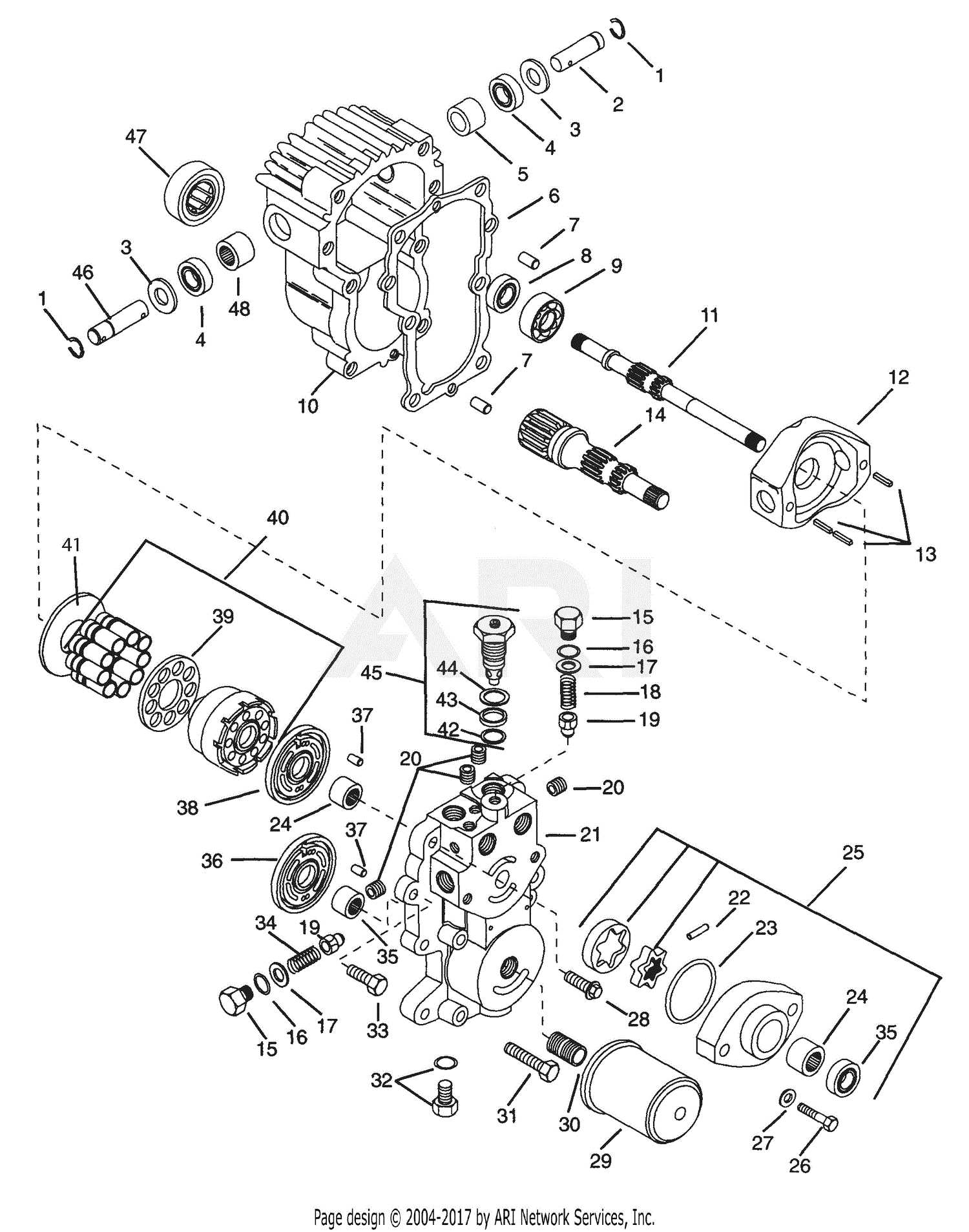

Understanding how a machine’s core mechanisms interact can provide valuable insight into its overall functionality. These intricate systems, made up of various interconnected elements, work together to achieve smooth operation and efficient performance. Each component plays a vital role in the coordination of movement, ensuring that energy is transmitted and utilized in the most effective way possible.

By examining the internal workings of this mechanical structure, one can better appreciate the harmony between different units. These elements are specifically designed to perform distinct functions, yet their cooperation is essential to maintaining the overall balance. Whether dealing with smaller devices or larger industrial machinery, recognizing the role of each section is crucial for proper maintenance and troubleshooting.

The following overview will guide you through the primary sections of this essential mechanism, explaining how they function individually and in relation to one another. With a clear understanding of these components, you will be better equipped to diagnose issues and ensure optimal performance.

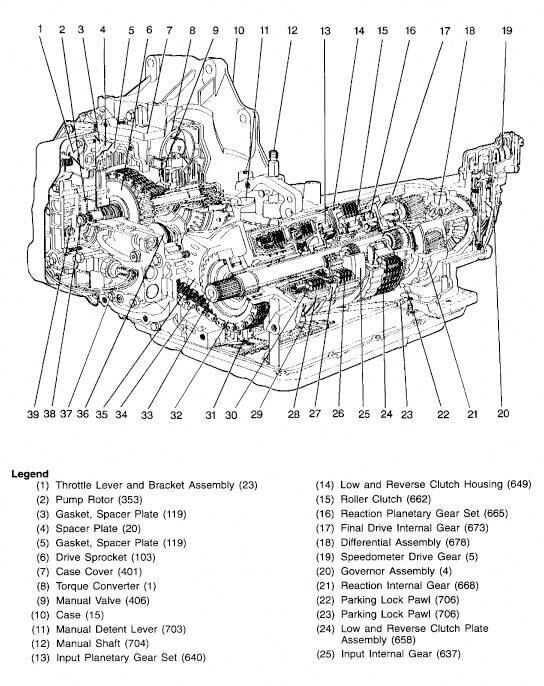

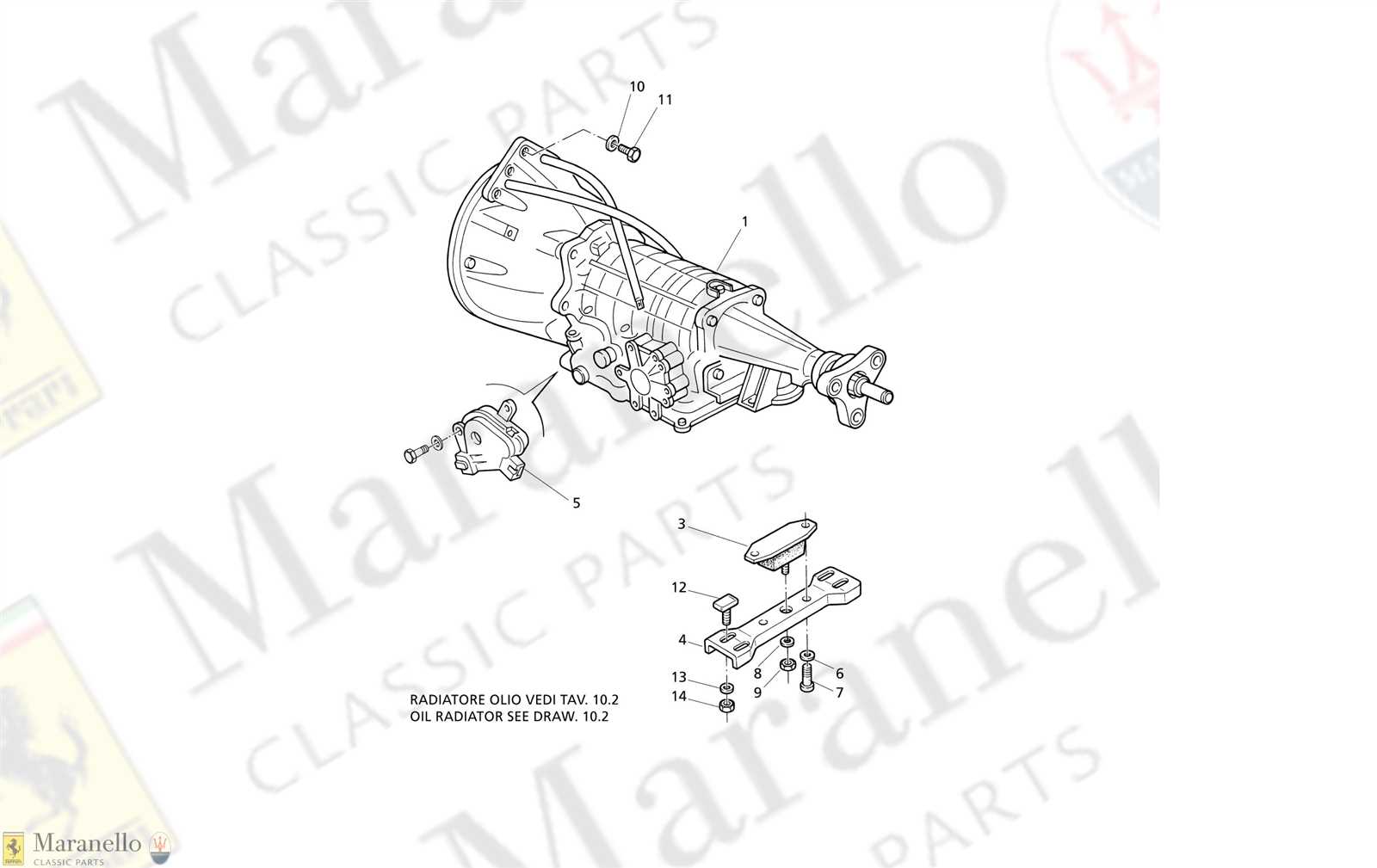

Understanding the Components in Transmission

Modern vehicles rely on a complex system that ensures the smooth transfer of power. Each element within this system plays a vital role in maintaining seamless energy flow, allowing for efficient movement. To grasp how these mechanisms work, it’s important to explore the key units involved and understand their distinct functions.

Core Mechanisms

The main units within the system collaborate to regulate speed and torque. These components are engineered to balance energy distribution and ensure that the right amount of force is applied to various driving conditions. Below is an overview of the primary mechanisms responsible for this process.

| Component | Function |

|---|---|

| Converter | Regulates energy input and adjusts to changing speeds. |

| Coupling Unit | Links various parts, ensuring smooth coordination of movement. |

| Torque Balancer | Manages power flow between the engine and the system, adapting to different driving needs. |

| Control Module | Automates adjustments, allowing for real-time modifications during operation. |

Synchronization

Role of the Torque Converter

The torque converter plays a crucial function in the operation of a vehicle’s drive system. It is responsible for transferring power from the engine to the rest of the mechanism, ensuring smooth acceleration and efficient energy distribution. The component works seamlessly to manage the engine’s output and maintain optimal performance under various driving conditions.

Below are some key functions of the torque converter:

- Power Transmission: It connects the engine and the drive system, allowing energy to flow efficiently.

- Fluid Coupling: Instead of a direct mechanical link, it uses fluid dynamics to transfer force, resulting in smoother operation.

- Multiplication of Torque: Under certain conditions, it increases the force from the engine, providing more power when needed.

- Idle Functionality: The converter allows the engine to run while the vehicle remains stationary, without stalling.

This device is essential for ensuring that the engine’s output is effectively utilized, while also contributing to the overall efficiency and durability of the drive system.

Exploring the Planetary Gear Set

The system of gears commonly referred to as a planetary setup operates with impressive efficiency and adaptability in various mechanisms. This arrangement allows for smooth coordination and seamless changes in movement, enhancing the performance of machinery. The unique interplay between the different gear components enables optimal speed variation and torque distribution without the need for complex configurations.

Key Components: The planetary configuration consists of three main elements: a central piece, multiple surrounding gears, and an external ring. Each element plays a crucial role in maintaining balance and directing motion, ensuring the smooth functioning of the entire setup.

Functionality and Versatility: This gear system excels in providing high flexibility for various operational needs. By adjusting the relationship between the different gears, the system can easily manage different rotational speeds and torque, making it ideal for a wide range of mechanical applications. The versatility of this configuration allows for precise control in both acceleration and deceleration processes.

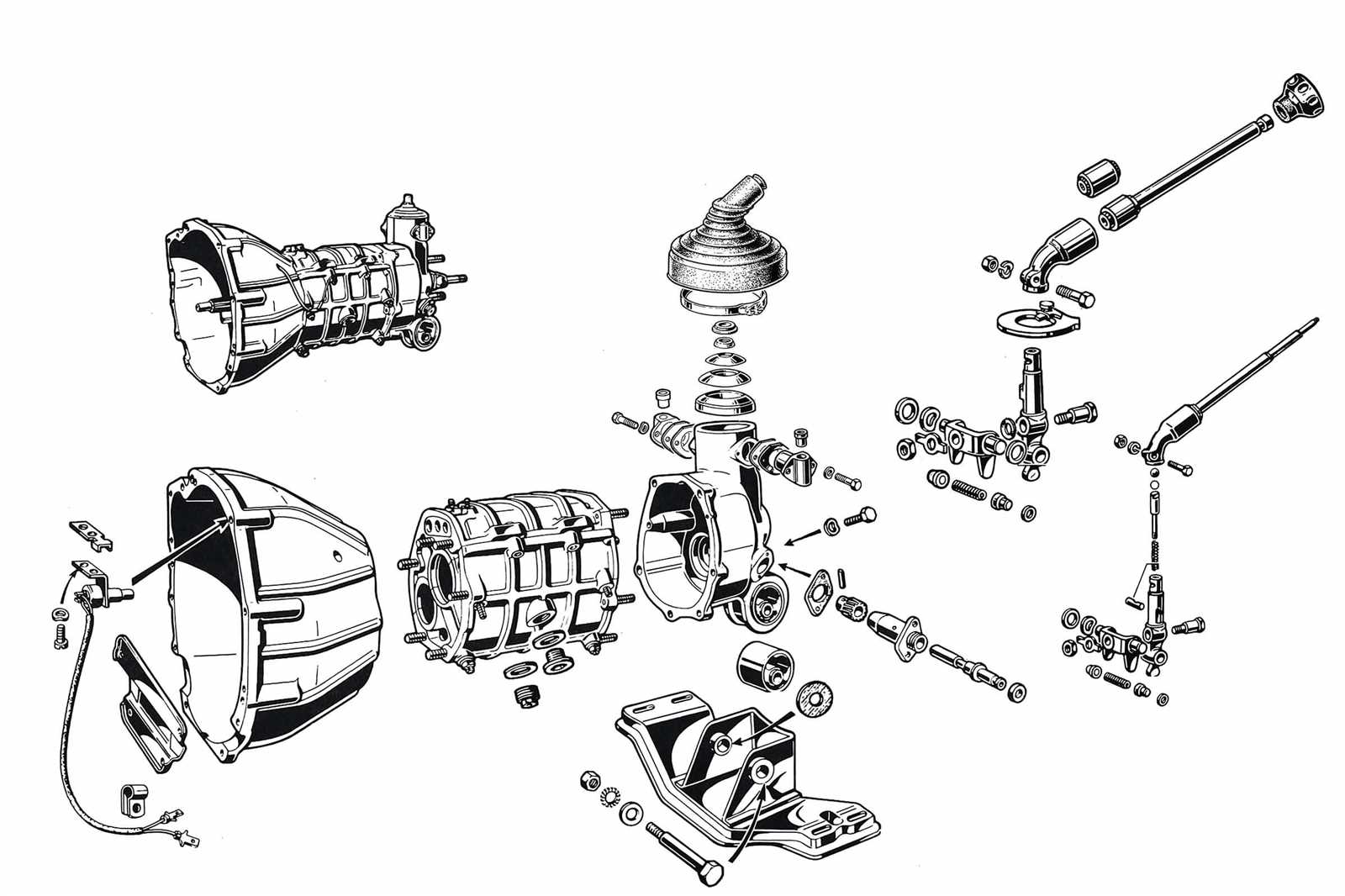

Functionality of the Clutch Assembly

The clutch assembly plays a vital role in ensuring smooth operation between the engine and other components of the vehicle’s power system. Its main objective is to regulate the transfer of rotational force, enabling efficient control over movement. This process allows the driver to seamlessly engage or disengage the driving force when needed, ensuring optimal control and safety during operation.

To better understand how the clutch assembly operates, let’s examine its key actions:

| Action | Description |

|---|---|

| Engagement | When the clutch is engaged, the flow of power is directed, allowing forward momentum. This provides the vehicle with the ability to move efficiently under controlled conditions. |

| Disengagement | In disengaged mode, power is momentarily interrupted, enabling gear changes without causing friction or damage. This prevents unwanted force from affecting the driving dynamics. |

| Control | The driver modulates the engagement through the pedal, which allows for precise adjustments during acceleration and deceleration. This ensures that power is applied efficiently. |

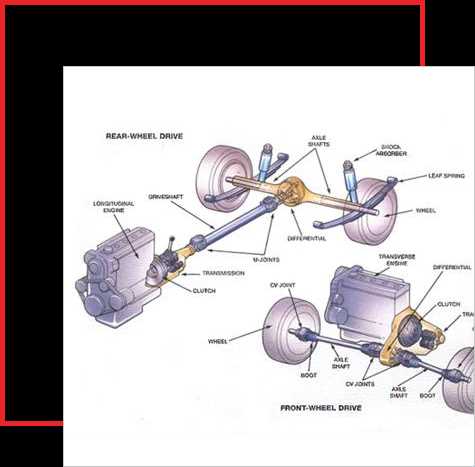

Identifying the Input and Output Shafts

Understanding the primary components involved in power transfer is crucial for grasping the function of mechanical systems. Two essential rotating elements, which facilitate the movement and control of force, are the input and output shafts. These components serve as the starting and ending points of energy conversion, each playing a distinct role in managing speed, torque, and direction.

Input shaft is the first connection to the power source, responsible for receiving rotational energy. It transmits the force into the system, initiating the conversion process. Its position and alignment often determine the efficiency of energy transfer.

Output shaft, on the other hand, is where the transformed energy exits. It directs the processed motion to the next part of the system, ensuring the desired performance. The behavior of this element is influenced by the interaction between various internal mechanisms, ultimately dictating how the final movement occurs.

Purpose of the Valve Body

The valve body serves a crucial function in the overall operation of an automatic gearbox, acting as the control center for fluid flow and pressure regulation. This component is essential for ensuring that various elements within the system work together efficiently to facilitate smooth gear shifting.

Primarily, the valve body performs the following key roles:

- Fluid Distribution: It directs hydraulic fluid to different areas of the system, enabling effective operation of clutches and bands.

- Pressure Regulation: The assembly manages hydraulic pressure, ensuring that components receive the appropriate amount of force required for engagement.

- Shift Control: It determines when and how shifts occur, affecting overall performance and responsiveness.

- Sensor Integration: The valve body often houses various sensors that monitor operational parameters, contributing to the adaptive functionality of the system.

By fulfilling these functions, the valve body plays an indispensable role in the efficiency and reliability of the overall mechanism, directly influencing vehicle performance and driving experience.

The Importance of the Transmission Fluid

Fluid plays a crucial role in ensuring the smooth operation of vehicle systems. It not only lubricates components but also aids in temperature regulation and hydraulic function. The effectiveness of this essential liquid directly impacts the overall performance and longevity of the system it supports.

Lubrication and Protection

The primary function of the fluid is to reduce friction between moving parts. By creating a protective barrier, it minimizes wear and tear, ensuring that components remain in optimal condition. This protection is vital for maintaining efficiency and preventing costly repairs that may arise from neglecting this important element.

Heat Management

Another critical aspect of this liquid is its ability to dissipate heat generated during operation. Excessive temperatures can lead to component failure and diminished performance. By effectively transferring heat away from critical areas, the fluid helps maintain an ideal working environment, contributing to the system’s reliability and effectiveness.

How the Governor and Modulator Work

The governor and modulator play crucial roles in managing the performance and efficiency of various systems. These components work in harmony to regulate fluid flow and pressure, ensuring optimal functioning under different operating conditions. Understanding their interactions is essential for grasping how systems maintain stability and responsiveness.

The Role of the Governor

The governor acts as a control mechanism that adjusts the output based on specific parameters. It ensures that the system operates within defined limits, responding to changes in demand and maintaining a steady performance. Key functions include:

- Monitoring speed variations

- Adjusting fluid flow to match engine load

- Maintaining equilibrium in performance

The Function of the Modulator

The modulator complements the governor by fine-tuning pressure levels and fluid distribution. Its primary responsibilities are to enhance responsiveness and efficiency by adapting to real-time conditions. Important aspects include:

- Regulating pressure based on load requirements

- Optimizing fluid movement for seamless operation

- Improving overall system efficiency

Together, the governor and modulator form a dynamic duo that ensures systems operate smoothly and effectively, adapting to various conditions to meet performance expectations.

Analyzing the Synchronizer Mechanism

The synchronizer mechanism plays a crucial role in ensuring smooth gear changes in various automotive systems. By effectively managing the engagement of gears, it contributes to overall performance and reliability. Understanding how this component operates is essential for diagnosing issues and optimizing functionality.

Key Functions of the Synchronizer

- Gear Engagement: Facilitates the connection between different gear sets, allowing for seamless transitions.

- Speed Matching: Aligns the rotational speeds of the gears to prevent grinding and enhance shifting comfort.

- Wear Reduction: Minimizes friction and wear on components, prolonging the lifespan of the entire system.

Components Involved

- Blocking Ring: Assists in speed matching by engaging with the gears to synchronize their velocities.

- Hub: Connects to the gear set and aids in the overall movement of the mechanism.

- Fork: Activates the synchronizer, enabling the smooth operation of gear changes.

Analyzing the operation of the synchronizer mechanism is vital for troubleshooting and enhancing the performance of the overall system. By focusing on its key functions and components, one can gain valuable insights into its impact on vehicle dynamics.