | Monthly | Check oil and coolant levels; top off as necessary. |

| Clean external surfaces | Bi-weekly | Remove dirt and salt buildup to prevent corrosion. |

| Examine electrical connections | Quarterly | Look for signs of wear; tighten or replace loose connections. |

| Check the condition of seals | Every season | Inspect for cracks or wear; replace damaged seals promptly. |

| Test performance | Annually | Conduct a test run to assess overall functionality and responsiveness. |

By adhering to these maintenance suggestions, you can ensure your marine components remain in peak condition, allowing for safe and enjoyable journeys on the water.

Common Issues with the 275 Outdrive

When it comes to marine propulsion systems, certain recurring problems can affect performance and reliability. Understanding these issues is crucial for maintaining optimal functionality and ensuring a smooth boating experience. Below are some prevalent concerns that users may encounter with these units.

| Issue | Description |

|---|---|

| Corrosion | Exposure to saltwater can lead to deterioration of metal components, affecting longevity and performance. |

| Overheating | Insufficient cooling flow or blockages can result in excessive heat buildup, causing potential damage to the engine. |

| Seal Failures | Worn or damaged seals can lead to leaks, allowing water to enter the system and compromise functionality. |

| Gear Engagement Issues | Problems with gear shifting can arise from worn components or misalignment, affecting maneuverability. |

| Vibration | Unusual vibrations can indicate imbalances or misalignment, potentially leading to further mechanical issues. |

Addressing these issues promptly can help maintain the integrity of the system and enhance overall performance. Regular inspections and maintenance are essential for preventing these common challenges.

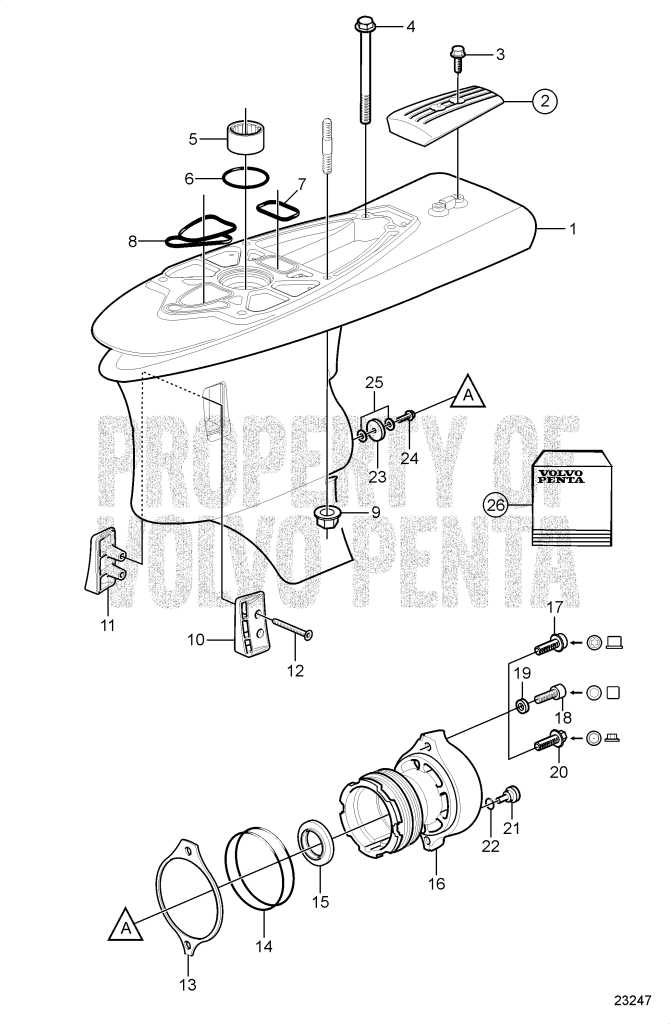

How to Read Parts Diagrams

Understanding the illustrations used for component identification is crucial for efficient maintenance and repairs. These visual representations simplify the process of locating individual elements within a mechanical assembly, aiding users in grasping complex structures and functions.

To effectively interpret these visual aids, follow these guidelines:

- Familiarize Yourself with Symbols: Each representation uses specific icons to denote various components. Learn the common symbols to enhance comprehension.

- Identify Key Sections: Typically, illustrations are divided into sections that correspond to different assembly parts. Recognizing these divisions helps in quickly locating the desired elements.

- Refer to the Legend: Most visuals include a legend or key that explains the symbols and colors used. Always consult this reference for clarity.

- Pay Attention to Numbering: Many illustrations use a numbering system to indicate parts. Ensure you understand the sequence to track components efficiently.

- Cross-Reference with Manuals: Utilize maintenance guides or user manuals alongside the illustrations for detailed information regarding each component’s function and maintenance requirements.

By mastering these techniques, users can navigate complex mechanical representations with confidence, facilitating more effective repairs and maintenance.

Finding Replacement Parts Online

Locating suitable components for marine equipment can often feel daunting. The vast array of available options online can lead to confusion. However, with the right approach and resources, securing the necessary replacements becomes manageable.

First, it is essential to utilize reliable platforms that specialize in marine gear. Websites dedicated to this niche often provide comprehensive inventories, allowing users to search by specific criteria. These can include model numbers, specifications, and compatibility details, ensuring that the selected items will fit seamlessly.

When browsing these sites, take advantage of customer reviews. Feedback from other users can offer insights into product quality and reliability. Additionally, comparison shopping across different platforms can help in identifying the best prices and available stock.

For those seeking rare or discontinued items, forums and online communities dedicated to boating can be invaluable. Engaging with experienced enthusiasts can yield recommendations for trusted suppliers or alternatives that might not be readily visible in standard searches.

Finally, remember to check the return policies and warranty information. Ensuring that there is a safety net in case of compatibility issues or defects will provide peace of mind when making purchases online.

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components offers numerous advantages for maintaining the performance and longevity of your marine machinery. These authentic elements are designed to meet specific engineering standards, ensuring a seamless fit and optimal functionality.

Quality Assurance: One of the primary benefits of selecting genuine components is the assurance of quality. Each piece undergoes rigorous testing and inspection processes to guarantee reliability and durability, which helps prevent premature failures and costly repairs.

Perfect Compatibility: Original components are engineered specifically for your equipment, resulting in perfect compatibility with existing systems. This eliminates the risks associated with using generic or aftermarket alternatives that may not integrate properly, leading to potential performance issues.

Enhanced Performance: By opting for authentic elements, users can experience improved overall performance. These components are optimized to work harmoniously with other parts, ensuring efficient operation and maximizing the effectiveness of your machinery.

Warranty Protection: Choosing original components often comes with the added benefit of warranty protection. This coverage provides peace of mind, knowing that if any issues arise, they can be addressed without incurring additional costs.

Long-Term Cost Savings: Although genuine components may have a higher initial purchase price, they often lead to significant long-term savings. Their durability and reliability reduce the likelihood of frequent replacements and repairs, making them a wise investment for any equipment owner.

In summary, utilizing original components significantly enhances the reliability, performance, and overall value of your machinery. Investing in these high-quality elements ultimately leads to a more efficient and satisfying experience.

Installation Guide for Outdrive Components

This section provides essential instructions for the proper setup of marine propulsion components. Following these guidelines ensures optimal performance and longevity of your equipment. Understanding the intricacies of the installation process is crucial for both novice and experienced users.

Preparation Steps

Before beginning the installation, gather all necessary tools and components. Ensure that the work area is clean and well-lit. It’s advisable to review the manufacturer’s specifications and guidelines to familiarize yourself with the particular requirements of your system. Proper preparation minimizes potential issues during the installation.

Installation Process

Start by securely positioning the component on the designated area. Align it according to the provided specifications. Use appropriate fasteners and follow the recommended torque settings to ensure a tight fit. It’s important to double-check all connections and seals to prevent leaks or operational failures. Finally, conduct a thorough inspection before testing the unit in a controlled environment.

Note: Regular maintenance checks are vital for sustaining functionality. Keeping a log of any adjustments or replacements made can help track the system’s performance over time.

By adhering to these guidelines, users can effectively install their marine propulsion components, contributing to a seamless and efficient boating experience.

Upgrading Your Volvo Penta System

Enhancing your marine propulsion system can significantly improve performance and longevity. Whether you’re looking to increase speed, enhance fuel efficiency, or ensure greater reliability, a thoughtful upgrade can make all the difference. This guide provides insights into the various aspects to consider when modernizing your equipment.

Choosing the Right Components

When selecting new elements for your system, prioritize quality and compatibility. Opt for parts that not only fit seamlessly but also enhance the overall efficiency of your vessel. Research manufacturers with a strong reputation for durability and performance. Consider consulting with professionals to determine the best options tailored to your specific needs.

Installation and Maintenance Tips

Proper installation is crucial for optimal functionality. Follow manufacturer guidelines meticulously, or enlist the help of experienced technicians. Regular maintenance checks are essential to ensure that all upgraded components are functioning correctly. This includes inspecting seals, lubricants, and electronic systems to prevent potential issues that could arise from neglect.

In conclusion, modernizing your marine system can lead to improved performance and enjoyment on the water. Invest time in researching and choosing the best options available to maximize your experience.